Abstract

Organic pollutants may reach the aquatic environment through oil spills during transportation and/or oil production processes, and most of the studies about oil degradation are mainly related to the role of bacteria and fungi in this process. Considering the vulnerability of the marine environment to oil accidents, the present work investigated the biodegradation of petroleum hydrocarbons in contaminated marine waters using Nannochloropsis oculata microalga at a laboratory scale. The biodegradation experiment was carried out in reactors with natural seawater, microalga strain, and petroleum (C1 indicates 0.04 g L−1 and C2 indicates 0.08 g L−1 of petroleum). A reactor without petroleum (C0) was carried out to assess the density of microalgae cells. Total petroleum hydrocarbons analysis was carried out through liquid–liquid extraction, and quantification was done by gas chromatography–flame ionization detection (GC-FID), while the cell counting was performed using a microscope equipped with a Neubauer chamber. N. oculata showed good adaptation to both concentrations, indicating its resistance against petroleum pollutants and its growth ability even in the presence of petroleum. N. oculata was able to degrade petroleum hydrocarbons for both concentrations (~ 83% of the light and ~ 60% of the heavy compounds for C1; and ~ 74% of the light and ~ 58% of the heavy compounds for C2 in 22 days) and the percentage of degradation for each simulation were 68 and 65% for C1 and C2 reactors, respectively. This is a pioneering and relevant study and may be helpful to further studies regarding N. oculata application and phycoremediation of dissolved oil.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

1 Introduction

Fossil fuels represent 80% of global primary energy consumption (Qari et al., 2017), and petroleum is considered the main energetic matrix worldwide and exerts great influence on the global economy. With industrialization and economic development, population needs have grown, and the environment has become more vulnerable to several impacts (Araújo et al., 2014). Petroleum activities are mainly developed in the marine environment, so the likelihood of accidents is greater in these areas.

According to Demirel et al. (2017), oil spillage can occur during exploration, extraction, transportation, or refining processes, and also from ships, oil tankers, accidents on offshore platforms, drilling rigs and wells, and occasional leaks in oil pipelines (Rios, 2014). Consequently, the environment will be impacted for many years, causing long-term adverse effects on mammals, mollusks, algae, fishes, and seabirds, in addition to causing damage to human health (Pi et al., 2015).

As petroleum arrives in aquatic environments, it becomes susceptible to several changes in its composition due to chemical, physical, and biological processes that determine its degradation rate and how long it will remain in the environment (Speight & El-Gendy, 2018). Temperature, petroleum viscosity, amount of spilled oil, density, and hydrodynamics of the affected region also influence the degradation process (Pi et al., 2015).

There are some remediation techniques for the degradation and removal of pollutants present in the soil or water (El-Sheekh et al., 2013). Bioremediation is based on organisms like plants (Moreira et al., 2013), bacteria, fungi (Moreira et al., 2016), and algae (Marques et al., 2020) and presents advantages in comparison to classical techniques once it is more versatile, cheaper, and does not change natural environmental conditions (Araújo et al., 2014), besides being environmentally friendly (Hamouda et al., 2016).

In aquatic environments, organic pollutants are susceptible to biodegradation through a series of organisms, but most of the studies are focused on the role of bacteria and fungi in the degradative processes (Dagley, 1978; Middelhoven, 1993). Thus, it is important to develop research to assess the possibility of using other microorganisms to biodegrade pollutants and treat contaminated water. An alternative is the utilization of microalgae since they have favorable characteristics that enable their use for wastewater treatment. In addition to promoting the reuse of microalgal biomass, microalgae can remove organic carbon for transformation into biomass for the generation of bioproducts (Marques et al., 2017), such as pigments, antioxidants, lipids for biofuels, carbohydrates, and proteins for biopolymer (Baumgardt et al., 2016).

Microalgae are unicellular and photosynthetic ubiquitous organisms and important primary producers in marine and freshwater systems (Faria et al., 2012). Microalgae are receiving much attention due to some characteristics like (i) quick growth under different growing conditions (Reyimu & Özçimen, 2017); (ii) cultivation in nonarable lands (Singh et al., 2011); (iii) useful for pollutants removal (Hammed et al., 2016), including those resulting from petroleum exploration (Ammar et al., 2018; Marques et al., 2021). Although some studies have been carried out on the use of microalgae for petroleum removal (El-Sheekh et al., 2013; Kalhor et al., 2017; Marques et al., 2021), these studies are recent and do not simulate situations of oil spills, as demonstrated in our study.

The genus Nannochloropsis is widely distributed in oceans, but they can grow in brackish or freshwater environments, playing significant roles in global carbon cycles and minerals cycles (Sukarni et al., 2014), and it is also used in the human diet due to its nutritional value (Carrera-Martinez et al., 2011). Nannochloropsis oculata (Droop) Hibberd, marine microalgae from the Monodopsidaceae family, have high growth rates, high lipid productivity, and resistance to adverse environmental conditions (Ribeiro et al., 2016). A high content of eicosapentaenoic acid (EPA C20:5n3) is widely used in the feeding of rotifers and fishes larvae (Rocha et al., 2003) and for human consumption (Liu et al., 2017).

There are some types of research about N. oculata and its applications as animal feed, biofuel production, and for human consumption, but there is not any research evaluating the capability of N. oculata in phycoremediation processes for petroleum removal from seawater. Thus, in this study, we aimed to examine the efficacy of N. oculata in the biodegradation of dissolved petroleum in natural seawater under experimental conditions. N. oculata was exposed to different dissolved oil concentrations, and their degradation efficiency was calculated by monitoring its capability of degradation, its growth in contaminated water, and the content of total petroleum hydrocarbon (TPH) in seawater samples.

This research is the first one to examine the efficacy of N. oculata in the biodegradation of petroleum hydrocarbons in natural seawater under experimental conditions, assisting in the composition of a database about this species and being helpful to other researches about phycoremediation of dissolved petroleum.

