Abstract

FG-06 is a microbial consortium screened from activated sludge of coking wastewater treatment plant, which has excellent heterotrophic nitrification-aerobic denitrification ability. The aim of the study is to evaluate the possible factors affecting its heterotrophic nitrification performance and the feasibility of its application in the treatment of coking wastewater in a sequencing batch reactor (SBR). Results indicate the consortium could grow and effectively remove ammonium when the salt concentration was below 50 g/L. In the range of pH 5.0–10.0, more than 97% NH4+-N was removed by the consortium. Adding 1000 mg/L phenol in the basal medium (BM) had no significant effect on its nitrification ability. However, when phenol was used as the sole carbon source, the removal efficiency of phenol and ammonium decreased with the increase of phenol concentration in the case of 1% inoculum dose, which was improved by increasing the inoculum size. The removal efficiency of phenol, NH4+-N and COD reached 99.63%, 98.41%, and 83.69% when 3% of the consortium was inoculated in actual coking wastewater in the batch test. Bioaugmentation experiment shows that the consortium could effectively improve the simultaneous removal performance of carbon and ammonium in the SBR.

Graphical Abstract

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

1 Introduction

Coking wastewater, a kind of complicated industrial wastewater is generated from the process of coal coking, coal gas purification, and byproduct recovery. The wastewater contains lots of inorganic and organic pollutants, most of the pollutants in the wastewater are refractory and toxic, which brings great difficulty to the wastewater treatment (Huang et al., 2016; Liu et al., 2021; Ren et al., 2018). Phenol is considered the most abundant compound and the important component of the chemical oxygen demand (COD) of coking wastewater (Tamang & Paul, 2021; Zhu et al., 2012; Zhu et al., 2015). Ammonia is another important pollutant in the wastewater. In order to obtain ideal effect, a series of physical, chemical and biological processes are usually employed together. However, biological process is the core of the wastewater treatment (Shi et al., 2020). At present, the main biotechnology for the wastewater treatment includes anoxic-oxic (A/O) and anaerobic-anoxic-oxic (A/A/O). In these conventional technologies, ammonium removal is realized by the process of autotrophic aerobic nitrification and heterotrophic anaerobic denitrification, in which carbon and ammonium could not be removed simultaneously because of the different requirement for nutrient and environment. Therefore, there are some disadvantages in these technologies, such as overlong hydraulic residence time, large space for structure and strict control of conditions. Furthermore, autotroph is sensitive to high concentration of organic matter and ammonium (Yang et al., 2018; Zhang et al., 2015).

Recently, heterotrophic nitrification-aerobic denitrification has drawn more attention. It is expected to overcome the shortcomings of the conventional technologies because of its capacity of simultaneous removal of ammonium and carbon. More and more strains with the capacity of heterotrophic nitrification-aerobic denitrification were continuously isolated from different environment (Gu et al., 2022; Song et al., 2023). Related research focuses on the isolation and characterization of pure strains, which will contribute to the development of efficient wastewater treatment processes (Medhi et al., 2017). However, compared with a single strain, a specific consortium may be more useful in pollutants degradation through the synergy among different strains, even in the removal of a single contaminant (Ahmad, 2022; Herrero & Stuckey, 2015; Shanmugam et al., 2017). Some studies reported that mixed culture is more efficient than pure culture in phenol degradation (Li et al., 2020; Marrot et al., 2006). Zhang et al obtained excellent removal effects of indole, pyridine and quinolone by inoculating quinoline-degrading strain and indole-degrading strain in the synthetic wastewater supplemented with phenol, indole, quinoline and pyridine (Zhang et al., 2021). Actually, more and more studies tend to use mixed strains from special environments, especially for the degradation of refractory substances (Bera et al., 2017; Swain et al., 2020).

However, actual coking wastewater is not only complex in composition, but also highly toxic. Therefore, it always needs to be reduced in toxicity and improved in biodegradability using anaerobic reaction section (Li et al., 2020), adding carrier or effective carbon source (Sun et al., 2019), and so on. Most of the research focus on the degradation of organic pollutants in the wastewater, while few studies on the simultaneous removal of nitrogen and carbon by heterotrophic nitrifier (Lu et al., 2009; Shi et al., 2020). The mixed culture FG-06, enriched from coking wastewater active sludge by our laboratory, could remove carbon and ammonium simultaneously under wide range of C/N 4-32. Meanwhile, the consortium could remove phenol and ammonium simultaneously in batch tests (Yang et al., 2017). In this study, we investigated the factors affecting the simultaneous removal ability of carbon and nitrogen by the consortium and applied it to the treatment of coking wastewater from a local iron and steel company. The result may provide useful information about heterotrophic nitrification for bioaugmentation in coking wastewater treatment.

