Abstract

The present study reports on the biotransformation of the brewer’s spent grain (BSG) in co-digestion with Jerusalem artichoke (JA, Helianthus tuberosus L.) phytomass by thermophilic (+55 °C) and mesophilic (+30 °C) anaerobic methanogenic communities. BSG is a by-product of the beer-brewing process generated in large amounts, in which utilization provokes a negative effect on the environment. In this study, we will show an effective conversion of BSG into biogas by selected microbial communities, obtained from different sources (animal manure and previously isolated microbial consortia). The stimulation of methanogenesis was reached by the co-digestion of JA’s phytomass (stem and leaves). The optimized conditions for microbial stable cultivation included the use of nutrient medium, containing yeast extract and trace element solution. The optimal BSG concentration in biogas production was 50 and 100 g L−1. Under thermophilic conditions, the maximum total methane production reached 64 %, and it comprised around 6–8 and 9–11 of L CH4 per 100 g of fermented BSG without and with co-digested JA, respectively, when the fresh inoculum was added. Although, after a year of re-cultivation, the values reduced to around 6–7, and 6–10 L CH4/100 g BSG, correspondingly, the selected microbial communities showed effective biotransformation of BSG. The supplementation of soil with the residual fermented BSG (10 %, w/w) resulted in the promotion of lettuce (Lepidium sativum L.) growth. The results obtained demonstrate a potential for complete BSG utilization via biogas production and application as a soil additive.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

The biotransformation of organic wastes into biofuel, the development of effective methods of distribution, and the exploitation and recycling of natural resources are the main trends in biotechnology nowadays. Biogas is an easily renewable source of alternative energy, which is produced by the conversion of almost any type of organic waste by anaerobic methanogenic microbial communities (Gunaseelan 1997; Björnsson and Mattiasson 2008; Fargione et al. 2008; Sebola et al. 2014). Biogas of microbial origin mainly consists of methane (55–75 % CH4) and carbon dioxide (CO2 25–45 %) with a trace amount of nitrogen (ammonia), hydrogen sulfide, oxygen, alkanes, aromatics and halo-aromatics, depending on consumed substrates and/or operating conditions (Glissmann et al. 2005; Petersson et al. 2007; Bochiwal et al. 2010). The biosynthesis of biogas is a complex microbiological process, performed by multi-component microbial communities, that may contain up to 60 bacterial and archaeal species growing under anoxic conditions, which close relations and coexistence is based on trophic interactions and exchange of intermediates and growth factors (Schink 1997; Zavarzin 1997; Lynd et al. 2002; Angelidaki et al. 2011; Ferry 2011; Tsavkelova and Netrusov 2012). Diverse types of organic substrates, such as livestock, cattle and poultry manure, household, municipal and industrial wastewater and sewage sludge are commonly used all over the world for biogas production (Bochiwal et al. 2010; Angelidaki et al. 2011). In order to make methane production more efficient and to enhance biogas amounts, the “pure” wastes can be supplemented with herbaceous co-substrates, such as underwood or different “energetic” plants such as miscanthus, sugarcane, maize, millet, sunflower, rapeseed, etc. (Weiland 2006; Antizar-Ladislao and Turrion-Gomez 2008). The use of co-substrates improve the nutrient balance and reduce the concentration of inhibitory intermediates for the effective development of the microbial community, and increase the biogas yield by 40–80 % (Weiland 2010; Sebola et al. 2014). Co-digestion helps to amend pH up to neutral values, increasing the C:N ratio that is of great importance for optimal activity of methanogenic microorganisms (Angelidaki et al. 2011; Goberna et al. 2013).

One of the prospective co-substrate plants is Helianthus tuberosus, a herbaceous perennial plant growing up to 2–3 m tall, and belonging to the same Asteraceae family as the sunflower (Helianthus annuus L.), which is considered as a potential substrate for biofuel production, including biodiesel, bioethanol, and biogas (Lehtomäki et al. 2008; Cheng et al. 2009; Razmovski et al. 2011; Menon and Rao 2012; Li et al. 2013; Gunnarsson et al. 2014). Cultivated for dietary fibre and inulin production, its aerial parts are used as forage for domestic and wild farm-animals and birds. Frost- and drought-tolerant H. tuberosus is undemanding to soil composition, and is highly resistant to pests and diseases that make it flourish in extreme abiotic conditions of temperate and cold regions (Bergh et al. 2003; Slimestad et al. 2010).

