The hydrodeoxygenation of methyl isobutyl ketone (MIBK) to give 2-methylpentane (2MP) in the liquid phase proceeds with high selectivity on bifunctional catalysts containing Pt nanoparticles and a Keggin heteropoly acid. This reaction was found to proceed most efficiently on a catalyst with 1% Pt and 25% H3PW12O40 on SiO2 (Pt/HPW/SiO2) at 170 °C to give 2MP with 73% selectivity and 52% conversion of MIBK, which is much higher than the efficiency of the previously described catalyst Pt/Cs2.5H0.5PW12O40 in the liquid phase.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Methyl isobutyl ketone (MIBK) is a key intermediate in the production of 2-methylpentane (2MP). The large-scale production of 2MP from MIBK is commercially attractive for obtaining biofuel [1, 2]. Many side-products are formed in the production of biofuel, which adds to the cost of this process [3, 4]. As a rule, catalysts useful for the conversion of MIBK to give 2MP in a one-step hydrogenation reaction most often contain two different active sites, namely, metal sites for catalysis of the step involving hydrogenation to give intermediate 4-methyl-2-pentanol (MP-ol) and acid sites, which effect the formation of 2MP after dehydration of the alcohol as shown by various workers [5, 6]. Efficiency has recently been demonstrated for a bifunctional heterogeneous catalyst containing Keggin heteropoly acids (HPA) with metallic platinum in many gas-liquid-phase reactions [1, 2, 7, 8]. KPA characteristically have strong Brønsted acidity, which is higher than for mineral acids and zeolites [9, 10]. This has led to the use of various heteropoly acids as catalysts in industrial processes. HPA supported on an oxide gives a solid acid catalyst with a broad range of pore geometry. For example, HPA on an SiO2 support has mesoporous structure with strong acidity [10]. In our previous affords, the conversion of MIBK to give 2MP was explored by the gas phase hydrogenation using a broad range of metals supported on acidic zeolite and HPA catalysts [2, 3]. Platinum on silicon dioxide gives 64% conversion of MIBK to 2MP with 47% maximum selectivity. However the conversion reached 99% using Pt-doped Cs2.5H0.5PW12O40 at 100 °C with 100% selectivity relative to 2MP [3]. There have been very few studies demonstrating the conversion of MIBK to give 2MP using a bifunctional catalyst in the liquid phase. To our knowledge, only Eissa et al. [5] have studied a heteropoly acid catalyst with platinum (Pt/Cs2.5H0.5PW12O40) for the liquid-phase hydrogenation of MIBK, which proceeded with only 9% conversion to give 2MP with 63% selectivity.

In the present work, we show that a platinum-containing catalyst with 25% H3PW12O40/SiO2 is an efficient bifunctional catalyst for the liquid-phase conversion of MIBK to give 2MP.