2 Materials and Methods

2.1 Stock Culture of Microalgae

In order to obtain enough volume of microalgae to perform the experimental tests, N. oculata cells were cultured for 10 days at the Bioenergy Laboratory and Catalysis (LABEC/UFBA). The microalgae strains used had already been isolated and identified by the LABEC team (LB2164). About 100 mL of microalgae strain, which is equivalent to 10% of the total volume of the experiment, was inoculated in a glass flask containing natural seawater and Conway culture medium (Walne, 1979), and it was submitted to constant aeration and luminosity during the growth period (10 days).

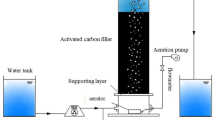

2.2 Biodegradation Experiment

The simulations were performed using 1 L reactors, with each concentration carried out in triplicate, except for the control reactors. The C1 reactors contained natural seawater, microalgae, and petroleum in a concentration of 0.04 g L−1, while the C2 reactors contained natural seawater, microalgae, and 0.08 g L−1 of petroleum. Furthermore, control reactors (CT1 and CT2) were considered, as they contained only natural seawater and petroleum in the same concentrations used in C1 and C2 reactors. These petroleum concentrations were used to test the microalgae tolerance, which is still not known in the literature. Considering that other microorganisms can tolerate between 0.05 and 0.075 g L−1 of petroleum (Essabri et al., 2019), a similar oil concentration range was chosen.

Using pre-cleaned amber glass bottles, natural seawater (12 L) was sampled on Porto da Barra beach, located in Salvador, Brazil. Natural seawater was filtered with a vacuum filtration system and fiber-glass filters (Whatman®, 47 mm diameter and 1.6 µm pore size), and about 800 mL of it was transferred to each reactor, which was sealed and placed in the vertical autoclave (Prismatec® and internal capacity of 137 L) for sterilization during 20 min at 120 °C.

The petroleum used in this experiment was from the Campos Basin due to its importance to Brazil’s economy and because the lowest viscosity compared to other available oils. With an automatic micropipette, a calculated volume of oil was added to each reactor to obtain concentrations of 0.04 and 0.08 g L−1. After this, the reactors were slightly shaken to improve petroleum dispersion, and then the microalgae were added. The hose and filter system were attached to each reactor to promote aeration, and then the reactors were sealed and placed on a shelf with coupled artificial lighting. Finally, the hose system was coupled to a compressor with a constant airflow of 3 L min−1, finishing the setting-up of the experiment.

2.3 Monitoring and Sampling Procedures

Monitoring was carried out daily, observing the conditions of luminosity and the temperature of the laboratory, besides evaluating any abnormality. All reactors were stirred at least once a day to homogenize the water column. To estimate cell density and spectroscopy, aliquots of 1.5 mL were taken from reactors C0.1, C1.1, and C2.1 every 3 days with a Pasteur pipette. On the first day of the experiment, aliquots were taken from each control reactor to quantify the amount of total petroleum hydrocarbon (TPH) at the beginning of the experiment. For total petroleum hydrocarbons (TPH) determination, 50 mL aliquots were taken from each reactor considering the days of the experiment: T0–first day, T8–8th day, T15–15th day, and T22–22nd day.

2.4 Analytical Methods

2.4.1 Total Petroleum Hydrocarbons (TPH) Determination

TPH quantification in the aqueous medium was carried out by liquid–liquid extraction based on the methodology of Moreira et al. (2015). The solvent used was pure dichloromethane (Merck, Darmstadt, Germany), and the extract was concentrated to 500 µL in a rotary evaporator (R-201/215, BÜCHI, Flawil, Switzerland), and then it was transferred to calcined vials (at 400 °C for 4 h in a muffle oven). The analyses were performed in a gas chromatograph with a flame ionization detector (GC-FID 7890B, Agilent Technologies, Santa Clara, California, USA) using capillary fused silica column DB-1 (15 m × 0.25 mm × 0.25 μm). Chromatographic conditions were: initial oven temperature at 40 °C for 2 min and heating rate of 10 °C min−1 to 300 °C for 12 min; injector and detector temperature of 300 °C with hydrogen as a carrier gas at 1.0 mL min−1 with constant flow and injection volume of 1 μL.

Samples were injected on the gas chromatograph, and the concentration of TPH was provided through a chromatogram containing the concentration of carbons (n-C8 to n-C40), which was used to assess and calculate the degradation of TPH by microalgae. The pristane/phytane ratio was used to determine the degree of petroleum degradation and was determined with the data provided by the chromatograms, which show the concentrations of n-C17 (pristane) and n-C18 (phytane) (Silva, 2011).

The unresolved complex mixture (UCM) is characterized in the chromatogram by the abrupt elevation of the baseline between carbons n-C13 to n-C36. The UCM represents a set of compounds formed by isomers and homologs of branched and cyclic hydrocarbons that cannot be identified and quantified individually by current chromatographic methods but suggests degradation of petroleum components (Silva, 2011).

2.4.2 Cellular Density

Cells counting was performed through microscopy (Binocular AxioStar Plus, Zeiss®) using a Neubauer chamber. Aliquots representing each concentration of petroleum were taken every 3 days, and the counting was made to evaluate if the density of microalgae would be affected by the different concentrations of petroleum.

2.4.3 Statistical Analysis

The data’s normality and homogeneity of variances were evaluated by Shapiro–Wilk and Bartlett tests, respectively. The data were analyzed using ANOVA. Analysis that showed heteroscedastic variance was tested with Kruskal–Wallis and Dunn’s posteriori test. Otherwise, treatments were compared using Tukey’s post hoc test. The concentration of oil (0.04 and 0.08 g L−1) and time of degradation were tested for concentrations of TPH and UCM parameters using bi-factorial ANOVA (p < 0.05). All statistical analysis was performed in the R environment (R Core Team, 2021), with a significance level of p < 0.05.

