Abstract

This study evaluated the behavior of a sequencing batch reactor (SBR) at laboratory-scale in removing the emerging contaminants, ibuprofen (IBP) and methylparaben (MPB), at different concentrations. Individual experiments were carried out for each pollutant and they were divided into six stages of operation, which included starting, load variation, and interim periods of system stabilization. The treated wastewater was synthetic, and it included the pollutions MPB or IBP, glucose as a co-substrate, macronutrients, and micronutrients. The inoculum used to start the reactor was an aerobic sludge from an SBR system used in the treatment of domestic wastewater, which presented with high-content organic material and featured good sedimentation characteristics. The removal percentages of the two compounds at concentrations of 300, 500, and 1000 μg/L were not similar. For MPB, high removal percentages (>96 %) were obtained, while for IBP, decreasing removal percentages were found with increases in analyte concentration, exhibiting average values of 51 ± 15.3, 26 ± 16.6, and 16 ± 5.4 %. Following the removal of IBP, this behavior showed pronounced effects in biomass inhibition during exposure to high concentrations of the pollutant.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

1 Introduction

The modernization and growth of society have extended the population’s consumption habits, leading to the use of a wide range of pharmaceuticals and personal care products (PPCPs). Their waste, dumped along with municipal and domestic sewage, has received much attention due to its ubiquity and adverse health effects (Fan and Wang 2012). The presence of these organic micropollutants has been detected in wastewater, surface water, and groundwater (Verlicchi et al. 2010) at concentrations ranging from nanograms per liter up to micrograms per liter (Suarez et al. 2012), with some pharmaceuticals being detected at concentrations >1000 μg/L in the effluent wastewater, corresponding to pharmaceutical industries (Kumar and Xagoraraki 2010).

The 2-(4-isobutyl-phenyl) propionic acid compound represents the first non-steroidal anti-inflammatory drug to be commercially available, known as ibuprofen (IBP) (Quero-Pastor et al. 2014); this compound is one of the active pharmaceutical ingredients commonly used worldwide (Ferrando-Climent et al. 2012). This drug is 17th on the list of the most commonly prescribed drugs (Quero-Pastor et al. 2014); its widespread use has translated into its presence in different environmental matrices, which has caused great concern regarding the effects that this pollutant can have on natural ecosystems and on the health of individuals. Significant effects have been reported for IBP with respect to the growth of several species of bacteria and fungi (Estevez et al. 2014). It has even been shown that the combination of IBP with other pharmaceuticals may prevent cell proliferation in human embryos (Ferrando-Climent et al. 2012). Moreover, it has been reported that chronic exposure of aquatic organisms to concentrations of IBP affects their reproduction, indicating that this compound may represent a risk to the environment (Girardi et al. 2013). A number of reports show that contact with IBP has generated effects on the reproduction of aquatic vertebrates, and it also exhibits genotoxic effects on fish (Collado et al. 2012) and cytogenetic effects in freshwater bivalves (Estevez et al. 2014).

Parabens are compounds that are commonly used as preservatives in a wide variety of food, as well as in pharmaceutical and personal care products, due to their antifungal and antibacterial properties (Aubert et al. 2012; Londoño and Peñuela 2015). It has been reported that parabens can disrupt the endocrine system, indicating that they possess weak estrogenic activity, and that this also has adverse effects on reproduction (Guadarrama et al. 2008; Lin et al. 2009.). Likewise, an association has been reported between the use of underarm cosmetics containing parabens and an increased incidence of breast cancer (Canosa et al. 2006; Lin et al. 2009; Vo et al. 2010; González et al. 2011). An even greater risk to human health has been reported due to the formation of mono and dichlorobiphenyls/brominated, as parabens in drinking water react with residual-free chlorine (Canosa et al. 2006; González et al. 2011). These organochlorine compounds are considerably more toxic to aquatic organisms than their respective parent compounds (Błędzka et al. 2014) Table 1.

Removal of these contaminants from wastewater is not fully efficient (Kosma et. al. 2014) because sewage treatment plants (STPs) were not designed for their removal. Physicochemical technologies, such as ultraviolet (UV) radiation, advanced oxidation processes, and activated carbon and membrane filtration, are treatments that can potentially improve the elimination of these compounds in STPs. However, implementation of these techniques would increase the cost of wastewater treatment (Carballa et al. 2007). One promising alternative in the removal process of these compounds can be determined via the evaluation of biological systems, so as to establish operational criteria and modify existing systems. This fact has launched a major scientific effort to understand the behavior and mechanisms of eliminating these contaminants by evaluating the development and optimization of treatment systems that can enable their removal from the residual aqueous matrix.