Brewer’s spent grain (BSG), forms up to 85 % of by-products of the brewing industry (Mussatto and Roberto 2006; Mussatto 2014). According to Mussatto (2014), the worldwide annual production of BSG has been estimated at approximately 38.6 × 106 t of agro-industrial residue. Around 3.4 million t of BSG are produced in Europe (Stojceska et al. 2008), and about 1.7 million in Brazil (in 2002) (Mussatto and Roberto 2006). In Japan about 95 % of BSG is used as cattle feed, while the remaining 5 %, due to its insufficient utilization, still provokes a negative effect on the environment (El-Shafey et al. 2004). In Africa, only 10 % is processed for agricultural purposes, whereas the remaining 90 % are disposed (Mbagwu and Ekwealor 1990). In Russia, it has annually accumulated around 1.2–2.0 million t (wet weight) of BSG, which is mainly disposed as landfills (Snitsar et al. 2004; Vorob’eva et al. 2005). Due to its rich protein and fiber (cellulose, hemicellulose, lignin) composition, BSG is used for animal feed and even as dietary supplements (Stojceska et al. 2008); it contains 15–30 % of protein, 19–28 % of polysaccharides, 9–25 % of cellulose, 7–28 % of lignin, about 10 % of lipids, minerals and vitamins (Mussatto and Roberto 2006; Stojceska et al. 2008; Aliyu and Bala 2011; Mussatto 2014). Nevertheless, BSG in Russia is purely processed into cattle feedstock nowadays (Snitsar et al. 2004; Vorob’eva et al. 2005), due to large beef import.

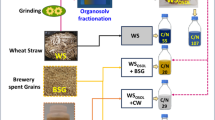

Due to the large bulk of BSG produced annually, its low costs and its high nutritional capacity as well as increasing energy costs, the biogas production from the BSG has been the subject of recent studies (Ezeonu and Okaka 1996; Panjičko et al. 2015). However, BSG is a lignocellulosic material (Mussatto 2014), which is usually slowly degraded under anaerobic conditions. Moreover, biogas production can be inhibited by phenolic intermediates of lignocellulose degradation, such as p-cresol (Sežun et al. 2011). Thus, the optimization of the microbial degradation of BSG is needed for its complete and effective biotransformation into biogas, particularly in temperate and cold climates. In this study, we report the usage of BSG as a substrate for biogas production. We aimed to select the active and stable thermophilic (+55 °C) and mesophilic (+30 °C) anaerobic microbial communities producing biomethane from BSG; to choose the optimal conditions for the maximum yield of biogas, including supplementation with co-substrate (Jerusalem artichoke). As an option for the complete utilization of BSG, we tested several concentrations of the fermented BSG in the plant in vitro assay, in order to show that it has no inhibitory effects and is potentially efficient in the plant growth promotion.

Materials and methods

Enrichment and cultivation of microbial communities

The enrichment of active biogas-producing microbial communities was performed in a mineral medium, containing yeast extract and peptone, as described previously (Tsavkelova et al. 2012a). BSG was used as a substrate (brewery of Moscow region) in the amount of 15, 50, 100, 200, and 500 g L−1. The leaves and stems (phytomass) of Jerusalem artichoke (H. tuberosus L.) were collected, frozen, and milled before use. This co-substrate was added to the amount of 10 g L−1. The selection of anaerobic communities was made using the manure of herbivore farm animals (cattle, sheep, horse, donkey and rabbits) as the inoculum, which was added into 30 mL of nutrient medium in 100 mL flasks in the amount of 10 % (v/v). The manure from horses and ponies, stable’s underlay, compost’s humus, fallen tree leaves, and droppings from rabbits were also used. The cultivation of microorganisms was carried out in rubber-stoppered flasks, where the air was replaced with argon, at 55 °C (for thermophilic communities, T) or 30 °C (for mesophilic communities, M). The activity of the microbial community was determined by the increase in methane concentration in biogas. Cultures were re-inoculated into fresh BSG medium after a maximum of methane production was reached. The experimental samples were given numbers (#) from 1 to 18. The variables of cultivation conditions are summarized in Table 1. The stability of the selected communities was examined by repeated passages onto fresh growth medium for a period of a year. The cultures were stored in 25 % glycerol under anaerobic conditions at −20 °C.

Gas chromatography

The content of the gaseous phase (CH4, CO2, and H2 concentrations) was analyzed using the gas chromatograph Crystal 2000 M (Chromatec, Russia) equipped with a thermal conductivity detector, a microcapillary column (15,000 × 2.5 mm) with activated carbon as the sorbent and argon as the carrier gas, 15 mL min−1 flow rate. The column thermostat temperature was 150 °C. The chromatograms were processed using Chromatec Analytic 2.5 (Russia) chromatography software. The total biogas production was considered as the sum of partial gas production at each time interval for 21 and 44 days of incubation for thermophilic and mesophilic communities, respectively. The methane concentration was measured every 2–5 days over the whole experimental period. The gas concentrations in the mixture and % of methane content was determined under standard temperature and pressure conditions, as

as previously described (Tsavkelova et al. 2012a, b), where ΣV gas is the total volume of individual gases (CH4, CO2, H2), and ΣV mixture is the total volume of biogas formed during the growth period. V gas at standard conditions (P = 1 atm, T = 273.15, K = 0 °C) was determined according to the Clapeyron–Mendeleev equation, considering PV/T = constant:

where a is the gas concentration, measured by chromatography (%), P is the pressure in the vial (bar), P standard is the pressure at standard conditions, T standard is the standard temperature, and V vial is the gas volume within the vial. ν = V gas /22.4.

