Abstract

Reactions of (3,5-dimethylpyrazolylmethyl)pyridine (L1) and (3,5-diphenylpyrazolylmethyl)pyridine (L2) with either [PdCl2(NCMe)2] or [PdClMe(COD)] afforded the respective neutral palladium complexes, [PdCl2(L1)] (1), [PdCl2(L2)] (2) and [PdClMe(L1)] (3). Treatment of complex 1 with equimolar amounts of PPh3 or PPh3/NaBAr4 produced the corresponding cationic complexes [Pd(L1)ClPPh3]Cl (4) and [Pd(L1)ClPPh3]BAr4 (5), respectively. Complexes 1–5 formed active catalysts in hydrogenation of alkenes and alkynes. Isomerization reactions were predominant in the hydrogenation reactions of terminal alkenes, while hydrogenation of alkynes involved a two-step process via alkene intermediates prior to the formation of the respective alkenes. The lack of induction periods in the hydrogenation reactions in addition to pseudo-first-order kinetics with respect to the substrates established the homogeneous nature of the active species.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Alkenes and alkynes constitute some of the most useful building blocks or components of the petrochemical, fine chemical, agrochemicals and pharmaceutical industries [1]. This is mainly due to their high reactivity and ability to be transformed to wide range of relevant products [2–7]. One of the most common transformations employed both in industry and research to convert alkenes and alkynes to other industrial products is hydrogenation using metal-based catalysts and molecular hydrogen, commonly referred to as high pressure hydrogenation [8, 9].

Several platinum group metal complexes of Ru, Rh, Ir, Pt and Pd have been extensively studied for the catalytic molecular hydrogenation of alkenes and alkynes under both heterogeneous and homogeneous conditions [5, 10, 11] Palladium complexes, in particular the Lindlar catalyst, have been known as effective catalysts for the hydrogenation of alkenes and alkynes [1, 11, 12]. The preference of palladium complexes in hydrogenation reactions is mainly due to their high surface-to-volume ratio compared to other platinum group metal complexes [13]. To date, most hydrogenation catalysts based on palladium are heterogeneous in nature, with few reports of promising homogeneous catalysts [14–16].

One group of palladium(II) complexes that have been widely used as homogeneous catalysts in alkene and alkyne hydrogenation reactions are those derived from phosphine-donor ligands [17–19]. For example, Drago and Pregosin [20] reported bidentate (2,5-dimethylphospholano)benzene palladium(II) complexes as effective hydrogenation catalysts of alkenes. Despite the success of phosphine-donor palladium catalysts in olefin hydrogenation reactions, a number of these catalysts are relatively unstable and sensitive to moisture and air [19]. Thus, the design and development of alternative ligand systems that could offer more stability as well as comparable catalytic activity to the phosphine compounds are gaining momentum. In one such report, Yilmaz et al. [21] employed S^O-chelated palladium acetate complexes as homogeneous catalysts in high pressure hydrogenation of styrene and 1-octene.

Nitrogen-donor palladium complexes also represent another promising alternative to the well-established phosphine-donor complexes due to their ease of syntheses, stability and lower sensitivity to moisture and air [22–27]. Examples of such complexes reported in the literature include bis(arylimino)acenaphthene palladium(0) [28] and pyridine-2-carbaldimine Pd(0) complexes [22] which have been shown to be very stable under hydrogen pressure and display excellent selectivity in the hydrogenation of a wide range of alkenes and alkynes. In this current contribution, we report the syntheses of palladium(II) complexes supported by (pyrazolylmethyl)pyridine ligands and their applications as catalysts in molecular hydrogenation of alkenes and alkynes. Detailed studies on the kinetics and chemoselectivity of these hydrogenation reactions have been performed and are herein discussed.

