Abstract

Unfavorable mobility ratio and reservoir heterogeneities contribute to water fingering phenomenon that leads to relatively low oil recovery factors in heavy oil fields. Experiments have shown that injection of oil-in-water emulsions can be used as an effective enhanced oil recovery (EOR) method, leading to substantial increase in the volume of oil recovered. Capillary-driven mobility alteration of the water phase by emulsion drops leads to not only more uniform macroscopic reservoir sweep, but also a pore scale reduction in the residual oil saturation. Despite recent developments, fundamental aspects of dilute oil-in-water emulsion flow through porous media and its application as an EOR method are still not clear. Experiments were performed in a 1D flow configuration using silica sandpacks and sandstone cores to determine the effect of permeability, emulsion drop size, dispersed phase concentration and size of injected emulsion bank on the volume of displaced oil, a crude heavy oil from Campos Basin (\(20^{\circ }\) API). X-ray computerized tomography images obtained during experiments in a Castlegate sandstone block in a 1/4 5-spot configuration revealed that emulsion acts both in the macroscale and pore scale, improving the macroscopic sweep and lowering the residual oil saturation.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

Oil and gas will keep their importance as one of the main sources of energy in the next decades. An important part of their future production will come from unconventional sources, such as shale, tight formations and viscous oil reservoirs.

The production of high-viscosity oils in onshore fields using different recovery strategies as steamflood, solvent injection and in situ combustion may lead to a large enough volume of recovered oil to cover the production cost and investment. In offshore high-viscosity oilfields, generally, water injection is the only economic viable alternative. Taking into account unfavorable mobility ratio and reservoir heterogeneities, the final oil recovery factors for these cases are, typically, \({<}\)20 %. Different enhanced oil recovery (EOR) methods are considered aiming the reduction of the mobility ratio between the water and oil phases to improve the efficiency of reservoir sweep or to mobilize trapped residual oil behind the displacement front (Alvarado and Manrique 2010). The addition of polymers and other additives into a lower-viscosity water phase can mitigate the unfavorable mobility ratio. One way to reduce residual oil saturation is to lower the interfacial tension between the water and oil phases using surfactants. Different alternatives to polymer and surfactant flooding have been studied with the goal of improving oil recovery at a minimum operational cost, including the injection of oil–water emulsions. Micronscale suspended drops in a continuous phase offer a mobility control mechanism based on capillary resistance, in contrast with viscosity enhancement of the displacing phase (Tallakstad et al. 2009).

McAuliffe (1973a, b) presented results of stable emulsion injection at Midway Sunset Oilfield. A 33,000 bbl emulsion bank (14 % oil content) was injected in this area. The production wells were monitored measuring the produced oil and water flow rate. The results showed a reduction in the water production and produced water salinity rise, indicating additional oil mobilization of previously unswept areas. The additional oil recovery was estimated in 55,000 bbl. Despite the promising results, the project was not converted to a full field application. Experiments designed to analyze the injection of oil–water emulsion after conventional water flooding have shown a higher oil recovery factor (Sarma et al. 1998; Mandal et al. 2010). Baldygin et al. (2014) evaluated the use of water-alternate-emulsion injection to displace oil from a sandpack using different water/emulsion flooding ratios. The results suggests that at least 20 % more oil is displaced with the proposed strategy compared to traditional flooding process.

It has been clear that the full understanding and design of enhanced oil recovery processes based on emulsion flooding rely on better understanding the flow of emulsions through porous media and the associated oil displacement mechanisms. Flow of emulsions through porous media is complex and not fully understood. Three traditional models have been used to describe flow of emulsions in porous media: (a) bulk viscosity (Alvarado and Marsden 1979; Abou-Kassem and Ali 1995; b) droplet retardation model (Devereux 1974) and (c) filtration model (Soo and Radke 1986a, b).

