Abstract

A series of experiments were performed to find out the impact of food waste on growth attributes and performance of broilers in a tropical climate. Two hundred and fifty-one-day-old broiler chicks were randomly separated into 5 groups, where each group comprised 50 animals. The broilers were fed with five different dietary treatments. Treatment 1 (T1), the diet consisted of food waste ingredients such as sprat heads, fish offal (protein), scraped coconut, and swill cooked rice as energy supplements; dietary treatment II (T2) diet was formulated with protein rich food waste; treatment III (T3) diet formulated with energy-rich food waste; treatment IV (T4) without any food waste materials, but a diet formulated with commercially available feed ingredients; and treatment V (T5), a 100% commercially-available broiler diet. Total feed intake per week and total weight gain were significantly (p < 0.05) higher in the commercial diet (T5) contrary to the formulated diets. The highest feed conversion ratio (FCR) was recorded in T3. The average dressing percentage was not significantly different (p > 0.05) in T1, T3, and T5. Average DM % in litter and DM % in feces were higher in T5, but average nitrogen % in droppings were lower in T4 and T5 compared to other diets. The study shows the potential application of food waste as an alternative feed in the broiler industry and its abundance and easy collection makes it a promising feeding regime in urban and suburban areas.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

“Wastes are by-products which, for economic or social reasons, are not fully utilized within the confines of the production unit, and are allowed to burden the natural environment” (Taiganides 1979). Utilization of waste generated in the poultry industry such as excreta, litter, left-over feed, dead birds, broken eggs, feathers, offal, and organic waste from slaughterhouses and municipal waste have attracted the interest of many scientists (Kelleher et al. 2002; Salminen and Rintala 2002; Garćia et al. 2005; Sanabria-Leόn et al. 2007). Likewise, use of food waste as an animal feed has been practiced for a long time (Truong et al., 2019). Generally, food waste contains plenty of crude proteins and also has higher energy values (Westendorf and Myer 2004). However, feed values of food waste vary depending upon the origin of waste (Westendorf 2000; Chae et al. 2000; Kwak et al. 2002). Food waste comprising grains or by-products has been able to improve animal performance (Myer et al. 1999; Chae et al. 2000; Walker 2000; Westendorf 2000), signifying the importance of crude protein and the dietary energy balance of food waste that is fed. Moreover, nutrients and bioactive compounds in food wastes may have beneficial impacts on animals (Georganas et al., 2020; Mechkirrou et al., 2021). High nutritional variation, nutritional imbalance, and low digestibility of nutrients of food waste can cause slow growth, inferior meat quality, and softening of the fat in some farm animals (So 1999; Myer et al. 1999; Chung 2001).

Waste from the household food and food industry in urban and peri-urban areas have created environmental problems in many countries, and prevention or minimization of generation, material recovery, recycling, upgrading, incineration, gasification, thermolysis, or disposal in controlled landfills are the methods of disposing or the controlling of accumulation of all forms of waste (Sakai et al. 1997; Debaere, 2000; Crowe et al. 2002; Koufodimos and Samara 2002; Joshi and Visvanathan, 2019). Nevertheless, some of these methods can cause other types of environmental issues such as air pollution, soil and ground water contamination, and the greenhouse gas emissions, which may lead to phenomena such as global warming (Kwak and Kang 2006, Dao et al., 2019; Siddiqui et al., 2021). Taiganides (1979) states that waste recycling is a highly developed art in some parts of the world, which, however, must be developed into science in order to endure the vigorous developments in modern scientific agricultural production operations. Therefore, the present study was conducted with the aim of evaluating the effects of replacing energy and protein supplementary ingredients in broiler diets with food waste, such as fish offal, cooked rice, scraped coconut, and sprat heads on growth performances and meat quality characteristics of broilers under a tropical climate.

Materials and method

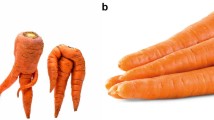

Food waste mixture manufacture

Experimental diets were formulated according to NRC 1994. Fresh food waste such as swill cooked rice, sprat heads, scraped coconut (after extracting coconut milk), and fish waste were collected from several restaurants and houses in the Kamburupitiya, Sri Lanka. Then, the collected food waste was oven dried at 65 °C for 6 h, and cooked rice and sprat heads were ground before feed formulation. The diets were formulated to be both iso-proteic and isoenergetic.

Crude protein and the gross energy value of food waste samples

Food waste samples were finely ground and analyzed for crude protein level by micro Kjeldahl method. Gross energy value was calculated by bomb calorimetric (6200 Calorimeter with 1108 Oxygen Bomb, Bucket and 1757 Printer, Parr Instrument Company, Illinois) method, referring to AOAC 1997.

