Abstract

The potential of using iron-oxidizing and sulfur-oxidizing bioleaching process for removal of heavy metals (HMs) was investigated at initial unadjusted pH of pig manure (PM). The indigenous iron-oxidizing and sulfur-oxidizing microorganisms enriched from PM were primarily Alicyclobacillus and Acidithiobacillus thiooxidans, respectively. After 12 days of bioleaching, 95% of Cu, 96.5% of Zn, 93.6% of Mn, and 92.7% of Cd were removed from the PM in sulfur-oxidizing bioleaching process. Besides, 92.9% of Cu, 94.1% of Zn, 91.9% of Mn, and 90.5% of Cd were removed in iron-oxidizing bioleaching process. Furthermore, 18.1% of TN, 63.3% of TP, 65.4% of TK, and 45.6% of TOC were leached from the PM in the sulfur-oxidizing bioleaching process, whereas only 21.6% of TN, 32.8% of TP, 4% of TK, and 49% of TOC were solubilized in the iron-oxidizing bioleaching process. The X-ray diffraction analysis results demonstrated that there was a large amount of sulfur remained in bioleached manure from the sulfur-oxidizing process which poses a potential risk of soil re-acidification. The Standards, Measurements and Testing Program extraction protocol study on fraction of P in PM showed that the amount of bioavailable P in the sulfur-oxidizing bioleaching process was dramatically declined, whereas it was elevated by 25.9% in the iron-oxidizing bioleaching process. The results obtained in this study indicated that both the sulfur- and iron-oxidizing bioleaching process were able to efficiently remove HMs from PM at initial unadjusted pH, whereas the iron-oxidizing process was proved better method in reserving the fertilizing property and more friendly to the environment.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

1 Introduction

With the development of intensive pig production, large amounts of pig manure (PM) have been generated annually and most of it was utilized as organic fertilizer to agriculture land (Leclerc and Laurent, 2017; Yang et al., 2017; Zhou et al., 2018). However, in order to minimize disease risk, promote growth, and improve the efficiency of feed utilization in intensive pig production, some trace metals such as Cu and Zn are broadly used in pig feed, which resulted in excessive amounts of those metals almost being completely excreted into feces and urine and led to a high concentrations of heavy metals (HMs) in PM (Long et al., 2004; Nicholson et al., 1999; Xiong et al., 2010). It has been reported that long-term application of such manure to agriculture soil could result in the accumulation of HMs in edible plants which may pose potential health risk to humans and animals (Girotto et al., 2013; Leclerc and Laurent, 2017; Maccari et al., 2016; Mccarthy et al., 2013; Xu et al., 2013; Zhou et al., 2005). Therefore, it is in urgent need of proper methods for management of PM before its direct land application.

Over the years, bioleaching has been well developed in the fields of extractive metallurgy of low grade ores, sewage sludge, and e-waste due to its low cost, nature- and eco-friendly, and simple operation (Feng et al., 2013; Gu et al., 2017; Kumar and Nagendran, 2009; Zeng et al., 2016), which provides an alternative to chemical leaching for removal of HMs from PM. Bioleaching process using iron-oxidizing bacteria and sulfur-oxidizing bacteria has been proved an efficient way to solubilize HMs from PM (Wei et al., 2018b; Zhou et al., 2012). Acidithiobacillus thiooxidans and Acidithiobacillus ferrooxidans are the most widely used sulfur-oxidizing bacteria and iron-oxidizing bacteria in bioleaching, but pre-acidification is generally required to support their growth (Wong et al., 2004), which raises operational cost and further limits the application of bioleaching on a larger scale. Bioleaching of sewage sludge at neutral pH using indigenous bioleaching bacteria has been reported (Pathak et al., 2009; Zeng et al., 2016). However, the PM is quite different with sewage sludge in constituents. The indigenous sulfur-oxidizing bacteria and iron-oxidizing bacteria isolated from PM at initial unadjusted pH is unclear and the effect of these two types of microorganism on bioleaching of HMs from PM still required a further study.