3 Results and Discussion

3.1 Removal of Total Hydrocarbon Petroleum (TPH)

The mean values of total petroleum hydrocarbon (TPH) in reactors without (CT1 and CT2) and microalgae (C1 and C2) are shown in Fig. 1.

Mean concentrations of TPH during 22 days for reactors with (C1 and C2) and without microalgae (CT1 and CT2). All reactors had seawater and dissolved oil in two concentrations − 0.04 (CT1 and C1) and 0.08 g L−1 (CT2 and C2). Bars indicate standard deviation (n = 3), which is not present in CT1 and CT2 because they were not carried out in triplicate

TPH values varied between 5932.73 to 3324.57 mg L−1 and between 11,226.31 to 23,081.16 mg L−1 for CT1 and CT2 reactors, respectively. For the reactors with microalgae, TPH values varied between 5932 and 9881 mg L−1 for C1 and 11,226 and 17,888 mg L−1 for C2. All results of the bifactorial analysis were significant for TPH data (Table 1). Tukey’s post hoc test showed significant differences between days zero and eight. The significant differences among TPH treatments are shown in Fig. 2, which highlights the post hoc results of treatments with different oil concentrations.

Boxplot of TPH concentrations (mg L−1) during 22 days for reactors with (C1 and C2) and without microalgae (CT1 and CT2). All reactors had seawater and dissolved oil in two concentrations − 0.04 g L−1 (CT1 and C1) and 0.08 g L−1 (CT2 and C2). Equal letters indicate that there is no significant difference between the treatments studied

In the CT1 reactors, TPH values decreased throughout the experiment, which may characterize the degradation of some compounds (degradation of 44%). Although TPH concentrations at T15 were very low (364.74 mg L−1), we cannot affirm that this result indicates a degradative process once some errors may have occurred during sampling or extraction. On the other hand, TPH values increased over time for CT2 reactors, which can be justified by the highest concentration of petroleum. Oil in higher concentrations needs more time to enhance its solubility and become more susceptible to degradative processes, which explains the non-reduction of TPH in that treatment.

Regarding reactors with microalgae (C1 and C2), it was observed the same behavior in TPH concentrations for both simulations. TPH values were higher on the eighth day due to the increase in the solubility of the petroleum in the water. The increase in hydrocarbons on days 8 and 15 in some reactors may result from microalgae’s oil production because the chromatograph does not distinguish oil from petroleum and oil of microalga. The TPH reduction in the T15 and T22 stages occurred due to the microalgae activities (degradation of 25 and 31% for C1 and 17 and 28% for C2, respectively).

The decrease in petroleum hydrocarbons at the end of the experiment followed the growth of microalgae. As the water was autoclaved before being used in the experiment, only the action of microalgae occurred in the experiment. The biodegradation of TPH is facilitated by the secretion of extracellular enzymes by the microorganisms in action, leading to the transformation of oily substances into less toxic compounds, which may explain the decrease in TPH in this work (Essabri et al., 2019).

Unresolved complex mixture (UCM) values varied between 4201.89 and 2461.55 mg L−1 and between 8273.70 and 17,450 mg L−1 for CT1 and CT2 reactors, respectively. The mean concentrations for C1 and C2 reactors varied between 2334 and 4986 mg L−1, from 5591 to 9641 mg L−1 for C1 and C2, respectively (Fig. 3). The bifactorial ANOVA showed significant differences in UCM concentrations among treatments and with interaction (days and treatments), but not during the time of biodegradation (Table 2). Figure 4 highlights the post hoc results of treatments with different oil concentrations, showing that C2 and CT2 reactors presented higher UCM concentrations than C1 and CT1 reactors. The ANOVA significant results from interactions (days and treatments) occurred between C2 (day 0) and C1 and CT2 (day 0) and C1.

Mean concentrations of the unresolved complex mixture (UCM) during 22 days for reactors with (C1 and C2) and without microalgae (CT1 and CT2). All reactors had seawater and dissolved oil in two concentrations − 0.04 g L−1 (CT1 and C1) and 0.08 g L−1 (CT2 and C2). Bars indicate standard deviation (n = 3) and are not present in CT1 and CT2 because they were not carried out in triplicate

Boxplot of UCM concentrations (mg L−1) during 22 days for reactors with (C1 and C2) and without microalgae (CT1 and CT2). All reactors had seawater and dissolved oil in two concentrations − 0.04 g L−1 (CT1 and C1) and 0.08 g L−1 (CT2 and C2). Equal letters indicate that there is no significant difference between the treatments studied

UCM refers to an indeterminate chemical fraction that is generally composed of recalcitrant compounds that are more difficult to biodegrade and includes alkenes, alkynes, cycloalkanes, monoaromatics, polycyclic aromatic hydrocarbons (PAHs), steranes, and polychlorinated biphenyls (PCBs) (Gregorio et al., 2016). In this study, UCM values followed the same pattern as TPH: increasing concentrations at the beginning of the experiment and decreasing in the final times. Although the expected was an increase in UCM concentration, the decrease found during the experiment may indicate that these microalgae have more complex metabolic routes than bacteria. Therefore, these microorganisms can biodegrade unresolved and recalcitrant compounds, corroborating the results found by Cao et al. (2013).

Walker et al. (1975) observed that the algae Prototheca zopfii was capable of degrading about 40% of crude oil when submitted to proper conditions, degrading a higher percentage of saturated hydrocarbons regarding aromatics. Cao et al. (2013) observed, through a laboratory experiment that degradation rates of crude oil were about 29.5%, 22.4%, and 18% using Scenedesmus obliquus, Oscillatoria sp., and Dunaliella tertiolecta, respectively.