The removal of IBP and MPB in biological systems has been seldom studied; some of the reported studies are controversial when establishing the biological removal to these compounds. In the present study, the behavior of an SBR system was evaluated under the application of different concentrations of IBP and MPB in a range of 300–1000 μg/L during operating conditions commonly employed to remove organic matter.

2 Materials and Methods

2.1 Description of the SBR Reactor

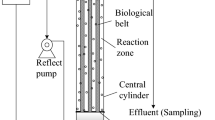

The SBR reactor used in this experiment was constructed in acrylic with an effective volume of 5.5 L; its overall height was 70 cm, and it had an inner diameter of 15 cm. The system (Fig. 1) has three quick-closing half-inch valves; one of these is located at the bottom of the reactor and enables blowdown, while the other two facilitate the entry and exit of the treated flow. The incoming flow enters by means of a peristaltic pump with a capacity of 6–600 RPM. Air is supplied through a copper pipe equipped with two pressure regulators, which supplies a flow of air without generating strong turbulence within the system that would otherwise affect the formation of the floc. Air is injected into the reactor by means of plastic tubing, in which stones are placed to generate fine air bubbles and facilitate the transfer of oxygen to the microorganisms. The system’s operation was configured via a programmable logic controller (PLC) (Londoño et al. 2014), which enabled the sequential development of each of the phases in the reactor’s operation cycle.

2.2 Inoculum

The inoculum used to start the reactor was an aerobic sludge from a treatment system of the wastewater recreational park, Comfenalco Tamarindos, located in San Jerónimo, Antioquia, Colombia. The treatment plant was an SBR system consisting of two units operating in parallel. The sludge was obtained from the purge volume of one of the operating units of the plant, which contained a concentration of total suspended solids (TSS) of 7130 ± 56.6 mg/L, a concentration of volatile suspended solids (VSS) of 5545 ± 7.1 mg/L, and a sedimentation rate of 2.24 ± 0.01 m/h.

2.3 Operational Strategy

The SBR system’s operational strategy was based on the implementation of different phases characterized by an increase in the concentration of PPCPs being studied. In the intermediate stages between charges, there were operating periods without addition of the contaminant in order to facilitate the stabilization time or recovery of the biomass. The chemical oxygen demand (COD) concentration provided by glucose remained constant throughout the experiment. Tables 2 and 3 present a summary of the operating conditions at each stage.

The cycles of operation were implemented for 6 h each; they were distributed in different sequential phases covering the filling, reaction, settling, and discharge processes, as shown in Fig. 2.

2.4 Composition of Synthetic Wastewater

A total of 24 L of synthetic wastewater composed of anhydrous glucose at a COD of 250 mg/L, as well as 1 mL of macronutrients and micronutrients (1 mL per liter of water), were prepared daily. Additionally, the synthetic water was enriched with the analyte of interest to each working concentration (300, 500, and 1000 μg/L of MPB or IBP); the analyte was previously diluted in methanol. The COD/N/P ratio in the synthetic water was 100/5/1.

2.5 Batch Testing

Batch experiments were performed to determine the aerobic biomass response versus the increased concentration of IBP, for which an OxiTop system was used; this was based on a respirometric method that measures of oxygen consumption from the air supplied to the microorganisms in a vessel closed with a temperature and constant agitation. The test was performed using minimum aerated distilled water for 6 h. Each liter of water contained 2 mL of 0.71 N ammonium chloride, 2 mL of 0.25 N calcium chloride, 2 mL of 0.41 N magnesium sulfate, 2 mL of ferric chloride (0.018 N), 2 mL of the trace elements solution, 6 mL of phosphate-buffered solution, and 1 mL of inoculum sediment. The trace element solution was composed per liter of water with the following compounds: MnSO4·4H2O (40 mg); 57 mg of H3BO3; ZnSO4·7H2O (43 mg); 35 mg of (NH4)6Mo7O24; and 100 mg of FeCl3-EDTA (APHA 2012). The tests were performed at three concentration levels: 300, 500, and 1000 μg/L of IBP. Likewise, abiotic test controls were created using sterilized samples of IBP (using the same three concentration levels) to analyze possible sources of abiotic degradation for the analyte. As a control test, glutamic acid (200 mg O2/L), which reported a BOD5 of 218 mg O2/L in the experiment, indicated adequate biomass activity.