Experimental section

Materials and instrumentation

All reactions were carried out under nitrogen atmosphere using a dual vacuum/nitrogen line and standard Schlenk techniques unless stated otherwise. Solvents were dried and distilled under nitrogen in the presence of suitable drying agents. PdCl2 (59 % Pd) and PPh3 (99 %) were purchased from Sigma-Aldrich while the sodium salt, NaBAr4 {Ar4 = (3,5-(CF3)2C6H3)4} (95 %), was obtained from Boulder Scientific and used without any further purification. All solvents were of analytical grade and were purchased from Merck Chemicals and dried using appropriate techniques. The compounds (2-(3,5-dimethylpyrazol-1-ylmethyl)pyridine (L1), 2-(3,5-diphenylpyrazol-1-ylmethyl)pyridine (L2) [29] and complexes [Pd(L1)Cl2] (1), [Pd(L2)Cl2] (2) and [Pd(L1)MeCl] (13) were prepared according to the literature procedures [30]. NMR spectra were recorded on a Bruker 400 Ultrashield instrument at room temperature in CDCl3 and DMSO-d6 solvents. The 1H (400 MHz) and 31P{1H} (162 MHz) chemical shifts are reported in δ (ppm) and referenced to the residual proton in the solvents for 1H and 85 % H3PO4 for 31P nuclei. All coupling constants (J) are measured in Hertz (Hz). Elemental analyses were performed on a Thermal Scientific Flash 2000, and mass spectra were recorded on an LC Premier micro-mass Spectrometer. Electron microscopy analyses were done on a JEOL JEM-1400X transmission electron microscope at the school of life sciences, University of KwaZulu-Natal.

Synthesis of cationic palladium(II) complexes

Synthesis of [{2-(3,5-dimethylpyrazol-1-ylmethyl)pyridine}PdPPh3Cl]Cl (4)

To a suspension of 1 (0.09 g, 0.24 mmol) in CH2Cl2 (5 mL), a solution of PPh3 (0.07 g, 0.27 mmol) in CH2Cl2 (5 mL) was added to give a light yellow precipitate. The mixture was stirred for 12 h and filtered to isolate compound 4 as light yellow solid. Yield = 0.10 g (62 %). 1H NMR (DMSO-d6): δ 2.40 (s, 3H, CH3, pz); 2.43 (s, 3H, CH3, pz); 5.79 (d, 2H, py-CH2-pz) 6.16 (d, 2H, pz, 3 J HH = 8.0 Hz); 7.66–7.61 (m, Ph); 7.94 (t, 1H, py, 3 J HH = 7.2 Hz); 8.12 (d, 1H, py, 3 J HH = 8.0 Hz); 8.79(d, 1H, py, 3 J HH = 8.4 Hz. 31P {H} NMR (DMSO-d6): δ 28.88 (s, 1P, PPh3). Anal. Calcd. For C29H28Cl2N3PPd: C, 55.6; H, 4.5; N, 6.7 %. Found C, 55.7; H, 4.0; N, 5.3 %. Positive mode (ESI–MS) m/z 525.94 (M+–ClMe2, 100).

Synthesis of [{2-(3,5-dimethylpyrazol-1-ylmethyl)pyridine} PdClPPh3]BAr4 (5)

To a suspension of 1 (0.10 g, 0.27 mmol) in CH2Cl2 (10 mL), PPh3 (0.08 g, 0.30 mmol) and NaBAr4 (Ar4 = 3,5-(CF3)2C6H3) (0.22 g, 0.27 mmol) were added and stirred under inert atmosphere for 12 h. The mixture was filtered and concentrated to approximately 3 mL. Hexane (10 mL) was then added to precipitate 5 as a yellow crystalline solid. Recrystallization of 5 using CH2Cl2/Hexane solvent mixture afforded single crystals suitable for X-ray analysis. Yield = 0.26 g (65 %). 1H NMR (CDCl3): δ 2.21 (s, 3H, CH3, pz); 2.28 (s, 3H, CH3, pz); 5.27 (d, 2H, py-CH2-pz) 6.06 (d, 2H, pz, 3 J HH = 8.0 Hz); 7.48–7.53 (m, Ph); 7.51 (s, 8H, BAr4) 7.71 (s, 4H, BAr4); 7.89 (t, 1H, py, 3 J HH = 7.2 Hz); 8.65 (d, 1H, py, 3 J HH = 8.0 Hz); 8.93(d, 1H, py, 3 J HH = 8.4 Hz. 31P {H} NMR (CDCl3): δ 27.85 (s, 1P, PPh3). Anal. Calcd. For C61H40ClF24N3PPd: C, 50.4; H, 2.8; N, 2.9 %. Found: C, 50.4; H, 2.9; N, 3.1 %. Positive mode (ESI–MS) m/z 555.36 (M+, –Cl, 40).