2 Materials and Methods

2.1 Bacterial Consortium and Culture Media

The microbial consortium FG-06 used in this study was isolated from the activated sludge in the aeration tank of coking wastewater treatment plant of Taiyuan Iron and Steel Company (Shanxi Province, China). The main water quality parameters of the coking wastewater were as follows: COD, 2610 ~ 2940 mg/L; NH4+-N (ammonia), 75.78 ~ 88.91 mg/L; pH 6.1 ~ 7.7. Acinetobacter spp. and Pseudomonas spp. were the two most dominant genera in the consortium (Yang et al., 2017). The consortium was stored in 25% glycerol solution at -80 °C and used after activation.

The basal medium (BM) contained (per liter): sodium succinate 3.473 g, (NH4)2SO4 0.472 g, MgSO4·7H2O 0.05 g, K2HPO4 0.2 g, NaCl 0.12 g, MnSO4·4H2O 0.01 g, FeSO4·7H2O 0.01 g. The phenol medium (PM) used the phenol of different concentration (200, 500, 800, 1000 mg/L) as the sole carbon source instead of sodium succinate in the BM. The initial pH of the media was set at 7.0 unless otherwise stated. The culture solution of 1 mL was inoculated into 100 mL BM and cultivated at 120 rpm and 30 °C for 48 h, which was used as the seed culture. A certain amount of seed culture was inoculated in the corresponding medium or wastewater according to the specific inoculum size in the following experiments.

2.2 Influencing Factors

To study the effect of salinity on the pollutant removal, the NaCl concentration was varied from 0 to 50 g/L in the BM, 0.12 g/L as the control (same concentration as the BM). For investigating the influence of pH, the initial pH of the BM was adjusted to 5, 6, 7, 8, 9, and 10, respectively.

In order to evaluate the effect of phenol on the nitrogen removal, phenol of 200, 500, 800 and 1000 mg/L was respectively added to the BM and the amount of sodium succinate was adjusted to maintain constant C/N ratio of 12. The inoculum size was 1% (v/v).

2.3 Pollutant Removal Performance with Phenol as a Sole Carbon Source

For testing the nitrogen removal performance using phenol as a sole carbon source, the PM with phenol of 200, 500, 800, and 1,000 mg/L was inoculated with 1% (v/v) of the seed culture, respectively. To determine the effect of inoculum size on phenol and ammonium degradation, 1%, 3%, 5%, 7%, and 9% of the seed consortium was inoculated in the PM containing 500 mg/L phenol.

2.4 Raw Coking Wastewater Treatment in Shake Flask Experiment

The coking wastewater used in the experiment was taken from the wastewater treatment plant of Taiyuan Iron and Steel Company (Shanxi Province, China). The seed culture of the consortium 3% (v/v) was inoculated in the sterilized coking wastewater and cultivated at 120 rpm, 30°C for 48 h. Then 3% of the culture solution was transferred to the fresh sterilized coking wastewater, meanwhile, the sterilized coking wastewater without inoculation used as a control.

In the experiments of Sections 2.2–2.4, samples (10–20 mL of each sample) were periodically collected to determine bacterial density and pH value, and then centrifuged (9280 ×g, 10 min) to obtain supernatant for testing. All experiments were carried out in triplicate.

2.5 Raw Coking Wastewater Treatment Using Sequencing Batch Reactor

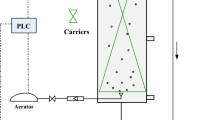

The consortium culture in the sterilized coking wastewater (as Section 2.4) was centrifuged at 9280 ×g for 10 min. The supernatant was discarded and the cell was used as inoculant in the following experiment. Figure 1 shows the sequencing batch reactor (SBR) device made of plexiglass. Two of the same reactors with a total volume of 7 L were operated at room temperature in parallel. The two reactors were both inoculated with 150 mL of the activated sludge from the coking wastewater treatment plant of Taiyuan Iron and Steel Corporation (Shanxi, China). After two days of aeration, two reactors entered into the startup period till obtaining stable state. Then reactor 1 as a bioaugmentation system was added with the cell of FG-06 at 3% (v/v) inoculum size. Reactor 2 was a reactor without the consortium as a control system. The two systems ran continuously with a cycle of 48 h which consisted of four phases: filling 0.5 h, aeration 45 h, settling 2.0 h and decanting 0.5 h. The DO (dissolved oxygen) of the system was controlled around 3-4 mg/L. The discharge ratio was 50 % in each cycle.

2.6 Analytical Methods

The growth of the consortium was determined by spectrophotometry at 600 nm (OD600). NH4+-N was determined by the method of Nessler’s reagent spectrophotometry at a wavelength of 420 nm. TN was detected by the alkaline persulfate oxidation with a UV spectrophotometric method (Pawlowski, 1994). Phenol was measured by the 4-aminoantipyrine spectrophotometric method (Fiamegos et al., 2002). COD was measured using a COD analyzer (DR 1010, HACH, USA) and pH was measured with a pH meter (PB-10, Sartorious, Germany).

