Abstract

The water distribution network needs to be rehabilitated when the network is unable to perform the desired function. In this study, a methodology is developed to identify the critical pipes in the water distribution network for its rehabilitation by using four network reliability metrics: supply shortage, pressure decline, energy loss per unit length, and the hydraulic uniformity index. These metrics consider different aspects of reliability of the water distribution network using pressure-dependent analysis to calculate the overall criticality of the pipes. In contrast to the conventional reliability index, the present study uses both the normal and abnormal conditions at nodes (fire demand) and pipe (pipe failure) and thus, provides more balance reliability metrics for the network. The literature shows that the node and pipe level metrics have been used separately, whereas in this study both the node and pipe level metrics are combined to develop the present methodology. The methodology is applied to four different water distribution networks, including one typical realistic water distribution network, the data for which is adopted from literature. The results show that the methodology can identify the critical pipes successfully to prioritize the water distribution network rehabilitation and found to be simple in implementation for practicing professionals. The results further show that the critical pipes are found to be located from the source on the paths that do not have a loop or around the nodes of higher demand. The study might also be useful for the extension plan of a water distribution network along with strengthening the deficient nodes/ pipes of the network.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

The water distribution network (WDN) is designed to satisfy the consumer demands at the required pressure at all the nodes. The rehabilitation of WDN is needed when the network is unable to perform the desired function when assessed using network reliability. The reliability of the water distribution network is defined as the ability of the network to provide an adequate supply to the consumers, under both normal and abnormal operating conditions (Goulter 1995; Xu and Goulter 1999). A water distribution system (WDS) may be unable to provide the demand flow at required pressure under three distinct situations (Xu and Goulter 1999; Tanyimboh 2003):

-

1.

The demand is exceeded due to an increase in population, expansion of the network, an increase in the standard of living, economic activities, fire demand, etc.

-

2.

The reduction in the delivery capacity of pipes due to failure of pipes, bursting of pipes, valves, etc.

-

3.

The reduction in the delivery capacity due to corrosion, deposition, and increase in the pipe roughness (tuberculation, encrustation, etc.).

The issue of reliability that arises out of the first and second situations are called hydraulic and mechanical reliability, respectively. The third situation is an operational issue denoting a failure condition and is not taken into consideration in this study. A critical pipe is a pipe that is more susceptible to change in the outflow and nodal pressure at a node under the three situations defined earlier. In other words, if the diameter or roughness factor or both of the critical pipes is changed, it will result in maximum change in nodal outflow and nodal head (Arulraj and Rao 1995). The identification of the critical pipe is essential for the rehabilitation of the network. The rehabilitation can only be sustainable if it is financially viable in terms of the hydraulic benefit obtained.

Over the past few decades, the concept of resilience has emerged as an important consideration in the planning and management of water infrastructure systems. Accordingly, various resilience measures have been developed for the quantitative evaluation and decision-making of systems (Shin et al. 2018). The resilience index (RI) is a well-known measure of WDN reliability based on nodal flow and excessive pressure (Todini 2000). Later, Prasad and Park (2004) developed the network resilience index (NRI) by considering network connectivity. The NRI is strongly related to the intrinsic capability of the system to overcome failure while satisfying the nodal demands and pressures. Jayaram and Srinivasan (2008) developed the modified resilience index (MRI) by considering the surplus energy and minimum required energy at nodes. Jeong et al. (2017) revisited the resilience indices by suggesting a new definition of surplus and minimum required head at nodes. It was found that the minimum required head at the demand node is critical for properly calculating the resilience indices. The application results revealed that the conventional resilience indices are significantly affected by the nodal elevation and are generally overestimated due to an incorrect calculation of the minimum required nodal head. Shin et al. (2018) provided a critical review of quantitative approaches to measure the water infrastructure systems resilience and recommended the improvement in resilience measures. Besides the resilience type indices, there are many other indicators based on the concept of energy. Cabrera et al. (2015) suggested three new indices for assessing the energy efficiency of the pressurized water distribution system and the potential energy-saving relative to the available technology. Dziedzic and Karney (2015) analyzed water distribution by prioritizing the energy into supplied, dissipated, and delivered to the system and found that less than 27 % of the energy supplied is only delivered to the users. Similarly, Hashemi et al. (2018) developed a set of energy metrics that characterize energy interactions at the spatial resolution of individual water mains.