Besides, one of the major concerns involving in bioleaching of PM is the potential loss of nutrients, which would certainly reduce its value as soil fertilizer and conditioner. During bioleaching, a low pH condition coupled with highly oxidizing environment was generally generated resulting in the leaching of PM bound nutrients. According to Wei et al. (2018a), a maximum of 19.1% N, 71% P, and 78.8% K were leached out during PM bioleaching using indigenous sulfur-oxidizing bacteria. Similar results have also been reported in bioleaching of soil and sewage sludge. Sulfur-oxidizing process being employed in bioleaching of HMs-contaminated soil led to the leaching of 30% N, 70% P, and 68% K. Report of Pathak et al. (2009) suggested that 32% N and 24% P were solubilized during sewage sludge bioleaching using indigenous iron-oxidizing bacteria. Dissolution of nutrients using indigenous sulfur-oxidizing bacteria has also been reported by Zhang et al. (2008) with a maximum of 20% N and 68% P solubilization during bioleaching. These available reports in literature confirmed that both sulfur-oxidizing process and iron-oxidizing process caused the nutrient loss from sludge or PM, but few paid attention to the differences between those two processes on the leaching rate and changes in bioavailability of nutrients which are important for direct land application.

The objective of this study was to isolate indigenous sulfur-oxidizing bacteria and iron-oxidizing bacteria and to make a comparative evaluation of HMs leaching efficiency by the two processes at initial unadjusted pH of PM. Besides, for further exploring the effect of sulfur-oxidizing process and iron-oxidizing process on fertilizer property of PM during bioleaching, a comparison of those two processes in terms of nutrients leaching is also investigated.

2 Materials and Methods

2.1 Pig Manure

Pig manure used in this study was collected from a local pig farm in Tianjin, China. The manure sample was transported to laboratory and stored at 4 °C for further use. The main physicochemical characteristics of PM were measured according to the Standard Methods (APAH, 1995) and listed in Table 1.

2.2 Bioleaching Inoculation Preparation and Iron- and Sulfur-Oxidizing Bacterium Enrichment

Original PM, taken from the local pig farm, was used as the seed for bioleaching bacteria enrichment. The PM containing high amount of nutrients does not need additional nutrients for the growth of sulfur-oxidizing bacteria and iron-oxidizing bacteria (Table 1). Three hundred milliliters of PM (solid content, 20 g/L) was added to 500 mL flasks, and 10 g/L sulfur or 20 g/L ferrous sulfate was added as energy source for pre-incubation. When the pH in sulfur-oxidizing process and iron-oxidizing process dropped below 2.0 and 2.5, respectively, the pre-incubation completed. Ten percent (v/v) of the pre-cultured inoculum was then transferred to a fresh PM. After four times of such transfer, the active inoculum rich in sulfur-oxidizing bacteria or iron-oxidizing bacteria was prepared.

To further investigate the sulfur-oxidizing bacteria and iron-oxidizing bacteria consortium in the inoculums, the Starkey and 9 K medium were utilized in the present study. The Starkey medium contained the following (g/L): (NH4)2SO4, 0.4; K2HPO4, 3; MgSO4·7H2O, 0.5; FeSO4·7H2O, 0.01; CaCl2·2H2O, 0.25. The 9 K medium contained the following (g/L): (NH4)2SO4, 3; KCl, 0.1; K2HPO4, 0.5; MgSO4·7H2O, 0.5; Ca(NO3)2, 0.01. The Starkey and 9 K medium autoclaved at 121 °C for 20 min were adjusted to pH 4.0 and 3.0 using sulfuric acid, and then 10 g/L of sulfur and 44.2 g/L of filter sterilized ferrous sulfate were added as energy source, respectively.

The sulfur-oxidizing bacteria and iron-oxidizing bacteria consortium were obtained through the enrichment process reported by Wang et al. (2016). The samples were sampled from the flasks and flushed softly with phosphate buffer (pH 2.0 and pH 7.2). The total DNA was extracted with MoBio PowerSoil DNA isolation kit (MoBio laboratories, Carsbad, CA, USA) according to the manufacturer’s instruction, and then the DNA was amplified with the PCR reactions carried out with Phusion High-Fidelity PCR Master Mix (New England Biolabs). Sequencing was performed by using the Illumina HiSeq 2500 platform (Illumina, San Diego, CA, USA). Sequences were further analyzed based on 16S rRNA gene clone library analysis according to Wei et al. (2018b).

2.3 Bioleaching Experiments

Bioleaching experiments were conducted in 500 mL Erlenmeyer flasks with a working volume of 300 mL. The solid content of PM was 20 g/L. Each flask was spiked with either 4 g/L of Fe2+ in the form of FeSO4·7H2O or 10 g/L of element sulfur. Ten percent (v/v) of either iron-oxidizing bacteria or sulfur-oxidizing bacteria was inoculated when necessary. The initial pH of PM in both iron-oxidizing process and sulfur-oxidizing process remained unadjusted. The experiment group without inoculation and ferrous sulfate or sulfur was set as control. The flasks were incubated in a gyratory shaker at 28 °C and 180 r/min. Each experiment was done in triplicate. During the experiment, the water loss via evaporation was compensated every day with distilled water based on weight loss.