Hydrogenation reactions of alkenes and alkynes

In a typical experiment, styrene (0.73 mL, 8.00 mmol), catalyst 1 (6 mg, 0.02 mmol) equivalent to a substrate-to-catalyst ratio of 400 and toluene (50 mL) were introduced into a stainless steel Parr autoclave (400 mL) fitted with an internal stirring and cooling system. The solution mixture was purged with hydrogen (three times) before the autoclave was finally charged with hydrogen and the pressure maintained at 5 bar at a constant temperature of 30 °C. The stirring speed was set to 600 rpm and stirring started to initiate the reaction. After the reaction period, excess pressure was vented off, samples withdrawn, filtered using 0.45-µm micro-filters and analyzed by Varian CP-3800 GC (ZB-5HT column 30 m × 0.25 mm × 0.10 µm) to determine the consumption of styrene. Ethyl benzene (97 %), cis-2-hexene (98 %), trans-2-hexene (97 %), octane (98 %) were received from Sigma-Aldrich and used as authentic standards to establish the identity of hydrogenation products. Percentage conversion of styrene to ethyl benzene was determined by comparing the peak intensities of styrene and ethyl benzene. Kinetics of the hydrogenation reactions were performed by monitoring the consumption of the substrates at regular time intervals. The rate constants for each experiment were derived from plots of ln[substrate]0/[substrate]t versus time (where [substrate]o = initial concentration of substrate at time 0 and [substrate]t = concentration of styrene at time t.

Results and discussion

Synthesis and characterization of new cationic palladium(II) 4 and 5 complexes

The compounds (2-(3,5-dimethylpyrazol-1-ylmethyl)pyridine (L1) and 2-(3,5-diphenylpyrazol-1-ylmethyl)pyridine (L2) and their respective neutral palladium(II) complexes, [Pd(L1)Cl2] (1), [Pd(L2)Cl2] (2) and [Pd(L1)MeCl] (3) were synthesized following reported literature procedures [29, 30]. The corresponding cationic palladium(II) complexes [Pd(L1)PPh3Cl]Cl (4) and [Pd(L1)PPh3Cl]BAr4 (5) were synthesized as shown in Scheme 1. Thus, treatment of a suspension of the neutral complex 1 with one molar equivalent of either PPh3 or PPh3/NaBAr4 afforded the corresponding cationic compounds 4 and 5, respectively (Scheme 1).

The new cationic palladium(II) complexes 4 and 5 were characterized by 1H NMR, 13C{H} NMR and 31P{H} NMR spectroscopies (Figures S1 and S2) and elemental analyses. For example, the 1H NMR spectrum of complex 5 (Figure S1) showed pyridine (N–CH) protons at 8.93 ppm compared to 8.53 ppm for the corresponding ligand, L1. 31P NMR spectra of complex 5 showed a singlet peak at 27.85 ppm (Figure S2) consistent with a coordinated PPh3 ligand [31, 32]. Micro-analyses data of compounds 4 and 5 were in good agreement with the proposed empirical formulae and confirmed their purity.

Hydrogenation reactions of styrene catalyzed by complexes 1–5

Preliminary investigations of the (pyrazolylmethyl)pyridine palladium(II) complexes 1–5 as catalyst precursors in hydrogenations of alkenes were performed using styrene as a model substrate. In a typical reaction, styrene (0.73 mL, 8.00 mmol), complex 1 (0.02 mmol, 0.25 mol %, substrate-to-catalyst ratio of 400), H2 pressure (5 bar) in toluene (50 mL) were used at stirring speed of 600 rpm (Scheme 2).