The degradation of aromatic compounds was observed for the first time in a study by Cerniglia et al. (1980), where the authors observed that the oxidation capacity of aromatic hydrocarbons is generalized in the algae kingdom. Later, other researchers found that algae are capable of different oxidizing types of hydrocarbons (not only aromatics) into less harmful compounds, suggesting its potential for the degradation of crude oil (Cao et al., 2013). It is essential to mention that the diversity of these organisms’ characteristics may influence their capacity for growth, adaptation, and reproduction and may also influence the petroleum bioremediation rates (Cao et al., 2013). Therefore, it is important to analyze in detail the characteristics of the organisms that will be used for bioremediation to improve these processes mentioned above.

Table 3 presents the concentrations of pristane and phytane and the pristane/phytane, pristane/n-C17 and phytane/n-C18 ratios for control experiment (reactors with natural seawater and petroleum).

The pristane/phytane ratio can be applied as an indicator of the origin of hydrocarbons in the environment. For this, values above 1 (usually between 3 and 5) indicate a predominance of biogenic sources (Steinhauer & Boehm, 1992), while values below or close to 1 indicate anthropogenic input of petroleum. In this study, values were higher than 1 for both control reactors (Table 3), indicating biological sources, which can be explained by the possible presence of microorganisms in the petroleum added to each reactor since the seawater was sterilized and, therefore, had no microorganisms.

The ratios pristane/n-C17 and phytane/n-C18 are used to estimate the degree of degradation of petroleum in the environment—values below 1 indicate the presence of degraded petroleum and values greater than 1 indicate recent/non-degraded petroleum. It occurs because both pristane and phytane are the main branched alkanes originating from the diagenesis of phytol (composed of phytoplankton, zooplankton, and bacteria) and are the first to be biodegraded by microorganisms (Silva, 2011; Steinhauer & Boehm, 1992). For both concentrations at control reactors, the values of these ratios were less than 1 at the end of the experiment (Table 3), indicating petroleum degradation and evidenced by the increase in the concentrations of TPH and UCM.

Pristane and phytane medium values and the pristane/phytane, pristane/n-C17, and phytane/n-C18 ratios for reactors with microalgae are shown in Table 4. None of the estimated concentrations showed a significant difference between the days sampled.

The pristane/phytane ratio used to assess the biogenic contribution presented an increase in T8 and, after that, decreased again in the C1 reactors, while the C2 reactors only observed a decrease in these ratios over time. The pristane/n-C17 and phytane/n-C18 ratios presented, in general, values smaller than 1, indicating the occurrence of degraded petroleum, but in this experiment, the utilization of these ratios as indicators of biodegradation is not indicated. According to Gassmann (1981), phytol is one of the constituents of chlorophyll, and its degradation, according to Figueiredo (1999), produces several alkanes isoprenoids, including pristane (oxidation reactions) and phytane (dehydration reactions).

3.2 n-alkanes Degradation

Concentrations of n-alkanes in the range of n-C8 to n-C40 were provided by chromatograms of each sample. To assess the degradation of n-alkanes, these compounds were separated regarding their boiling points (BP). Thus, low molecular weight n-alkanes (LMW) are those with BP under 350 °C, while high molecular weight n-alkanes (HMW) are those with BP higher than 350 °C. The results of LMW and HMW found for both concentrations at T0 and T22 are shown in Fig. 5 to visualize the degradation better.

Values for C1 reactors varied between 430.39 and 74.71 mg L−1 and 794.18 and 315.37 mg L−1 for LMW and HMW, respectively, at T0 and T22. For C2 reactors, values varied between 845.14 to 219.76 mg L−1 for LMW and from 905.76 to 384.65 mg L−1 for HMW at T0 and T22, respectively.

The degradation of each reactor was calculated considering the difference in the amount of LMW and HMW n-alkanes at T0 and T22. The values found for the degradation of C1 reactors were 83 and 60% for LMW and HMW, respectively. For C2 reactors, the values varied between 74 (LMW) and 58% (HMW). The difference observed between the degradation of LMW and HMW n-alkanes can be related to the amount of petroleum added in each simulation. According to Kalhor et al. (2017), high concentrations of some petroleum compounds can inhibit microorganisms, reducing their metabolic rates and, consequently, influencing their degradation rate.

Moreover, the degradation of each concentration was also calculated considering all n-alkanes at T0 and T22, and the values were 68% (C1 concentration) and 65% (C2 concentration). Although the results were similar, it was observed that the initial concentration of petroleum might harm the removal rate (or degradation rate), as reported by Del’Arco and De França (2001) and Ferreira et al. (2012). Once the concentration of the C2 reactor was double of C1, the similarity between the degradation rates is justified by the requirement of more time for petroleum to become more available to the degradative process.

Studies regarding the biodegradation of n-alkanes by microalgae are still recent. N. oculata has been shown to degrade these compounds, as mentioned before, and our findings show the effectiveness of this microalga in the degradation of petroleum compounds, being similar to those reported by Ibrahim and Gamila (2004) and Ammar et al. (2018).

In contrast, the degradation percentage found in this study was lower than those reported by El-Sheekh et al. (2013) and Kalhor et al. (2017). Possibly if the experiment provided cultivation with heterotrophic conditions, it would increase the efficiency in removing n-alkanes, as discussed in a study by Lowrey et al. (2016), which states that there are some species of microalgae capable of removing organic carbon when subjected to heterotrophic conditions.

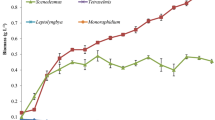

3.3 Cell Counting and Growth

Figure 6 shows the cell’s abundance. In the reactors without petroleum but with microalga (C0), the cell number initially was 1.95 × 106 cell mL−1 and reached 1.06 × 106 cell mL−1 at the end of the experiment. For C1 reactors, values varied initially from 2.20 × 106 to 1.01 × 106cell mL−1 on the last day, and for C2 reactors, values were 2.04 × 106 cell mL−1 on the first day to 5.63 × 105 cell mL−1 on the end of the experiment.