The bulk viscosity model considers the emulsion as a single-phase non-Newtonian fluid. This is the same approach used to model the flow of polymeric solutions in porous media. The viscosity at each position is written as a function of an average local shear rate. The model is adequate to describe only the flow of concentrated emulsions with average drop size smaller than the average pore throat diameter. The droplet retardation model introduces one term to consider the flow restriction experienced by an oil droplet as it passes through a pore throat. The increased flow resistance is modeled as a local permeability reduction. The main limitation of this model is that it predicts that porous media permeability returns to its original level if clean water is injected after emulsion. Experimental results have shown that the permeability reduction remains even after several pore volumes of clean water injected at the same flow rate.

Soo and Radke (1986a, b) adapted the filtration theory to describe the flow of dilute emulsions in porous media. In their approach, the impairment of porous media is a combination of two mechanisms: (a) pore blockage (size exclusion) and (b) droplet retention caused by interactions between oil drop and pore walls. These mechanisms are correlated. For example, if some droplet retention occurs, there is a pore areal reduction that can potentialize a future pore blockage event at the same place. Both processes cause irreversible local permeability reduction. The global effect is modeled by the introduction of a filtration coefficient. These models are not able to describe an important aspect of emulsion flow in porous media: The permeability reduction caused by the oil drops is more pronounced at smaller differential pressure or lower capillary number. Moreover, the parameters associated with the model have to be obtained by macroscopic flow measurements, and new measurements would be necessary for each different porous medium.

Romero et al. (2011) proposed a capillary network model to seek macroscopic flow description based on the physics of emulsion flow at the pore scale. Oil droplet flow through a pore throat is more complex than the transport of solid particles. Solid particle are captured in a pore throat mainly by a size exclusion mechanism. Oil drops can deform and flow through pore throats smaller than their sizes. The mobility change is the result of competition between viscous and capillary forces. For drops larger than the pore throat diameter, there is a critical capillary number below which the mobility is drastically reduced (Cobos et al. 2009). Despite the simplifying hypothesis used in the proposed capillary network model, its predictions agree with the nonlinear pressure drop—flow rate relation obtained experimentally in the flow of oil–water emulsions through sandstone cores of different permeabilities. Recent results clearly relate macroscopic flow behavior to pore-scale flow of emulsion (Moradi et al. 2014).

This capillary dependence was observed in experiments of oil displacement by emulsion injection reported by Guillen et al. (2012a). Residual oil was mobilized after the injection of an emulsion slug following water injection. The amount of mobilized oil during emulsion injection was much smaller at high flow rate (high capillary number). Guillen et al. (2012b) have shown that emulsion flow behavior in porous media affects the displacement of oil by a water phase in a multiscale manner. Pore blockage by the dispersed phase of an emulsion diverts the flow path at the pore level, dislodging previously trapped oil ganglia, leading to changes in the residual oil saturation. In macroscopic terms, pore blockage by emulsion drops reduces the aqueous-phase mobility, leading to a more uniform sweep. The multiscale effect of emulsion injection can also be observed in the relative permeability curves presented by Engelke et al. (2013).

Despite recent developments, some fundamental aspects of emulsion flow in porous media and the use of dilute oil-in-water emulsions as an EOR agent are still not clear. The design of field-scale operations requires full understanding of how emulsion drop size, dispersed phase concentration and size of injected emulsion bank affects the oil displacement, and how the multiscale mechanisms observed in emulsion injection act in a three-dimensional flow. The goals of this research were to study these aspects of oil–water emulsion flow through porous media and its application as an EOR method for heavy oil. The effect of permeability of porous media, size of drops, dispersed phase concentration and size of the injected emulsion bank on the volume of displaced oil was studied by analyzing the one-dimensional oil displacement flow through cylindrical silica sandpack and sandstone cores. The multiscale effect on emulsion injection in a three-dimensional flow was studied by analyzing the evolution of the water phase saturation during alternate water and emulsion injection in \(1/4\) 5-spot configuration sandstone block.