2.6 Analytical Methods

Dissolved organic carbon (DOC), COD, TSS, VSS, dissolved oxygen (DO), pH, and the sludge volumetric index (SVI) were performed at the laboratory of the Group of Diagnosis and Control of pollution (GDCON) according to the protocols set out in the standard methods (APHA 2012). The GDCON laboratory is accredited by the Environmental Research Institute under the Ministry of Environment of Colombia (IDEAM) to carry out these analyses.

Quantification of MPB and IBP was performed by liquid chromatography coupled with mass spectrometry using a direct reading ACQUITY UPLC BEH C18 column (2.1 mm × 50 mm; particle size 1.7 μm). The flow rate of the mobile phase was 0.3 mL/min with an injection time of 12.7 min. Two mobile phases for the analysis of the samples were used. One phase was 0.01 % formic acid in water and the other was 0.01 % formic acid in methanol.

3 Results and Discussion

3.1 Biodegradability Test

The percentage of IBP removal, as assessed through the trial batch, was determined by decreasing the concentration of the compound according to the concentrations measured at the beginning and end of the test. The results of the DOC for the samples (Fig. 3a) at the end of the experiment showed >80 % removal, while for the blanks, the DOC concentration remained unchanged, indicating the absence of abiotic action during the test.

The sterilized blanks B300, B500, and B1000 μg/L did not show any reduction in the concentration of IBP (Fig. 3b), which eliminates possible abiotic removal mechanisms for the compound. Collado et al. (2012), in a series of biodegradation tests using concentrations between 10–1000 μg/L of IBP, showed the absence of abiotic removal mechanisms for IBP in the system, including volatilization and photodegradation. Moreover, sludge adsorption studies have shown percentages of IBP sorption below 0.5 %, indicating that sorption is not an important mechanism in the removal of this contaminant (Carballa et al. 2007). Additionally, the reported values of log kd IBP vary between 1.0 and 1.8, which are small values; therefore, IBP does not appear to suffer from appreciable sorption in sludge (Carballa et al. 2008).

IBP presented with average removal percentages of 40 ± 4.7, 23 ± 1.3, and 22 ± 3.4 % for samples of M 300, M 500, and M 1000 μg/L, respectively. These results demonstrated low removal of the pollutant with percentages below 50 %. Different studies have evaluated IBP removal in systems based on active sludge. Carballa et al. (2004, 2007) reported the removal of 60–70 % for IBP in a treatment train (preliminary, primary, and secondary biological). Similarly, Hijosa et al. (2010) reported efficiencies of 40 % for IBP in summer seasons for an activated sludge system. Similarly, Reif et al. (2011) reported 98 % removal for an activated sludge plant with a similar treatment train for IBP. With the sequencing batch membrane bioreactor, removal efficiencies were reported for IBP in the range of 50–90 % (Serrano et al. 2011). These studies allow us to estimate a removal range for IBP between 40–98 %. However, the maximum removal values of IBP obtained during this test were below of the range mentioned above. This highlights the poor biodegradation of IBP in the experimental conditions evaluated.

Thus far, the issue of IBP biodegradability is controversial; it is unclear which factors are involved in the removal of the IBP in aqueous systems given the wide range of variability in its removal values. This behavior is related to the biodegradation constant or to the reaction rates (kbiol), which range from 0.72 to 17.44 L g SST−1 day−1 (Collado et al. 2012). The kbiol values are associated with the biodegradation rates of the compound; thus, compounds with kbiol values in the range of 0.1–10 present with partial biodegradation of the analyte (20–90 %), while for higher values, kbiol values above 10 L g SST−1 day−1 have high biodegradation.

The kbiol values of activated sludge systems vary in the range of 9–35 L g SST−1 day−1 (Collado et al. 2012). This can be the reason as to why there is great variability in the removal values of IBP in aerobic systems. Some attribute the variability in biodegradation rates to differences in the initial charge of the compound, while others also highlight the importance of the sludge’s composition (i.e., its biomass diversity, the types of primary substrates, and other such factors) and the experimental conditions used (Collado et al. 2012). Additionally, Collado et al. (2012) found that the higher the concentration of IBP, the lower the value of kbiol; the authors also observed decreasing values of kbiol with a decrease in biomass concentration.