2.4 Analytical Methods

The total solid (TS) content of PM was measured by drying the manure sample at 105 °C in an oven till constant weight. Organic matter content was measured by TOC analyzer (Multi N/C 300, Analytik Jena, Germany). The concentrations of TN, TP, and TK in PM were measured according to the Standard Methods (APAH, 1995). The Standards, Measurements, and Testing (SMT) Program (Medeiros et al., 2005) extraction protocol was used to analyze P fractions in raw and bioleached manure, the details of SMT protocol as shown in Table 2. The PM sample was analyzed by X-ray diffraction (XRD) (Ulitma IV, Rigaku, Japan).

The variations in PM of pH and ORP were measured every day using a pH/ORP meter (HI 8242, HANNA, Italy). During the experiment, 5 mL of sample was withdrawn from the flasks at 1-day interval and centrifuged at 12,000 r/min for 15 min, then filtered through a 0.45 μm filter. The filtrate was used for analyzing concentrations of sulfate, Fe2+ and soluble HMs (Cu, Zn, Mn, and Cd). The concentrations of sulfate and Fe2+ were measured according to the Standard Methods (APAH, 1995). The concentrations of HMs were measured by an atomic absorption spectrophotometer (TAS-990, Persee, China).

3 Results and Discussion

3.1 Indigenous Sulfur-Oxidizing and Iron-Oxidizing Bacteria

The enriched bacterial community in those sulfur-oxidizing and iron-oxidizing processes was clarified from the analysis of data based on 16S rRNA gene clone library analysis (Fig. 1). All clones sequenced in sulfur-oxidizing culturing process had a 98% sequence similarity to Acidithiobacillus thiooxidans which has been widely used in bioleaching of HMs from sewage sludge and soil (Kumar and Nagendran, 2009; Zeng et al., 2016). All clones sequenced in iron-oxidizing culturing process had a 96% sequence similarity to Alicyclobacillus (Fig. 1a), a kind of microorganism that could take ferrous iron and organic matter as energy source (Guo et al., 2009; Mehrotra and Sreekrishnan, 2017), of which Alicyclobacillus ferripilum and Alicyclobacillus aeris accounted for 46.4% and 35.6% (Fig. 1b), respectively. Furthermore, A. aeris is also reported to be able to use element sulfur and sulfide as energy source, which would be helpful for the solubilization of HMs from PM (Guo et al., 2009; Zeng et al., 2016).

3.2 Variations in pH and ORP during Bioleaching

The variations in pH of the PM during 12 days of bioleaching were shown in Fig. 2a. It was found that in the control without the addition of energy source and inoculum, the pH dropped only slightly from an initial value of 8.62 to 7.65 on the 12th day. This indicated a lower acid production, as no inoculum of active microbes and no energy source were provided to support the indigenous sulfur-oxidizing bacteria and iron-oxidizing bacteria of the PM. In the sulfur-oxidizing process, the indigenous sulfur-oxidizing bacteria was able to oxidize sulfur, resulting in a reduction of pH from 7.3 to 2 in 4 days, then slowly to 1.5 in 10 days and eventually to 1.4 on the 12th day. In the iron-oxidizing process, the indigenous iron-oxidizing bacteria was capable of oxidizing Fe2+ in the presence of oxygen, leading to a sharp reduction of pH from 6.34 to 4.25 in 1 day and gradually to lower than 2.5 on the 10th day and eventually to 2.4 on the 12th day.

The variations in ORP were shown in Fig. 2b. In the control, ORP achieved a maximum of − 94 mV from an initial value of − 413 mV on the 12th day. In the iron-oxidizing bioleaching process, the oxidation of Fe2+ led to a rapid increase in the ORP from − 212 mV to 143 mV in 1 day and then to 557 mV on the 10th day and finally to 575 mV on the 12th day. In the sulfur-oxidizing bioleaching process, the oxidation of sulfur also led to an increase in the ORP but with a slower rate. The ORP increased from − 408 mV to 2.5 mV in 4 days and then to 290 mV on the 10th day and finally to 293 mV on the 12th day.

