Abstract

Tetrameric Ti(IV)–calix[4]arene complexes were synthesized and characterized as well as grafted on a hydroxylated SiO2 inorganic support as an example of patterned Lewis-acid sites on an inorganic oxide surface. These complexes consist of a novel calixarene organic ligand with varying lengths of tethers to a central aromatic core, and with the calixarene coordinating four titanium(IV)-cations via tetrahedral recognition on the lower rim. Catalysis of these materials was investigated with a probe reaction consisting of the epoxidation 1-octene with tert-butylhydroperoxide as the oxidant, and a comparison of their hydrolytic stability was performed. The oligomeric calix[4]arenes showed similar behavior in catalysis to the monomeric control, with the exception of the material with the shortest tether length, which shows a 1.3-fold higher activity that may be due to a modest cooperativity effect. In hydrolytic leaching tests, the oligomeric complexes showed higher stability compared to the monomeric complex, and this stability appeared to be more thermodynamic rather than kinetic in nature. We hypothesize that encapsulatation of the tetrameric active site within a silica mesopore of the support contributes to this stability.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

The oxidation catalysis work of Prof. Mark Davis has been an enormous influence on our efforts in synthesizing isolated Ti active sites within a well-defined and tunable organic-ligand sphere [1, 2]. Inspired by Davis group design, synthesis, and characterization of Lewis-acidic metal heteroatom sites that are located within the framework of zeolites, we developed grafted metallocalixarene complexes on inorganic oxides as an emerging class of Lewis-acid catalysts for reactions involving oxygen transfer (such as olefin epoxidation using organic hydroperoxide) as well as hydride transfer (such as MPV reduction) [3–5].

These catalysts have heretofore consisted of grafted metallocalixarenes that are site isolated and randomly arranged on the surface; that is, there is no possibility of patterning surface sites in these materials, since chemisorption of each site occurs irreversibly, up to the maximum surface coverage corresponding to the jamming limit. Scheme 1a shows an example of a catalyst surface using grafted Ti(IV)–calixarene sites on dehydroxylated silica. The calixarene enforces a pseudotetrahedral geometry around the Ti center as well as acts as a silica-ligand surrogate electronically [3, 4, 6, 7]. The organic-ligand effect in this class of materials is invoked to explain the observed ~2-fold higher catalytic activity per Ti site when compared with conventional Ti-on-silica catalysts [8–11].

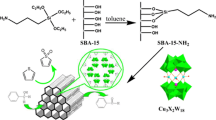

Here, in this manuscript, we use the calixarene ligand as a versatile nanoscale organizatioanal scaffold, and demonstrate a patterned surface assembly of grafted Lewis-acid sites on the surface of silica, using the tetrameric calixarene-based ligand shown in Fig. 1. Each assembly consists of four grafted Ti(IV)–calixarene sites, which are tethered to the aromatic core of the ligand. The length of the tether (controlled to be 5, 10, and 11 methylene units) connecting each site to the core thereby patterns the grafted sites and controls their local density on the surface, when using this approach, and results in the type of patterned Lewis-acid surface sites shown in Scheme 1b.

A crucial feature that requires demonstration when patterning sites according to Scheme 1b is whether all four Ti(IV)–calixarene complexes comprising an assembly actually graft to the silica support; or, alternatively, whether one or more of these complexes with the tetramer remain unbound and tethered off of the surface. To investigate this question, we use catalysis as a sensitive probe of Ti(IV)–calixarene-site grafting on the surface of silica. This probe is based on our previous demonstration of catalytic activity in olefin epoxidation using organic hydroperoxide, when using grafted Ti(IV)–calixarene sites as catalyst, and the lack of activity for all Ti(IV)–calixarene complexes that were unanchored to silica—in solution [4]. In order to assess the anchoring of all Ti(IV)–calixarene sites in the tetrameric assembly, we compare the per-calixarene-site catalytic activity of sites in Scheme 1a, b for epoxidation of 1-octene with tert-butylhydroperoxide. If the per-calixarene-site activity is the same for both, then this is consistent with complete grafting of all four Ti(IV)–calixarene sites within an assembly in Scheme 1b. On the other hand, if this per-site activity in Scheme 1a is greater than that in Scheme 1b, this suggests that some of calixarene units within the tetrameric site assembly did not graft to silica, since sites lacking grafted connectivity have been previously shown to be inactive for this reaction. We employ dilute coverages of Ti(IV)–calixarene sites on the surface of silica to avoid interactions and entanglements between sites that ultimately arise and prevent complete anchoring of each site within a tetrameric assembly, at higher coverages.