3.2 Startup and Operation of the SBR System

3.2.1 Reactor Performance for Stages I, III, and V

In stage I, under the application of IBP, the SBR system was optimized; thus, some modifications and/or substitutions occurred to enhance system performance. Additionally, the response of the reactor with different ages of sludge (ϴc) (6, 8, and 12 days) was evaluated, so as to achieve good operation and high removal efficiencies of DOC. The best response was obtained for the 8-day-old sludge, mainly based on its characteristics, including its settling properties and the presence of activated and slightly mineralized sludge. Sludges with an age above 8 days presented development of filamentous organisms and low biomass settleability, and those with an age below 8 days showed a high loss of microorganisms in the SBR system.

The DOC concentrations in the influent of the system were similar for these periods (stages I, III, and V) since glucose was the sole source of organic carbon. Moreover, the higher percentage of DOC removal achieved in the SBR reactor operation under the application of IBP was presented for each stage, with removals averaging 91 ± 10.7, 94 ± 2.2, and 94 ± 32.2 % (Fig. 4), corresponding to stages I, III, and V, respectively. Similarly, in the case of experimentation with different concentrations of MPB, a high removal efficiency of DOC was achieved, with average values of 95 ± 2.8, 97 ± 0.3, and 97 ± 0.9 % for stages I, III, and V, respectively. Figure 5 shows the behavior of the SBR in the removal of DOC for all stages under the application of MPB and IBP.

The high efficiencies that were found for the SBR system in the two scenarios (experimentation with IBP and MPB) allowed us to understand that the reactor’s operational conditions were suitable for its enhanced performance. Furthermore, the values obtained during the operation of the reactor are similar to those reported in the removal efficiency of DOC for this kind of system, which can vary between 95 and 97 % (Moreno and Buitrón 2002; Ben et al. 2009; Suresh et al. 2011).

3.2.2 Reactor Performance for Stages II, IV, and VI

These stages are characterized by the application of loads of IBP and MPB in the order of increasing concentration. By applying different concentrations of MPB, the percentages of DOC removal showed no negative effects on the system, with average removal values of 97 ± 0.7, 97 ± 0.6, and 97 ± 0.8 % reached for stages II, IV, and VI, respectively; these values are similar to those observed during the stages in which the contaminant was not applied. Additionally, the removal percentages are consistent with those reported for the removal of DOC with these technologies, which shows that the application of MPB did not generate instability within the system. The test under the application of different loads of IBP (Fig. 4) showed removal averages of 75 ± 5.6, 57 ± 17.5, and 47 ± 15.9 % for stages II, IV, and VI, respectively. These results demonstrated a decline in DOC removal with increasing analyte concentrations. This becomes obvious from the first load applied, which passes DOC removal of 91 ± 10.7 to 75 ± 5.6 %. It has been reported that increased loads of IBP can decrease the rate of the compound’s biological degradation, and it can also generate inhibitory effects on the system—a condition that is reflected in the removal of DOC (Collado et al. 2012; Estevez et al. 2014).

A similar behavior was obtained with the removal of IBP, with a declining trend observed with increasing concentration of IBP; average removal values of 51 ± 15.3, 26 ± 16.6, and 16 ± 5.4 % were recorded for stages II, IV, and VI, respectively (Fig. 5). These removal values that were obtained for IBP in the SBR system reaffirm the results registered during the biodegradation test, in which the maximum removal was 40 ± 4.7 % for a load of 300 μg/L, while the removal percentages for concentrations of 500 and 1000 μg/L were 23 ± 1.3 and 22 ± 3.4 %, respectively.

The aforementioned findings enable us to understand that not only do the operational conditions of systems influence the removal of IBP, but they also affect the concentration to be degraded. It is clear that the greater the concentration of IBP, the less effective the aerobic system that is used to remove it. This indicates that the higher the concentration of IBP, the smaller the kbiol value, and the more reduced its removal (Collado et al. 2012).