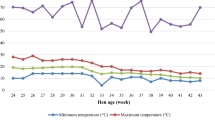

Experimental design

Briefly, 250 unsexed commercial avian broiler chicks (1-day old, approximately 48 g body weight, Indian River strain) were randomly allocated to five dietary treatment groups (ten birds/pen with five pens per treatment). The broilers were housed in a concrete-floored experimental cage between 1 and 42 days of age. Feeds and water were supplied in the morning and the residues were collected around the same time of the following day, and weighed.

Dietary treatment

Four experimental diets were formulated. Treatment I (T1) diet was formulated with rice polish, soybean oil meal, scraped coconut, dried rice, sprats, fish offal, L lysine, D Methionine, and vitamin-mineral mixture. Dietary treatment II (T2) diet consisted of rice polish, soybean oil meal, sprats, fish offal, yellow maize meal, coconut oil, L lysine, D methionine. and vitamin-mineral mixture, while treatment III (T3) diet was formulated with rice polish, soybean oil meal, gingerly oil meal, fish meal, scraped coconut, dried rice, DCP, shell powder, D methionine, salt, and vitamin-mineral mixture. Treatment IV (T4) was formulated without any food waste materials, but formulated with commercially available feed ingredients such as rice polish, yellow maize meal, coconut oil, soybean oil meal, gingerly oil meal, fish meal, DCP, shell powder, D methionine, salt, and vitamin-mineral mixture. Treatment V (T5) was the commercially available broiler diet, without any food wastes. (See Tables 1 and 2 for proximate composition).

Parameters measured

Weekly weight gain, daily feed, and water intakes were recorded. The average dressing percentage and the average weights of various body parts were measured separately in processing, using 25 samples from each dietary treatment. The samples of litter were collected from five random places from each cage excluding the areas surrounding the feeder and the drinker, and the samples of the same treatment were pooled before the analysis. Then, the average dry matter (DM %) content of litter was analyzed. The ammonia emission of litter was calculated referring to the method described in Atapattu et al. (2008), with minor modifications.

The poultry feces from each cage were collected using a small shovel and the samples from the same treatment were mixed together. Then, the DM % and average nitrogen % in droppings were analyzed.

Determination of the fatty acid composition of chicken skin and abdominal fat

Chicken skin and abdominal fat from 42-days-old broilers were taken separately in each treatment, and fatty acid composition was determined by the GC-MS method according to the method described by Klinkesorn et al. (2004). The fatty acids from chicken skin and chicken abdominal fat were prepared according to Senanayake and Shahidi (1999) and Wanasundara and Shahidi (1999) with slight modifications. Fatty acids methyl esters were prepared referring the method of Jham et al. (1982), with modification for scale up.

The GC analysis was carried out using a Perkin–Elmer Autosystem XL (The Perkin–Elmer Corporation, Norwalk, CT) equipped with a PERMABOND-FFAP DF-0.25 fused-silica capillary column 25 m × 0.25 mm id (MACHEREY-NAGEL, Germany) and FID detector, and operated in a split mode with split ratio 100:1. The injector and detector temperatures were 245 °C and 250 °C, respectively. The column temperature was held at 150 °C for 0.5 min, then programmed to 170 °C at 4 °C/min, further programmed to 195 °C at 5vC/min; the final temperature was 215 °C at 10 °C/min from 195 °C and held for 7.5 min. The carrier gas used was helium, set at a flow rate of 0.5 mL/min (15 psi). The content of fatty acid methyl ester as g/100 g oil was calculated with 19:0 as internal standard according to Joseph and Ackman (1992).

Statistical analysis

The experimental design was a completely randomized design and the experimental data were analyzed using SAS Windows version and Minitab statistical package. The data were subjected to ANOVA using the general linear model procedure of SAS V 8.1 (SAS Institute Inc, 2019). The Duncan test was applied to determine the differences among means, and it was considered as significant if p < 0.05.

Results

Growth performance and carcass characteristics

Feed intake

The average feed intake per bird (Table 3) was significantly different (p < 0.05) among five dietary treatments in earlier weeks. The weekly intake of the commercial diet was the highest, and of four experimental formulations, T1 had the highest feed intake in earlier weeks. The feed intakes of birds increased with the progress of age, and the difference among the feed intakes of five diets began to decreases after the 4th week.