Plant assay

In order to investigate the complete utilization of fermented BSG, we used it as a bio-fertilizer. To study the influence of the fermented BSG on the plant growth and development, the lettuce (Lepidium sativum L.) seeds were taken into plant assay. The residue of processed BSG was added to the soil in the ratio of 5, 10 and 20 % (w/w). The seeds (10 per pot) were planted at a depth of 0.5–0.7 cm. The incubation temperature was 22 °C with day/night photo-period of 12 h, and daily watering. In the preliminary experiments, the plants were incubated for over 2 weeks, but the clearest, most visual differences between the variables could be seen on the 5th to 6th day of incubation. The evaluation of plant growth parameters was performed on the 5th day by measuring the height of the aerial plant parts (stem) and the weight of the germinated seeds, which were taken out of the pots, washed, and blotted dry before measuring the fresh weight.

Statistics

All experiments on biogas production were repeated three times with two replicates in each. The plant experiments were repeated five times with three replicates in each. The data performed as a calculation of the mean values of repetitions ±SD. To evaluate the effect of BSG on plant growth, the values were separated by Student’s t test (p ≤ 0.05). The data were analyzed with Microcal Origin program, OriginLab (http://www.originlab.com).

Results

In order to optimize the cultivation conditions for the most effective biogas production by microbial communities, we added different amounts of BSG (15, 50, 100 and 500 g L−1), as well as supplemented the nutrient medium with additional co-substrate (Table 1). In preliminary studies (data not shown), we showed that biodegradation of BSG in concentrations higher than 500 g L−1 is inhibited, and is ineffective under 15 g BSG L−1. Considering the poor digestibility of inulin that forms the major part of the underground tubers, the aerial phytomass (stem and leaves) of Jerusalem artichoke (JA, H. tuberosus L.) was chosen as a co-substrate and an activator for biogas production by methanogenic communities.

It is known that the source of inoculum, containing the initial microbial community is essential for the effective substrate biotransformation. In this study, among several investigated inoculums, the most active biogas production was noticed when the farm animal manure was added; the cumulative methane yield with inoculums from cattle, donkey and sheep manure comprised 57, 54, and 52 %, respectively (data not shown). The minimal methane production was observed with droppings from rabbits, due to the overproduction of H2 and succeeding acidification that totally inactivated the methane biosynthesis. Low amounts of producing methane were also detected for the stable’s underlay, compost’s humus and fallen tree leaves. Thus, the mixture of manure from herbivores domestic animals (cattle, donkey, sheep, and horse) was chosen as a combined inoculum. Another source was cellulose-degrading methanogenic microbial communities #1 and #3, isolated previously (Table 1, Tsavkelova et al. 2012a, b).

For BSG biotransformation into biogas, we used the previously designed medium (Tsavkelova et al. 2012b), considering that it should not contain expensive ingredients and remain suitable for cultivation of diverse groups of microorganisms, forming a methanogenic consortium. Preliminary experiments under thermophilic conditions showed that supplementation with 500 g L−1 of BSP resulted in a high hydrogen production (18 %) and fast pH decrease (up to 3.5 and lower). Even under the constant neutralization of pH, the methane biosynthesis by communities’ #4T and #11T did not exceed 1.5 %; and no further biotransformation of BSG was noticed. When 200 g L−1 were used, the amount of producing methane comprised only 5–10 % after 14 days of incubation. When 15 g of BSG per L were added, the cumulative methane reached only 19.7 % (community #1T). The maximum biomethane production was observed in microbial communities cultivated with 50 and 100 g L−1 of BSG, and comprised 45–60 %, correspondingly within 10–16 days of incubation.

The most effective substrate biotransformtion by thermophhilic communities that we noticed was when phytomass of H. tuberosus was added to 100 g L−1 of BSG with an inoculum taken from the manure mixed from several animals (#3T and #10T, Fig. 1a). This combination resulted in the production of 61.0 % of methane in biogas, whereas with no JA addition, only 53.6 % of methane was detected. Thermophilic communities #2T and #9T, hydrolyzing 50 g L−1 of BSG, did not overly exceed methane biosynthesis under JA supplementation, and produced in both conditions around 50 % of methane (Fig. 1a). On the contrary, biogas production by mesophilic communities was stimulated after adding the co-substrate (Fig. 1a, b). In general, it takes a longer period for mesophilic communities to utilize BSG. While methanogenesis in the thermophilic communities reached its maximum after 15 days of cultivation, the highest amounts of biogas with 50.4 % (no JA) and 58.3 % (with JA) of methane in mesophilic communities were accumulated over 30–44 days of incubation. Although previously selected microbial communities were able to effectively produce biogas from cellulose and food waste (Tsavkelova et al. 2012b), in this study they were not active under thermophilic conditions. Methane production did not exceed 15–17 % for communities #5T and #6T, and comprised only 23–25 % after supplementation with JA (#7T and #12T). Under mesophilic conditions, the microbial community alone (communities #15M and #17M) also did not show any significant activity, but the mixed communities #16M and #18M were able to produce 50.2 and 54.9 % of CH4, without and with JA supplementation, respectively (data not shown). However, both consortia reduced biogas production in the subsequent re-cultivation.