2 Oil Displacement in 1D Flow Configuration

2.1 Materials, Methods and Experimental Setup

The experimental setup is sketched in Fig. 1. The water phase used in the oil displacement experiments was a sodium chloride (NaCl) solution in deionized water with concentrations of 36.5 and 100 g/L to match the salinity of seawater and formation water, respectively. The oil used to saturate the porous media and to prepare the emulsions was a Brazilian Crude oil from Campos Basin \((22^{{\circ }}\,\hbox {API}/\mu _{\mathrm{o}} = 30\) cP @ \(20\,^{\circ }\)C). A commercial surfactant, Steol CS-330® (Stepan Company), was used to stabilize the produced emulsions. Surfactant solution was prepared adding 5 mL of CS-330 in 1 L of the saline solution. This particular surfactant was chosen because it is a very effective emulsifier, but it does not produce ultralow interfacial tension. The interfacial tension between oil and saline solution (salt concentration of 36.5 g/L) was \(\sigma = 22.85\) dyn/cm. By adding surfactant, it dropped to \(\sigma = 0.67\) dyn/cm. Emulsions were prepared “in line” using two HPLC pumps (Series III, Scientific Systems Inc.) and filters with 5-, 10-, 25-, 60- and 90-\(\upmu \)m mesh. We assumed that the maximum oil droplet diameter of the emulsion matched the filter mesh size for all conditions tested. The emulsion oil content was kept constant at 3.3 % by volume.

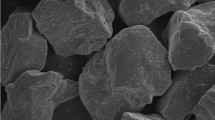

The porous media used in the 1D configuration experiments were sandpacks and sandstone (Berea) cores, which enabled studying oil displacement at a large range of permeabilities. The sandpacks were 1 ft long with 1 in diameter and were prepared using silica sand (Ottawa F110, US Silica Co.). A glass tube was slowly filled with sand, which was compacted for approximately 20 min using a rubber hammer. The sandpacks had average porosity of 39.3 % and average permeability of 6300 mD. The Berea sandstone cores had average porosity of 17.9 % and average permeability of 58 mD (see Table 1).

\(\hbox {CO}_{2}\) was forced through the porous media at low pressure for approximately 20–30 min to remove air. \(\hbox {CO}_{2}\) was then displaced by the saline solution with higher salt concentration (simple model of formation water), which was later displaced by the oil, until irreducible water saturation was achieved. For the sandpacks, the average irreducible water saturation was \(\hbox {S}_{\mathrm{wi}} = 10.7\,\%\); for the Berea sandstone, the average irreducible water saturation was \(\hbox {S}_{\mathrm{wi}} = 25\,\%\).

The solution with the same salinity of seawater and emulsions was injected alternately for a total time of 3 pore volumes at a constant injection rate of 0.3 mL/min. This injection rate corresponds to a Darcy velocity of \(2.5\times 10^{-6}\) m/s and a capillary number of \(7.7\times 10^{-7}\) during water injection and \(2.6\times 10^{-5}\) during emulsion injection. The difference in capillary number is related to the lower interfacial tension of the emulsion, due to presence of surfactant in its continuous phase.

During the experiments, oil and water productions and injection pressure were measured. Experiments with the sandpacks were used to determine the effect of different oil recovery strategies on oil displacement, changing: (a) volume of water and emulsion injected and (b) oil drop size distributions. The effect of the permeability was evaluated by repeating some of the experiments using the Berea sandstone cores.

2.2 Results

Table 2 presents the conditions explored in the sandpack experiments. The second injected slug was either a surfactant solution, i.e., the continuous phase of the emulsion, or an oil–water emulsion. As mentioned before, the maximum oil drop diameter of the emulsion was taken to be equal to the filter mesh size used and the average pore throat diameter was estimated by the Carman–Kozeny equation using the measured porosity and permeability of each sandpack. The ratio of drop to pore throat diameter varied from 0.4 to 1.6.

Figure 2 shows the evolution of the oil recovery factor, defined as the ratio of the produced oil volume to the initial volume of oil inside the porous medium, for experiments #1 to #4. Experiment 1 corresponds to the injection of 3 pore volumes of the model seawater. Experiment #2 corresponds to alternated injection of seawater/surfactant solution/seawater, 1 pore volume of each phase. These are base case scenarios for comparison with the experiments at which emulsions were injected. Experiments #3 and #4 are alternated injection of seawater/emulsion/seawater. The difference between them is the maximum emulsion drop diameter. It is important to mention that for the emulsion injection cases, the volume of oil injected as the dispersed phase of the emulsion was discounted from the volume of produced oil, since we could not distinguish residual oil from emulsion oil in the effluent. Therefore, the values reported in Fig. 2 correspond to net oil production. Water breakthrough occurred after the injection of approximately 0.3 pore volumes for all cases. The differences in the oil recovery at the end of the first water slug injection may be associated with the variation on the permeability and pore structure of the different sandpacks. The relative difference among all experiments was approximately 10 %, much smaller than the difference observed at the end of the alternate injection scheme.