Daily water consumption

The average daily water consumption per bird is presented in Table 4. The daily water consumption increased with the age of the bird. Birds supplied with T1 and T2 exhibited higher water consumption compared to other diets, and the difference was significant (p < 0.05) from the rest of the treatments in the first 3 weeks. The difference between T1 and T2 was not significant (p > 0.05). However, in the 4th and 5th weeks, no significant difference (p>0.05) in the daily water consumption of the birds of all five treatments was observed, and again in the 6th week, a significant difference (p < 0.05) was found between T1, T2, and the rest of the treatments.

Weight gain

The weekly record of weight gain per bird is depicted in Table 5. A significantly higher (p < 0.05) total weight gain was recorded in the birds fed with the commercial diet (2535.33 ± 148.4 g/bird) than formulated diets. Of the formulated ones, birds fed with T1 and T3 showed the highest (2131.33 ± 114.5 g/bird) and the lowest (1948.66 ± 160.9 g/bird) total weight gains, respectively, but they were not significantly different (p > 0.05). The weekly weight gain increased with the age of the birds, with a marked increment in the fourth week and then it decreased gradually in all treatments. In earlier weeks, the weight gain was significantly different (p < 0.05) among the five treatments, but the differences became less among the formulated diets after the third week. In the sixth week, the highest weight gain was reported in T1 (392.67 ± 45.8 g/ bird), while T5 had the lowest (303.33 ± 95.0).

Feed conversion ratio (FCR)

The feed conversion ratio for the whole period of T3 (1.925 ± 0.050) was the highest and was significantly higher (p < 0.05) than T1, T2, and T5, but was not significantly different (p > 0.05) from T4 (1.779 ± 0.097) (Table 6). The FCR of T5 (1.709 ± 0.135) was not significantly different (p > 0.05) from T1 (1.670 ± 0.075) and T2 (1.683 ± 0.199). As revealed by Table 6, the FCR increased from week 1 to 3, and then slightly declined in the 4th week and again increased up to the 6th week in all treatments. The highest FCR was observed in the 6th week in all five treatments.

Dressing percentage and yield parts

As revealed by Table 7, feeding with commercial diet resulted in a significantly higher (p < 0.05) average fresh weight, average dressing weight with and without gizzard, liver, and heart (G, L, H) in the broilers compared to the test dietary treatments. However, no significant difference (p > 0.05) was observed in the abovementioned parameters among the four formulated diets. Average dressing % was not significantly different (p > 0.05) in T1, T3, and the commercial diet. There was no significant difference (p > 0.05) in the weight of drumsticks among the five treatments. The weights of thighs were significantly lower (p < 0.05) in T1, T3, and T4 than the commercial. But the weights of thighs were not significantly different (p > 0.05) in treatment 2 with the commercial diet. The weights of back parts were significantly (p < 0.05) higher in the commercial diet than four dietary treatments. The highest weight for breast (700.0 ± 113.0 g) and leg (52.6 ± 1.3 g) was recorded in T5, but the neck weight was lowest (34.3 ± 2.1 g) in the commercial diet. The highest neck weight was reported in T2 (82.4 ± 35 g).

The quality of litter material and analysis of droppings

Ammonia emission of litter was the highest in T3, but it was not significantly different (p > 0.05) from T4. T2 showed the lowest ammonia emission (Table 8). The average dry matter % of litter was significantly higher (p < 0.05) in the commercial diet compared to the test diets.

As shown in Table 9, DM % of feces were higher in the commercial diet than the test diets, but it was not significant (p > 0.05). Moreover, average nitrogen % in droppings was lower in T4 and the commercial diet rather than the diets made by using food waste, but the difference was not significant (p > 0.05).

Fatty acid composition of broiler chicken skin and abdominal fat

As demonstrated in Table 10, the saturated fatty acids in both broiler skin and abdominal fat ranged between 36.3 and 58.2 %. The saturated fatty acid content of both skin and abdominal fat of broilers fed with the commercial diet were the lowest (41.9 and 36.6 %), while the highest values were recorded in T3. Of the saturated fatty acids, C 16:0 (palmitic acid) was the most prominent. Except for T5, the content of saturated fatty acids of abdominal fat was slightly higher than the skin fat. The monounsaturated fatty acid content ranged between 25.3 and 45.9%, with the highest in the commercial diet and the lowest in T3. The most prominent monounsaturated fatty acid in all five treatments was C 18:1, which is oleic acid. In all five dietary treatments, the monounsaturated fatty acid content in skin fat was higher compared to that of abdominal fat. The highest and the lowest polyunsaturated fatty acid content were reported in abdominal fat (17.9%) and skin fat (4.2%) of T5, respectively. Of the polyunsaturated fatty acids, C 18:2n-6 (linoleic acid) was the most abundant.