All the complexes showed significant catalytic activities in the hydrogenation of styrene to afford 100 % ethyl benzene and conversions between 17 and 98 % within 2 h (Figure S3). Control experiments conducted without the use of any complex under similar reaction conditions afforded conversions of 3 and 6 % within 1 and 6 h, respectively, confirming that complexes 1–5 were responsible for the observed higher conversions. After establishing that complexes 1–5 form active catalysts in hydrogenation of alkenes, detailed kinetics and chemoselectivity studies were conducted to evaluate the effect of catalyst structure, identity of substrate and reaction parameters on these hydrogenation reactions. The subsequent sections systematically present the findings of these investigations.

Effect of catalyst structure on the kinetics of hydrogenation of styrene

In order to investigate the effect of catalyst structure, hydrogenation reactions were carried out for all the complexes 1–5, using styrene as a model substrate over a 2 h period (Table 1). To determine the rate constants (k obs) for each complex and the order of reactions with respect to styrene substrate, plots of ln[Sty]0/[Sty]t versus time were constructed (Figure S4). The linearity of the graphs established that the hydrogenation reactions using complexes 1–5 as catalysts obey pseudo-first-order kinetics with respect to styrene substrate as shown in Eq. 1.

The observed rate constant (k obs) for each complex was thus derived from the gradients of the plots in Figure S4 (Table 1). The cationic complex 5 showed the highest catalytic activity, exhibiting k obs of 1.508 h−1 compared to its neutral analog, complex 1 (k obs of 0.787 h−1). Interestingly, the cationic complex 4, bearing the Cl− counter anion showed lower catalysis (k obs = 0.935 h−1) compared to 5, containing the BAr4 counter anion. This trend clearly demonstrated the significance of complex solubility in controlling their respective catalytic activities. Complex 5 showed the highest solubility in most organic solvents in comparison with complexes 1–4. Indeed, the methylated palladium(II) complex 3 showed better solubility than 1, 2 and 4, and concomitant higher catalytic activity (Table 1, entries 1–5). In addition, replacing the smaller pyrazolyl methyl substituent in 1, with a bulkier phenyl group in 2, resulted in an increase in k obs from 0.787 h−1 (TOF = 152 h−1) to 1.027 h−1 (TOF = 174 h−1).

Generally the complexes showed good stability under the specified hydrogenation conditions as shown by the minimum amount of zero-valent palladium nanoparticles formed. Indeed, attempts to isolate the nanoparticles to catalyze the hydrogenation of styrene did not give any catalytic activity. This was, however, consistent with the pseudo-kinetics of the reactions and lack of induction periods which largely supported homogeneous nature of the active species.

Effect of catalyst concentration and hydrogen pressure on the kinetics of hydrogenation reactions of styrene

In order to establish the effects of catalyst concentration and pressure on the hydrogenation reactions of styrene, the hydrogenation reactions were carried out at different substrate-to-catalyst ratios and hydrogen pressures using complex 2. The substrate-to-catalyst ratio was thus varied from 400 to 1200 at constant initial concentration of styrene (Table 1, entries 2, 6–8). Plots of ln[Sty]0/[Sty]t vs time at various catalyst concentrations were linear (Figure S5). From the data in Table 1, it was evident that the rates of hydrogenation reactions were dependent on the substrate-to-catalyst ratio (Table 1, entries 2, 6–8). For example, k obs of 1.027 h−1 (TOF = 174 h−1) and 0.420 h−1 (330 h−1) were observed at substrate-to-catalyst ratios of 400 and 1200, respectively (Table 1, entries 2 and 8). However, it is important to note that higher TOFs were observed at lower catalyst concentrations (higher substrate-to-catalyst ratios) despite the lower rate constants. This observation indicated that increasing catalyst loading did not increase the catalytic activity by a similar magnitude. Thus, from these experiments, lower catalyst loading (high substrate-to-catalyst ratios of 800 and 1200) was qualitatively superior since they give higher turnover frequencies.