After the injection of 3 pore volumes, the smallest oil recovery was obtained for the injection of synthetic seawater (experiment #1), e.g., RF \(\sim \) 49 %. In the case of alternate injection with surfactant solution (experiment #2), an increase in oil recovery factor is obtained, reaching close to 56 % at the end of the experiment. The extra amount of oil displaced can be associated with the reduction in residual oil saturation due to the lower interfacial tension between oil and aqueous phase. Experiment #2 was performed so that the effect of the emulsion drops on oil displacement could be analyzed separately from interfacial tension reduction effect. For the alternate injection using emulsions (experiments #3 e #4), the recovery factor was again increased. For the smaller drop emulsion (experiment #3), it was close to 57 %, approximately the same as obtained with the surfactant solution. For the larger emulsion drop diameter (experiment #4), the recovery factor was close to 65 %. The extra amount of oil displaced can be attributed to the aqueous-phase flow rearrangement caused by partial pore throat blockage and consequent residual oil saturation reduction. Similar behavior was observed by Guillen et al. (2012a) using mineral oil as dispersed phase.

The effect of emulsion slug size and time of injection is shown in Fig. 3. Experiments #6 and #7 correspond to the injection of emulsions with approximately the same size distribution of experiments #3 and #4, but larger emulsion slug (1.5 PV) and earlier emulsion injection (at 0.5 PV). The evolution of the oil recovery factor for the model seawater injection is also shown as reference (experiment #1). Larger emulsion bank and earlier emulsion injection time led to a higher final recovery factor. For the 25-\(\upmu \)m mesh size emulsion, the final recovery factor grew from approximately 0.58 (experiment #3) to approximately 0.65 (experiment #6). For larger drop diameter (60-\(\upmu \)m mesh size), the increase in recovery factor was from 0.65 (experiment #4) to close to 0.7 (experiment #7). The greater number of drops led to an even stronger flow redistribution in the pore scale, yielding a higher amount of oil displaced when compared to the 1 PV emulsion bank.

The results suggest that larger emulsion drops lead to a higher recovery factor. However, this is not always the case. If the emulsion drops are too large and the capillary number is low enough, most of the drops will be trapped near the injection point and will not affect the rest of the porous space. The evolution of the oil recovery factor for emulsions with different drop sizes (25-, 60- and 90-\(\upmu \)m mesh sizes) is presented in Fig. 4. Again, the 3 PV model seawater injection is shown as reference. The final recovery factor obtained with the 90 \(\upmu \)m emulsion was lower than the other two, close to 55 %. It is important to note that, in the experiment, the emulsion drops were not large enough so they would behave as a mobile oil ganglion. Figure 5 shows a photo of the external appearance of the sandpack at the end of the process. It is clear that, for the 90 \(\upmu \)m emulsion, most of the drops were trapped by the capillary forces, but the trapping occurred very near the injection point and did not affect most of the sandpack.

The effect of dispersed phase concentration on oil recovery is presented in Fig. 6, which shows the final oil recovery factor at the end of the injection of each slug for different dispersed phase concentration of the emulsion (second slug). All emulsions were prepared using the 60-\(\upmu \)m-mesh filter. Increasing the emulsified oil content, i.e., having a larger number of drops, amplifies the mobility control of the water phase. It is important to note that even with the 0.1 % dispersed phase concentration, emulsion injection led to a higher volume of oil displaced than the surfactant solution injection.