In general, the first three days of cultivation were the period of adaptation to water contaminated with oil by N. oculata, and the decrease observed may also be associated with the stress caused during the set-up of the experiment or the consumption of nutrients. C1 reactors showed the largest and best density of microalgae, reaching its maximum on the 10th day with 2.66 × 106 cell mL−1, and for C2 reactors was observed a greater adaptation of the microalgae to the contaminant, reaching maximum density on the 16th day with 2.58 × 106 cell mL−1 (Fig. 6).

From the 3rd to the 16th day, the microalgae showed good adaptation to both oil concentrations and the period of growth and consumption of nutrients available in the medium. From the 17th day onwards, there was a decline in microalgae growth in all reactors, which may have occurred due to the consumption of available nutrients. Previous studies report that this species of microalgae can adapt and grow in water contaminated with oil (produced water and PW), while PW is toxic to other species of microalgae (Picochlorum sp. and Scenedesmus sp.) (Das & Chandran, 2011).

The composition of oil has a predominance of hydrocarbon compounds: 84 to 87% carbon, 11 to 14% hydrogen, 0 to 8% sulfur, and 0 to 4% oxygen and nitrogen. These compounds are necessary for microalgae growth and can be removed from contaminated water (Mujtaba et al., 2015). So, due to being capable of growth in sites contaminated by petroleum, it is possible that algae have fast adaptation like physiological acclimation, modifying some gene expression, and can be used as a technique for the biological treatment of saline water contaminated by oil or even water produced from oil activities (Al-Ghouti et al, 2019; Díaz-Baez et al., 2004).

3.4 Potential of Nannochloropsis for Biodiesel Production

This genus of microalga has shown to be promising in its use for the treatment of different wastewater mainly contaminated with some oil, whether from petroleum or palm oil mill effluent (POME) (Emparan et al., 2020). Nannochloropsis microalgae were immobilized and grown in 10% POME oil, showing efficiency in removing 71% organic carbon (325 to 94.25 mg L−1) with a higher concentration of 1.27 g L−1 and the FTIR spectroscopic analysis showed an increase in the lipid, protein, and carbohydrate during the POME treatment process, demonstrating the use of this species for wastewater treatment and generation of biodiesel (lipids) and biopolymers (protein and carbohydrate) (Emparan et al., 2020).

Nannochloropsis spp. have attracted interest from algal biodiesel researchers due to its high accumulation rate of lipids in biomass. In some research, it has been shown that this species can reach 36.95 ± 0.91% up to 60.35 ± 1.20% lipid content with daily productivity at 158.76 ± 13.83 mg L−1 d−1 (Ma et al., 2016). Future studies will undoubtedly be developed to better investigate the use of marine microalgae in the treatment of contaminated saline water regarding the biodegradation of polluting organic compounds, in addition to assessing the biofixation of CO2 during wastewater treatment (Ding et al., 2020) and verifying the potential for reusing microalgae biomass for the generation of liquid and gaseous biofuels (Boopathy et al., 2017; Singhania et al., 2019).

Taher et al. (2020) evaluated the use of Nannochloropsis spp. as promising for biodiesel generation with the economic factor, where they estimated that to produce 1000 tons/year of biodiesel, the manufacturing costs and revenue was estimated at $21,843,000 and $27,940,000/year, respectively. Other studies show that costs can range from $0.49 to $21.81/kg. This variation is due to the type and scale used for cultivation, source of nutrients used, biomass productivity, lipid content, and more being supplied by wastewater that optimizes the generation of biomass and value-added products (Chisti, 2008).

Considering that microalgae can remove organic carbon for transformation into biomass, recycling and reusing the waste generated can save land resources and reduce environmental impacts by opening up a new economy, in addition to helping to guarantee new jobs and provide value-added raw materials (Nizami et al., 2017).

4 Conclusions

N. oculata grew even in the presence of petroleum, demonstrating its adaptative capacity and resistance to adverse environmental conditions such as nutrient limitation and the presence of organic pollutants. Additionally, this microalga showed to be capable of degrading petroleum compounds, including unresolved and recalcitrant compounds, which is an important and relevant discovery in this study. The development of more studies about this species is necessary to ratify our results, in addition to assisting in the composition of a database about this species. More extended experimental tests using other types of petroleum and investigating the metabolic paths and the enzymes involved in the biodegradation process seem viable and can be an alternative for obtaining more robust results. Likewise, correcting some possible errors in the sampling procedure and monitoring physical and chemical parameters (such as temperature and pH of each reactor) and nutrient analysis seems important too.

Data Availability

The datasets generated during and/or analyzed during the current study are available from the corresponding author upon reasonable request.

References

Al-Ghouti, M. A., Al-Kaabi, M. A., Ashfaq, M. Y., & Da’na, D. A. (2019). Produced water characteristics, treatment and reuse: A review. Journal of Water Process Engineering, 28(September 2018), 222–239. https://doi.org/10.1016/j.jwpe.2019.02.001

Ammar, S. H., Khadim, H. J., & Mohamed, A. I. (2018). Cultivation of Nannochloropsis oculata and Isochrysis galbana microalgae in produced water for bioremediation and biomass production. Environmental Technology and Innovation, 10, 132–142. https://doi.org/10.1016/j.eti.2018.02.002

Araújo, A. M., Golçalves, C., Nascimento, E. M., Júnior, J. M., Silva, J. C., Oliveira, M. A. De, Brisa, P., Pires, P. H., & Machado, E. C. (2014). Protocolo para biorremediação de águas contaminadas por petróleo e derivados. 55–63. https://doi.org/10.18674/exacta.v7i1.973