Many researchers have compared WDS reliability indicators to identify the most reliable ones. Raad et al. (2010) compared the performance of four conventional indicators (Resilience Index, Network Resilience, Flow Entropy, and a Mixed Surrogate Measure) by application to four WDS benchmark problems. The results of their study showed that the resilience index demonstrates the best performance under pure stochastic demand variation. However, it lags when compared to the network resilience measure in terms of reliability under pipe failure conditions. Monsef et al. (2019) considered six well-known conventional reliability indices for the assessment of five different water distribution systems under a large number of randomly generated abnormal operating conditions, such as nodal demand changes, and pipe burst conditions. For the water distribution systems considered, it is found that despite having higher reliability indicator values, the networks are unable to tolerate abnormal conditions adequately. The research further suggested a stochastic method, based on the correlation between the value of reliability indices and the ability of the water distribution system to operate in abnormal conditions. However, authors simulated the pipe failures using demand-driven analysis which has been found to be major caveats of the study (Tanyimboh et al. 2020).

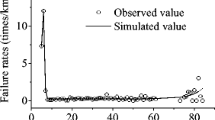

Frequent pipe breaks in water distribution networks are one of the major challenges facing water utilities worldwide. Hence, several predictive break models have been developed to assist water utilities for future planning, prioritizing, and decision-making of maintenance, rehabilitation, and replacement. Considering damaged pipelines into account, He and Yuan (2019) proposed a framework for identifying critical facilities in WDS from the standpoint of recovery resilience. The priority with which a damaged pipeline needs to be restored to minimize WDS service loss and the impact of delaying such priority on the loss of service is taken as criticality metrics. Moslehi and Jalili-Ghazizadeh (2020) have proposed a field data-based methodology to statistically investigate the relationship between operating pressures and pipe break rates in water distribution networks. The obtained pressure thresholds confirm that the break rates increase rapidly for specific maximum pressure ranges, which can be used to implement effective pressure management. Izadi et al. (2020) have proposed an asset-based methodology to measure the resilience of a WDN for the most troubled WDNs in a province of central Iran. The considered WDN was found to be suffering from a high rate of pipe failure. The proposed approach was based on the impacts of failure of every single asset on the performance of the system resiliency. Amiri-Ardakani and Najafzadeh (2021) have carried out a field investigation to study the pipes break rate in the eight zones of Yazd’s water distribution network of Iran. An artificial intelligence-based approach has been employed to model pipe break rates associated with the WDN. The replacement of existing pipes is frequently adopted as a strategy for the rehabilitation of water distribution networks by the water companies. A comparison between resilience and entropy indices has been provided in the framework of the optimal rehabilitation of an existing network under limited budget constraints (Cimorelli et al. 2018). Later, Mu et al. (2021) developed a novel multiple reservoirs network optimization (MRNO) model to identify the diameters of pipes for reliable water distribution network design. The results demonstrated that the network reliability of the considered water distribution system has improved along with the reduction in pipe costs.

Furthermore, Marlim et al. (2019) proposed an element-based simulation approach to prioritize network maintenance. The element-based approach uses the failure of one element at a time by considering several critical indices. The procedure uses a Python package to call the EPANET toolkit functions for pressure-driven analysis repeatedly. Recently, Jeong and Kang (2020) observed that the conventional reliability indices mainly focus on nodal pressure and available discharge. They proposed a new link-based reliability index called hydraulic uniformity index (HUI) that considers pipe head loss distribution throughout a network. However, the approach uses the demand-driven method for evaluating the HUI. Tanyimboh (2003) has observed that the pressure-dependent modeling of the water distribution system is an invaluable tool to account for the pressure deficiency and the hydraulic failure condition. Later, the need for using pressure-dependent analysis (PDA) in the improvement of the reliability of water distribution systems has been realized by several researchers (Gupta et al. 2018; Wu 2007; Fujiwara and Li 1998).

The literature review shows that the majority of indices proposed in the past focuses on the individual aspect of the water distribution system at nodes only. In contrast to the conventional approach, the current research focuses on the element-based approach of reliability. Also, the indices developed in the past considered either hydraulic or mechanical reliability. Owing to these limitations, this study considers both hydraulic and mechanical reliability by simulating the normal and abnormal demand conditions (fire demand) at nodes and failure of pipes at the element level to identify the critical pipes. Thus, the resilience of the water distribution network against normal and abnormal operating conditions at nodal and element levels are analyzed. The work proposes four index metrics to identify the critical pipes to prioritize network rehabilitation. Some of the index metrics, such as energy loss per unit length, and the hydraulic uniformity index used in this study, are proposed by some researchers but not yet applied in the reliability analysis of WDN. Furthermore, the shortcoming of the earlier approach of using the EPANET toolkit function for pressure-dependent analysis is eliminated by using the non-iterative implementation of Gorev and Kodzhespirova (2013) for pressure-dependent simulation.