Variations in ORP and pH during bioleaching are indicators of the growth of microorganisms (Kumar and Nagendran, 2007; Pathak et al., 2009). The increase of ORP in sulfur-oxidizing process was ascribed to the oxidation of sulfur to sulfate by sulfur-oxidizing bacteria (Eq. 1), which was coupled with a drastic decrease of pH. In iron-oxidizing process, the increase in ORP was caused by the oxidation of Fe2+ to Fe3+ (Eq.2), which took place naturally in the presence of air and also occurred through biological oxidation. Then, the hydrolysis of ferric iron to ferric hydroxide (Eq. 3) and jarosite (Eq. 4) led to the decrease of pH.

The results obtained in this study indicated that both indigenous iron-oxidizing and sulfur-oxidizing bacteria were well-grown and highly efficient at an initial unadjusted pH of the PM without additional nutrients. Comparing the two processes, sulfur-oxidizing bacteria oxidized the sulfur resulting in a lower pH in the sulfur-oxidizing process, while the Fe2+ oxidation by iron-oxidizing bacteria leading to a higher ORP in the iron-oxidizing process.

3.3 Changes in Sulfate Production and Fe2+ Oxidation during Bioleaching Process

Variations of sulfate concentration and Fe2+ oxidation in sulfur-oxidizing and iron-oxidizing process, respectively, were shown in Fig. 3. It was found that, in iron-oxidizing bioleaching process, the Fe2+ oxidation rapidly increased to 36.7% in 1 day, and then a lag phase occurred and lasted for 5 days. This could be ascribed to that the iron-oxidizing bacteria need to adapt to the new cultivation condition, which was consistent with the result reported by Wei et al. (2018b). After the lag phase, the Fe2+ oxidation continued to rise rapidly in day 6 and achieved 100% on the 10th day. In sulfur-oxidizing process, sulfur was oxidized by sulfur-oxidizing bacteria, which resulted in a liner increase of sulfate concentration with time. After 12 days of bioleaching, the concentration of sulfate increased from 295 to 8273 mg/L. Based on this result, it was found that about 72.4% of sulfur was not utilized during sulfur-oxidizing bioleaching process. The residual sulfur in bioleached PM was not easy to be removed, which once applied to agriculture land with PM will lead to the acidification of soil. Thus, the residual sulfur may affect the practical application of sulfur-oxidizing process, and was necessary to be handled before the further disposal of bioleached PM. Chen et al. (2003) reported that some recoverable forms of sulfur for sewage sludge bioleaching process was reusable in the batch tests. However, the application of these recoverable forms of sulfur in PM bioleaching still needs to be further investigated.

3.4 Solubilizations of HMs

The solubilizations of Cu, Zn, Mn, and Cd in the control as well as in the sulfur-oxidizing process and iron-oxidizing process were shown in Fig. 4. As shown in Fig. 4a, in the control, only 2.3% of Cu were solubilized in 12 days at PM pH 6.75 and ORP − 94 mV. In the sulfur-oxidizing process, Cu began to be solubilized on the 4th day when the pH and ORP of PM achieved lower than 2 and higher than 2.5 mV, respectively. After that, there was a drastic increase in Cu solubilization and 92% of Cu was solubilized on the 9th day at manure pH 1.5 and ORP 284 mV. In the iron-oxidizing process, Cu started to be solubilized on the 3rd day when the pH and ORP of PM reached 4.0 and 211 mV, respectively. A subsequent moderate increase of Cu solubilization from 3.9% on the 3rd day to 24.8% on the 7th day was then observed, which was in accordance with the slight changes in pH and ORP in the same period of time. After that, Cu solubilization dramatically increased and achieved 92% on the 10th day at pH 2.4 and ORP 557 mV. These results indicated that high solubilization of Cu can be obtained in both sulfur-oxidizing process and iron-oxidizing process, and this can be ascribed to the low pH and high ORP of PM achieved in the two processes. The previous results have also reported that both pH and ORP played a critical role in Cu solubilization during PM bioleaching (Wei et al., 2018b; Zhou et al., 2012).