Baumgardt, F. J. L., Filho, A. Z., Brandalize, M. V., Da Costa, D. C., Antoniosi Filho, N. R., Abreu, P. C. O. V., Corazza, M. L., & Ramos, L. P. (2016). Lipid content and fatty acid profile of Nannochloropsis oculata before and after extraction with conventional solvents and/or compressed fluids. Journal of Supercritical Fluids, 108, 89–95. https://doi.org/10.1016/j.supflu.2015.11.003

Boopathy, R., Rene, E. R., López, M. E., Annachhatre, A. P., & Lens, P. N. L. (2017). Special issue on environmental biotechnologies for sustainable development. International Biodeterioration and Biodegradation, 119, 1–3. https://doi.org/10.1016/j.ibiod.2017.03.007

Cao, X., Xiong, Y., & Lund, J. (2013). The effects of micro-algae characteristics on the bioremediation rate of deepwater horizon crude oil. Journal of Emerging Investigators, 1–7.

Carrera-Martinez, D., Mateos-Sanz, A., Lopez-Rodas, V., & Costas, E. (2011). Adaptation of microalgae to a gradient of continuous petroleum contamination. Aquatic Toxicology, 101(2), 342–350. https://doi.org/10.1016/j.aquatox.2010.11.009

Cerniglia, C. E., Gibson, D. T., & Van Baalen, C. (1980). Oxidation of naphthalene by cyanobacteria and microalgae. Journal of General Microbiology, 116(2), 495–500. https://doi.org/10.1099/00221287-116-2-495

Chisti, Y. (2008). Biodiesel from microalgae beats bioethanol. Trends in Biotechnology, 26(3), 126–131. https://doi.org/10.1016/j.tibtech.2007.12.002

Dagley, S. (1978). Microbial catabolism, the carbon cycle and environmental pollution. Naturwissenschaften, 65(1978), 85–95. https://doi.org/10.1007/BF00440546

Das, N., & Chandran, P. (2011). Microbial degradation of petroleum hydrocarbon contaminants: An overview. Biotechnology Research International, 2011, 1–13. https://doi.org/10.4061/2011/941810

Del’Arco, J. P., & De França, F. P. (2001). Influence of oil contamination levels on hydrocarbon biodegradation in sandy sediment. Environmental Pollution, 112(3), 515–519. https://doi.org/10.1016/S0269-7491(00)00128-7

Demirel, Y. T., Yati, I., Donmez, R., & Bulbul Sonmez, H. (2017). Clean-up of oily liquids, fuels and organic solvents from the contaminated water fields using poly(propylene glycol) based organogels. Chemical Engineering Journal, 312, 126–135. https://doi.org/10.1016/j.cej.2016.11.124

Gregorio, S., Siracusa, G., Becarelli, S., Mariotti, L., Gentini, A., & Lorenzi, R. (2016). Isolation and characterization of a hydrocarbonoclastic bacterial enrichment from total petroleum hydrocarbon contaminated sediments: Potential candidates for bioaugmentation in bio-based processes. Environmental Science and Pollution Research, 23(11), 10587–10594. https://doi.org/10.1007/s11356-015-5944-y

Díaz-Baez, M. C., López, M. C. B., & Ramírez, A. J. E. (2004). Pruebas de toxicidad acuática: fundamentos y métodos. Revista Ingeniería e Investigación, 29(1), 140–142. https://doi.org/10.25267/rev_atl-mediterr_prehist_arqueol_soc.2009.v11.08

Ding, G. T., Yasin, N. H., Takriff, M. S., Kamarudin, K. F., Salihon, J., Yaakob, Z., & Hakimi, N. I. N. M. (2020). Phycoremediation of palm oil mill effluent (POME) and CO2 fixation by locally isolated microalgae: Chlorella sorokiniana UKM2, Coelastrella sp. UKM4 and Chlorella pyrenoidosa UKM7. Journal of Water Process Engineering, 35(September 2019), 101202. https://doi.org/10.1016/j.jwpe.2020.101202

El-Sheekh, M. M., Hamouda, R. A., & Nizam, A. A. (2013). Biodegradation of crude oil by Scenedesmus obliquus and Chlorella vulgaris growing under heterotrophic conditions. International Biodeterioration and Biodegradation, 82, 67–72. https://doi.org/10.1016/j.ibiod.2012.12.015

Emparan, Q., Jye, Y. S., Danquah, M. K., & Harun, R. (2020). Cultivation of Nannochloropsis sp. microalgae in palm oil mill effluent (POME) media for phycoremediation and biomass production: Effect of microalgae cells with and without beads. Journal of Water Process Engineering, 33(November 2019), 101043. https://doi.org/10.1016/j.jwpe.2019.101043

Essabri, A. M. A., Aydinlik, N. P., & Williams, N. E. (2019). Bioaugmentation and biostimulation of total petroleum hydrocarbon degradation in a petroleum-contaminated soil with fungi isolated from olive oil effluent. Water, Air, and Soil Pollution, 230(3). https://doi.org/10.1007/s11270-019-4127-8

Faria, G. R., Paes, C. R. P. S., Castro, D. J. F. A., Tinoco, N. A. B., Barbarino, E., & Lourenço, S. O. (2012). Effects of the availability of CO 2 on growth, nutrient uptake, and chemical composition of the marine microalgae Chlorella sp. and Nannochloropsis oculata, two potentially useful strains for biofuel production. International Research Journal of Biotechnology, 3(5), 2141–5153. http://www.interesjournals.org/IRJOB

Ferreira, T. F., Coelho, M. A. Z., & Miguez Da Rocha-Leão, M. H. (2012). Factors influencing crude oil biodegradation by Yarrowia lipolytica. Brazilian Archives of Biology and Technology, 55(5), 785–791.