2 Methodology

2.1 Pressure Dependent Analysis for Calculating the Actual Flow

The pressure-dependent analysis is performed utilizing Eq. (1) by using the non-iterative implementation method of (Gorev and Kodzhespirova (2013). This equation is proposed initially by Wagner et al. (1988) by assuming the flow to be proportional to the square root of the nodal head. Thus, the flow operates under three modes, namely, normal or full supply, reduced supply, and no supply as described (Wagner et al. 1988; Gorev and Kodzhespirova 2013) below:

where \(Q_j^{avai}\) = actual available outflow at node j; \(Q_j^{req}\) = required demand at node j; \(H_j^{avai}\) = the actual head available at node j; \(H_j^{min}\) = the nodal head below which there would be no outflow; and \(H_j^{des}\) = the desired nodal head at which the required demand is satisfied in full.

2.2 Calculation of Critical Index

2.2.1 Supply Shortage and Pressure Decline Index

If the available flow at the node is less than the required normal demand, there will be deficit at the nodes. The level of dissatisfaction is proportional to the ratio of available supply to demand. Hence, the supply shortage \((SS_i)\) is calculated using Eq. (2) by taking the ratio of available supply to demand at each node during the isolation of a pipe i and defined (Marlim et al. 2019) as

where \((SS_i)\) = the supply shortage index for the isolation of pipe i; \(Q_{{avai},j}\) = available supply and \(Q_{n,j}\) = normal supply at the node j due to isolation of pipe i respectively. nnode = number of nodes in the network. The value of \((SS_i)\) varies between 0 to 1 with zero as no shortage and one as maximum shortage in flow. The supply shortage can be calculated only when the the network operates under pressure dependent condition since the demand driven analysis assumes that demand is fully met irrespective of pressure at nodes.

When a pipe fails, the pressure at the nodes decreases due to change in the flow path. The reduction in pressure at the nodes is measured using pressure decline index Eq. (3). Thus, the pressure decline index \(PD_i\) at node i is measured using the ratio of declined pressure to normal pressure due to isolation of pipe i while considering the normal nodal demand as a weighing factor (Marlim et al. 2019)

where \(PD_i\) = the pressure decline index for isolation of pipe i; \(P_{e,j}\) = the pressure at node j after an event and \(P_{n,j}\) = normal pressure at the nodes j. The value of \((PD_i)\) also varies between 0 to 1 with zero as no pressure deficit and one as maximum pressure deficit in the flow.

2.2.2 Energy Dissipation Per Unit Length and Hydraulic Uniformity Index

The energy dissipated per unit length of pipe (Eq. 4) is conceptualized as an indicator of the condition pipe (Dziedzic and Karney 2015) and, therefore, in this study, the energy dissipated for unit time per unit length (\(\Delta E_i\)) is considered as another index for assessing the reliability of the network. This index can take any finite value.

where \(\Delta E_i\) = energy loss per unit length through pipe i; \(E_{dissipated}\) = energy dissipation through pipe i, \(\gamma\) = unit weight of water; \(Q_i\) = flow through pipe i and \(H_{loss}\) = head loss through the pipe i.

The hydraulic uniformity index HUI is defined by Jeong and Kang (2020) as the ratio of the hydraulic gradient of individual pipe \(HG_i\) to the equivalent hydraulic gradient \(HG_{equi}\). The detailed discussion on HUI is given by Prasad (2021) and its value for a pipe can be calculated using (Eq. 5).

where \(hl_{eqi}\) = the equivalent head loss of a system; \(HG_{eqi}\) = the equivalent hydraulic gradient of a system; \(hl_i\) = the head loss in the ith pipe; \(L_i\) = the length of the ith pipe; \(HUI_i\) = the hydraulic uniformity index of the ith pipe; and npipe = number of pipes in the network.