Though Ti(IV)-catalyzed epoxidation is not a reaction that is expected to benefit from cooperativity between sites given the mechanism invoked [3, 4], the patterning of Lewis-acid sites as demonstrated here enables application to systems where such catalytic cooperativity is thought to be important. Cooperative effects in catalysis enhance the activity of a reaction as a result of tuning the structure, size, shape of molecules comprising several active sites in close geometrical proximity [12]. These have been previousy observed in epoxidation catalysis when using soluble metal–salen complexes as the catalyst active site. Two metal–salen complexes cooperate within the mechanism wherein one is thought to activate the epoxide as a Lewis acid while the other binds the nucleophile (hydroxide in HKR). Such bimetallic cooperativity between two salen complexes is consistent with the observed second-order kinetics for HKR when using metal–salen catalysts, as well as full characterization of the bound nucleophile when using trimethylsilylazide and phenol [13]. Jacobsen originally demonstrated that the cooperativity between two Co–salen complexes and corresponding rate of HKR could be accelerated by synthesizing catalyst active site structures consisting of a dimeric metal–salen complex [14].

We also wished to investigate the stability of anchored grafted sites against leaching in protic solvent environments, and in particular wished to investigate whether there is additional stability garnered when using the oligomeric ligands (Scheme 1b) versus the monomeric ligand (Scheme 1a). When using Ti sites during olefin epoxidation catalysis, these protic solvent environments and accompanying organic hydroperoxide adsorption and alkoxide desorption events have previously been identified as major contributors to active-site aggregation and deactivation [3]. We use leaching tests that simulate these harsh conditions in order to compare and contrast the hydrolytic stability of the small monodentate (Scheme 1a) to a larger tetradentate (Scheme 1b) site attachment to the silica surface. We hypothesize that this stability may be enhanced both by virtue of increased denticity of attachment to the surface as well as the possibility of confinement via encapsulation of the larger assembly (Scheme 1b) within a mesopore on the silica support.