The methane yield (mL L−1), produced by thermophilic (in black) and mesophilic (in grey) communities in first (a) and fifth (b) passage of cultivation on BSG without (black dots) and with (white dots) supplementation of JA. Thermophilic communities (in black): # 2 (filled square), 9 (open square), 3 (filled triangle), 10 (open triangle); mesophilic communities (in grey): #13 (filled circle), 14 (open circle). The experiments were repeated three times by two replicates in each. The values are the mean of the replicates; variations within the experiments are less than 5 %

Thus, in order to select stable anaerobic communities with permanent activity and no deterioration in biogas biosynthesis, we re-cultivated the selected communities on the new portions of BSG for several (5–6) passages during a year. Among the thermophilic communities, the most active and stable were #2T, #3T, #9T, and #10T, whereas #13M and #14M were selected among the mesophilic ones. After 1 year of cultivation, the amounts of producing biogas reduced and comprised 50–59 and 50–57 % of cumulative methane, correspondingly (Fig. 2). In the first passage, the cumulative methane content for communities #2T, #3T, #9T, and #10T was 4.1, 6.2, 5.4, and 8.6 L CH4 L−1 of medium, respectively. Thus, converting to the amounts of the treated BSG, the methane production comprised 8.2, 6.2, 10.8, and 8.6 L CH4 per 100 g of BSG. Our results show a very effective biotransformation of the BSG into biogas, particularly with the co-digestion of JA (communities’ #9T, #10T and #14M; Fig. 1b). Although by the end of 1 year of re-cultivation, the tested communities slightly reduced its biosynthesis to 7.4, 5.6, 10.0, and 6.1 L CH4 per 100 g of BSG, correspondingly. The mesophilic communities #13M and 14M produced 4.8 and 5.8 L CH4 per 100 g of BSG, without and with JA co-substrate, in the first passage, and 3.5 and 6.0 L after a year of re-cultivation, respectively.

The maximal methane yield produced by thermophilic (a) and mesophilic (b) communities in the beginning (in black) and after a year (in grey) of cultivation on BSG without (communities #2, 3, and 13) and with (#9, 10, and 14) co-digestion of JA. The experiments were repeated three times by two replicates in each. The values are the mean of the replicates

When the chosen nutrient medium for cultivation of anaerobic microbial communities was substituted by tap water only, the time of BSG biotransformation increased by more than twice, although methane yield still comprised 57.2–64.5 %. However, the further re-cultivation resulted in a significant reduction in biogas production, up to 25 %, due to the insufficient content of nutrients, particularly vitamins and growth factors that are critically required for methanogenic archaea.

The complete utilization of BSG, including the remaining solid residue after microbial biotransformation, raises a question on its further treatment. In order to show that the fermented BSG is not toxic and can be applied as bio-fertilizer, improving the plant growth, we used a plant assay. The L. sativum seeds were germinated in soil mixed with the final sediment and remained after biogas production by anaerobic microbial community. The most effective plant growth stimulation was observed with 10 % (w/w) of fermented BSG added to the soil and resulted in biomass (wet weight) enhancement of 1.4 times more than in control (untreated soil). The plant biomass cultivated in substrate and supplemented with 1, 5 and 20 % was 1.10, 1.20, and 1.02 times higher, respectively (Fig. 3). When the vegetative part (stem) was measured, the height of the untreated plants comprised 2.4 ± 0.02 mm, whereas other values were 2.6 ± 0.11, 2.7 ± 0.23, 3.4 ± 0.30, and 3.1 ± 0.38 for 1, 5, 10, and 20 % of added fermented BSG to soil. Thus, the promotion of the biomass weight of the seedlings, treated with fermented BSG, reached 10–20 % compared to the control variables. During the period of plant incubation (over 2 weeks), no inhibitory effects of fermented BSG were detected.

Discussion

The anaerobic fermentation of the wastes reduces their volume and total mass and, in addition, yields energy and generates solid or liquid fertilizer. Our results clearly show that the anaerobic digestion of the BSG by selected microbial communities is an efficient way for its biotransformation into biogas. The temperature at which substrate digestion occurs affects its conversion, kinetics, stability, effluent quality and the methane yield (Sánchez et al. 2001). The anaerobic decomposition of organic matter and biogas formation usually takes less time and provides higher biogas yield under thermophilic rather than mesophilic conditions (Gallert and Winter 1997; Kardos et al. 2011). We also revealed that the BSG bioconversion was faster and more active in thermophilic communities, cultivating in 100 g L−1 of BSG, and reached 50–60 % of methane content. Although, while less energy demand required for bioreactor heating is among the main advantages of mesophilic biogas production, thermophilic systems are more favorable due to its larger biogas output capacity and higher methane gas content (Kardos et al. 2011).