The pollutant removal efficiency is calculated by R = (C0–Cn)/C0 × 100, and removal rate by Ra = (C0 – Cn)/t, where C0 is the initial concentration, Cn is the final concentration at the given time and t is the treatment time. Each treatment was performed in triplicate and results were presented as means ± SD (standard deviation of means). Statistical analysis and graphical work were carried out by using Excel and Origin 8.0.

3 Results and Discussion

3.1 Factors Influencing the Performance of the Pollutant Removal

Salinity is a key factor which influences the growth and metabolism of microorganism. High salinity, one of the feature of a coking wastewater, may result in dehydration, plasmolysis, and even cell disintegration (Wang et al., 2016; Zhai et al., 2018). Therefore, it is important to investigate the tolerance of the consortium to salinity. Figure 2 shows the effect of salinity on the growth and ammonium removal of the consortium. It was obvious that the growth rate was affected by salinity, especially at 40 and 50 mg/L. When NaCl was below 30 g/L, the ammonium removal performance had no significant difference among the different groups. When the concentration exceeded 30 g/L, the ammonium removal efficiency declined slightly, 85.17% at 40 g/L, and 71.76% at 50 g/L in 48 h, respectively. Mannina et al. reported that the nitrification efficiency in a MBR system was decreased by 20 g/L (2.0 %) NaCl (Mannina et al., 2016). Zhai et al. found the denitrification activity of both the traditional biofilm reactor and biofilm electrode reactor was inhibited as the salinity increased from 0.0 to 1.0% (10 g/L) (Zhai et al., 2018). Therefore, higher halotolerance microorganism is very important for the treatment of hypersaline wastewater. Salt-tolerant nitrifier is conducive to nitrogen removal under hyperosmotic environment (Miao et al., 2020; Zerva et al., 2021). However, conventional nitrifying bacteria are sensitive to high salinity (Song et al., 2023). Compared with autotrophic nitrifier, heterotrophic nitrifier has better stress resistant and adaptability to high salt environment (Jin et al., 2019). Our previous study shows that Acinetobacter spp. and Pseudomonas spp., typical heterotrophic nitrifier, were the most dominant species in the consortium (Yang et al., 2017). Most literatures reported the optimal salinity of heterotrophic nitrifier was fewer than 4% (40 g/L) (Kim et al., 2016; Liu et al., 2012; Padhi & Maiti, 2017; Wang & Han, 2012). Hu et al. reported that the growth of Acinetobacter sp. and Pseudomonas sp. was completely inhibited at the salinity of 3% (30 g/L) and 5% (50 g/L), respectively. Moreover, the ammonium removal efficiency of Pseudomonas sp. at 3% salinity (30 g/L) in 48 h was only about 50% (Hu et al., 2021). In this study, the consortium showed better growth and ammonium removal performance even at the salt concentration of 50 g/L. Therefore, it could be defined as a halotolerant mixed bacterial consortium.

The value of pH is another important influence factor in nitrogen removal. For either an autotrophic or heterotrophic nitrifier, the nitrification will be inhibited when the pH is too low or too high (Cao et al., 2021; Zeng et al., 2020). It has been reported that the optimum pH value for nitrifier in pure culture is 7–9, and Ph 6 is the lower limit (Hayatsu et al., 2008). In this study, the consortium FG-06 performed efficient nitrification at the range of Ph 5.0-10.0, and NH4+-N removal efficiency reached above 97% (Fig. 3a). This is due to the fact that its growth has not been greatly affected by the Ph fluctuation (Fig. 3b). Therefore, the consortium FG-06 could adapt to a wide range of Ph. Whatever the initial Ph, the final Ph of the experiments became alkaline (about Ph 9), which is different from autotrophic nitrification. In the above experiments, with the removal of the NH4+-N, TN and COD were also removed simultaneously and effectively (data not shown).