This condition indicates that the high removal percentages of IBP reported for the activated sludge systems mentioned above are related to the initial concentration of IBP. For activated sludge systems, Carballa et al. (2007) reported IBP removal rates in the range of 60–70 %, with an initial analyte concentration in the effluent of 0.14 μg/L. For a similar system featuring activated sludge, Reif et al. (2011) reported a removal rate of 98 % for IBP, with an initial analyte concentration at the entrance of the plant of 7.5 μg/L. This indicates that high removal efficiencies in these systems are related to the low concentration of the treated contaminant. This is a condition that cannot be interpolated to the results obtained in this study because the tested concentrations are significantly larger. Additionally, the contributions offered by Collado et al. (2012) showed the effect of the charge of the compound on the contaminant degradation rate and the effect of the microbial population, which indicates that the lower the IBP load and the higher the concentration of solids, the more efficient the removal. This approach explains the low rates of removal obtained with the increase in compound load. Similarly, it is wise to think that each load that was evaluated due to its difference in concentration had a particular effect on the biological populations in the reactor, which contributed to its decline over time.

The behavior of the removal of MPB (Fig. 5), which was evaluated at identical loads of IBP, showed a growing trend in removal in association with increased analyte concentrations, with removal values >97, >98, and >99.0 % for loads of 300, 500, and 1000 μg/L, respectively. Studies that were conducted to assess MPB removal using biological systems have shown high efficiencies. González et al. (2011) reported removal values of 99.4 %, while Fan and Wang (2012), using an aerated biofilm system, achieved MPB biodegradation rates of 95.5 %. The results obtained in this study present values that are consistent with those reported for this compound, indicating that MPB can be removed efficiently in an SBR system under the operational conditions employed.

During the MPB treatment tests, the effluent pH values ranged from 6.37 to 7.71 with a mean value of 7.18 ± 0.33; for the IBP assay, the pH values were between 5.88 and 7.37, with a mean of 6.72 ± 0.56. In this study, the pH was maintained at appropriate values for optimal biomass performance, which is generally in the range of 6.5–8.5. Meanwhile, the DO aeration cycles presented a global average of 5.5 ± 0.87 and 5.0 ± 0.98 mg O2/L for trials with MPB and IBP, respectively. These values indicate that in the aeration cycles, there is an adequate supply of DO for the oxidation of organic matter, which also meets the demand of the microbial mass, allowing the residual of DO to be maintained above 2 mg/L.

3.2.3 Variation of the Biomass

During the system’s operation, concentrations of TSS and VSS in the treatment of MPB and IBP exhibited a decreasing trend (Fig. 6). For IBP, this behavior was more pronounced for concentrations of TSS and VSS of 1860 and 1535 mg/L, respectively, while at the end of the experiment, values of 770 mg/L for TSS and 578 mg/L for VSS were recorded. This decreasing trend in biomass showed the inhibitory effects exerted by high concentrations of IBP on the microbial populations in the reactor. To this point, it should be noted that while an increase in IBP was three times greater than its initial charge, the reduced biomass concentration was more than 50 % of the starting concentration. This explains the consequent reduction of the system’s efficiency in the removal of IBP as a possible consequence of the fall in the rate of biological degradation (kbiol). In the case of MPB, the little reduction in biomass did not result in any adverse effects on the efficiency of the compound’s removal or the system’s operation.

Furthermore, the SVI results varied in the range of 101–105 mL/g for the tests that were conducted with the application IBP loads, whereas for the test under an applied load of MPB, the SVI variation range was 49–75 mL/g. These values, according to Molina et al. (2008), feature an appropriate level of “settleability” in the IBP test, as they fall in the 100–150 range, while for the MPB test, very good settling properties were found, with values ranging from 0 to 100. These conditions of settleability yielded good performance of the SBR system for each cycle of operation, achieving solid mass retention within the reactor for a shorter period of time than that estimated during the sedimentation phase.

4 Conclusions

IBP removal in the SBR system under the applied operating conditions presented with removal percentages below 51 %. The percentage decreased significantly with increasing analyte concentrations, demonstrating that high concentrations of the compound cannot be removed efficiently through the system due to the strong inhibitory effects of IBP on the biomass. However, MPB showed high removal percentages above 97 %. Additionally, increases in analyte concentrations did not generate adverse effects in the treatment system. Contrary to our expectations, an increase in the contaminant resulted in improvements in the reactor’s operation response, indicating that the application of an SBR system for the removal of this contaminant is viable.

References

APHA. 2012. Standard methods. For the examination of water and wastewater. 22nd. edited by Eugene W Rice, Rodger B Baird, Andrew D Eaton, and Leonore S Clesceri. Washington: American Public Health Association, American Water Works Association, Water Environment Federation.