Discussion

Feed intake, daily water consumption, and weight gain

Both feed intake and daily water consumption of the birds increased with age due to the increasing body weight, which augments energy and nutrient requirements. However, the feed intake in formulated diets was lower compared to that of commercial diet. Food waste-based feed may have undesirable anti-nutritional, physical, and sensory characteristics (Boumans et al.,2022), which may have negative effects on these parameters.

The water consumption is closely linked with feed intake, and it is regulated by several factors, including age, sex, environment, and feed content (McCreery, 2015). Higher sodium chloride levels of feed can result in high water intakes (McCreery, 2015). Therefore, high daily water consumption in birds fed with T1 and T2 than the other diets can be attributed to their high salty nature. Dao et al. (2019) have also reported high sodium content in food waste samples collected, with the aim of processing them to be used as poultry feed. Generally, commercial broilers have an intestinal transit time of 4–8 h (Lavorgna et al., 2014). Increased water intake may reduce the feed transit time through the gut, thus reducing the gut efficiency. This can increase the risk of dysbacteriosis; hence negatively affect intestinal microbiota balance (Johnson, 2019). Moreover, increased water consumption can result in wet droppings, which may lead to high litter moisture. This supplies favorable conditions for the parasite Eimeria, increasing the risk of coccidiosis, as well as is foot problems such as hock burn or pododermatitis (Lavorgna et al., 2014; Johnson, 2019).

The weekly weight gain of broilers corresponds to their feed intake. Hence, the highest weight gain of the birds fed with commercial diet can be due to the high feed intake. A study conducted in South Korea has found that the weight gain of broilers fed with a diet incorporated with 10–30% of dried leftover foods was lower compared to the birds fed with control diet without any leftover food (Cho et al. 2004). However, the same study has reported higher feed intake of the birds fed with 20–30% of dried leftover foods with the addition of proteins compared to the control group. Both the total feed intake and the total body weight gain of the broilers in the current study are higher compared to Cho et al. (2004). Mechkirrou et al., (2021) have reported low feed intake, weight gain, and meat yield of poultry fed with a lab-prepared diet based on kitchen waste. Moreover, Hossein and Dahlan, 2015, investigated the effects of incorporation of dehydrated processed food waste (DPFW) into the diet of free-range village chicken. The study revealed a decrease in feed intake and body weight gain, and a higher FCR, when DPFW levels of the diet were increased beyond 20%. According to the findings, the substitution of 20% of poultry feed with DPFW had no negative impact on the growth performance of village chickens.

Feed conversion ratio (FCR)

The highest FCR recorded in T3 corresponds to the low weight gain. Increased water consumption is also associated with higher feed conversion ratios (McCreery, 2015). Hence, higher water intake levels of broilers in this study can be a possible reason for high FCR. Cho et al. (2004) has reported that the FCE of broilers decreased with the increasing dried leftover food content in their diets. Also, the viscosity of the diet has a great impact on the FCR. Iji et al. (2001) reported that increased FCR in chicks fed with highly viscous diets incorporated with non-starch polysaccharides, which may be due to the low weight gain caused by low efficiency of nutrients.

Dressing percentage and yield parts

The highest average dressing percentage of birds fed with T1 and the commercial diet corresponds to the high weight gain. According to Esteve-Garcia and Mack (2000), the carcase weight, carcase yield, and breast weight and the breast yield of broilers were positively affected by the supplementation with methionine and betaine showing a significant role of such ingredients in improving the carcase yield. However, the breast weight values recorded in Esteve-Garcia and Mack (2000) was much lower (198.5–278.4 g) compared to the current study (700–462.6 g). This may be due to the variations in diet, climatic conditions, and broiler breeds.

The quality of litter material and droppings

The control of the litter and excreta quality has a major impact in reducing environmental and animal welfare problems as well as decreasing the productive losses (Yalçın et al. 2017). Average DM % in litter and feces were higher in the commercial diet compared to the other diets because of the high-water consumption stemming from the highly salty nature of diets made by using food wastes. Higher dry matter content (86.3%) in poultry litter compared to the present study has been reported by Deshck et al. (1998). This can be due to the air-dried state of litter at the time of collection. The season and time of collection have a strong impact on the dry matter content of poultry litter (Deshck et al. 1998).