Emulsion injection was also effective in lower permeability media. Figure 7 shows final oil recovery factor obtained at the end of each injected slug for model seawater, seawater–surfactant, solution–seawater and seawater–emulsion–seawater schemes in Berea sandstone plugs. The permeability, porosity and initial saturation of each core used are presented in Table 3. The results, during emulsion injection, are similar to those obtained with sandpacks. The displaced oil volume during the second pore volume injection varied from 4.8 (seawater injection) to 13.9 % (emulsion prepared using 25-\(\upmu \)m-mesh frit).

3 Three-Dimensional Oil Displacement Flow with X-ray Tomography Monitoring

3.1 Experiment Setup and Procedure

A 3D alternate water/emulsion/water injection experiment was performed using X-ray tomography techniques to visualize the evolution of water saturation during the oil displacement process (Wellington and Vinegar 1987). A 14 \(\times \) 14 \(\times \) 3.6 \(\hbox {cm}^{3}\) square Castlegate sandstone block (K \(=\) 340 mD) was completed in a \(1/4\) five-spot configuration. The same oil used in the 1D configuration experiments was used in this analysis. The viscosity ratio between the oil and water phase was approximately 30. The initial oil saturation of the block was 0.65. Figure 8 sketches a block cross section showing well completion details.

The injection sequence was: (a) 0.5 pore volume of model seawater at a flow rate of 0.5 mL/min; (b) 1 pore volume of emulsion (prepared using a 25 \(\upmu \)m frit at 1 % dispersed phase concentration) at a flow rate of 1 mL/min and (c) 1 pore volume of model seawater at 1 mL/min. All images were acquired using a 16-channel GE BrightSpeed Tomograph.

The intensity of light produced by the crystal detectors of an X-ray tomographic scanner is proportional to the number of photons received, which is a function of the number of photons that are absorbed by the material placed between the source and the detector. Therefore, the values measured represent the beam attenuation. It depends on X-ray energy level, material density and chemical composition. At 100 KeV, this coefficient is proportional to the atomic number of the element. Therefore, heavy weight atoms, as potassium iodide, produce more attenuation than light ones. Based on this principle, in this experiment, the water phase was doped with potassium iodide (KI) at a concentration of 100 g/L to enhance the response of regions swept by the injected water phase. It is important to note that the water phase surface tension is lowered with the addition of KI. The interfacial tension between oil and seawater with potassium iodide was 6.13 mN/m and with the surfactant solution with KI was 0.08 mN/m. The experimental conditions were such that the capillary number varied from approximately \(10^{-6}\) (close to the wells) to \(10^{-7}\) (far from the wells) during the first water injection and approximately from \(10^{-5}\) (close to the wells) to \(10^{-4}\) (far from the wells) during emulsion injection.

During a tomographic acquisition, the X-ray source or the sample rotates to acquire the medium response at different incidence angles. After signal deconvolution, it is possible to calculate the relative attenuation coefficient matrix, expressed as Hounsfield units (HU), for each sample point.

where, \(\mu _{({x,y}) }\)—attenuation coefficient at coordinates (x, y), \(\mu _{\mathrm{w}}\)—pure water attenuation coefficient.

By convention, all medical tomographs are calibrated using \(\hbox {HU}_{\mathrm{water}} = 0\) and \(\hbox {HU}_{\mathrm{air}} = -1000\). X-ray tomographic acquisitions were done each 10 min (=0.07 PV injected). During the data processing, 3D maps were generated containing the HU differential response showing where the original fluid (undoped) was replaced by injection fluid (doped). At the beginning of each phase (water, emulsion and water) injection, a new initial acquisition (“zero”) was set to analyze the changes of the saturation maps during each step of the experiment.

3.2 Oil Production Curve

The evolution of the oil recovery factor and the injection pressure is shown in Figs. 9 and 10. The recovery factor at the end of the first water injection (0.5 PV) was approximately 33 %. In order to estimate the oil recovery that would be obtained after a 2.5 PV water flooding, the inlet pressure and the evolution of oil produced during the first water slug (first 0.5 PV) were used to estimate the relative permeability curves of a black oil simulation model, which was then used to extrapolate the oil recovery factor. The results are also presented in Fig. 9 as the continuous curve in the plot. The predicted final oil recovery at the end of 2.5 PV of water injection was approximately 42 %.