For hydraulically uniform pipes, the hydraulic gradient line should be uniformly falling. It has also been found that the hydraulic uniform network is more reliable under the abnormal condition, and hence, HUI can successfully serve as a reliability indicator for a WDN. A HUI of greater than 1.0 indicates that the pipe is under-designed, degrading the system performance by introducing excessive head loss. On the contrary, an HUI of less than 1.0 indicates that the pipe is over-designed. Therefore, the ideal value of HUI of individual pipe should be close to 1.0. Hence, the deviation of the HUI value from its ideal value is used to measure the criticality of pipe and rank the HUI metrics.

2.3 Identification of Critical Pipes

The method consists of calculating the criticality index at nodal and pipes level by imposing the normal and abnormal conditions at the nodes and pipes level. First, the model simulates the normal operating condition using EPANET, and then an individual pipe is closed one at a time sequentially. Once a pipe is closed, the available pressure becomes typically less than the required pressure. After that, the pressure-dependent analysis is performed, and the criticality index \(SS_i\) and \(PD_i\) are calculated. Then an abnormal demand is imposed at each node sequentially. The network is simulated using pressure dependant analysis to calculate the flow and pressure at each node and pipe. Further, the energy loss per unit length of the pipe (\(\Delta E\)) and the hydraulic uniformity index (HUI) is calculated for each pipe under the abnormal condition at the particular node. The abnormal demand is then imposed at another node, and again (\(\Delta E\)) and (HUI) for all the pipes are calculated. For individual pipes, the average value of (\(\Delta E\)) and (HUI) are calculated. The methodology is presented in the flow chart shown in Fig. 1. Thus, for each pipe, all the four metrics \(SS_i\), \(PD_i\), (\(\Delta E\)), and (HUI) are calculated for the network. The pipes are ranked based on individual indices from 1 to npipe, where npipe is the number of pipes of the network. Rank 1 indicates the most critical pipe, and ranks npipe indicates the least critical pipe. With the four indices, the overall criticality of the individual pipes is estimated assuming the same weightage for each metric. The overall criticality is calculated by summing the rank of each index, and then the summed values are ranked. If the values of two or more index metrics are the same for two or more pipes, it is assigned the same rank. Similarly, if the sum of the ranks for two or more pipes are the same, it is assigned the same overall ranking. The same overall ranking indicates that the pipes under considerations are equally critical.

3 Application

Four example networks are adopted from the literature to demonstrate the methodology. The first is a series network, the second is a loop network, the third is a combination of series and loop network, and the fourth is the realistic typical water distribution network of Itanagar city of Arunachal Pradesh (India).

3.1 Example Network 1: Single Source Series Network

A series network (Fig. 2) of Gupta and Bhave (1996) is being taken as the first example to demonstrate the present methodology. The network consists of a source reservoir and four nodes, namely J2, J3, J4, and J5 with corresponding demand of 120, 120, 180, and 60 \(m^3/h\) respectively. The elevations of nodes are 90, 88, 90, and 85 m, respectively. The diameter of pipes in series is 400, 350, 300, and 300 mm respectively with each of length 1000 m. The Hazen-Williams coefficient of the entire pipe is 130. The reservoir elevation is taken as 135 m and the minimum and desired pressure at all the demand nodes are taken as 15 m and 30 m respectively. When an additional fire demand of 180 \(m^3/h\) occurs at a node in a sequence the network becomes pressure-deficient.

Example network 1 (Gupta and Bhave 1996)

3.2 Example Network 2: Single Source Two Loop Network

A single-source two-loop network with six demand nodes linked by eight pipes (Fig. 3) has been considered as a second example, which is adopted from Ang and Jowitt (2006). The demand for all the nodes under normal operating conditions is 25 L/s, and the nodal elevation for all the demand nodes is shown in Fig. 3. All the pipes are 1000 m in length with the Hazen-Williams coefficient of 130. The reservoir elevation is taken as 135 m and the minimum and desired pressure at all the demand nodes are taken as 15 m and 30 m respectively. The demand-driven analysis shows that the head developed at all the nodes is greater than nodal elevation under normal operating conditions. When the network is subjected to pipe failures one by one sequentially, the available pressure at some nodes becomes less than the required pressure needed for full discharge. Hence, the nodes receive only the partial discharge depending on the nodal pressure as defined by Eq. 1. Also, when an additional demand of 50 L/s is introduced at a node at a time to simulate the abnormal demand conditions, the available pressure at some of the nodes again becomes less than the desired pressure and thus, exhibit the partial discharge

Example network 2 (Ang and Jowitt 2006)

3.3 Example Network 3: Hanoi Network

The third illustrated example is also a well-known piping system used widely as a benchmark network (Fig. 4). The network consists of 32 nodes, 34 pipes, and 3 loops. A reservoir at node 1 with a hydraulic head of 100 m feeds the network with all the nodes located at zero elevation, as shown in Fig. 4. All the pipes have a Hazen-Williams coefficient of 130. The nodes have the minimum available hydraulic head of 30 m when operated under demand-driven conditions. The nodal demands along with the length and diameters of pipes are given by Haghighi et al. (2011). The abnormal conditions of the network is simulated by considering pipe failure condition and a fire demand of 5000 \(m^3/h\) at nodes in a sequence. The minimum and desired pressure at all the nodes are taken as 30 m and 60 m respectively.