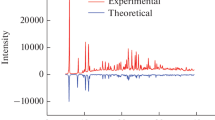

Further plots of the −ln(k obs) versus −ln[2] enabled us to establish the order of reaction with respect to catalyst 2 (Fig. 1a). From the slope of the graphs, the order of the reaction with respect to catalyst was obtained as 1.025 ± 0.101 h−1. Therefore, the hydrogenation reactions of styrene follow pseudo-first-order kinetics with respect to catalyst 2 and the rate law may be represented as given in Eq. 2. In addition, the nonzero y-intercept at −6.83 is consistent with the hydrogenation reactions taking place in the absence of any catalyst [33].

The effect of hydrogen pressure on the kinetics of the hydrogenation reactions of styrene was also investigated using complex 2 by varying the pressure from 5 to 12.5 bars. A plot of ln [Sty]0/[Sty]t versus time at different hydrogen pressures gave linear graphs (Figure S6). The k obs were found to increase with increase in hydrogen pressure. As an illustration, k obs of 1.027 and 2.353 h−1 were reported at hydrogen pressures of 5 and 10 bar, respectively (Figure S6). Construction of a plot of ln k obs versus hydrogen pressures allowed us to determine the order of reaction with respect to hydrogen concentration as 0.16 ± 0.01 using catalyst 2 (Fig. 1b). Fractional and very low reaction orders with respect to hydrogen concentration are indicative of a fast dissociative adsorption process followed by surface reaction, which is likely to be the rate determining step [34, 35]. Thus, the overall rate law for the hydrogenation of styrene catalyzed by complex 2 can be represented by Eq. 3.

Influence of alkene and alkyne substrates on the kinetics of hydrogenation reactions

The scope of alkene and alkyne substrates that could effectively undergo hydrogenation using complex 2 as a catalyst was studied using 1-hexene, 1-octene, 1-hexyne, 1-octyne and phenylacetylene (Table 2). To determine the k obs for each substrate, plots of ln[substrate]0/[substrate]t versus time were constructed (Figure S7). From Table 2, it was evident that the nature of the alkene/alkyne substrate affected both the catalytic activity and product distribution of catalyst 2 in the respective hydrogenation reactions. Generally, alkynes showed higher reactivity compared to the corresponding alkenes. For example, k obs of 6.657 and 1.631 h−1 were recorded for 1-hexyne and 1-hexene, respectively (Table 2, entries 1 vs. 5). This was expected and has been attributed to the high reactivity of the triple bonds in alkynes compared to double bonds in alkenes [36–39]. The substrate reactivities were also found to be dependent on the alkene chain length. For instance, k obs of 1.631 and 1.150 h−1 were obtained for 1-hexene and 1-octene substrates, respectively (Table 2, entries 5 vs. 6). This phenomenon is largely associated with the poor coordination ability of the longer chain alkenes to the active metal center [4, 5]. Interestingly, for the alkyne series, both 1-hexyne (6.657 h−1) and 1-octyne (6.593 h−1) showed similar rate constants (Table 2, entries 1 vs. 2).

The chemoselectivity and regio-selectivity of the hydrogenation reactions catalyzed by complex 2 were also extensively investigated. Hydrogenation reactions of terminal alkenes were observed to produce both the respective alkenes and internal isomers. Thus, it was evident that there occurred tandem hydrogenation and isomerization reactions (Figure S8). For example, hydrogenation reactions of 1-hexene produced final compositions of hexanes, cis-2-hexene and trans-2-hexene in yields of 40, 18 and 42 %, respectively, within the 2 h period investigated (Fig. 2a). It is therefore clear that catalyst 2 favored isomerization (60 % internal isomers) over hydrogenation (40 % hexanes) reactions. The larger composition of the trans-2-hexene could be assigned to the steric restrictions present in the cis-isomer [40, 41]. Tandem hydrogenation and isomerization reactions are typical of palladium(II) based catalysts due to the presence of empty d-orbitals which interact with the π-orbitals of the alkenes in activating the adjacent C–H bonds [42].