During emulsion injection, the inlet pressure shows a series of peaks, which are associated with the flow of the oil drops through the pore throats (Cobos et al. 2009; Moradi et al. 2014). This pore-scale mobility reduction is responsible for the water flow path rearrangement and consequently changes in sweep efficiency and residual oil saturation. Oil recovery factor during emulsion injection rises above the predicted values for water flooding. During the second waterflood, the injection pressure curve becomes almost flat, indicating that the emulsified oil drops were no longer flowing through pore throats. At the end of experiment, the recovery factor reached approximately 47 %.

3.2.1 Initial Waterflood

Figure 11 shows the differential HU response map after 0.20 and 0.50 PV of injected water. Blue areas are regions of the porous medium where the X-ray attenuation did not change, i.e., remained unswept by the water phase. Highlighted areas show region from which oil phase was displaced by the injected water doped with KI. The red areas indicate regions of higher water saturation, i.e., where the oil displacement process was more efficient. The waterfront presents the expected pattern of a \(1/4\) five-spot configuration for a high viscosity ratio between the oil and water phases. The map at the end of the first water flooding is shown in Fig. 11b. Unfavorable mobility ratio caused instabilities in the displacement front leading to low final oil recovery factor and premature water breakthrough at the producer well.

3.2.2 Emulsion Injection

A new tomographic “zero-time” acquisition was taken after the initial waterflood. After that, 1 pore volume of oil-in-water emulsion slug was injected. The evolution of the water saturation field is presented in Fig. 12. The red and green regions are “nonzero responses”, regions where additional fluid replacement has occurred during emulsion injection, i.e., regions where the oil saturation has changed. The blue areas correspond to regions without any important fluid substitution.

The highlighted regions of Fig. 12, where oil saturation has changed during the emulsion slug injection, can be divided in two types: The first one is close to the injection well, an area that had already been swept by the water phase during the first water flooding. The second region is near to the previous displacement front, expanding it to areas previously unswept by water. The first region indicates a reduction of residual oil saturation. The second region indicates a better macroscopic sweep of the porous media. The images clearly show that emulsion flooding improves oil displacements in two different scales, leading to more uniform sweep and lowering the residual oil saturation. Such effects in both the macroscale and microscale are usually only observed by combining two different recovery chemical methods such as injection of surfactant–polymer solution.

3.2.3 Final Waterflood

A final water slug of 1 PV followed the emulsion injection. Again, a new tomographic “zero-time” acquisition was considered with the saturation field at the end of emulsion flooding. Figure 13 presents the differential HU responses during the final waterflood. As in the emulsion flooding, the highlighted areas are in two different regions: close to the waterfront and in areas that had already been swept by the water phase, indicating a reduction in the oil saturation. Water flows through the new paths, leading to a higher injection pressure and a slight increase in the oil recovery factor, from 0.45 to 0.47.

4 Final Remarks

Emulsion injection has been used as an EOR method both in field- and laboratory-scale tests. Despite recent advances, fundamental understanding of the different physical mechanisms involved in the process is still not complete. In this work, we have used 1D and 3D flow configurations of oil displacement by water and emulsion injection to study this process.

Results of the 1D experiments in sandpacks and sandstone cores have shown enhancement in oil recovery after emulsion injection. A parametric analysis allowed a better understanding of the effect of different process parameters in the efficiency of oil displacement. The results also confirm that the injected emulsion has to be properly designed in terms of its drop size, disperse phase concentration and injection rate, in order to achieve the desired water phase mobility control and consequently enhanced oil recovery.

The X-ray tomographic images obtained during emulsion injection in a 3D sandstone block clearly show that the injection of an emulsion slug following water flooding changed the oil saturation in two different regions of the porous media, near the injection well and near the displacement front. Emulsion injection not only reduced the residual oil saturation in areas already swept by the water phase, but also improved the macroscopic sweep of the reservoir. Combined effect in both the macroscale and microscale are usually only observed by combining two different recovery chemical methods such as injection of surfactant–polymer solution.