2 Experimental

2.1 Synthesis of the Tetrameric p-tBu-calix[4]arenes

The synthesis of oligomeric calixarenes 4, 5, and 6 was performed using a multiple-step strategy, which is summarized in Scheme 2. In the first step, commercially available p-tert-Bu-calix[4]arene was mono-alkenylated using the corresponding commercially available 1-bromo-alkene, in the presence of 1.3 equivalents of CsF as a weak base, following a general monoalkylation protocol (step I in Scheme 2) [15]. Yields of 1a–c were modest and in the range between 36 and 49 %, due to a low conversion rate and formation of disubstituted-calixarene byproducts. In the next synthetic step, calixarenes 1a–c were reacted with trichloromethylsilane in an intramolecular tripodal silicon protection coupling, that has been previously reported to proceed with high yield (step II In Scheme 2) [16]. Thus, mono-alkene-calixarenes 1a–c were reacted with 2 equivalents of trichloromethylsilane and 2 equivalents of triethylamine in dry toluene. The reaction mixture was stirred at room temperature for 18 h yielding the desired products 2a–c in high yields (77–84 %). This was performed to protect the three OH-groups, to allow a Pd-catalyzed Heck-type cross-coupling reaction in the next step, for formation of styrenic derivatives [17]. In the case of unactivated substrates such as alkenes possessing aliphatic alkyl chains, the reaction can be performed in sufficient yield by using the specific Pd-phosphine catalysts consisting of: Pd2(dba)3/P(t-Bu)3 [18], PdAc/Dave phosphine [19], and Tedicyp [20, 21] A multiple-Heck coupling reaction of 1,3,5 tribromobenzene with p-alkene-ethylbenzoate using Pd2(dba)3/t-Bu3P catalyst was previously reported to synthesize a trisubstituted product in 97 % yield [22]. In our approach, we used tetra-bromobenzenes as a connecting core for our tetrameric-calixarene product (step III in Scheme 2). Synthesis of the tetrameric calixarenes was performed by reaction of 1,2,4,5-tetrabromobenzene with 4.0 eq. of Si-capped-calixarene-alkenes 2a–c in the presence of 25–30 mol% of [Pd(t-Bu3P)2] and 4 eq. of the high boiling organic base Cy2NMe at 140 °C for 18 h. The reaction was monitored by [1] H NMR spectroscopy through the disappearance of alkene-proton resonances of the starting reactant, which reflects the end of the reaction. The resulting mixture was hydrogenated on Pd/(–C–) catalyst without further purification (step IV in Scheme 2). Full hydrogenation was achieved using 30 wt-% Pd/(–C–) catalyst in a methylene chloride/methanol (100/10: v/v) mixture, in a pressurized Parr bomb under hydrogen (50 atm) for 24 h following a general hydrogenation protocol [22]. Isolated yields of 3a–c were greater than 60 %. The final tetramers 4, 5 and 6 bearing twelve free OH-groups were obtained via deprotection, by treatment of the Si-protected precursor with excess TBAF in THF at room temperature for 18 h (step V in Scheme 2). Column chromatography yielded the final products as white solids.

2.2 Synthesis of Calixarene-Substituted Ti-Complexes and Immobilization on Inorganic Supports

The tetrameric complexes [{p-tBu-calix[4]-(O)3TiCl(CH2)x}4C6H2] (7–9; x = 5, 10, 11) can be synthesized by adding four equivalents of TiCl4 to a toluene solution of the corresponding tetrameric ligands 4–6. The precursor compounds readily react to form Ti-Ocalix bonds under elimination of HCl (see Scheme 3). After a few minutes no hydroxyl protons of the starting material could be detected by 1H NMR spectroscopy, and the desired tetrameric species are formed in high selectivities and yields.

Bridging methylene protons give rise to a set of four doublets in the 1H NMR spectrum between 3.23 and 5.01 ppm. The methylene groups of the alkyl chain bound directly to the fourth lower-rim oxygen of the calixarene ligand posesses a distinct triplet resonance at 4.41 ppm (for 7), 4.45 ppm (for 8), and 4.45 ppm (for 9). All other protons as well as some toluene molecules residing in the cavity of the calixarene units can be detected at the expected chemical shifts.

A further attempt to characterize the Ti-complexes of the calixarene-tetramer ligand by mass spectrometry failed due to their instability under the harsh conditions required. It was not possible to receive the corresponding molecular weight signals of the target complexes 7–9. Instead heavy fragmentation-units in the region between m/z = 3100 and 3600 indicate the initial formation of the tetrameric calixarene ligand.

2.3 Grafting of the Ti–Calixarene Complexes

The synthesized complexes 7–10 (Scheme 4) were grafted to a dehydroxylated silica support in order to synthesize solid catalysts. The synthesis of 10 has been previously published [23, 24].

The silica-support material was Selecto silica, (32–63 µm, pH range 7, 230–400 mesh) which had been pretreated at 800 °C for 4 h in order to achieve a partially dehydroxylated surface of the support. Ti–calixarene complexes were grafted by refluxing a slurry containing either 75 µmol of complex 10 or 18.75 µmol of complexes 7–9 per gram pretreated silica gel in toluene for 24 h. This was performed to maintain the same dilute coverage of grafted Ti–calixarene surface complexes in all materials, which in turn enables their direct comparison. In the lower panel of Scheme 4, the grafting of complexes 7–10 to the surface of pretreated silica is shown.