The bioconversion of manure alone results in a relatively low biogas production, and many biogas plants are operated by co-fermentation, together with non-agricultural organic wastes, harvesting residues and crops (Weiland 2006). In this study, we also combined the biotransformation of BSG, co-digested with the phytomass of H. tuberosus and mixed manure as a source of anaerobic microbial community. The additional supplementation of the nutrient media with JA promoted biogas formation, that comprised 8.6 L of CH4 per 100 g of BSG. Even after a year of re-cultivation, the methanogenic activity of thermophilic microbial communities remained high with 6.1 L CH4/100 g BSG. Moreover, in re-cultivated mesophilic communities, the exogenous JA phytomass significantly promoted biogas production and contributed to high levels of methane yield (6.0 L CH4/100 g BSG). Frost- and drought-tolerant H. tuberosus is highly resistant to pests and diseases, which cause it to flourish in extreme abiotic conditions of temperate and cold regions (Bergh et al. 2003; Slimestad et al. 2010). The potential of this plant as feedstock for production of inulin, protein, and bioethanol production has been recently reported (Gunnarsson et al. 2014). In this study, we confirmed the utilization of its aerial parts (leaves and stems) in a biorefinery concept for biogas production.

The anaerobic batch digestion of BSG, together with 20 % of chicken droppings and cow rumen liquor as inoculum, lead to a cumulative biogas yield of 3.5 L per 100 g of BSG after 15 days of incubation (Ezeonu and Okaka 1996). The bioconversion of fresh and ensiled above-ground parts of the JA alone into biogas was reported to yield in 480–680 L kg−1 of organic material (Gunnarson et al. 1985). Several boreal energy crops, including JA, timothy-clover grass and reed canary grass also gave the methane yields of 2900–5400 m3 CH4 ha−1 (Lehtomäki et al. 2008). Thus, JA as feedstock for biogas production as sole substrate or as a co-substrate (this study) has great potential, particularly under conditions of temperate and boreal climate zones.

BSG was reported as a suitable addition to media for cultivation of certain fungi (Aspergillus, Penicillum, Pleurotus, Trichoderma) and bacteria (Streptomyces, Lactobacillus, Bifidobacterium, Bacillus) (Novik et al. 2007; Terrasan et al. 2010; Aliyu and Bala 2011; Mussatto 2014). Other authors reported on the effective co-digestion of BSG with plant residues and animal manure under mesophilic conditions. Goberna et al. (2013) showed that supplementation of BSG with peach flesh residues, juice residues, sewage sludge and pig slurry co-substrates enhanced biogas production, although the methane yield was significantly different, being ranked as follows: pig slurry > sewage sludge > peach flesh residues > mixed juice residues (2788.8, 2186.9, 1686.0, 1433.0 mg CH4 g−1, respectively). Uzodinma and Ofoefule (2008) fermented BSG with abattoir cow liquor, and this increased the amount of biogas produced 3.3 times compared to BSG alone in a 25-day incubation period. Ezekoye and Ezekoye (2009) reported on 2.5 times improved biogas production, which resulted from the fermentation of cow dung with BSG. BSG co-digested with rice husk and incubated in a batch operation resulted in 150 L of biogas on the 47th day of incubation under mesophilic temperatures with a methane content of 52.3 % (Ezekoye and Okeke 2006).

The complex structure of anaerobic communities consists of a diverse group of microorganisms, including hydrolytics, syntrophs, acetogens, and methanogens (Ferry 1993; Schink 1997; Lynd et al. 2002; Ferry 2011), although the composition of an efficient microbial consortium varies depending on inoculum sources, substrate and growth conditions. In this study, we showed that the mixed manure (originated from cattle, donkey, sheep and horses) was the best source for BSG degrading methanogenic community enrichment. Our attempts to enrich effective consortia from other sources, such as compost humus or fallen tree leaves, did not succeed. Previously (Tsavkelova et al. 2012a, b), we have also shown that communities isolated from the herbivorous livestock manure were the most efficient and stable cellulose-degraders and biogas producers, when they were cultivated on different cellulose-containing substrates (different types of paper). Additionally to the newly enriched communities from the manure, we also tested those previously selected microbial communities for their capacity for BSG biotransformation. However, neither thermophilic (#5T, #6T) nor mesophilic (#15M, #16M) consortia showed high activity in BSG conversion into biogas, in contrast to the newly selected communities, enriched from the mixed manure source, a pool of vast diversity of microorganisms.