After the solids removal, oilfield produced waters can be considered as a diluted oil-in-water emulsion. The results obtained here suggest that, using filters to control solids content and emulsified oil drop size distribution, produced water can be used as an EOR agent to improve the final oil recovery factor and also contributing to debottleneck facilities in mature oilfields.

References

Abou-Kassem, J.H., Ali, S.M.: Modelling of emulsion flow in porous media. J. Can. Pet. Technol. 34(6), 30–38 (1995)

Alvarado, V., Manrique, E.: Enhanced oil recovery: an update review. Energies 3(9), 1529–1575 (2010)

Alvarado, D.A., Marsden, S.S.: Flow of oil-in-water emulsions through tubes and porous media. SPE J. 19(6), 369–377 (1979)

Baldygin, A., Nobes, D.S., Mitra, S.K.: Water-alternate-emulsion (WAE): a new technique for enhanced oil recovery. J. Pet. Sci. Eng. 121, 167–173 (2014)

Cobos, S., Carvalho, M.S., Alvarado, V.: Flow of oil-water emulsions through a constricted capillary. Int. J. Multiph. Flow 35, 507–515 (2009)

Devereux, O.F.: Emulsion flow in porous solids: I. a flow model. Chem. Eng. J. 7(2), 121–128 (1974)

Engelke, B., Carvalho, M.S., Alvarado, V.: Conceptual darcy-scale model of oil displacement with macroemulsion. Energy Fuels 27, 1967–1973 (2013)

Guillen, V.R., Romero, M.I., Carvalho, M.S., Alvarado, V.: Capillary-driven mobility control in macro emulsion flow in porous media. Int. J. Multiph. Flow 94, 197–206 (2012a)

Guillen, V.R., Carvalho, M.S., Alvarado, V.: Pore scale and macroscopic displacement mechanism in emulsion flooding. Transp. Porous Media 94, 197–206 (2012b)

Mandal, A., Samanta, A., Bera, A., Ojha, K.: Characterization of oil–water emulsion and its use in enhanced oil recovery. Ind. Eng. Chem. Res. 49(24), 12756–12761 (2010)

McAuliffe, C.D.: Crude oil-in-water emulsions to improve fluid flow in an oil reservoir. J. Pet. Technol. 25(6), 721–726 (1973a)

McAuliffe, C.D.: Oil-in-water emulsions and their flow properties in porous media. J. Pet. Technol. 25(6), 727–733 (1973b)

Moradi, M., Kazempour, M., French, J.T., Alvarado, V.: Dynamic flow response of crude oil-in-water emulsion during flow through porous media. Fuel 135, 38–45 (2014)

Romero, M.I., Carvalho, M.S., Alvarado, V.: Experiments and network model of flow of oil-water emulsion in porous media. Phys. Rev. E 84, 046305 (2011)

Sarma, H.K., Maini, B.B., Jha, K.: Evaluation of emulsified solvent flooding for heavy oil recovery. J. Can. Pet. Technol. 37(7), 55–62 (1998)

Soo, H., Radke, C.J.: A filtration model for the flow of dilute, stable emulsions in porous media—I. Theory. Chem. Eng. Sci. 41(2), 263–272 (1986)

Soo, H., Radke, C.J.: A filtration model for the flow of dilute, stable emulsions in porous media—II. Parameter evaluation and estimation. Chem. Eng. Sci. 41(2), 273–281 (1986)

Tallakstad, K.T., Knudsen, H.A., Ramstad, T., Løvoll, G., Måløy, K.J., Toussaint, R., Flekkøy, E.G.: Steady-state two-phase flow in porous media: statistics and transport properties. Phys. Rev. Lett. 102, 074502 (2009)

Wellington, S.L., Vinegar, H.J.: X-ray computerized tomography. J. Pet. Technol. 39(8), 885–898 (1987)

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

de Farias, M.L.R., Campos, E.F., de Souza, A.L.S. et al. Injection of Dilute Oil-in-Water Emulsion as an Enhanced Oil Recovery Method for Heavy Oil: 1D and 3D Flow Configurations. Transp Porous Med 113, 267–281 (2016). https://doi.org/10.1007/s11242-016-0692-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11242-016-0692-0