The microbial breakdown of nitrogenous wastes such as undigested proteins and excretory uric acid is responsible for the formation of ammonia, and pH, moisture content, and temperature of litter and the type of litter material are factors that directly control the ammonia emissions from litter (Atapattu et al. 2008). The ammonia emissions from litter (paddy husk) in the current study is significantly lower compared to the values recorded in Atapattu et al. (2008) for paddy husk (33.0–44.0 mg/kg of litter per h), refused tea (13.0–13.2 mg/kg of litter per h), and saw dust (34.2–54.0 mg/kg of litter per h) litter. The ammonia emissions of litter also increase with the progress of the cycle (Atapattu et al. 2008). The accumulation of manure, which mixes with the litter material and removal of both materials together at the end, can be the reason for this (Kellerher et al. 2002).

A total nitrogen content of 3.56% (dry weight) in poultry manure has been reported by Guerra-Rodriguez et al. (2001), which is slightly higher compared to the values observed in the present study. Typically, poultry manure comprises substantial amount of organic nitrogen which can be attributed to the presence of high amounts of proteins and amino acids (Kellerher et al. 2002). Jacob et al. (2000) reported reduced nitrogen content in excreta of broiler and layer chickens fed with low protein diets. Moreover, studies have discovered that the reduction of dietary crude protein levels (Ferguson et al. 1998; Nahm 2003) and application of liquid alum in broiler litter surface (Armstrong et al. 2003) have significantly reduced the ammonia emissions in poultry operations.

Fatty acid composition of broiler chicken skin and abdominal fat

The abdominal fat contents of broilers have showed an increasing trend with the dietary methionine supplementation (Esteve-Garcia and Mack 2000). Higher oleic and palmitic acid levels in skin and abdominal fat of the present study agrees with Whitehead (1986), which reported that fatty acids of chicken body mainly consist of the above two components. Cho et al. (2004) have reported that plasma and meat of broilers fed with diets supplemented with dried leftover food contained mainly palmitic acid, linoleic acid, oleic acid, and stearic acid. It has also discovered that the plasma DHA and EPA contents increased with the increasing content of dried leftover food. The abdominal fat composition of broilers is significantly affected by the degree of hepatic lipogenesis, nature of the dietary fat, where the feeding with polyunsaturated fats results in a deposition of unsaturated fatty acids in broilers (McLeod 1982). It has been reported that short chain fatty acids dominate the abdominal fat of birds fed with coconut oil, and feeding with soybean oil have increased the content of linoleic acid in abdominal fat (Pan et al. 1979). The high amount of saturated fatty acid content in T3 may be due to feeding the birds with an energy rich diet, with a higher amount of saturated fatty acids.

Siddiqui et al. (2021) have shown that food waste is a low-cost protein rich feed ingredient. The findings of the current study suggest that food waste could be exploited as an alternative feed ingredient in the diet of broilers, which would be a more economical alternative compared to the commercial feeds. Moreover, the abundance and easy collection make it an effective feeding regime in urban and/or peri-urban areas, revealing an effective way of food waste management. However, there are some limitations in the usage of food waste as animal feed. Dao et al. (2019) have reported that the nutrient composition of food wastes varied depending on the source. Also, the quality of food waste may vary in the same place in different seasons (Siddiqui et al., 2021). Hence, the nutrient variability of food wastes gives rise to complications in their applications as animal feed (Georganas et al., 2020; Boumans et al., 2022). However, the variation of chemical composition of food waste can be minimized when it is collected from many places (Kawashima 2004). According to Garcia et al. (2005), a more balanced nutritional composition has been reported from restaurant and household waste.

Also, food wastes are high in moisture, and perishable items such as fish offal have a very short shelf life (Siddiqui et al., 2021). Another drawback of using food waste as poultry feed is that they contain undesirable substances such as mycotoxins and microorganisms, as well as plastic fragments from food packaging materials. Hence, great care should be taken in segregating suitable organic materials when preparing feed. Although harmful microorganisms are destroyed during heat processing, mycotoxins are heat resistant.

Moreover, due to the potential risks of disease outbreaks, use of food waste as an animal feed is banned in some countries, while special processing conditions need to be applied in the countries where the use of food waste in animal feed is permitted (Truong et al., 2019). Leib et al. (2016) have reported that in Minnesota State of the USA, food waste should be subjected to a mandatory heat treatment at 100 °C for 30 min before feeding poultry. However, higher temperatures may decrease the availability of proteins due to denaturation (Kawashima 2004). In our study, food wastes were oven dried at 65 °C for 6 h prior to feed formulation, which aids in the reduction of moisture content, hence, microbial load. It also lessens the effects of anti-nutritional factors and improves the handling and processing of waste (Garcia et al. 2005).