2.4 Catalytic Epoxidation of 1-Octene with TBHP

For epoxidation catalysis investigations, experiments were conducted in octane with 0.03 M TBHP (0.03 M, 0.60 mmol) in 20 mL octane and 25 mg of catalysts 11–13 at 50 and 80 °C. 1-octene was introduced in a 6.9-fold excess (0.021 M, 4.18 mmol) relative to TBHP. Samples were dried at room temperature overnight and for another 2 h at 120 °C in vacuo. Furthermore 200–300 mg of molecular sieve was added to the reaction-flask before conducting catalysis. All reagents were detected using gas chromatography (GC). No other products besides 1,2-epoxyocten and the by-product tert-butanol could be detected (Scheme 5).

3 Results and Discussion

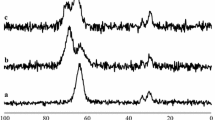

3.1 Characterization of Grafted Ti–Calix[4]arene Complexes on Silica

The calixarene and Ti surface density of materials 11–14 was determined by thermogravimetric analysis (TGA), and ICP-MS, and are summarized in Table 1 (Fig. 2). The ratio calixarene:titanium should be one, because each calixarene should define a coordination environment surrounding a single Ti center that it is associated to. In the case of the monomeric titanium-material 11 and the tetrameric materials 12–13 a nearly equimolar ratio of calixarene:Ti indicates that the molecule precursor was grafted properly, without fragmentation or decomposition of the starting materials. If this ratio deviates from one, free calixarene or titanium reside in the material. For material 14, the titanium content was significantly higher than expected. This suggests that some of the grafted Ti species in this material are not complexed to a calixarene, and requires further investigation as to the cause. Therefore, as a precaution, in the following investigation, 14 was not used or characterized further since its coordination environment surrounding grafted Ti centers may significantly deviate from the other materials where a calixarene ligand defines this environment. For thermogravimetric analysis, samples were heated from 20 to 800 °C with a ramp rate of 5 °C per min, up to 125 °C and a ramp rate of 10 °C per min steps until 800 °C. From 120 to 130 °C the temperature was held for 24 min to facilitate water evaporation. At a specific temperature the organic ligands begin to combust, and the weight loss was calculated in the area between 200 and 800 °C.

For all materials, the measured TGA loadings are slightly lower than the 75 µmol/g of calixarenes initially loaded in the reactor for grafting, which suggests that approximately 80 % of the calixarenes originally in solution consequently grafted during anchoring to the silica support.

The titanium loading of material 11 was independently confirmed by a UV–Vis assay for Ti sites involving the material after TGA-measurement. To do this, the remaining titanium was extracted off of the calcined sample (after TGA), and the remaining sample after TGA was suspended in 1 mL H2SO4 and stirred for 1 h at room temperature. Subsequently 0.14 mL H2O2 were added, and the sample was diluted to 10 mL of deionized water. The absorbance of the solution was measured with UV–Vis at λmax = 408 nm. Using the magnitude of intensity, the concentration of titanium could be calculated for 11 at 61 µmol/g by UV–Vis spectroscopy.

3.2 Catalytic Epoxidation of 1-Octene with TBHP

Catalysis experiments were conducted using TBHP (0.60 mmol, 0.03 M) in 20 mL octane and 25 mg of catalysts 11–13 at 50 and 80 °C with 1-octene (4.18 mmol, 0.021 M) as olefin. The turnover numbers (TON) as a function of time for the epoxidation of 1-octene catalyzed by materials 11–13 are plotted in Fig. 3 (50 °C) and in Fig. 4 (80 °C).