Hanoi Network (Jeong and Kang 2020)

3.4 Example Network 4: Itanagar Water Distribution Network

The Itanagar (India) Water Distribution Network is adopted from Sivakumar and Prasad (2014) and is shown in Fig. 5. This typical Itanagar WDN consists of 48 junction nodes, 48 pipes, two clear water reservoirs (CWRs) at nodes 49 and 50, three tanks at 51, 52, and 53, two pumps at 49 and 50, and two flow control valves (FCVs) at 51 and 52, particularly, for gravity cum pumping supply system. The entire Itanagar network area is divided into three zones viz., Zone I (Mowb II Zone) nodes 1 to 18, Zone II (Microwave Zone) nodes 19 to 24, and Zone III (R K Mission Zone) nodes 25-42. A detailed description of the Itanagar water network is given by Sivakumar and Prasad (2015).

Example network 4 (Sivakumar and Prasad 2014)

Further, Tabesh et al. (2002) proposed the values of 7 m for a minimum head below which no flow can be discharged and a value of 14 to 15 m as the desired head at which the required demand is satisfied in full. Keeping in view of the real-life WDN of Itanagar (India), the value of \(H_j ^{min}\) and \(H_j ^{des}\) are taken as 7 m and 15 m respectively for pressure-dependent analysis.

4 Results and Discussion

Table 1 shows the supply shortage (SS), pressure decline (PD), energy loss per unit length \((\Delta E)\) and hydraulic uniformity index (HUI) for the series network of example 1. The SS and PD of the pipes P1, P2, and P3, are very high indicating that the deficiency in supply and pressure is very high for these pipes in normal and abnormal operating conditions. However, these metrics for pipe P4 are found to be low. The HUI value of the pipes P1, P2, and P3, are close to 1.0, indicating uniformly decreasing hydraulic gradient. The energy loss for pipes P1, P2, and P3 is high and uniformly decreasing, whereas for pipe P4, the energy loss is very small. The pipe criticality decreases in the direction of flow in this series network. Similarly, the overall criticality value of all the pipes of the network is very high, except for the farthest pipe from the source. Table 2 shows SS, PD, \(\Delta E\) and HUI metrics for single reservoir two-loop network (example 2). In this network, the SS and PD values for pipe P1 are equal to 1.0. These values of SS and PD show that pipe P1 is the most critical pipe since this pipe feeds both the loops of the network. The \(\Delta E\) of pipe P1 is also very high, indicating higher energy loss. Further, the HUI value of this pipe is greater than 1.5, indicating an under-designed pipe. The other pipes (P2 to P8) of the network have very small SS and PD values. It is because all the downstream nodes/pipes can receive the discharge from the alternate routes under normal and abnormal operating conditions. Owing to the same value of SS and PD for pipes P4-P8 are assigned the same rank. Consequently, the overall ranking of P2 and P3, as well as P6 and P8, are the same.