Although the use of food waste as poultry feed may be cost effective, costs associated with food waste collection, transportation, segregation, storage, and processing also should be taken into consideration (Siddiqui et al., 2021). Another important consideration is that the quantity of generated food wastes from different sources may vary in different regions and seasons; hence, the sustainability of food waste as a continuous feed material in adequate quantities should be analyzed.

Furthermore, the use of food wastes to animals is banned in the European Union since 2001, after the foot and mouth disease outbreak. Hence, there are potential burdens to export food waste fed poultry to the countries where the use of food wastes as an animal feed is banned.

According to our findings, broilers fed the diets based on food waste exhibited low growth performances compared to that of commercial diet. Therefore, we suggest that it is better to substitute some proportion of commercial feed in broiler diets with food waste, rather than feeding the broilers on diets based entirely on food waste. Hence, further studies should be conducted in order to find the best substitution percentage of food waste in broiler diets to gain the highest economical advantage, simultaneously preserving the growth performances.

Abbreviations

- DHA:

-

Docosahexaenoic acid

- DM,:

-

Dry matter

- EPA:

-

Eicosapentaenoic acid

- FCE:

-

Feed conversion efficiency

- FCR:

-

Feed conversion ratio

References

AOAC. 1997. Association of Official Analytical Chemists International Official Methods of Analysis (16th edn). (AOAC: Arlington).

Armstrong, K. A., Burns, R. T., Walker, F. R., Wilhelm, L. R. and Raman, D. R. 2003. Ammonia concentrations in poultry broiler production units treated with liquid alum. In ‘Proceedings of the Air Pollution from Agriculture Operations III’ pp. 116–122, (Research Triangle Park: North Carolina).

Atapattu, N. S. B. M., Senaratna, D. and Belpagodagamage, U. D. 2008. Comparison of ammonia emission rates from three types of broiler litters. Poultry Science, 87, 2436-2440.

Boumans, I. J. M. M., Schop, M., Bracke, M. B. M., de Boer, I. J. M., Gerrits, W. J. J. and Bokkers, E. A. M., 2022. Feeding food losses and waste to pigs and poultry: Implications for feed quality and production. Journal of Cleaner Production, 378, 134623.

Chae, B. J., Choi, S. C., Kim, Y. G., Kim, C. H. and Sohn, K. S. 2000. Effects of feeding dried food waste on growth and nutrient digestibility in growing-finishing pigs. Asian-Austral. Journal of Animal Science, 13, 1304-1308.

Cho, Y. M., Lee, G. W., Jang, J. S., Shin, I. S., Myung, K. H., Choi, K. S., Bae, I. H. and Yang, C. J. 2004. Effects of feeding dried leftover food on growth and body composition of broiler chicks. Asian-Australasian Journal of Animal Sciences, 17, 386-393.

Chung, J. C. 2001. Strategy for active recycling of food waste. Journal of Korea Solid Wastes Engineering Society, 18, 22-29.

Crowe, M., Nolan, K., Collins, C., Carty, G. and Donlon, B. 2002. Biodegradable municipal Waste Management in Europe Part I: Strategies and Instruments. (European Environment Agency: Copenhagen).

Dao, T. H., Jayasena, V., Hagare, D., Boyle, N., Rahman, M. and Swick, R. A., 2019. Potential to produce poultry feed from food wastes. In: 30th Annual Australian Poultry Science Symposium, pp. 204-207, (Sydney, Australia).

Debaere, L. 2000. Anaerobic digestion of solid waste: state of the art. Water Science and Technology, 41, 283-290.

Deshck, A., Abo-Shehada, M., Allonby, E., Givens, D. I. and Hill, R. 1998. Assessment of the nutritive value for ruminants of poultry litter. Animal Feed Science and Technology, 73, 29-35.

Esteve-Garcia, E. and Mack, S. 2000. The effect of DL-methionine and betaine on growth performance and carcase characteristics in broilers. Animal Feed Science and Technology, 87, 85-93.

Ferguson, N. S., Gates, R. S., Taraba, J. L., Cantor, A. H., Pescatore, A. J., Straw, M. L., Ford, M. J. and Burnham, D. J. 1998. The effect of dietary protein and phosphorus on ammonia concentration and litter composition in broilers. Poultry Science, 77, 1085-1093.

Garćia, A. J., Esteban, M. B., Márquez, M. C. and Ramos, P. 2005. Biodegradable municipal solid waste: Characterization and potential use as animal feedstuffs. Waste Management, 25, 780-787.