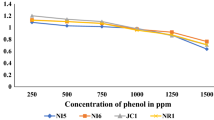

Phenol is the characteristic pollutant of a coking wastewater. Although it is degraded more readily than other aromatic compounds, high concentration of phenol has bio-toxicity. Fang et al. reported that phenol was a typical inhibitor which would exert negative impact on the nitrogen removal in a coal gasification wastewater (Fang et al., 2013). For testing the tolerance to phenol, the effect of initial phenol concentration on the simultaneous removal of phenol and nitrogen by FG-06 was studied over the initial concentration range of 200–1000 mg/L. The results showed that adding phenol had little effect on the pollutant removal ability (Fig. 4). When 200, 500 or 800 mg/L of phenol was added in the BM, the concentration of phenol and NH4+-N decreased more than 50% at 12 h and almost to zero at 24 h. The maximum removal rate of NH4+-N was 7.26, 7.17, and 7.08 mg/L/h, respectively. When 1000 mg/L phenol was added, the consortium grew well, but its degradation rate was slightly decreased than the other three concentrations. The NH4+-N and phenol were removed completely at 36 h and 48 h at the maximum removal rate of 5.67 and 30.64 mg/L/h, respectively. In the process of heterotrophic nitrification-aerobic denitrification, ammonia is oxidized to NO2- or NO3- , then denitrified to N2. Therefore, if nitrate and nitrite generated in nitrification can be completely reduced through denitrification, TN would be removed effectively. However, insufficient carbon sources or other reasons will lead to accumulation of NO2- or NO3-, affecting the removal efficiency of TN. In the study, the degradation rate of TN by FG-06 was consistent with NH4+-N, indicating no intermediates accumulated in the process. In addition, the change of pH value in the nitrogen removal showed the same trend in the four phenol concentration groups, from neutral to alkaline. It is well known that carbon source plays an important role in heterotrophic nitrification and greatly affects the efficiency of nitrogen removal (Kim et al., 2016; Padhi & Maiti, 2017). In the study, FG-06 showed high tolerance to phenol and simultaneous removal capacity of ammonium and phenol, which makes it a good candidate for the biotreatment of coking wastewater.

Some small molecular acids such as acetate, butyrate, citrate, lactate, succinate, may play the role of co-metabolite substrate to promote the degradation of refractory organic compounds (Wang & Han, 2012). Therefore, to verifying the possibility, the consortium was inoculated in the PM. With the initial inoculum size of 1%, the simultaneous removal performance of phenol and ammonium by FG-06 is shown in Fig. 5. At initial phenol concentrations of 200 mg/L, the consortium was able to degrade the phenol and nitrogen simultaneously and phenol was completely removed at 24 h. The removal efficiency of NH4+-N and TN within 48 h was 95.08% and 90.74%, respectively. When the phenol concentration was 500 mg/L and 800 mg/L, phenol and NH4+-N could not be completely removed by FG-06. The maximum removal efficiency of NH4+-N and phenol was 91.36% and 93.90% at 500 mg/L, 80.34% and 88.08% at 800 mg/L, respectively. When the concentration reached 1000 mg/L, the performance of the consortium was significantly affected by phenol, the removal efficiency of NH4+-N and TN was less than 30%, and the residual phenol was still very high, 811.49 mg/L at 48 h. Under the four concentrations, the trend of pH value was the same, all from neutral to acidic, which was different from the above experiment of the mixed carbon. The decrease of pH value may be due to the metabolites of phenol. Acidic environment is not conducive to the growth of bacteria, but also to the denitrification of heterotrophic nitrifier. Similar phenomenon has also been observed in our previous study about heterotrophic nitrification (Liu et al., 2012). Because succinate can easily involve in tricarboxylic acid cycle, it is often used as a good candidate for carbon source of denitrification and co-metabolic substrate (Lauchnor & Semprini, 2013; Xi et al., 2022). From the characteristic of the above experiments, sodium succinate may indeed play the role of co-metabolism in removal of phenol and ammonium.

It is well-known that increasing the inoculum size can shorten the lag phase of bacterial growth. Some literatures reported that the inoculum size strongly affects the success of aerobic bioaugmentation (Nzila et al., 2016). For investigating the role of inoculum size on phenol and NH4+-N degradation, the consortium of 1%, 3%, 5%, 7%, and 9% was inoculated in the PM containing phenol of 500 mg/L. The result is showed in Fig. 6. It is clear that the minimum dosage of 1% was not conducive to the pollutant removal by the consortium. For the inoculum size of 3–9%, 500 mg/L phenol was completely degraded within 24 h and COD was almost thorough removed within 48 h. At 1% inoculum size, it took about 60 h for phenol to be completely degraded, while COD cannot be completely removed even at 60 h. However, inoculum size had no significant effect on the nitrogen removal performance except 1% group. Considering the possible influence of excessive culture on the experiment, we chose 3% as the inoculation amount for subsequent experiments.

3.2 Performance of the Coking Wastewater Treatment in Shake Flask Experiment

The consortium was used to treat the coking wastewater in the shake flask. As shown in Fig. 7, the consortium grew slowly and the value of OD600 reached the maximum on 6 d, indicating that the consortium can still survive in the extreme environment of the coking wastewater. As the bacteria grew, the pollutant was gradually removed. However, the removal rate was far lower than that in the PM. The concentration of phenol, NH4+-N and COD decreased to the minimum on 7 d at the removal efficiency of 99.63%, 98.41%, and 83.69%, respectively. At the end of the experiment, the residual COD was still high. Generally, most of the residual COD after biological treatment of coking wastewater are composed of non-biodegradable or refractory matters, which should be further removed by physical-chemical treatment to meet the discharge standard (Li et al., 2018; Wei et al., 2019).