We aim to utilize epoxidation catalysis activity of the tetrameric materials 12–13 in order to lend support to the tetranuclear complexes indeed being bound in a tetrapodal fashion to the silica support, where all four calixarenes are grafted per molecule. As reported in previously, an unattached (homogenous) Ti-calixarene complex would be expected to exhibit no epoxidation catalytic activity compared to an immobilized Ti-site on silica [3], since a Ti–O–Si bond to the silica support imparts high activity and selectivity in this class of grafted-calixarene catalysts [25]. Thus for a material where not all four titanium-sites are immobilized to the support, a significantly lower per-Ti activity compared to the monomeric material 11 would be expected. Yet the similar 1-octene epoxidation activity at 50 °C for materials 11 (monomeric) and 13 (x = 10) [while catalyst 12 (x = 5) is slightly more active as discussed above] confirms the similar covalent attachment to the surface of silica for all Ti–calixarene complexes (Table 2). Such a uniform Ti(IV)–calixarene grafting in the tetrameric assembly of 12 and 13 is enabled by the relatively low surface coverage used during synthesis; for a different set of materials (not described here), which were synthesized using the same tetrameric complexes except at higher surface coverage (in excess of 150 micromole/g of Ti(IV)–calixarene sites), a lower per-Ti site activity was observed, which was interpreted to indicate incomplete grafting of Ti(IV)–calixarene sites at these higher coverages.

Figure 3 illustrates a slight effect of local site density of grafted surface sites on epoxidation catalysis, for 12 and 13 relative to 11, which enchances the activity for the immobilized Ti-oligomers compared to its monomeric analogue. Materials 12–13 exhibit a similar catalytic activity over a period of 7.5 h at 50 °C. Only a slightly higher activity for material 12 can be observed (factor 1.3). The shorter chain length of material 12 (x = 5) creates the highest local density of sites and apparently this high density of sites creates a microsolvation environment that is most favorable for catalysis.

In Fig. 4, the turnover number (TON) as a function of time for catalytic epoxidation at 80 °C for the same reaction and catalysts are illustrated. Again catalyst 12 shows the highest activity (factor 1.3) compared to monomeric catalyst 11 (Table 3).

We attribute the observed decrease in the catalytic activity due to competitive inhibition by the TBA (alcohol) product, even at these relatively low conversions. Previous experiments showed that the catalyst wasn`t decomposed because the catalysts could be recycled [3]. Table 4 summarizes the turnover frequencies (TOF) for all materials at both catalysis-temperatures.

While epoxidation of internal olefins such as cyclohexene proceeds to conversions and selectivities above 95 %, lower rates were observed for the epoxidation of terminal olefins such as 1-octene, and conversions decreased to 30 % and selectivities to 66 % respectively. The reason for the lower selectivity was previously discussed to be due to decomposition of TBHP mediated by the Ti catalyst under the applied reaction conditions [3, 8].

3.3 Investigations on the Robustness of Ti–Calixarene Grafting in Catalysts

To investigate the intrinsic hydrolytic stability of the anchored Ti sites, which has been previously attributed to be a limiting factor in catalyst deactivation under the protic conditions required for epoxidation catalysis using organic hydroperoxide [11], we compared the hydrolytic stability of the various catalysts by an intentional leaching test, in which catalyst is subjected to harsh protic-solvent conditions in a wash, in order to indirectly assess the solvothermal stability of the grafted Ti-calixarene active sites. These conditions are meant to represent an accelerated-aging surrogate for the actual conditions used in epoxidation catalysis under industrial conditions. For this purpose, the grafted materials 11–13 were stirred in a water/isopropanol (1:1) mixture. After 1 and 4 h, the materials were recovered by vacuum filtration, washed with water/isopropanol (1:1) and toluene, and dried for 3 h at 120 °C in vacuo. The treated catalysts were analyzed by TGA in order to determine the amount of the organic contents that leached from the silica surface when treated by this procedure. These aqueous alcohol conditions are relevant to catalysis because industrial epoxidation catalysis using organic hydroperoxide can involve excess alcohol as well as water [11] and because excess alcohol formed during organic hydroperoxide reaction can inhibit and deactivate catalysts (vide supra) via coordination to the grafted Ti sites.

Calixarene contents, before and after this leaching test are presented in Fig. 5. To calculate the weight loss caused by the leaching tests, the TGA data sets before and after leaching were compared. For a quantitative comparison, all plots were normalized with respect to a proper control sample (Fig. 5; Table 5), which consisted of silica treated with the same isopropanol aqueous solution under identical conditions (the control for this silica consisted of untreated silica).