Georganas, A., Giamouri, E., Pappas, A. C., Papadomichelakis, G., Galliou, F., Manios, T., Tsiplakou, E., Fegeros, K. and Zervas, G., 2020. Bioactive compounds in food waste: A review on the transformation of food waste to animal feed. Foods, 9, 1–18.

Guerra-Rodriguez, E., Diaz-Ravina, M. and Vazquez, M. 2001. Composting of chestnut burr and leaf litter with solid poultry manure. Bioresource Technology, 78, 107-109.

Hossein, S. and Dahlan, I., 2015. Growth performance of free-range village chickens fed dehydrated processed food waste Malaysian Journal of Animal Science, 18, 77–86.

Iji, P. A., Saki, A. A. and Tivey, D. R. 2001. Intestinal development and body growth of broiler chicks on diets supplemented with non-starch polysaccharides. Animal Feed Science and Technology, 89, 175-188.

Jacob, J. P., Ibrahim, S., Blair, R., Namkung, H. and Paik, I. K. 2000. Using enzyme supplemented, reduced protein diets to decrease nitrogen and phosphorus excretion of white leghorn hens. Asian Australasian Journal of Animal Science, 13, 1743-1749.

Jham, G. N., Teles, F. F. F. and Campos, L. G. 1982. Use of aqueous HCI/MeOH as esterification reagent for analysis of fatty acids derived from soybean lipids. Journal of the American Oil Chemists Society, 59, 132-133.

Johnson, R., 2019. Water utilization in broilers. The Poultry Site. https://www.thepoultrysite.com/articles/water-utilisation-in-broilers (Accessed on 22/01/2023).

Joseph, J. D. and Ackman, R. G. 1992. Capillary column gas chromatography method for analysis of encapsulated fish oil and fish oil ethyl esters: collaborative study. Journal of Association of Official Analytical Chemical International, 75, 488-506.

Joshi, P. and Visvanathan, C., 2019. Sustainable management practices of food waste in Asia: Technological and policy drivers. Journal of Environmental Management, 247, 538–550.

Kawashima, T. 2004. The use of food waste as a protein source for animal feed - current status and technological development in Japan. In ‘Protein sources for the animal feed industry.’ (FAO Expert Consultation and Workshop: Bangkok, Thailand), 29 April-3 May, 2002, pp. 303-309.

Kelleher, B. P., Leahy, J. J., Henihan, A. M., O’Dwyer, T. F., Sutton, D. and Leahy, M. J. 2002. Advances in poultry litter disposal technology-a review. Bioresource Technology, 83, 27-36.

Klinkesorn, U., H-Kittikun, A., Chinachoti, P. and Sophanodora, P. 2004. Chemical transesterification of tuna oil to enriched omega-3 polyunsaturated fatty acids. Food Chemistry, 87, 415–421.

Koufodimos, G. and Samara, Z. 2002. Waste Management options in southern Europe using field and experimental data. Waste Management, 22, 47-59.

Kwak, W. S. and Kang, J. S. 2006. Effect of feeding food waste-broiler litter and bakery by-product mixture to pigs. Bioresource Technology, 97, 243-249.

Kwak, W. S., Kang, J. S. and Chung, J. D. 2002. Evaluation of nutritional characteristics of different sources of food residues in autumn and comparisons with NRC nutrient requirements for swine. Journal of Animal Environmental Science, 8, 87-98.

Lavorgna, M., Vancraeynest, D. and Stanev, V., 2014. Evaluating wet droppings as a useful guide to bird health International Poultry Production, 22, 11–13

Leib, E. B., Balkus, O., Rice, C., Maley, M., Taneja, R., Cheng, R., Alvoid, T., Civita, N. and Alvoid, T., 2016. Leftovers for Livestock: A Legal Guide for Using Excess Food as Animal Feed, The Harvard Food Law and Policy Clinic and the Food Recovery Project at the University of Arkansas School of Law.

McCreery, D. H. (2015). Water Consumption Behavior in Broilers. Graduate Theses and Dissertations. University of Arkansas, Fayetteville.

Mcleod, J. A. 1982. Nutritional Factors Influencing Carcase Fat in Broilers-A Review. World's Poultry Science Journal, 38, 194-200.

Mechkirrou, L., Arabi, M., Ouhssine, M. and Afilal, M. E. A., 2021. Food Waste reuse as a feed for organic chicken: A case study. E3S Web of Conferences, 234, 00090.

Myer, R. O., Brendemuhl, J. H. and Johnson, D. D. 1999. Evaluation of dehydrated restaurant food waste products as feedstuffs for finishing pigs. Journal of Animal Science, 77, 685-692.