In summary, the consortium could adapt to the harsh environment and achieve the simultaneous removal of carbon and ammonia from the coking wastewater. Figure 8 shows the possible mechanism of pollutant removal from the coking wastewater by FG-6. Ammonia nitrogen was transformed into NH2OH through AMO (Ammonia oxidase), NH2OH was further transformed NO2- through HAO (Hydroxylamine oxidase), NO2- was oxidized into NO3- through NxR (Nitrite oxidoreductase), and NO3- was reduced to NO2- and eventually to N2 through a series of NR (Nitrate reductase) and NiR (Nitrite reductase) (Pan & Liu, 2023). Furthermore, various organic pollutants in coking wastewater were transformed into various intermediate metabolites through a series of biodegradation processes, and further mineralized into CO2 and H2O. Particularly, there were lots of N - heterocyclic compounds (NHCs) in coking wastewater (Ma et al., 2018; Wu et al., 2018). These compounds would degrade and release ammonia nitrogen, which can also be removed by FG-06.

3.3 Bioaugmentation Performance in Coking Wastewater Treatment

Two parallel SBR reactors were started up for testing the bioaugmentation performance of the consortium. The SBR system ran continuously for 18 days before the addition of the consortium FG-06. As shown in Fig. 9, two reactors showed the similar performance, the effluent concentration was gradually stable after 12 day’s operation. The removal efficiency of COD and NH4+-N was around 65% and 45%, respectively. Phenol could be completely removed at the final stage of the startup period. After that, reactor 1 was bioaugmented with the consortium, reactor 2 was used as a control. It can be seen from Fig. 10 that phenol could be removed completely throughout the whole period in the two reactors. Because the indigenous bacteria could effectively degrade phenol, the contribution of the consortium could not be reflected from the phenol removal performance. However, reactor 1 achieved the high removal efficiency of COD and NH4+-N comparing with the control. The COD of the effluent of reactor 1 was 490±56.57 mg/L, which was generally 130±70.71 mg/L lower than that of the reactor 2. In the first cycle of bioaugmentation application of FG-06, the NH4+-N content in the effluent of reactor 1 was about 32.08 mg/L which was lower than the reactor 2 (about 54.16 mg/L). On the 20th day, the removal efficiency of NH4+-N in reactor 1 gradually stabilized, and reached 63.57% at the best time, while about 45% in reactor 2. The results show that the consortium could strengthen the simultaneous removal of COD and ammonium in treating the raw coking wastewater. Coking wastewater contains a lot of toxic and refractory compounds, especially N - heterocyclic compounds, which are not only difficult to be degraded, but also release ammonia nitrogen after degradation. The heterotrophic nitrifier FG-06 has strong stress resistance and the ability of simultaneous nitrogen and carbon removal, therefore, the addition of the consortium FG-06 was a feasible way of removing organic compounds and ammonium from the coking wastewater.

4 Conclusions

The consortium exhibited efficient NH4+-N removal efficiency under the salinity of 0–5% and the pH of 5-10. Additional phenol had no significant effect on the removal efficiency of ammonium and phenol, which, however, decreased with the increase of phenol concentration when phenol was used as the sole carbon source under 1% inoculum dose. The impact was reduced by the increasing the inoculums dose. In the batch test, NH4+-N and COD in actual coking wastewater could be removed simultaneously. The bioaugmented SBR could degrade 63.57% of NH4+-N, 76.84% of COD and 100% of phenol. The bioaugmentation with the consortium FG-06 could be considered as an effective and economical technology for the treatment of coking wastewater.

Data Availability

Data availability All the data analyzed during the study are original data and included in the manuscript.

References

Ahmad, I. (2022). Microalgae–Bacteria Consortia: A Review on the Degradation of Polycyclic Aromatic Hydrocarbons (PAHs). Arabian Journal for Science and Engineering, 47, 19–43. https://doi.org/10.1007/s13369-021-06236-9

Bera, S., Roy, A. S., & Mohanty, K. (2017). Biodegradation of phenol by a native mixed bacterial culture isolated from crude oil contaminated site. International Biodeterioration & Biodegradation. https://doi.org/10.1016/j.ibiod.2017.04.002

Cao, X., Zhou, X., Xue, M., Chen, J., & Li, S. (2021). Evaluation of nitrogen removal and N2O emission in a novel anammox coupled with sulfite-driven autotrophic denitrification system: Influence of pH. Journal of Cleaner Production, 321, 128984. https://doi.org/10.1016/j.jclepro.2021.128984

Fang, F., Han, H., Zhao, Q., Xu, C., & Zhang, L. (2013). Bioaugmentation of biological contact oxidation reactor (BCOR) with phenol-degrading bacteria for coal gasification wastewater (CGW) treatment. Bioresource Technology, 150, 314–320. https://doi.org/10.1016/j.biortech.2013.09.119