As can be seen from Fig. 4b, the solubilization of Zn in sulfur-oxidizing process achieved 92.3% on the 5th day at manure pH lower than 2 and ORP higher than 2.5 mV and 96.5% on the 12th day when the pH was 1.43 and ORP was 293 mV as compared to 1.3% in the control at PM final pH 6.75 and ORP − 94 mV. In iron-oxidizing process, the solubilization of Zn rapidly achieved 53.8% in 1 day when the PM pH and ORP reached 4.25 and 144 mV, respectively. After that, there was a gradual increase in Zn solubilization and 92.7% Zn was leached from PM on the 9th day at pH 2.6 and ORP 471 mV, which increased to a maximum of 94.1% when pH and ORP of PM reached 2.4 and 575 mV, respectively, on the 12th day.

As shown in Fig. 4c and d, the solubilization of Mn and Cd showed a similar pattern with Zn. Within 5 days, 91.8% Mn and 89.4% Cd were solubilized in sulfur-oxidizing process when the PM pH and ORP reached lower than 2 and higher than 2.5 mV, respectively, and then increased gradually and achieved a maximum of 93.6% and 92.7% on the 12th day at PM pH 1.43 and ORP 293 mV. In iron-oxidizing process, a rapid solubilization of Mn (63.4%) and Cd (60.3%) was observed on the 1st day when the PM pH and ORP reached 4.25 and 144 mV, respectively, and a maximum of 91.9% Mn and 90.5% Cd were solubilized on the 12th day at PM pH 2.4 and ORP 575 mV. Nevertheless, only 2.3% Mn and 3.4% Cd were leached from PM on the 12th day at PM final pH 6.75 and ORP − 94 mV in the control.

As can be seen from above results, both sulfur-oxidizing process and iron-oxidizing process were able to remove HMs from PM at initial unadjusted pH using indigenous sulfur-oxidizing and iron-oxidizing microorganisms. The oxidation of sulfur and ferrous ion in sulfur-oxidizing process and iron-oxidizing process, respectively, both led to significant decline of pH and increase of ORP, which further resulted in solubilization of HMs from PM. After 12 days of bioleaching, 95% Cu, 96.5% Zn, 93.6% Mn, and 92.7% Cd in sulfur-oxidizing process were leached compared to 92.9% Cu, 94.1% Zn, 91.9% Mn, and 90.5% Cd in iron-oxidizing process. The sulfur-oxidizing process was observed to be more efficient in solubilizing HMs than the iron-oxidizing process during PM bioleaching. But when bioleaching for more than 10 days, the HMs in iron-oxidizing process can also achieve a leaching efficiency of higher than 90%, and there was no obvious difference in HMs solubilization between those two processes.

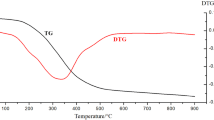

3.5 XRD Analysis

XRD analysis of raw and bioleached PM was shown in Fig. 5. The result showed that after 12 days of bioleaching, a large amount of sulfur was found unoxidized and remained in PM in sulfur-oxidizing bioleaching system. This was consistent with the results observed in Fig. 3. The residual sulfur can hardly be removed from PM and might result in soil re-acidification in PM resource utilization. Thus, the problem of low sulfur oxidation efficiency must be solved before the application of sulfur-oxidizing process in removal of HMs from PM.

In iron-oxidizing process, Fe2+ was completely oxidized to Fe3+ (Fig. 3). However, only a small amount of Fe3+ (about 600 mg/L) was detected in the leachate at the end of bioleaching experiment. The XRD analysis result of bioleached manure from iron-oxidizing process showed that there was a large amount of iron precipitation, such as jarosite and iron phosphate, formed during bioleaching (Fig. 5). This gave an exploration to the low concentration of Fe3+ observed after bioleaching. The result from Fig. 5 also revealed that calcium phosphate and silicon phosphate were found in raw PM, but not in bioleached PM. This could be attributed to the acidification of PM during bioleaching which resulted in the dissolution of those types of phosphate and further built a favorable environment for iron phosphate precipitation. On the other hand, the presence of iron-oxidizing bacteria and ammonium solubilized from PM provided conditions for the formation of jarosite (Liao et al., 2009), which further contributed to Fe3+ precipitation. In addition, it has been reported that the formation of iron precipitation may adversely affect the solubilization of HMs during bioleaching by co-precipitation (Liao et al., 2009). However, no obvious influence was observed on HMs solubilization in the present study. Instead, the precipitate contained phosphorus and potassium implied that the formation of iron precipitate during bioleaching may be helpful for reserving the nutrients in PM, and this has been investigated in the following part.