BSG is mainly composed of protein and fibres (cellulose, hemicellulose and lignin), where sugar corresponds to approximately half of the dry weight of BSG composition (Stojceska et al. 2008; Mussatto 2014). Thus, enriched methanogenic consortia consists of cellulolytic and peptolytic bacteria, such as Clostridium spp. as well as methanogenic archaea (reviewed in Lynd et al. 2002; Tsavkelova and Netrusov 2012). The activity of hydrolytics results in acidification and a decrease in pH that inhibits methanogenesis; although acetoclastic methanogenesis is more sensitive to changes in pH, hydrogenotrophic methanogens are able to grow at a lower pH (Ferry 1993). We showed that under substrate (BSG) concentrations at 500 g L−1 the overproduction of the hydrogen and acidic metabolites totally inhibited the biogas production. The supplementation with 50 and 100 g L−1 of BSG allowed us to keep a neutral pH (by adjusting it to 7.0 with KOH), avoiding the drop in pH caused by the rapid acidification.

It is known that inoculation with rumen filtrate favors high rates of cellulose hydrolysis followed by biogas production (Weimer et al. 1990). Recent studies revealed that the addition of hydrolytic bacteria improved BSG hydrolysis, which resulted in more efficient acidogenesis, acetogenesis and accelerated methanogenesis (Čater et al. 2015). The average methane content (%) of BSG bioconversion to biogas comprised 56 %. The authors showed that Pseudobutyrivibrio xylanivorans Mz5T and co-cultures of Fibrobacter succinogenes S85 with Clostridium cellulovorans and P. xylanivorans Mz5T with F. succinogenes S85 enhanced the lignocellulose degradation and elevated methane production (+17.8, +4.9, and +6.9 %, respectively). In other experiments, the biodegradability of BSG in a single-stage and two-stage solid-state anaerobic digestion (SS-AD) has been carried out. It was shown that SS-AD technology provides better results, achieving biodegradation of 63.5 % and a methane yield of up to 58.7 L kg−1 of raw BSG (vs 55.3 L kg−1 comparing to the single-stage system) (Panjičko et al. 2015).

Microbial communities selected under investigated conditions were shown to produce 550–640 mL of cumulative methane per L of biogas that meets the demands of biogas production from other organic substrates. We also showed the importance for the selection of the anaerobic communities with an optimal microbial composition for BSG hydrolysis and methane biosynthesis. Such consortia are able to keep their activity during long period of re-cultivation without additional portions of new inoculums. The selection of adapted microbial communities allowed us to avoid a BSG pre-treatment stage. The usage of JA as a co-substrate enhanced the biogas yield, particularly in mesophilic communities, that provides an advantage in a more ergonomic use of biogas plants in temperate and cold climates. While raw biogas mixture can be used for combustion and for further upgrade, including the integrated gas separation membranes that we successfully applied previously (Teplyakov et al. 1996), the solid residual might be utilized as an additive to soil in agriculture. We showed that in moderate amounts of 5–20 %, the fermented BSG is not toxic to the tested plants and vice versa and it stimulates the plant growth, most likely due to remaining nitrogen, phosphorous and other nutrients. Thus, our study suggests a potential way for the complete utilization of such abundant brewery side products as BSG.

References

Aliyu S, Bala M (2011) Brewer’s spent grain: a review of its potentials and applications. Afr J Biotechnol 10(3):324–331. doi:10.5897/AJBx10.006

Angelidaki I, Karakashev D, Batstone DJ, Plugge CM, Stams AJ (2011) Biomethanation and its potential. Methods Enzymol 494:327–351. doi:10.1016/B978-0-12-385112-3.00016-0

Antizar-Ladislao B, Turrion-Gomez JL (2008) Second-generation biofuels and local bioenergy systems. Biofuels Bioprod Biorefin 2(5):455–469. doi:10.1002/bbb.97

Bergh J, Freeman M, Sigurdsson B, Kellomäki S, Laitinen K, Niinistö S, Peltola H, Linder S (2003) Modelling the short-term effects of climate change on the productivity of selected tree species in Nordic countries. For Ecol Manag 183:327–340. doi:10.1016/S0378-1127(03)00117-8

Björnsson P, Mattiasson B (2008) Biogas as a resource-efficient vehicle fuel. Trends Biotechnol 26(1):7–13. doi:10.1016/j.tibtech.2007.09.007

Bochiwal C, Malley C, Chong JPJ (2010) Biomethane as an energy source. In: Timmis KN (ed) Handbook of hydrocarbon and lipid microbiology. Springer, Berlin, pp 2810–2815

Čater M, Fanedl L, Malovrh Š, Logar RM (2015) Biogas production from brewery spent grain enhanced by bioaugmentation with hydrolytic anaerobic bacteria. Biores Technol 186:261–269. doi:10.1016/j.biortech.2015.03.029

Cheng Y, Zhou W, Gao C, Lan K, Gao Y, Wu Q (2009) Biodiesel production from Jerusalem artichoke (Helianthus tuberosus L) tuber by heterotrophic microalgae Chlorella protothecoides. JCTB 84(5):777–781. doi:10.1002/jctb.2111

El-Shafey EI, Gameiro M, Correia P, de Carvalho J (2004) Dewatering of brewers’ spent grain using a membrane filter press: a pilot plant study. Sep Sci Technol 39:3237–3261. doi:10.1081/SS-200028775