Fiamegos, Y., Stalikas, C., & Pilidis, G. (2002). 4-Aminoantipyrine spectrophotometric method of phenol analysis: Study of the reaction products via liquid chromatography with diode-array and mass spectrometric detection. Analytica Chimica Acta, 467, 105–114. https://doi.org/10.1016/S0003-2670(02)00072-7

Gu, X., Leng, J., Zhu, J., Zhang, K., Zhao, J., Wu, P., Xing, Q., Tang, K., Li, X., & Hu, B. (2022). Influence mechanism of C/N ratio on heterotrophic nitrification- aerobic denitrification process. Bioresource Technology, 343, 126116. https://doi.org/10.1016/j.biortech.2021.126116

Hayatsu, M., Tago, K., & Saito, M. (2008). Various players in the nitrogen cycle: Diversity and functions of the microorganisms involved in nitrification and denitrification. Soil Science and Plant Nutrition, 54, 33–45. https://doi.org/10.1111/j.1747-0765.2007.00195.x

Herrero, M., & Stuckey, D. C. (2015). Bioaugmentation and its application in wastewater treatment: A review. Chemosphere, 140, 119–128. https://doi.org/10.1016/j.chemosphere.2014.10.033

Hu, J., Yan, J., Wu, L., Bao, Y., Yu, D., & Li, J. (2021). Simultaneous nitrification and denitrification of hypersaline wastewater by a robust bacterium Halomonas salifodinae from a repeated-batch acclimation. Bioresource Technology. https://doi.org/10.1016/j.biortech.2021.125818

Huang, Y., Hou, X., Liu, S., & Ni, J. (2016). Correspondence analysis of bio-refractory compounds degradation and microbiological community distribution in anaerobic filter for coking wastewater treatment. Chemical Engineering Journal, 304, 864–872. https://doi.org/10.1016/j.cej.2016.05.142

Jin, P., Chen, Y., Yao, R., Zheng, Z., & Du, Q. (2019). New insight into the nitrogen metabolism of simultaneous heterotrophic nitrification-aerobic denitrification bacterium in mRNA expression. Journal of Hazardous Materials. https://doi.org/10.1016/j.jhazmat.2019.03.023

Kim, H., Kim, J., Shin, S. G., Hwang, S., & Lee, C. (2016). Continuous fermentation of food waste leachate for the production of volatile fatty acids and potential as a denitrification carbon source. Bioresource Technology, 207, 440–445. https://doi.org/10.1016/j.biortech.2016.02.063

Lauchnor, E. G., & Semprini, L. (2013). Inhibition of phenol on the rates of ammonia oxidation by Nitrosomonas europaea grown under batch, continuous fed, and biofilm conditions. Water Research. https://doi.org/10.1016/j.watres.2013.04.052

Li, C.-M., Wu, H.-Z., Wang, Y.-X., Zhu, S., & Wei, C.-H. (2020). Enhancement of phenol biodegradation: Metabolic division of labor in co-culture of Stenotrophomonas sp. N5 and Advenella sp. B9. Journal of Hazardous Materials. https://doi.org/10.1016/j.jhazmat.2020.123214

Li, J., Yuan, X., Zhao, H., Li, F., Lei, Z., & Zhang, Z. (2018). Highly efficient one-step advanced treatment of biologically pretreated coking wastewater by an integration of coagulation and adsorption process. Bioresource Technology, 247, 1206–1209. https://doi.org/10.1016/j.biortech.2017.09.019

Liu, H., Xu, T., Li, C., Liu, W., & Lichtfouse, E. (2021). High increase in biodegradability of coking wastewater enhanced by Mn ore tailings in Fenton/O3 combined processes. International Journal of Environmental Science and Technology, 18, 173–184. https://doi.org/10.1007/s13762-020-02816-8

Liu, Y., Li, Y., & Lv, Y. (2012). Isolation and characterization of a heterotrophic nitrifier from coke plant wastewater. Water Science and Technology, 65, 2084–2090. https://doi.org/10.2166/wst.2012.120

Lu, Y., Yan, L., Wang, Y., Zhou, S., Fu, J., & Zhang, J. (2009). Biodegradation of phenolic compounds from coking wastewater by immobilized white rot fungus Phanerochaete chrysosporium. Journal of Hazardous Materials, 165, 1091–1097. https://doi.org/10.1016/j.jhazmat.2008.10.091

Ma, Q., Zhang, X., & Qu, Y. (2018). Biodegradation and Biotransformation of Indole: Advances and Perspectives. Frontiers in Microbiology. https://doi.org/10.3389/fmicb.2018.02625

Mannina, G., Cosenza, A., Di Trapani, D., Capodici, M., & Viviani, G. (2016). Membrane bioreactors for treatment of saline wastewater contaminated by hydrocarbons (diesel fuel): An experimental pilot plant case study. Chemical Engineering Journal, 291, 269–278. https://doi.org/10.1016/j.cej.2016.01.107