We also used phenylacetylene substrate to study the product distribution of alkynes over time using complex 2. The choice of phenylacetylene was due to the inability of its alkene intermediate (styrene) to undergo isomerization reactions. Two main products ethyl benzene and styrene were produced over the 2 h reaction period (Fig. 2b). From Fig. 2b, it was clear that the concentration of ethyl benzene in the reaction mixture was minimal until all the phenylacetylene was reduced to styrene. This was followed by gradual increase in the composition of ethyl benzene to a maximum of 86 % and concomitant decrease in the amount of styrene to 14 %. This indicated that hydrogenation reactions of phenylacetylene occurred in two steps: first hydrogenation to styrene followed by the hydrogenation of styrene to ethyl benzene (Scheme 3) [7, 43–45]. Thus, using catalyst 2, it is possible to selectively produce alkenes from alkynes by controlling the hydrogenation reaction time.

Conclusions

We have successfully demonstrated that neutral and cationic Pd(II) complexes of (pyrazolylmethyl)pyridine ligands form active catalysts in hydrogenation reactions of alkenes and alkynes under mild conditions. The catalysts showed 100 % selectivity in the hydrogenation of styrene to form ethyl benzene. On the other hand, isomerization reactions of terminal alkenes to internal alkenes were favoured over hydrogenation reactions. Hydrogenations reactions of alkyne substrates produced alkenes as intermediates prior to the formation of alkenes. Kinetics studies of the hydrogenation reactions reveal pseudo-first-order dependency on the catalysts and substrates and have established the homogenous nature of the active species.

Supporting information

Supplementary materials contain analytical, spectroscopic characterization data of complexes 1–5, kinetics plots and GC chromatograms of the products

References

Corvaisier F, Schurman Y, Fecant A, Thomazeau C, Raybaud P, Toulhoat H, Farrusseng D (2013) J Catal 307:352–361

Vallianatou KA, Frank DJ, Antonopoulou G, Georgakopoulos S, Siapi E, Zervou M, Kostas ID (2013) Tetrahedron Lett 54:397–401

Wang D-S, Chen Q-A, Lu S-M, Zhou Y-G (2012) Chem Rev 112:2557–2590

Hoelscher HE, Poynter WG, Weger E (1954) Chem Rev 54:575–592

Harmon R, Gupta SK, Brown DJ (1973) Chem Rev 73:21–52

Schmidt O (1933) Chem Rev 12:363–417

Jackson SD, Shaw LA (1996) Appl Catal A Gen 134:91–99

Negeshi E (2002) Handbook of organopalladium chemistry for organic synthesis, vol 2. Wiley & Sons, New York, pp 2753–2758

Devries JG, Elsevier CJ (2007) The handbook of homogeneous hydrogenation, vol 1. Wiley, Weinheim

Nerozzi F (2012) Platin Met Rev 56:236–241

Chen Q-A, Ye Z-S, Duan Y, Zhou Y-G (2013) Chem Soc Rev 42:497–511

Zhang Y, Liao S, Xu Y, Yu D (2000) Appl Catal A Gen 192:247–251

Harraz FA, El-Hout SE, Killa HM, Ibrahim IA (2012) J Catal 286:184–192

Ulan JG, Maier WF (1987) J Org Chem 52:3132–3142

Liua R-J, Croziera PA, Smith CM, Huculc DA, Blacksond J, Salaita G (2005) Appl Catal A Gen 282:111–121

Aramendia MA, Borau V, Jimenez C, Marinas JM, Porras A, Urbano FJ (1997) J Catal 172:46–54

Osborn JA, Jardine FH, Young JF, Wilkinson G (1966) J Am Chem Soc A 1711–1732

Hoveyda AH, Evans DA, Fu GC (1993) Chem Rev 93:1307–1370

van Leeuwen PWNM, Chadwick JC (2005) Homogeneous catalysis, activity-stability-deactivation. Wiley, Weinheim