Further, Table 3 shows the network reliability metrics of example 3 (Hanoi network). In this network, pipes 1 and 2 have SS and PD values of 1.0, whereas the other pipes have relatively smaller values. The SS and PD values are found to be dependent on the diameter, location of the pipe, and the demand required from the corresponding nodes. The HUI and \(\Delta E\) values for pipes 1 and 2 are also very high. It can be observed from this network that some pipes at the downstream end are in series still the metrics values are comparable with the other pipes, unlike the series connection at the upstream end. It might happen because these pipes are located at the downstream side, and the number of nodes/pipes of these series connections are small in comparison to the total nodes/pipes of the network. Table 3 shows that the series pipes near the source are very critical since the failure of these two pipes (P1 and P2) affects the reliability of the whole water distribution network. The criticality of the pipes of this network is grouped based on percentile score, assuming the higher percentile as indicative of a higher criticality. The criticality groups are: pipes 1, 2, 19, 3, 20, 23, 4, 6, 5 and 7 have 75-100 percentile; pipes 8, 18, 9, 24, 25, 13, 34 and 10 have 50-75 percentile; pipes 26, 29, 17, 32, 33, 14, 11, 21 and 12 have 25-50 percentile and pipes 31, 30, 16, 22, 28, 27 and 15 have less than 25 percentile. To validate the results obtained by the proposed methodology, the results of the Hanoi network are compared with the results of Jeong and Kang (2020) for the same network. To improve the reliability of the same network, Jeong and Kang (2020) have replaced 17 pipes out of 34 pipes, either enlarging or reducing the pipe diameter. It is observed that the 16 of the pipes replaced fail under the percentile criticality groups of 75-100 and 50-75 percentile, which validates the proposed methodology. Furthermore, in addition to identifying the critical pipes, the present methodology can identify the criticality ranking of pipes. It can also be observed from Table 3 that all the high-demand nodes such as nodes 6, 7, 18, and 23 are under the most criticality group.

The results of the supply shortage (SS), pressure decline (PD), and the energy loss per unit length \((\Delta E)\) for example 4 (Itanagar WDN) are shown in Table 4. In the network (Fig. 5), the diameter of the pipes is relatively large with low demand from the demand nodes. Also, the average head loss of the network is high, and the flow through the pipes is small. These parameters ultimately make the average hydraulic gradient of the network a higher quantity (Eq. 5). Also, more than 50% of the nodes are only demand nodes and the remaining are the junction nodes. Owing to the small value of HUI and low difference among HUI values, the HUI metrics have not been included in the analysis of this network (Table 4). The calculated HUI value shows that most of the pipes have a very small HUI value of less than 0.01 and the difference of the HUI value of the different pipes is small. Jeong and Kang (2020) have defined these kinds of pipes as over-designed pipes, whose diameters can conveniently be reduced to get the uniform hydraulic gradient. Further, the maximum supply shortage (SS) and pressure decline (PD) for pipe 47 are 0.435 and 0.321 respectively in comparison to a very high value of the examples 1 to 3. This might be because of the reason that in example 4, there are several sources (reservoirs and tanks) supplying water through the different paths to the demand nodes. The energy loss per unit length \((\Delta E)\) for this network is also smaller in comparison to the examples 1 to 3 except for pipes 43 and 44. The pipes 43 and 44 have an extremely high value of \((\Delta E)\) because these pipes are directly connected with the pump dissipating huge energy in imparting the pressure energy to the flow. The percentile criticality groups of pipes are: pipes 47, 48, 27, 4, 19, 29, 20, 30, 6, 10, 38, 45 and 8 have 75-100 percentile; pipes 31, 46, 36, 24, 7, 12, 33, 15, 1,11, 43 and 5 have 50-75 percentile; pipes 9, 2, 44, 16, 22, 32, 14, 26, 23, 34, 35 and 25 have 25-50 percentile, and the remaining pipes have less than 25 percentile criticality.

A few common features for all the examples can be observed from Tables 1 to 4. The supply shortage and pressure deficiency decrease as one more from source to periphery of the network. These tables indicate that the criticality of the pipes decreases from the source. The pipe nearer to the source is more critical since the failure of the upstream pipe affects all the pipes downstream of it. Similar observations are also made by Marlim et al. (2019). For all the networks, the pipes that are closer to the source tend to have a higher overall criticality value compared to other pipes in the network. The failure of pipes sourcing from the reservoir would result in a huge loss, as the effect will pulsate downstream, affecting more users. Further, the critical pipes are found to be located from the source on the paths that do not have a loop or around the nodes of higher demand. Similarly, the pipes closer to the source experience more energy loss compared to the pipes located away. The same has been observed by Hashemi et al. (2018) and Dziedric and Karney (2015), which further validate the proposed methodology. Moreover, it is observed that all four different metrics provide the different aspects of reliability, and hence, their overall criticality rank may provide a balanced and reasonably good result. The result of the four indices does not show an identical trend, whereas some index shows a distinct trend. Thus, by considering all the indices as a sum, the overall criticality provided more balanced results for the identification of critical pipe for the rehabilitation of the network. As such, the study can identify the location of critical pipes along the main and the branch line.