The data in Fig. 5 demonstrates that the water/isopropanol treatment quantitatively leaches the organic content of 11 (monomeric material), which implies its hydrolytic instability. The slight negative weight loss reported in the top panel of Fig. 5 for 11 is due to a slight uncertainty in the weight loss remaining after hydrolytic treatment, due to the imperfect cancellation of the control material. This control material consisted of a silica support that was treated under the same hydrolytic-treatment conditions, and resulted in an isopropoxylated silica support. The control weight loss was essentially subtracted out from the calixarene-containing sample after hydrolytic treatment, and the slightly negative weight may result from a little more alkoxide capping on the control relative to the calixarene-anchored material. In this fashion the weight of calixarene in Fig. 5 for all materials is a slight lower bound.

In contrast, tetrameric materials 12 (x = 5) and 13 (x = 10) exhibit a higher resistance to leaching with 74 % (12) and 70 % (13), respectively, of the organic calixarene ligand being leached, and where some ligand is absolutely remaining following the leaching test. Furthermore, a leaching-test after 1 h showed similar results as summarized in Table 5, except for material 13. This is consistent with a uniform distribution of sites, except in 13, where there may be a slight distribution of sites, which possess a range of timescales for leaching. Hydrophobicity effects can be excluded because 12 (x = 5) and 13 (x = 10) exhibit a similar stability in the leaching test. If hydrophobicity would play a significant role one would expect that the material 12 would be less stable towards this hydrolytic treatment due to its shorter chain length making it less hydrophobic than its analogue with more extended alkyl tethers.

A possible explanation to account for the observed increased stability of the oligomeric sites might be due to the different binding modes of a titanium site towards the surface of the silica support, as shown in Fig. 6. In general there are two different possibilities for a Ti site to bind to the mesoporous silica support: trapped inside of a mesopore that is complementary in size and shape to the site or on the surface in an exposed fashion that is not enveloped by a mesopore. The first of these (metal centers located inside a silica mesopore) is shown in (Fig. 6 I and III). The second possibility (exposed on the surface of the supporting material) is shown in (Fig. 6 II and IV). A possible explanation for the higher stability observed for the tetradentate Ti-materials 12 and 13 might be due to the trapping of the tetrameric site within a silica mesopore as in III, which results in confined encapsulation of the hydrophobic site within a pore of the inorganic material, thereby rendering it less accessible to the polar protic reagents. In contrast, the much smaller monomeric site 11 is coordinated in a less confined and more labile fashion because its size is not complementary to the mesopores of the silica support. Indeed, for the monomeric material 11, there is no distinction between Ti-sites being bound within a pore or on the surface of the support, and hydrolytic treatment leaches quantitatively. The size of the silica mesopore is expected to play an important role. If the pore is too small the tetrameric calixarene material cannot be encapsulated inside a cleft, due to the steric demands of the bulky ligands. Our hypothesis therefore is that III in Fig. 6 explains the stability of the oligomeric calixarenes towards the leaching test. In summary, oligomeric grafted molecules 12 and 13 showed a greater stability towards hydrolytic treatment compared to the monodentate material 11.

Table 5 summarizes the amounts of the leached organic contents in all four materials after hydrolytic treatment.

4 Conclusion

The goal of this investigation was the patterning of grafted calix[4]arene sites on an inorganic support. In order to demonstrate attachment of all four entities within a molecule, we synthesized titanium(IV) complexes (Scheme 4) grafted on an inorganic support, and characterized these complexes in the epoxidation reaction of 1-octene with tert-butylhydroperoxide, since this reaction is sensitive to attachment of each Ti site to the silica surface. Furthermore the hydrolytic stability of these materials was also investigated and compared. Both tetrameric materials 12 and 13 feature very similar per-calexarene-site activities in the epoxidation reaction of 1-octene using organic hydroperoxide, compared with 11, and this result suggests complete anchoring of all Ti-calixarenes within the molecule. We observed a slight enhancement in the catalytic activity of 12 relative to 11 and 13 during olefin epoxidation using organic hydroperoxide. We also observed an enhancement in the hydrolytic stability for tetrameric-site materials 12 and 13 compared to the monomeric analogue 11. Altogether, the data presented here are consistent with patterned grafted sites in materials 12 and 13 when using tetameric calixarene molecules as ligands.