3.6 Effect of Different Bioleaching Process on Nutrients Leaching

Figure 6 showed the variations of TP, TN, TK, and TOC in PM before and after bioleaching. It was found that both bioleaching processes led to the dissolution of nutrients, but they were different in leaching efficiency, especially for TP and TK. After 12 days of bioleaching, the content of TP in iron-oxidizing bioleaching process was decreased from 30.2 to 20.3 g/kg; the leaching ratio was 32.8%. However, in sulfur-oxidizing process, TP in the bioleached PM was reduced to 11.4 g/kg, and the leaching ratio was reached up to 63.3%, nearly twice that (32.8%) of iron-oxidizing process. It was reported that the solibilization of P can be significantly influenced by the pH during bioleaching (Zhang et al., 2008). The lower the pH, the higher the P dissolution. In present study, the sulfur-oxidizing process caused a lower pH (1.4) than that (2.4) in the iron-oxidizing process during bioleaching (Fig. 2a), and this could be one of the reasons for the higher P loss in sulfur-oxidizing process. On the other hand, the P was partially reserved by the formation of iron phosphate in the iron-oxidizing process (Fig. 5), which may contribute to the reduction of P loss.

In iron-oxidizing process, the content of TK in PM decreased from 15.0 to 14.4 g/kg, the leaching ratio only achieved 4%, much lower than that (65.4%) in sulfur-oxidizing bioleaching process. K in PM was easily to be leached out under acid condition (Wei et al., 2018a). The high leaching efficiency of TK in sulfur-oxidizing process was primarily attributed to the low pH. And most of the K dissolved in the leachate in iron-oxidizing process by acidification was deposited by the formation of jarosite, which greatly reduced the K loss.

Besides, there was no obvious difference observed in TN loss during the two bioleaching process (Fig. 6). The contents of TN in bioleached manure from iron-oxidizing process and sulfur-oxidizing process were 24.5 g/kg and 25.6 g/kg, respectively. Since the nitrogen in PM was mainly existed as organic forms (Wei et al., 2018b), the dissolution of TN could be caused by the nitrogen release from organic matters, and by the decomposition of organic matters and proteins from microorganisms in acid environment (Nareshkumar and Nagendran, 2008). The similar solubilization of TN indicated that the chemical digestion and biological degradation in those two processes had no evident difference in dissolving this kind of N-containing organic matter. This was further confirmed by the similar leaching ratio of organic matter (TOC) (49% for Fe and 45.6% for S) obtained in the two processes.

3.7 Effect of Different Bioleaching Process on the Content of Available P in PM

For further investigation of the effect of different bioleaching processes on P dissolution, the different P fractions in raw and bioleached PM were analyzed using a SMT extraction protocol (Fig. 7). It was found that in sulfur-oxidizing process, all forms of P in PM were drastically decreased due to the acidifying and oxidizing environment. However, in iron-oxidizing process, the NAIP was increased significantly instead of decreasing. Furthermore, IP was consisted of NAIP and AP, which accounting for 91% of TP in raw PM. Hence, the decrease of TP in iron-oxidizing process was primarily resulted from the dissolution of AP. According to the XRD analysis results (Fig. 5), bioleaching led to the solubilization of calcium phosphate and silicon phosphate (AP) from PM, and this kind of P was partially reserved by the formation of iron phosphate, which finally resulted in the increase of NAIP. NAIP and OP are considered to be bioavailable (Huang et al., 2015). Therefore, the iron-oxidizing bioleaching process significantly increased the content of bioavailable P. After 12 days of bioleaching, the bioavailable P (NAIP + OP) was greatly increased from 14 to 18.9 g/kg, making a rise of 25.9%. The results indicated that the nutrients can be better reserved in iron-oxidizing process.

4 Conclusion

The results demonstrated that both sulfur- and iron-oxidizing process can successfully solubilize heavy metals from PM at initial unadjusted pH using indigenous bioleaching microorganisms (A. thiooxidans and Alicyclobacillus), which was more than 90% of solubilization after 12 days of bioleaching. Large amount of unoxidized sulfur was remained in bioleached PM during sulfur-oxidizing treatment, which may cause soil re-acidification. Also, lower pH achieved in sulfur-oxidizing process may also require larger amount of alkali to neutralize the PM, resulting in a higher operational cost. Besides, the iron-oxidizing process was proved better method in reserving fertilizing properties of the bioleached PM. Therefore, the iron-oxidizing process appeared to be more suitable for removal of heavy metals from PM than the sulfur-oxidizing process. However, it still warrants further detailed studies to prove the feasibility of iron-oxidizing bioleaching process in removal of HMs from PM for engineering application, which are undergoing in our lab.