Figueiredo, L. H. M. (1999). Investigação das Contribuições Orgânicas Antrópicas e Naturais em Sedimentos Costeiros Utilizando-se Hidrocarbonetos Marcadores. Pontificia Universidade Católica do Rio de Janeiro.

Gassmann, G. (1981). Chromatographic separation of diasteriomeric isoprenoids for the identification of fossil oil contamination. Marine Pollution Bulletin, 12(3), 78–84. https://doi.org/10.1016/0025-326X(81)90197-1

Hammed, A. M., Prajapati, S. K., Simsek, S., & Simsek, H. (2016). Growth regime and environmental remediation of microalgae. Algae, 31(3), 189–204. https://doi.org/10.4490/algae.2016.31.8.28

Hamouda, R. A. E. F., Sorour, N. M., & Yeheia, D. S. (2016). Biodegradation of crude oil by Anabaena oryzae, Chlorella kessleri and its consortium under mixotrophic conditions. International Biodeterioration and Biodegradation, 112, 128–134. https://doi.org/10.1016/j.ibiod.2016.05.001

Ibrahim, M. B. M., & Gamila, H. A. (2004). Algal bioassay for evaluating the role of algae in bioremediation of crude oil: II. Freshwater phytoplankton assemblages. Bulletin of Environmental Contamination and Toxicology, 73(6), 971–978. https://doi.org/10.1007/s00128-004-0521-y

Kalhor, A. X., Movafeghi, A., Mohammadi-Nassab, A. D., Abedi, E., & Bahrami, A. (2017). Potential of the green alga Chlorella vulgaris for biodegradation of crude oil hydrocarbons. Marine Pollution Bulletin, 123(1–2), 286–290. https://doi.org/10.1016/j.marpolbul.2017.08.045

Liu, J., Song, Y., & Qiu, W. (2017). Oleaginous microalgae Nannochloropsis as a new model for biofuel production: Review & analysis. Renewable and Sustainable Energy Reviews, 72(January), 154–162. https://doi.org/10.1016/j.rser.2016.12.120

Lowrey, J., Armenta, R. E., & Brooks, M. S. (2016). Nutrient and media recycling in heterotrophic microalgae cultures. Applied Microbiology and Biotechnology, 100(3), 1061–1075. https://doi.org/10.1007/s00253-015-7138-4

Ma, X.-N., Chen, T.-P., Yang, B., Liu, J., & Chen, F. (2016). Lipid Production from Nannochloropsis. Marine Drugs, 14(4), 61. https://doi.org/10.3390/md14040061

Marques, I. M., Moreira, Í. T. A., Melo, N. R., Oliveira, A. C. V., Wicks, W. S. F. F., & Souza, L. C. (2017). Protótipo Para Tratamento De Águas Residuais Urbanas Utilizando a Espécie De Microalga Chlorella vulgaris Com Vistas À Geração De Bioprodutos. RDE – Revista de Desenvolvimento Econômico, 1(2017), 183. https://doi.org/10.21452/rde.v3nesp.5407

Marques, I. M., Melo, N. R., Oliveira, A. C. V., & Moreira, Í. T. A. (2020). Bioremediation of urban river wastewater using Chlorella vulgaris microalgae to generate biomass with potential for biodiesel production. Research, Society and Development, 9(7), e823974882. https://doi.org/10.33448/rsd-v9i7.4882

Marques, I. M., Oliveira, A. C. V., de Oliveira, O. M. C., Sales, E. A., & Moreira, Í. T. A. (2021). A photobioreactor using Nannochloropsis oculata marine microalgae for removal of polycyclic aromatic hydrocarbons and sorption of metals in produced water. Chemosphere, 281(May), 130775. https://doi.org/10.1016/j.chemosphere.2021.130775

Middelhoven, W. J. (1993). Catabolism of benzene compounds by ascomycetous and basidiomycetous yeasts and yeastlike fungi. A literature review and an experimental approach. Antonie Van Leeuwenhoek, 63(2), 125–44. https://doi.org/10.1007/BF00872388

Moreira, I. T. A., Oliveira, O. M. C., Triguis, J. A., Queiroz, A. F. S., Ferreira, S. L. C., Martins, C. M. S., Silva, A. C. M., & Falcão, B. A. (2013). Phytoremediation in mangrove sediments impacted by persistent total petroleum hydrocarbons (TPH’s) using Avicennia schaueriana. Marine Pollution Bulletin, 67(1–2), 130–136. https://doi.org/10.1016/j.marpolbul.2012.11.024

Moreira, Í. T. A., Oliveira, O. M. C., Silva, C. S., Rios, M. C., Queiroz, A. F. S., Assunção, R. V., & Carvalho, A. P. N. (2015). Chemometrics applied in laboratory study on formation of oil–spm aggregates (OSAs) — A contribution to ecological evaluation. Microchemical Journal, 118, 198–202. https://doi.org/10.1016/j.microc.2014.09.007

Moreira, Í. T. A., Oliveira, O. M. C., Azwell, T., Queiroz, A. F. S., Nano, R. M. W., Souza, E. S., Dos Anjos, J. A. S. A., Assunção, R. V., & Guimarães, L. M. (2016). Strategies of bioremediation for the degradation of petroleum hydrocarbons in the presence of metals in mangrove simulated. Clean - Soil, Air, Water, 44(6), 631–637. https://doi.org/10.1002/clen.201300939

Mujtaba, G., Rizwan, M., & Lee, K. (2015). Simultaneous removal of inorganic nutrients and organic carbon by symbiotic co-culture of Chlorella vulgaris and Pseudomonas putida. Biotechnology and Bioprocess Engineering, 20(6), 1114–1122. https://doi.org/10.1007/s12257-015-0421-5