5 Summary and Conclusions

The rehabilitation of the water distribution network is needed when the network is unable to deliver adequate demand at desired pressure under normal and abnormal operating conditions. In this study, four network reliability metrics such as the supply shortage, pressure decline, energy loss per unit length, and the hydraulic uniformity index are used to rank the criticality of pipes in a water distribution network for its rehabilitation. In comparison to the conventional reliability index, the present study uses both nodal and element level reliability for the normal and abnormal conditions of nodes and pipes and therefore, provide more balance reliability metrics for the network. The metrics supply shortage and pressure decline assess the resilience of node due to pipe failure whereas the metrics energy loss per unit length and hydraulic uniformity index assess the resilience of pipe under abnormal demand conditions. The methodology was found to successfully identify the critical pipes and the overall criticality ranking for all four water distribution networks and is simple to implement. It is observed that the four metrics considered follow nearly a similar criticality pattern. The result shows that the pipes nearer to the source is found to be more critical, and the criticality of the pipes decreases as one moves from the source to the periphery. Further, the critical pipes are found to be located from the source on the paths that do not have a loop or around the nodes of higher demand. It is observed that in order to make the WDN more resilient, the network needs to be connected with multiple sources (reservoirs and tanks) in loops so that in case of abnormal conditions, the demand in requisite pressure can be delivered through alternate routes. Thus, to rehabilitate the series connection, the pipes need to be connected in loops. It is also observed that the pipes, closer to the source experience more energy loss compared to the pipes located away. Moreover, before the rehabilitation of the network locally, the whole network needs to be analyzed as a single unit. Thus, this study has been found to have the potential to prioritize the rehabilitation plan or extension plan of a network. The study might also be useful to strengthen deficient nodes/pipes of a network.

Data Availability

Some or all data, models, or code that support the findings of this study are available from the corresponding author upon reasonable request.

References

Amiri-Ardakani Y, Najafzadeh M (2021) Pipe break rate assessment while considering physical and operational factors: a methodology based on global positioning system and datadriven techniques. Water Resour Manag 35. https://doi.org/10.1007/s11269-021-02911-6

Ang WK, Jowitt PW (2006) Solution for water distribution systems under pressure-deficient conditions. J Water Resour Plann Manag 132(3), 175–182

Arulraj GP, Rao HS (1995) Concept of significance index for maintenance and design of pipe networks. J Hydrau Eng 121(11), 833–837

Cabrera E, Gomez E, Cabrera E Jr, Soriano J, Espert V (2015) Energy assessment of pressurized water systems. J Water Resour Plann Manag 141(8):04014095

Cimorelli L, Morlando F, Cozzolino L, Aniello AD, Pianese D (2018) Comparison among resilience and entropy index in the optimal rehabilitation of water distribution networks under limited-budgets. Water Resour Manag 32:3997–4011

Dziedzic R, Karney BW (2015) Energy metrics for water distribution system assessment: case study of the Toronto network. J Water Resour Plann Manag 141(1), 1–11

Fujiwara O, Li J (1998) Reliability analysis of water distribution networks in consideration of equity, redistribution, and pressure-dependent demand. Water Resour Res 34(7), 1843–1850

Gorev NB, Kodzhespirova IF (2013) Noniterative implementation of pressure-dependent demands using the hydraulic analysis engine of EPANET 2. Water Resour Manag 27(10), 3623–3630

Goulter I (1995) Analytical and simulation models for reliability analysis in water distribution systems. Improving efficiency and reliability in water distribution systems, E Cabrera and AF Vela (Editors.), Kluwer Academic, London, 235–266

Gupta R, Bhave PR (1996) Comparison of methods for predicting pressure-deficient-network performance. J Water Resour Plann Manag 122(3), 214–217

Gupta R, Abdy Sayyed MAH, Tanyimboh TT (2018) Discussion of “New pressure-driven approach for modeling water distribution networks” by HA Mahmoud, D Savic, and Z Kapelan. J Water Resour Plann Manag 144(6):07018006

Haghighi A, Samani HMV, Samani ZMV (2011) GA-ILP Method for Optimization of Water Distribution Networks. Water Resour Manag 25:1791–1808

Hashemi S, Filion YR, Speight VL (2018) Examining the energy performance associated with typical pipe unit head loss thresholds. J Am Water Works Assn 110(9), 15–27

He X, Yuan Y (2019) A framework of identifying critical water distribution pipelines from recovery resilience. Water Resour Manag 33:3691–3706

Izadi A, Yazdandoost F, Ranjbar R (2020) Asset-based assessment of resiliency in water distribution networks. Water Resour Manag 34:1407–1422