References

APAH. (1995). Standard methods for the examination of water and waste-waters. In American public health association. Washing-ton: DC.

Chen, S. Y., Chiu, Y. C., Chang, P. L., & Lin, J. G. (2003). Assessment of recoverable forms of sulfur particles used in bioleaching of contaminated sediments. Water Research, 37, 450–458.

Feng, S., Yang, H., Xin, Y., Gao, K., Yang, J., Liu, T., Zhang, L., & Wang, W. (2013). A novel and highly efficient system for chalcopyrite bioleaching by mixed strains of Acidithiobacillus. Bioresource Technology, 129, 456–462.

Girotto, E., Ceretta, C. A., Rossato, L. V., Farias, J. G., Tiecher, T. L., De, C. L., Schmatz, R., Brunetto, G., Schetinger, M. R., & Nicoloso, F. T. (2013). Triggered antioxidant defense mechanism in maize grown in soil with accumulation of cu and Zn due to intensive application of pig slurry. Ecotoxity Environmental Safe, 93, 145–155.

Gu, W., Bai, J., Dong, B., Zhuang, X., Zhao, J., Zhang, C., Wang, J., & Shih. (2017). Enhanced bioleaching efficiency of copper from waste printed circuit board driven by nitrogen-doped carbon nanotubes modified electrode. Chemical Engineering Journal, 324, 122–129.

Guo, X., You, X. Y., Liu, L. J., Zhang, J. Y., Liu, S. J., & Jiang, C. Y. (2009). Alicyclobacillus aeris sp. nov., a novel ferrous- and sulfur-oxidizing bacterium isolated from a copper mine. International Journal of Systematic and Evolutionary Microbiology, 59, 2415–2420.

Huang, W., Cai, W., Huang, H., Lei, Z., Zhang, Z., Tay, J. H., & Lee, D. J. (2015). Identification of inorganic and organic species of phosphorus and its bio-availability in nitrifying aerobic granular sludge. Water Research, 68, 423–431.

Kumar, R. N., & Nagendran, R. (2007). Influence of initial pH on bioleaching of heavy metals from contaminated soil employing indigenous Acidithiobacillus thiooxidans. Chemosphere, 66, 1775–1781.

Kumar, R. N., & Nagendran, R. (2009). Fractionation behavior of heavy metals in soil during bioleaching with Acidithiobacillus thiooxidans. Journal of Hazardous Materials, 169, 1119–1126.

Leclerc, A., & Laurent, A. (2017). Framework for estimating toxic releases from the application of manure on agricultural soil: National release inventories for heavy metals in 2000-2014. Science of the Total Environment, 590-591, 452–460.

Liao, Y., Zhou, L., Bai, S., Liang, J., & Wang, S. (2009). Occurrence of biogenic schwertmannite in sludge bioleaching environments and its adverse effect on solubilization of sludge-borne metals. Applied Geochemistry, 24, 1739–1746.

Long, C., Yu-jun, W., Dong-mei, Z., & Yuan-hua, D. (2004). Heavy metals pollution in poultry and livestock feeds and manures under intensive farming in Jiangsu Province, China. Journal of Environmental Science, 16, 371–374.

Maccari, A. P., Baretta, D., Paiano, D., Leston, S., Freitas, A., Ramos, F., Sousa, J. P., & Klauberg-Filho, O. (2016). Ecotoxicological effects of pig manure on Folsomia candida in subtropical Brazilian soils. Journal of Hazardous Materials, 314, 113–120.

Mccarthy, G., Lawlor, P. G., Gutierrez, M., & Gardiner, G. E. (2013). Assessing the biosafety risks of pig manure for use as a feedstock for composting. Science of the Total Environment, 463-464, 712–719.

Medeiros, J. J. G., Cid, B. P., & Gómez, E. F. (2005). Analytical phosphorus fractionation in sewage sludge and sediment samples. Analytical and Bioanalytical Chemistry, 381, 873–878.

Mehrotra, A., & Sreekrishnan, T. R. (2017). Heavy metal bioleaching and sludge stabilization in a single stage reactor using indigenous acidophilic heterotrophs. Environmental Technology, 38, 1–16.

Nareshkumar, R., & Nagendran, R. (2008). Changes in nutrient profile of soil subjected to bioleaching for removal of heavy metals using Acidithiobacillus thiooxidans. Journal of Hazardous Materials, 156, 102–107.