Nizami, A. S., Rehan, M., Naqvi, M., Ouda, O., Shahzad, K., Syamsiro, M., Waqas, M., Miandad, R., Asam, Z. U. Z., & Mohammad Ismail, I. (2017). Energy, economic and environmental savings by waste recycling: A case study of Madinah City. Energy Procedia, 142, 910–915. https://doi.org/10.1016/j.egypro.2017.12.146

Pi, Y., Xu, N., Bao, M., Li, Y., Lv, D., & Sun, P. (2015). Bioremediation of the oil spill polluted marine intertidal zone and its toxicity effect on microalgae. Environmental Sciences: Processes and Impacts, 17(4), 877–885. https://doi.org/10.1039/c5em00005j

Qari, H., Rehan, M., & Nizami, A. S. (2017). Key issues in microalgae biofuels: A short review. Energy Procedia, 142, 898–903. https://doi.org/10.1016/j.egypro.2017.12.144

R Core Team (2021). R: A language and environment for statistical computing. R Foundation for Statistical Computing, Vienna, Austria. URL https://www.R-project.org/.

Reyimu, Z., & Özçimen, D. (2017). Batch cultivation of marine microalgae Nannochloropsis oculata and Tetraselmis suecica in treated municipal wastewater toward bioethanol production. Journal of Cleaner Production, 150, 40–46. https://doi.org/10.1016/j.jclepro.2017.02.189

Ribeiro, D. M., Junior, P. L. D. S., Teles, V. C., Soares, I. P., Garcia, L. C., Abreu, P. C. V, & Brasil, B. dos S. A. F. (2016). Caracterização da composição química da biomassa da microalga Nannochloropsis oculata cultivada em tanque aberto tipo raceway (pp. 123–129). https://ainfo.cnptia.embrapa.br/digital/bitstream/item/150662/1/III-EnPI-2016-125-131.pdf

Rios, M. C. (2014). Capacidade do sedimento do Estuário do Paraguaçu-BA de formar agregado óleo-material particulado em suspensão (OSA). Universidade Federal da Bahia.

Rocha, J. M. S., Garcia, J. E. C., & Henriques, M. H. F. (2003). Growth aspects of the marine microalga Nannochloropsis gaditana. Biomolecular Engineering, 20(4–6), 237–242. https://doi.org/10.1016/S1389-0344(03)00061-3

Silva, C. S. (2011). Hidrocarbonetos saturados em sedimentos da zona intermareal na Baía de Todos os Santos – Bahia. (Monografia de graduação em oceanografia – Instituto de Geociências). Salvador, Bahia: Universidade Federal da Bahia.

Singh, A., Nigam, P. S., & Murphy, J. D. (2011). Renewable fuels from algae: An answer to debatable land based fuels. Bioresource Technology, 102(1), 10–16. https://doi.org/10.1016/j.biortech.2010.06.032

Singhania, R. R., Sim, S. J., & Rene, E. R. (2019). Special issue on “liquid and gaseous biofuels: Current status and perspectives.” Bioresource Technology Reports, 8, 100316. https://doi.org/10.1016/j.biteb.2019.100316

Speight, J. G., & El-Gendy, N. S. (2018). Bioremediation of marine oil spills. In Introduction to Petroleum Biotechnology. https://doi.org/10.1016/b978-0-12-805151-1.00011-4

Steinhauer, M. S., & Boehm, P. D. (1992). The composition and distribution of saturated and aromatic hydrocarbons in nearshore sediments, river sediments, and coastal peat of the Alaskan Beaufort Sea: Implications for detecting anthropogenic hydrocarbon inputs. Marine Environmental Research, 33(4), 223–253. https://doi.org/10.1016/0141-1136(92)90140-H

Sukarni, S., Hamidi, N., Yanuhar, U., & Wardana, I. N. G. (2014). Potential and properties of marine microalgae Nannochloropsis oculata as biomass fuel feedstock. International Journal of Energy and Environmental Engineering, 5(4), 279–290. https://doi.org/10.1007/s40095-014-0138-9

Taher, H., Giwa, A., Abusabiekeh, H., & Al-Zuhair, S. (2020). Biodiesel production from Nannochloropsis gaditana using supercritical CO2 for lipid extraction and immobilized lipase transesterification: Economic and environmental impact assessments. Fuel Processing Technology, 198(July 2019), 106249. https://doi.org/10.1016/j.fuproc.2019.106249

Walker, J. D., Colwell, R. R., & Petrakis, L. (1975). Degradation of petroleum by an alga, Prototheca zopfii. Applied Microbiology, 30(1), 79–81. https://doi.org/10.1128/am.30.1.79-81.1975

Walne, P. R. (1979). Culture of bivalve molluscs: 50 years’ experience at Conwy (No. Ed. 2). Fishing News Books Ltd.

Acknowledgements

The authors are grateful to the Instituto de Geociências (IGEO)/Universidade Federal da Bahia—UFBA; to LEPETRO Centro de Excelência—Petróleo, Energia e Meio Ambiente, and its technical team for the support during the experiment and analysis; to Emerson Sales for the assistance with the microalgae strain; to Lara Câncio for the collaboration during the sampling and all the laboratory procedures; to Guilherme Mesquita and Mariana Suzarte for the support with the analysis.

Funding

This work was supported by the Coordenação de Aperfeiçoamento de Pessoal de Nível Superior—Brazil (CAPES) [funding code 001, 2014]. Júlia Cintra also thanks Fundação de Amparo à Pesquisa do Estado da Bahia (FAPESB) for the scholarship (BOL1034/2017).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of Interest

The authors declare no competing interests.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Almeida, J.C., Marques, I.M., de Souza, J.R.B. et al. Phycoremediation of Coastal Marine Water Contaminated with Dissolved Oil by Nannochloropsis oculata. Water Air Soil Pollut 233, 469 (2022). https://doi.org/10.1007/s11270-022-05951-9

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s11270-022-05951-9