Aubert, N., Ameller, T., & Legrand, J. J. (2012). Systemic exposure to parabens: pharmacokinetics, tissue distribution, excretion balance and plasma metabolites of [14C]-methyl-, propyl- and butylparaben in rats after oral, topical or subcutaneous administration. Food and Chemical Toxicology, 50, 445–454.

Ben, W., Qiang, Z., Pan, X., & Chen, M. (2009). Removal of veterinary antibiotics from sequencing batch reactor (SBR) pretreated swine wastewater by Fenton’s reagent. Water Research, 43(17), 4392–402.

Błędzka, D., Gromadzińska, J., & Wąsowicz, W. (2014). Parabens. From environmental studies to human health. Environment International, 67, 27–42.

Canosa, P., Rodríguez, I., Rubí, E., Negreira, N., & Cela, R. (2006). Formation of halogenated by-products of parabens in chlorinated water. Analytica Chimica Acta, 575(1), 106–13.

Carballa, M., Omil, F., Lema, J. M., Llompart, M., García-Jares, C., Rodríguez, I., & Ternes, T. (2004). Behavior of pharmaceuticals, cosmetics and hormones in a sewage treatment plant. Water Research, 38(12), 2918–26.

Carballa, M., Omil, F., & Lema, J. M. (2005). Removal of cosmetic ingredients and pharmaceuticals in sewage primary treatment. Water Research, 39(19), 4790–4796.

Carballa, M., Omil, F., & Lema, J. M. (2007). Calculation methods to perform mass balances of micropollutants in sewage treatment plants. Application to pharmaceutical and personal care products (PPCPs). Environmental Science & Technology, 41(3), 884–90.

Carballa, M., Finkb, G., Omil, F., Lema, J., & Ternes, T. (2008). Determination of the solid–water distribution coefficient (Kd) for pharmaceuticals, estrogens and musk fragrances in digested sludge. Water Research, 42, 287–295.

Collado, N., Buttiglieri, G., Ferrando-Climent, L., Rodriguez-Mozaz, S., Barceló, D., Comas, J., & Rodriguez-Roda, I. (2012). Removal of ibuprofen and its transformation products: experimental and simulation studies. The Science of the Total Environment, 433, 296–301.

Estevez, E., Hernandez-Moreno, J. M., Fernandez-Vera, J. R., & Palacios-Diaz, M. P. (2014). Ibuprofen adsorption in four agricultural volcanic soils. The Science of the Total Environment, 468–469, 406–414.

Fan, C., & Wang, H. C. (2012). Degradation of methyl paraben by the aerated pebble-bed biofilm system. APCBEE Procedia, 1, 299–303.

Ferrando-Climent, L., Collado, N., Buttiglieri, G., Gros, M., Rodriguez-Roda, I., Rodriguez-Mozaz, S., & Barceló, D. (2012). Comprehensive study of ibuprofen and its metabolites in activated sludge batch experiments and aquatic environment. The Science of the Total Environment, 438C, 404–413.

García-Cuerva, L. N. (2010). Nuevas metodologías para la determinación de nonilfenol, sus derivados etoxilados y parabenos en muestras medioambientales. universidad complutense de madrid, 186.

Girardi, C., Nowak, K., Carranza-Diaz, O., Lewkow, B., Miltner, A., Gehre, M., Schäffer, A., & Kästner, M. (2013). Microbial degradation of the pharmaceutical ibuprofen and the herbicide 2,4-D in water and soil—use and limits of data obtained from aqueous systems for predicting their fate in soil. The Science of the Total Environment, 444, 32–42.

González, I., Quintana, J., Rodrıguez, I., & Cela, R. (2011). Evaluation of the occurrence and biodegradation of parabens and halogenated by-products in wastewater by accurate-mass liquid chromatography-quadrupole-time-of-flight-mass spectrometry (LC-QTOF-MS). Water Research, 45, 6770–6780.

Guadarrama, P., Fomine, S., Salcedo, R., & Martínez, A. (2008). Construction of simplified models to simulate estrogenic disruptions by esters of 4-hydroxy benzoic acid (parabens). Biophysical Chemistry, 137(1), 1–6.