Ezekoye VA, Ezekoye BA (2009) Characterization and storage of biogas produced from the anaerobic digestion of cow dung, spent grains/cow dung, and cassava peels/rice husk. PJST 10(2):898–904

Ezekoye VA, Okeke CE (2006) Design, construction, and performance evaluation of plastic biodigester and the storage of biogas. PJST 7(2):176–184

Ezeonu FC, Okaka ANC (1996) Process kinetics and digestion efficiency of anaerobic batch fermentation of brewer’s spent grains (BSG). Process Biochem 31(1):7–12. doi:10.1016/0032-9592(94)00064-6

Fargione J, Hill J, Tilman D, Polasky S, Hawthorne P (2008) Land clearing and the biofuel carbon debt. Science 319(5867):1235–1238. doi:10.1126/science.1152747

Ferry JG (ed) (1993) Methanogenesis. Ecology, physiology, biochemistry and genetics. Chapman & Hall, New York

Ferry JG (2011) Fundamentals of methanogenic pathways that are key to the biomethanation of complex biomass. Curr Opin Biotechnol 22(3):51–57. doi:10.1016/j.copbio.2011.04.011

Gallert C, Winter J (1997) Mesophilic and thermophilic anaerobic digestion of source-sorted organic wastes: effect of ammonia on glucose degradation and methane production. Appl Microbiol Biotechnol 48:405–410. doi:10.1007/s002530051071

Glissmann K, Hammer E, Conrad R (2005) Production of aromatic compounds during methanogenic degradation of straw in rice field soil. FEMS Microbiol Ecol 52(1):43–48. doi:10.1016/j.femsec.2004.10.004

Goberna M, del Mar Camacho M, Lopez-Abadia JA, García C (2013) Co-digestion, biostimulation and bioaugmentation to enhance methanation of brewer’s spent grain. Waste Manag Res 31(8):805–810. doi:10.1177/0734242X13497078

Gunaseelan VN (1997) Anaerobic digestion of biomass for methane production: a review. Biomass Bioenergy 13(1–2):83–114. doi:10.1016/S0961-9534(97)00020-2

Gunnarson S, Malmberg A, Mathisen B, Theander O, Thyselius L, Wünsche U (1985) Jerusalem artichoke (Helianthus tuberosus L.) for biogas production. Biomass 7:85–97. doi:10.1016/0144-4565(85)90036-8

Gunnarsson IB, Svensson S-E, Johansson E, Karakasheva D, Angelidaki I (2014) Potential of Jerusalem artichoke (Helianthus tuberosus L.) as a biorefinery crop. Ind Crops Prod 56:231–240. doi:10.1016/j.indcrop.2014.03.010

Kardos ÁJ, Palkó G, Oláh J, Barkács K, Záray G (2011) Comparing of mesophilic and thermophilic anaerobic fermented sewage sludge based on chemical and biochemical tests. Appl Ecol Environ Res 9(3):293–302

Lehtomäki A, Viinikainen TA, Rintala JA (2008) Screening boreal energy crops and crop residues for methane biofuel production. Biomass Bioenergy 32(6):541–550. doi:10.1016/j.biombioe.2007.11.013

Li L, Li L, Wang Y, Du Y, Qin S (2013) Biorefinery products from the inulin-containing crop Jerusalem artichoke. Biotechnol Lett 35:471–477. doi:10.1007/s10529-012-1104-3

Lynd LR, Weimer PJ, van Zyl WH, Pretorius IS (2002) Microbial cellulose utilization: fundamentals and biotechnology. Microbiol Mol Biol Rev 66(3):506–577. doi:10.1128/MMBR.66.3.506-577.2002

Mbagwu JSC, Ekwealor GC (1990) Agronomic potential of brewers’ spent grains. Biol Wastes 34(4):335–347. doi:10.1016/0269-7483(90)90034-P

Menon V, Rao M (2012) Trends in bioconversion of lignocellulose: biofuels, platform chemicals and biorefinery concept. Prog Energy Combust 38(4):522–550. doi:10.1016/j.pecs.2012.02.002

Mussatto SI (2014) Brewer’s spent grain: a valuable feedstock for industrial applications. J Sci Food Agric 94:1264–1275. doi:10.1002/jsfa.6486

Mussatto SI, Roberto IC (2006) Chemical characterization and liberation of pentose sugars from brewer’s spent grain. J Chem Technol Biotechnol 81:268–274. doi:10.1002/jctb.1374

Novik GI, Wawrzynczyk J, Norrlow O, Szwajcer-Dey E (2007) Fractions of barley spent grain as media for growth of probiotic bacteria. Microbiology 76(6):804–808. doi:10.1134/S0026261707060227

Panjičko M, Zupančič GD, Zelić B (2015) Anaerobic biodegradation of raw and pre-treated brewery spent grain utilizing solid state anaerobic digestion. Acte Chem Slov 62:1–9. doi:10.17344/acsi.2015.1534