Nahm, K. H. 2003. Current pollution and odor control technologies for poultry production. Avian Poultry Biology Review, 14, 151-174.

NRC. 1994. Nutrient requirements of poultry. (9th Revised edn). (National Academy Press: Washington DC).

Pan, P. R., Dilworth, B. C., Day, E. V. and Chen, T. C. 1979. Effect of season of year, sex and dietary fats on broiler performance, abdominal fat and preen gland secretion. Poultry Science, 58, 1564.

Sakai, S., Sawell, S. E., Chandler, A. J., Eighmy, T. T., Kosson, D. S. and Vehlow, J. 1997. World trend in municipal solid waste management. Waste Management, 16, 341-350.

Salminen, E. and Rintala, J. 2002. Anaerobic digestion of organic solid poultry slaughterhouse waste-a review. Bioresource Technology, 83, 13-26.

Sanabria-Leόn, R., Cruz-Arroyo, L. A., Rodríguez, A. A. and Alameda, M. 2007. Chemical and biological characterization of slaughterhouse wastes compost. Waste Management, 27, 1800-1807.

SAS Institute Inc. 2019. SAS® Enterprise Guide® 8.1: User’s Guide. Cary, NC: SAS Institute Inc.

Senanayake, S. P. J. N. and Shahidi, F. 1999. Enzymatic incorporation of docosahexaenoic acid into borage oil. Journal of the American Oil Chemists’ Society, 76, 1009-1015.

Siddiqui, Z., Hagare, D., Jayasena, V., Swick, R., Rahman, M. M., Boyle, N. and Ghodrat, M., 2021. Recycling of food waste to produce chicken feed and liquid fertilizer. Waste Management, 131, 386–393.

So, M. H. 1999. Current drive and counterplan for recycling of food waste as animal feed. ‘Symposium on recycling of food waste as feed. 1999. 7.2.’ National Livestock Research Institute, (Suwon: Korea)

Taiganides, E. P. 1979. Wastes are…. resources out of place. Agricultural wastes, 1, 1-9.

Truong, L., Morash, D., Liu, Y. and King, A., 2019. Food waste in animal feed with a focus on use for broilers. International Journal of Recycling of Organic Waste in Agriculture, 8, 417–429.

Walker, P. 2000. Food Residuals: Waste product, by-product, or coproduct. In: L Michael (eds) Food waste to Animal Feed. Iowa State University Press: Iowa

Wanasundara, U. N. and Shahidi, F. 1999. Concentration of omega 3-polyunsaturated fatty acids of seal blubber oil by urea complexation: optimization of reaction conditions. Food Chemistry, 65, 41-49.

Westendorf, M. L. 2000. Food waste as animal feed: An introduction. In: L. Michael (eds), Food waste to Animal Feed. (Iowa State University Press: Iowa)

Westendorf, M. L. and Myer, R. O. 2004. Feeding food wastes to swine. In ‘Florida cooperative extensive service press’. (Institute of food and agricultural sciences: University of Florida)

Whitehead, C. C. 1986. Nutritional factors influence fat in poultry. Feedstuff, 20, 31.

Yalçın, S., Gebeş, E. S., Şahin, A., Duyum, H. M., Escribano, F. and Ceylan, A. 2017. Sepiolite as a feed supplement for broilers. Applied Clay Science, 148, 95-102.

Data availability statement

The datasets generated and/or analyzed during the current study are available from the corresponding author on reasonable request.

Author information

Authors and Affiliations

Contributions

R. A. U. J. Marapana and T. R. Seresinhe contributed to the study conception and design. Material preparation and data collection and analysis were performed by W. M. P. B. Weerasinghe, G. S. A. Senanayake, P. R. D. Perera, and R. A. A. P. Marapana. The first draft of the manuscript was written by R. A. U. J. Marapana and R. A. S. N. Ranasinghe. All authors commented on previous versions of the manuscript. All authors read and approved the final manuscript.

Corresponding author

Ethics declarations

Ethics approval

I confirm that the study has received approval from the ethics committee of the University of Ruhuna, Sri Lanka.

Competing interest

The authors declare no competing interest.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Marapana, R.A.U.J., Weerasinghe, W.M.P.B., Senanayake, G.S.A. et al. Conversion of energy and protein rich food waste as an alternative feed ingredient in broiler feed formulation. Trop Anim Health Prod 55, 101 (2023). https://doi.org/10.1007/s11250-023-03516-4

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s11250-023-03516-4