References

Khouw CB, Dartt CB, Labinger JA, Davis ME (1994) J Catal 149:195–205

Dartt CB, Davis ME (1996) Appl Catal A 143:53–73

Notestein JM, Iglesia E, Katz A (2004) J Am Chem Soc 126:16478–16486

Notestein JM, Andrini LR, Kalchenko VI, Requejo FG, Katz A, Iglesia E (2007) J Am Chem Soc 129:1122–1131

Nandi P, Matvieiev YI, Boyko VI, Durkin KA, Kalchenko VI, Katz A (2011) J Catal 284:42–49

Imamura S, Nakai T, Utani K, Kanai H (1996) J Catal 161:495–497

Notestein JM, Katz A (2006) Chem Eur J 12:3954–3965

Sheldon RA (1980) J Mol Catal 7:107–126

Sheldon RA, Van Doorn JA (1973) J Catal 31:427–437

Sheldon RA, Van Doorn JA, Schram CWA, De Jong AJ (1973) J Catal 31:438–443

Oyama ST (2008) In: Oyama ST (ed) Mechanisms in homogeneous and heterogeneous epoxidation catalysis. Elsevier, Amsterdam, pp 355–371

Helms B, Fréchet JMJ (2006) Adv Synth Catal 348:1125–1148

Nielsen LPC, Stevenson CP, Blackmond DG, Jacobsen EN (2004) J Am Chem Soc 126:1360–1362

Konsler RG, Karl J, Jacobsen EN (1998) J Am Chem Soc 120:10780–10781

Groenen LC, Ruël BHM, Casnati A, Verboom W, Pochini A, Ungaro R, Reinhoudt DN (1991) Tetrahedron 47:8379–8384

Shang S, Khasnis DV, Burton JM, Santini CJ, Fan M, Small AC, Lattman M (1994) Organometallics 13:5157–5159

Cabri W, Candiani I (1995) Acc Chem Res 28:2–7

Littke AF, Fu GC (2001) J Am Chem Soc 123:6989–7000

Xu H-J, Zhao Y-Q, Zhou X-F (2011) J Org Chem 76:8036–8041

Berthiol F, Doucet H, Santelli M (2003) Tetrahedron Lett 44:1221–1225

Fall Y, Berthiol F, Doucet H, Santelli M (2007) Synthesis 11:1683–1696

Lengkeek NA, Boulos RA, McKinley AJ, Riley TV, Martinac B, Stewart SG (2011) Aust J Chem 64:316–323

Friedrich A, Radius U (2004) Eur J Inorg Chem 21:4300–4316

Zanotti-Gerosa A, Solari E, Giannini L, Floriani C, Re N, Chiesi-Villa A, Rizzoli C (1998) Inorg Chim Acta 270:298–311

Crocker M, Herold RHM, Guy Orpen A, Overgaag MTA (1999) Dalton Trans 21:3791–3804

Acknowledgments

We acknowledge the LyondellBasell Corporation and the U.S. Department of Energy Basic Energy Sciences (DE-FG02-05ER15696) for financial support, and Dr. Ying-Jen Wanglee for technical contributions to this Project.

Author information

Authors and Affiliations

Corresponding authors

Rights and permissions

About this article

Cite this article

Winner, L., Daniloff, G., Nichiporuk, R.V. et al. Patterned Grafted Lewis-Acid Sites on Surfaces: Olefin Epoxidation Catalysis Using Tetrameric Ti(IV)–Calix[4]arene Complexes. Top Catal 58, 441–450 (2015). https://doi.org/10.1007/s11244-015-0385-x

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11244-015-0385-x