Nicholson, F. A., Chambers, B. J., Williams, J. R., & Unwin, R. J. (1999). Heavy metal contents of livestock feeds and animal manures in England and Wales. Bioresource Technology, 70, 23–31.

Pathak, A., Dastidar, M. G., & Sreekrishnan, T. R. (2009). Bioleaching of heavy metals from sewage sludge by indigenous iron-oxidizing microorganisms using ammonium ferrous sulfate and ferrous sulfate as energy sources: A comparative study. Jounal of Hazardous Materials, 171, 273–278.

Wang, S., Yue, Z., Yan, W., Chen, L., Mahadevan, G. D., & Feng, Z. (2016). Enhanced bioleaching efficiency of metals from E-wastes driven by biochar. Jounal of Hazardous Materials, 320, 393–400.

Wei, X., Liu, D., Liao, L., Wang, Z., Li, W., & Huang, W. (2018a). Bioleaching of heavy metals from pig manure with indigenous sulfur-oxidizing bacteria: Effects of sulfur concentration. Heliyon, 4, e00778.

Wei, X. C., Liu, D. F., Li, W. J., Liao, L. R., Wang, Z. D., Huang, W. W., & Huang, W. L. (2018b). Biochar addition for accelerating bioleaching of heavymetals from swine manure and reserving the nutrients. Science of the Total Environment, 631-632, 1553–1559.

Wong, J. W. C., Xiang, L., Gu, X. Y., & Zhou, L. X. (2004). Bioleaching of heavy metals from anaerobically digested sewage sludge using FeS2 as an energy source. Chemosphere, 55, 101–107.

Xiong, X., Li, Y., Li, W., Lin, C., Han, W., & Yang, M. (2010). Copper content in animal manures and potential risk of soil copper pollution with animal manure use in agriculture. Resource Conservatons and Recycling, 54, 985–990.

Xu, Y., Yu, W., Ma, Q., & Zhou, H. (2013). Accumulation of copper and zinc in soil and plant within ten-year application of different pig manure rates. Plant, Soil and Environment, 59, 492–499.

Yang, X., Li, Q., Tang, Z., Zhang, W., Yu, G., Shen, Q., & Zhao, F. J. (2017). Heavy metal concentrations and arsenic speciation in animal manure composts in China. Waste Management, 64, 333–339.

Zeng, J., Gou, M., Tang, Y. Q., Li, G. Y., Sun, Z. Y., & Kida, K. (2016). Effective bioleaching of chromium in tannery sludge with an enriched sulfur-oxidizing bacterial community. Bioresource Technology, 218, 859–866.

Zhang, P., Yi, Z., Zhang, G., Zou, S., Zeng, G., & Zhen, W. (2008). Sewage sludge bioleaching by indigenous sulfur-oxidizing bacteria: Effects of ratio of substrate dosage to solid content. Bioresource Technology, 100, 1394–1398.

Zhou, D. M., Hao, X. Z., Wang, Y. J., Dong, Y. H., & Cang, L. (2005). Copper and Zn uptake by radish and pakchoi as affected by application of livestock and poultry manures. Chemosphere, 59, 167–175.

Zhou, J., Zhou, L., Liu, F., Zheng, C., & Deng, W. (2012). Transformation of heavy metals and the formation of secondary iron minerals during pig manure bioleaching by the co-inoculation acidophilic thiobacillus. Environmental Technology, 33, 2553–2560.

Zhou, H., Meng, H., Zhao, L., Shen, Y., Hou, Y., Cheng, H., & Song, L. (2018). Effect of biochar and humic acid on the copper, lead, and cadmium passivation during composting. Bioresource Technology, 258, 279–286.

Funding

This work was financially supported by the Agro-Environment Protection Institute (AEPI) of the Ministry of Agriculture (MOA) of China (No. 2016YFD0801002-01), Tianjin Rural Work Committee of China (No. 201601190), and Open Foundation of the Heilongjiang Provincial Key Laboratory of Environmental Microbiology and Recycling of Argo-Waste in Cold Region (201716).

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Wei, X., Li, J., Huang, W. et al. Comparative Study of Iron-Oxidizing and Sulfur-Oxidizing Bioleaching Processes for Heavy Metal Removal and Nutrient Leaching from Pig Manure. Water Air Soil Pollut 231, 34 (2020). https://doi.org/10.1007/s11270-020-4415-3

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s11270-020-4415-3