Marrot, B., Barrios-Martinez, A., Moulin, P., & Roche, N. (2006). Biodegradation of high phenol concentration by activated sludge in an immersed membrane bioreactor. Biochemical Engineering Journal, 30, 174–183. https://doi.org/10.1016/j.bej.2006.03.006

Medhi, K., Singhal, A., Chauhan, D. K., & Thakur, I. S. (2017). Investigating the nitrification and denitrification kinetics under aerobic and anaerobic conditions by Paracoccus denitrificans ISTOD1. Bioresource Technology. https://doi.org/10.1016/j.biortech.2017.03.084

Miao, S., Jin, C., Liu, R., Bai, Y., Liu, H., Hu, C., & Qu, J. (2020). Microbial community structures and functions of hypersaline heterotrophic denitrifying process: Lab-scale and pilot-scale studies. Bioresource Technology. https://doi.org/10.1016/j.biortech.2020.123244

Nzila, A., Abdur Razzak, S., & Zhu, J. (2016). Bioaugmentation: An Emerging Strategy of Industrial Wastewater Treatment for Reuse and Discharge. International Journal of Environmental Research and Public Health, 13, 846. https://doi.org/10.3390/ijerph13090846

Padhi, S. K., & Maiti, N. K. (2017). Molecular insight into the dynamic central metabolic pathways of Achromobacter xylosoxidans CF-S36 during heterotrophic nitrogen removal processes. Journal of Bioscience and Bioengineering, 123, 46–55. https://doi.org/10.1016/j.jbiosc.2016.07.012

Pan, Y., & Liu, D.-F. (2023). Tapping the Potential of Wastewater Treatment with Direct Ammonia Oxidation (Dirammox). Environmental Science & Technology, 57, 7106–7108. https://doi.org/10.1021/acs.est.3c02342

Pawlowski, L. (1994). Standard methods for the examination of water and wastewater, 18th edition: Arnold E. Greenberd, Lenore S. Clesceri, Andrew D. Eaton (Editors) Water Environment Federation, Alexandria, USA, 1992; 1025 pp; US$120 (Hardcover); ISBN 0-87553-207-1. Science of The Total Environment, 142, 227–228. https://doi.org/10.1016/0048-9697(94)90332-8

Ren, J., Li, J., Chen, Z., & Cheng, F. (2018). Fate and wetting potential of bio-refractory organics in membrane distillation for coke wastewater treatment. Chemosphere, 208, 450–459. https://doi.org/10.1016/j.chemosphere.2018.06.002

Shanmugam, B. K., Easwaran, S. N., Lakra, R., Deepa, P. R., & Mahadevan, S. (2017). Metabolic pathway and role of individual species in the bacterial consortium for biodegradation of azo dye: A biocalorimetric investigation. Chemosphere, 188, 81–89. https://doi.org/10.1016/j.chemosphere.2017.08.138

Shi, J., Xu, C., Han, Y., & Han, H. (2020). Enhanced anaerobic degradation of nitrogen heterocyclic compounds with methanol, sodium citrate, chlorella, spirulina, and carboxymethylcellulose as co-metabolic substances. Journal of Hazardous Materials, 384, 121496. https://doi.org/10.1016/j.jhazmat.2019.121496

Song, K., Gao, Y., Yang, Y., Guo, B.-Q., & Wang, Y.-Z. (2023). Performance of simultaneous carbon and nitrogen removal of high-salinity wastewater in heterotrophic nitrification-aerobic denitrification mode. Journal of Environmental Chemical Engineering, 11, 109682. https://doi.org/10.1016/j.jece.2023.109682

Sun, G., Wan, J., Sun, Y., Li, H., Chang, C., & Wang, Y. (2019). Enhanced removal of nitrate and refractory organic pollutants from bio-treated coking wastewater using corncobs as carbon sources and biofilm carriers. Chemosphere. https://doi.org/10.1016/j.chemosphere.2019.124520

Swain, G., Sonwani, R. K., Giri, B. S., Singh, R. S., Jaiswal, R. P., & Rai, B. N. (2020). Collective removal of phenol and ammonia in a moving bed biofilm reactor using modified bio-carriers: Process optimization and kinetic study. Bioresource Technology. https://doi.org/10.1016/j.biortech.2020.123177

Tamang, M., & Paul, K. K. (2021). Advances in treatment of coking wastewater – a state of art review. Water Science and Technology, 85, 449–473. https://doi.org/10.2166/wst.2021.497

Wang, W., & Han, H. (2012). Recovery strategies for tackling the impact of phenolic compounds in a UASB reactor treating coal gasification wastewater. Bioresource Technology, 103, 95–100. https://doi.org/10.1016/j.biortech.2011.10.002