Petersson A, Thomsen M, Hauggaard-Nielsen H, Thomsen A-B (2007) Potential bioethanol and biogas production using lignocellulosic biomass from winter rye, oilseed rape and faba bean. Biomass Bioenergy 31(11–12):812–819. doi:10.1016/j.biombioe.2007.06.001

Razmovski RN, Šćiban MB, Vučurović VM (2011) Bioethanol production from Jerusalem artichoke by acid hydrolysis. Rom Biotech Lett 16(5):6497–6503

Sánchez E, Borja R, Weiland P, Travieso L, Martin A (2001) Effect of substrate concentration and temperature on the anaerobic digestion of piggery waste in a tropical climate. Process Biochem 37(5):483–489. doi:10.1016/S0032-9592(01)00240-0

Schink B (1997) Energetics of syntrophic cooperation in methanogenic degradation. MMBR 61(2):262–280

Sebola R, Tesfagiorgis H, Muzenda E (2014) Production of biogas through anaerobic digestion of various waste: review. In: Proceedings of international conference on chemical, integrated waste management and environmental engineering (ICCIWEE’2014), Johannesburg, pp 196–201

Sežun M, Grilc V, Zupancic GD, Logar RM (2011) Anaerobic digestion of brewery spent grain in a semi-continuous bioreactor: inhibition by phenolic degradation products. Acta Chim Slov 58:158–166

Slimestad R, Seljaasen R, Meijer K, Skar SL (2010) Norwegian-grown Jerusalem artichoke (Helianthus tuberosus L.): morphology and content of sugars and fructo-oligosaccharides in stems and tubers. J Sci Food Agric 90(6):956–964. doi:10.1002/jsfa.3903

Snitsar A, Kirilov M, Jakhin A, Ryzjov D, Avylov Ch, Son K (2004) Brewery spent grain in starter mixed fodder for calves (in Russian). Dairy Beef Cattle Farming 2:11–13

Stojceska V, Ainsworth P, Plunkett A, Ibanoğlu E, Ibanoğlu Ş (2008) Cauliflower by-products as a new source of dietary fibre, antioxidants and proteins in cereal based ready-to-eat expanded snacks. J Food Eng 87(4):554–563. doi:10.1016/j.jfoodeng.2008.01.009

Teplyakov V, Sostina E, Backman I, Netrusov A (1996) Integrated membrane systems for gas separation in biotechnology: potential and prospects. World J Microbiol Biotechnol 12(5):477–485. doi:10.1007/BF00419461

Terrasan CRF, Temer B, Duarte MCT, Carmona EC (2010) Production of xylanolytic enzymes by Penicillium janczewskii. Bioresour Technol 101:4139–4143. doi:10.1016/j.biortech.2010.01.011

Tsavkelova EA, Netrusov AI (2012) Biogas production from cellulose-containing substrates (a review). Appl Biochem Microbiol 48(5):421–433. doi:10.1134/S0003683812050134

Tsavkelova EA, Egorova MA, Petrova EV, Netrusov AI (2012a) Thermophilic anaerobic microbial communities that transform cellulose into methane (biogas). Moscow Univ Biol Sci Bull 67(2):75–81. doi:10.3103/S0096392512010099

Tsavkelova EA, Egorova MA, Petrova EV, Netrusov AI (2012b) Biogas production by microbial communities via decomposition of cellulose and food waste. Appl Biochem Microbiol 48(4):377–384. doi:10.1134/S0003683812040126

Uzodinma EO, Ofoefule AU (2008) Effect of abattoir cow liquor waste on biogas yield of some agro-industrial wastes. Sci Res Essays 3(10):473–476

Vorob’eva S, Draganov I, Bogoljubova N (2005) Brewery spent grain in calf’s food ration. Anim Husb Russ (Russ) 3:31–33

Weiland P (2006) Biomass digestion in agriculture: a successful pathway for the energy production and waste treatment in Germany. Eng Life Sci 6(3):302–309. doi:10.1002/elsc.200620128

Weiland P (2010) Biogas production: current state and perspectives. Appl Microbiol Biotechnol 85(4):849–860. doi:10.1007/s00253-009-2246-7

Weimer PJ, Lopez-Guisa JM, French AD (1990) Effect of cellulose fine structure on kinetics of its digestion by mixed ruminal microorganisms in vitro. Appl Environ Microbiol 56(8):2421–2429

Zavarzin GA (1997) Methane emission from the territory of Russia. Microbiology (Rus) 66(5):558–561

Acknowledgments

We thank Andrej I. Shestakov for technical assistance in gas chromatography experiments, and we cordially thank Mr. Paul Girling for grammatically editing the manuscript.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Rights and permissions

About this article

Cite this article

Malakhova, D.V., Egorova, M.A., Prokudina, L.I. et al. The biotransformation of brewer’s spent grain into biogas by anaerobic microbial communities. World J Microbiol Biotechnol 31, 2015–2023 (2015). https://doi.org/10.1007/s11274-015-1951-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11274-015-1951-x