Drago D, Pregosin PS (2002) Organometallics 21:1208–1215

Yilmaz F, Mutlu A, Unver H, Kurtca M, Kani I (2010) J Supercrit Fluids 54:202–209

van Laren MW, Duin MA, Klerk C, Naglia M, Rogolino D, Pelagatti P, Bacchi A, Pelizzi C, Elsevier CJ (2002) Organometallics 21:1546–1553

Chan K-T, Tsai Y-H, Lin W-S, Wu J-R, Chen S-J, Liao F-X, Hu C-H, Lee HM (2010) Organometallics 29:463–472

Borriello C, Ferrara ML, Orabona I, Panunzi A, Ruffo F (2000) J Chem Soc Dalton Trans 2545–2550

Dayan O, Demirmen S, Özdemir N (2015) Polyhedron 85:926–932

Dayan S, Arslan F, Ozpozan NK (2015) Appl Catal B Environ 164:305–315

Gulcemel S, Gokce AG, Cetinkaya B (2013) Dalton Trans 42:7305–7311

van Laren MW, Elsevier CJ (1999) Angew Chem Int Ed 38:3715–3717

Watson AA, House DA, Steel PJ (1987) Inorg Chim Acta 130:167–176

Ojwach SO, Guzei IA, Darkwa J (2009) J Organomet Chem 694:1393–1399

Zeng F, Yu Z (2009) Organometallics 28:1855–1862

Serratrice M, Cinellu MA, Maiore L, Pilo M, Zucca A, Gabbiani C, Guerri A, Landini I, Nobili S, Mini E, Messori L (2012) Inorg Chem 51:3161–3171

Walling C, Bollyky L (1964) J Am Chem Soc 86:3750–3752

Rheinlander PJ, Herranz J, Durst J, Gasteiger HA (2014) J Electrochem Soc 161:F1448–F1457

Kim MH, Lee EK, Jun JH, Kong SJ, Han GY, Lee BK, Lee T-J, Yoon KJ (2004) Int J Hydrogen Energy 29:187–193

Teschner D, Revay Z, Borsodi J, Havecker M, Knop-Gericke A, Schlogl R, Milroys D, Jackson SD, Torres D, Sautet P (2008) Angew Chem Int Ed 47:9274–9278

Yoshida H, Zama T, Fujita S, Panpranot J, Arai M (2014) RSC Adv 4:24922–24928

Costa M, Pelagatti P, Pelizzi C, Rogolino D (2002) J Mol Catal A Chem 178:21–26

Bond GC (1966) Discuss Faraday Soc 41:200–214

Okitsu K, Yue A, Tanabe S, Matsumoto H (2000) Chem Mater 12:3006–3011

Hallman PS, McGavey BR, Wilkinson G (1968) J Chem Soc A 3143–3150

Bernas A, Kumar N, Mäki-Arvela P, Kul’kova NV, Holmbom B, Salmi T, Murzin DY (2003) Appl Catal A Gen 245:257–275

Kamiguchi S, Takaku S, Kodomari M, Chihara T (2006) J Mol Catal A Chem 260:43–48

Carruther W, Coldham I (2004) Modern methods of organic synthesis, 4th edn. Cambridge University Press, Cambridge

Dobrovolna Z, Kacer P, Cerveny L (1998) J Mol Catal A Chem 130:279–284

Acknowledgments

The authors are grateful for the financial support received from the University of KwaZulu-Natal.

Author information

Authors and Affiliations

Corresponding author

Electronic supplementary material

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Ojwach, S.O., Ogweno, A.O. Neutral and cationic (pyrazolylmethyl)pyridine palladium(II) complexes: kinetics and chemoselectivity studies in hydrogenation of alkenes and alkynes. Transit Met Chem 41, 539–546 (2016). https://doi.org/10.1007/s11243-016-0050-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11243-016-0050-7