Wang, Z., Gao, M., Wei, J., Ma, K., Pei, J., Zhang, J., Zhou, Y., Yang, Y., & Yu, S. (2016). Long-term effects of salinity on extracellular polymeric substances, microbial activity and microbial community from biofilm and suspended sludge in an anoxic-aerobic sequencing batch biofilm reactor. Journal of the Taiwan Institute of Chemical Engineers, 68, 275–280. https://doi.org/10.1016/j.jtice.2016.09.005

Wei, C., Wu, H., Kong, Q., Wei, J., Feng, C., Qiu, G., Wei, C., & Li, F. (2019). Residual chemical oxygen demand (COD) fractionation in bio-treated coking wastewater integrating solution property characterization. Journal of Environmental Management, 246, 324–333. https://doi.org/10.1016/j.jenvman.2019.06.001

Wu, D., Yi, X., Tang, R., Feng, C., & Wei, C. (2018). Single microbial fuel cell reactor for coking wastewater treatment: Simultaneous carbon and nitrogen removal with zero alkaline consumption. Science of The Total Environment, 621, 497–506. https://doi.org/10.1016/j.scitotenv.2017.11.262

Xi, H., Zhou, X., Arslan, M., Luo, Z., Wei, J., Wu, Z., & Gamal El-Din, M. (2022). Heterotrophic nitrification and aerobic denitrification process: Promising but a long way to go in the wastewater treatment. Science of The Total Environment, 805, 150212. https://doi.org/10.1016/j.scitotenv.2021.150212

Yang, J. X., Zhao, B., An, Q., Huang, Y. S., & Guo, J. S. (2018). Bioaugmentation with A. faecalis strain NR for achieving simultaneous nitrogen and organic carbon removal in a biofilm reactor. Bioresource Technology, 247, 871–880. https://doi.org/10.1016/j.biortech.2017.09.189

Yang, Y., Liu, Y., Yang, T., & Lv, Y. (2017). Characterization of a microbial consortium capable of heterotrophic nitrifying under wide C/N range and its potential application in phenolic and coking wastewater. Biochemical Engineering Journal, 120, 33–40. https://doi.org/10.1016/j.bej.2016.12.008

Zeng, X., Huang, J. J., Hua, B., & Champagne, P. (2020). Nitrogen removal bacterial strains, MSNA-1 and MSD4, with wide ranges of salinity and pH resistances. Bioresource Technology, 310, 123309. https://doi.org/10.1016/j.biortech.2020.123309

Zerva, I., Remmas, N., Melidis, P., & Ntougias, S. (2021). Biotreatment efficiency, hydrolytic potential and bacterial community dynamics in an immobilized cell bioreactor treating caper processing wastewater under highly saline conditions. Bioresource Technology. https://doi.org/10.1016/j.biortech.2021.124694

Zhai, S., Ji, M., Zhao, Y., Pavlostathis, S. G., & Zhao, Q. (2018). Effects of salinity and COD/N on denitrification and bacterial community in dicyclic-type electrode based biofilm reactor. Chemosphere, 192, 328–336. https://doi.org/10.1016/j.chemosphere.2017.10.108

Zhang, S., Sha, C., Jiang, W., Li, W., Zhang, D., Li, J., Meng, L., & Piao, Y. (2015). Ammonium removal at low temperature by a newly isolated heterotrophic nitrifying and aerobic denitrifying bacterium Pseudomonas fluorescenswsw-1001. Environmental Technology. https://doi.org/10.1080/09593330.2015.1035759

Zhang, X., Song, Z., Tang, Q., Wu, M., Zhou, H., Liu, L., & Qu, Y. (2021). Performance and microbial community analysis of bioaugmented activated sludge for nitrogen-containing organic pollutants removal. Journal of Environmental Sciences, 101, 373–381. https://doi.org/10.1016/j.jes.2020.09.002

Zhu, X., Liu, R., Liu, C., & Chen, L. (2015). Bioaugmentation with isolated strains for the removal of toxic and refractory organics from coking wastewater in a membrane bioreactor. Biodegradation, 26, 465–474. https://doi.org/10.1007/s10532-015-9748-z

Zhu, X., Tian, J., & Chen, L. (2012). Phenol degradation by isolated bacterial strains: kinetics study and application in coking wastewater treatment. Journal of Chemical Technology & Biotechnology, 87, 123–129. https://doi.org/10.1002/jctb.2691

Acknowledgements

This work was supported by the Natural Science Foundation of Shanxi province (202103021224106).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Competing Interests

The authors declare no competing interests.

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Liu, Y., Ma, S., Yang, Y. et al. Characteristics of a Heterotrophic Nitrifier Consortium and Its Application in Coking Wastewater. Water Air Soil Pollut 234, 635 (2023). https://doi.org/10.1007/s11270-023-06656-3

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s11270-023-06656-3