Jayaram N, Srinivasan K (2008) Performance-based optimal design and rehabilitation of water distribution networks using life cycle costing. Water Resour. Res. 44(1):W01417

Jeong G, Wicaksono A, Kang D (2017) Revisiting the resilience index for water distribution networks. J Water Resour Plann Manag 143(8):04017035

Jeong G, Kang D (2020) Hydraulic Uniformity Index for Water Distribution Networks. J Water Resour Plann Manag 146(2):04019078

Marlim MS, Jeong G, Kang D (2019) Identification of critical pipes using a criticality index in water distribution networks. Appl Sci 9(19):4052

Monsef H, Naghashshzadegan M, Farmani R, Jamali A (2019) Deficiency of reliability indicators in water distribution networks. J Water Resour Plann Manag 145(6):04019022

Moslehi I, Jalili-Ghazizadeh M (2020) Pressure-pipe breaks relationship in water distribution networks: a statistical analysis. Water Resour Manag 34:2851–2868

Mu T, Li Y, Li Z, Wang L, Tan H, Zheng C (2021) Improved network reliability optimization model with head loss for water distribution system. Water Resour Manag 35:2021–2114

Prasad RK (2021) Discussion of “Hydraulic Uniformity Index for Water Distribution Networks” by Gimoon Jeong and Doosun Kang. J Water Resour Plann Manag 147(5):07021003

Prasad TD, Park NS (2004) Multiobjective genetic algorithms for the design of water distribution networks. J Water Resour Plann Manag 130(1), 73–82

Raad DN, Sinske AN, Vuuren Van JH (2010) Comparison of four reliability surrogate measures for water distribution systems design. Water Resour Res 46(5):W05524

Shin S, Lee S, Judi DR, Parvania M, Goharian E, McPherson T, Burian SJ (2018) A systematic review of quantitative resilience measures for water infrastructure systems. Water 10:164

Sivakumar P, Prasad RK (2014) Simulation of water distribution network under pressure-deficient condition. Water Resour Manag 28(10), 3271–3290

Sivakumar P, Prasad RK (2015) Extended Period Simulation of Pressure-Deficient Networks Using Pressure Reducing Valves. Water Resour Manag 29(5), 1713–1730

Tabesh M, Tanyimboh TT, Burrows R (2002) Head-driven simulation of water supply networks. Int J Eng 15(1), 11–22

Tanyimboh TT (2003) Reliability analysis of water distribution system. Urban and Rural Water Systems for Sustainable Development: Proceedings of the 30th IAHR Congress, Ganoulis J, Maksimovic C, Kaleris V (Editors), Thessaloniki, 321-328

Tanyimboh TT, Gupta R, Abdy Sayyed MAH, Rathi S (2020) Discussion of “Deficiency of Reliability Indicators in Water Distribution Networks” by H. Monsef, M. Naghashzadegan, R. Farmani, and A. Jamali. J Water Resour Plann Manag 146(11):07020003

Todini E (2000) Looped Water distribution networks design using a resilience index-based heuristic approach. J Urban Water 2:115–122

Wagner J, Shamir MU, Marks DH (1988) Water distribution reliability: Simulation methods. J Water Resour Plann Manag 114(3), 276–294

Wu ZY (2007) Discussion of “Solution of water distribution system under pressure-deficient conditions” by WK Ang and PW Jowitt. J Water Resour Plann Manag 133(6), 570

Xu C, Goulter IC (1999) Reliability-based optimal design of water distribution networks. J Water Resour Plann Manag 125(6), 352–362

Acknowledgements

The author thanks the editors and anonymous reviewers for their constructive suggestions in revision and publication. The comments and suggestions by editors and reviewers have greatly improved the quality of the article.

Funding

No funds, grants, or other supports were received.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Ethical Approval

All procedures performed in studies involving human participants were in accordance with the ethical standards of the institutional and/or national research committee and with the 1964 Helsinki declaration and its later amendments or comparable ethical standards. This article does not contain any studies with animals performed by any of the authors. Informed consent was obtained from all individual participants included in the study.

Consent to Publish

The author gives the Publisher the permission of the author to publish the research.

Conflict of Interest

There is no conflict of interest.

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Prasad, R.K. Identification of Critical Pipes for Water Distribution Network Rehabilitation. Water Resour Manage 35, 5187–5204 (2021). https://doi.org/10.1007/s11269-021-02994-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11269-021-02994-1