Hijosa, M., Matamoros, V., Sidrach, J., Martin-Villacorta, R., Bécares, E., & Bayona, J. (2010). Comprehensive assessment of the design configuration of the constructed wetlands for the removal of pharmaceuticals and personal care products from urban wastewaters. Water Research, 44, 3669–78.

Kosma, C. I., Lambropoulou, D. A., & Albanis, T. A. (2014). Investigation of PPCPs in wastewater treatment plants in Greece: occurrence, removal and environmental risk assessment. The Science of the Total Environment, 466–467, 421–438.

Kumar, A., & Xagoraraki, I. (2010). Pharmaceuticals, personal care products and endocrine-disrupting chemicals in U.S. surface and finished drinking waters: a proposed ranking system. The Science of the Total Environment, 408(23), 5972–5989.

Lin, Y., Ferronato, C., Deng, N., Wu, F., & Chovelon, J. (2009). Photocatalytic degradation of methylparaben by TiO2: multivariable experimental design and mechanism. Applied Catalysis B: Environmental, 88, 32–41.

Londoño, Y. A., Muriel, M., Ospina, N. L., & Peñuela, G. (2014). Implementation and automation of a sequencing batch reactor with a logo-oba6 programmable low-cost controller. Revista Politecnica, 10, 95–103.

Londoño, Y. A., & Peñuela, G. A. (2015). Anaerobic biological treatment of methylparaben in an expanded granular sludge bed (EGSB). Water Science and Technology, 71(11), 1604–1610.

Molina, F., Rodriguez, D. C., & Puerta, B. E. 2008. Manual de laboratorio de procesos biológicos. Universidad de Antioquia. Medellín, 55

Moreno, J., & Buitrón, G. (2002). Optimización de Un Biorreactor Aerobio Para El Tratamietno de Aguas Residuales Industriales. Computación y Sistemas, Número especial:074–082

Quero-Pastor, M. J., Garrido-Perez, M. C., Acevedo, A., & Quiroga, J. M. (2014). Ozonation of ibuprofen: a degradation and toxicity study. The Science of the Total Environment, 466–467, 957–964.

Reif, R., Santos, A., Judd, S., Lema, J., & Omil, F. (2011). Occurrence and fate of pharmaceutical and personal care products in a sewage treatment works. Journal of Environmental Monitoring, 13(1), 137–144.

Serrano, D., Suárez, S., Lema, J., & Omil, F. (2011). Removal of persistent pharmaceutical micropollutants from sewage by addition of PAC in a sequential membrane bioreactor. Water Research, 45(16), 5323–5333.

Soni, M. G., Burdock, G., Taylor, S. L., & Greenberg, N. (2001). Safety assessment of propyl paraben: a review of the published literature. Food and Chemical Toxicology: An International Journal Published for the British Industrial Biological Research Association, 39(6), 513–32.

Soni, M. G., Taylor, S. L., Greenberg, N. V., & Burdock, G. A. (2002). Evaluation of the health aspects of methyl paraben: a review of the published literature. Food and Chemical Toxicology, 40(10), 1335–73.

Suárez, S., Reif, R., Lema, J., & Omil, F. (2012). Mass balance of pharmaceutical and personal care products in a pilot-scale single-sludge system: influence of T, SRT and recirculation ratio. Chemosphere, 89(2), 164–171.

Suresh, S., Tripathi, R., & Gernal, M. N. (2011). Review on treatment of industrial wastewater using sequential batch reactor. International Journal of Science Technology and Management, 2(1), 64–84.

Verlicchi, P., Galletti, A., Petrovic, M., & Barcelo, D. (2010). Hospital effluents as a source of emerging pollutants. Journal of Hydrology, 389, 416–428.

Vo, T. T., Yoo, Y. M., Choi, K. C., & Jeung, E. B. (2010). Potential estrogenic effect(s) of parabens at the prepubertal stage of a postnatal female rat model. Reproductive Toxicology, 29(3), 306–316.

Acknowledgments

The authors would like to thank the GDCON group and the 2014–2015 Sustainability Research Fund of the University of Antioquia for funding this project. English language editing of this manuscript was provided by Journal Prep.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Londoño, Y.A., Peñuela, G.A. Biological Removal of Different Concentrations of Ibuprofen and Methylparaben in a Sequencing Batch Reactor (SBR). Water Air Soil Pollut 226, 393 (2015). https://doi.org/10.1007/s11270-015-2654-5

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s11270-015-2654-5