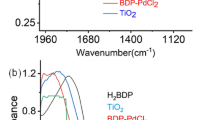

We used samples of hydrates of heteropoly acid H3PW12O40 (HPW, 99%) and Pt(acac)2 from Sigma-Aldrich and Aerosil 300 silicon dioxide (SBET = 300 m2/g) from Degussa. The amount of water in the heteropoly acid was determined by TGA. The supported HPA catalysts were prepared by wet impregnation of the silicon dioxide support with an aqueous solution of HPA and drying at 150 °C and pressure 10–3 kPa for 1.5 h. The sample of cesium 12-tungstophosphate, Cs2.5H0.5PW12O40 (CsPW) was prepared according to Izumi [11] by the dropwise addition of the required amount of aqueous cesium carbonate to an aqueous solution of H3PW12O40 to give CsPW as a white precipitate. The material was isolated, dried in a furnace, and roasted at 150 °C and pressure 10–3 kPa for 1.5 h. Finally, the material was ground to give particles with diameter 45-180 μm. The bifunctional Pt-HPA catalysts were prepared by wet impregnation of the acid component, for example, 25% HPW/SiO2 with 0.02 M Pt(acac)2 in benzene at room temperature for 1 h with subsequent slow evaporation of the benzene in a rotary evaporator at room temperature [8]. The catalyst was dried in vacuum at 150 °C and 10–3 kPa and then reduced in a furnace in a hydrogen stream at 250 °C for 2 h. The platinum content was determined by inductively coupled plasma atomic emission spectroscopic analysis. The platinum dispersion (D) defined as the metal fraction on the surface, D = Pts/Pttotal, was determined by the pulse chemisorption of CO in a helium stream at 50 °C using a Micrometrics TPD/TPR 2900 instrument with 20 mg catalyst sample, 50-μL pulses of pure CO; the adsorption stoichiometry was Pts : CO = 1. The platinum dispersion was determined using the same instrument by pulse hydrogen adsorption with H2/O2 titration. The catalysts were reduced using a hydrogen stream at 250 °C for 2 h to convert the metal precursor Mn+ into M0. Then, 20 mg catalyst was subjected to the action of air at room temperature for several hours in order to permit oxygen adsorption on the metal atoms on the catalyst surface. A series of 20-μL pulses of pure H2 (at 75 °C) was injected into the stream every 3 min until the catalyst was saturated with hydrogen; the adsorption stoichiometry Pts : H2 = 1.5. The mean diameter of the metal particles (d, nm) was calculated using the empirical equation d = 0.9/D [12]. TEM/STEM-EDX was used to find the platinum particle diameter for the Pt/25% HPW/SiO2 catalyst (mean diameter of the surface particles) to confirm the comparative H2 and CO chemisorption measurements. Table 1 gives the texture and platinum dispersion of the catalysts studied.

Table 1 gives the platinum dispersion in the freshly-prepared catalysts. These data indicate that the mean platinum particle diameter in the catalysts varies from 3.3 to 8.2 nm. The results obtained using H2 and CO chemisorption are very similar. The mean platinum particle diameter for the 1% Pt/25% HPW/SiO2 catalyst obtained by gas chemisorption (3.3 nm) is in accord with the value of 2.5 nm obtained from scanning transmission electron microscopy (STEM). Figure 1 shows a STEM-EDX image of this catalyst with Pt particle diameter in the range 0-14 nm. The mean Pt particle diameter in the catalysts increased in the series: 1% Pt/25% HPW/SiO2 < 1% Pt/CsPW < 1% Pt/HPW. Table 1 shows that the catalyst with 1% Pt/HPW is a mesoporous solid with a very small surface area. 1% Pt/CsPW has a relatively large surface area (106 m2/g) and low porosity. The catalyst with 1% Pt/25% HPW/SiO2 has a large surface area (189 m2/g) and greater porosity.

The liquid-phase hydrodeoxygenation of MIBK was carried out in a 300-mL Parr semibatch reactor. A sample of 25 mL MIBK and 0.25 g reduced catalyst (after treatment in a hydrogen atmosphere for 2 h at 250 °C) were placed into the reactor and stirred at 780 rpm at 170 °C with 10 atm H2 for 4 h. The resultant gas was released and the reactor was cooled to room temperature. The solution was filtered and then analyzed by gas chromatography on a Shimadzu GC-17 chromatograph equipped with a flame ionization detector (FID) using a 30-m × 0.25-mm × 0.25-μm RTX-5 (G27) capillary column.

The hydrogenation of MIBK was carried out on a series of solid acid catalysts derived from phosphorus-tungsten heteropoly acid containing Pt in the liquid phase. Various workers [2, 3, 6, 8, 13, 14] have reported that platinum is an efficient transition metal for the hydrogenation of ketones to give alkanes in gas and liquid phases. The reaction was carried out at 170 °C in an optimized reaction system described by Eissa et al. [5]. The Pt/HPW catalyst initially demonstrated poor selectivity relative to 2MP and the color of the reaction medium changed, indicating that platinum was washed out of the catalyst. This could explain the low selectivity (<1%) for 2MP using this catalyst. The conversion of MIBK was 32% to give undetermined amounts of volatile hydrocarbons (C1-C5 cracking products) and traces of a secondary alcohol (4-methyl-2-pentanol) due to incomplete alcohol dehydration as shown in the scheme below. Platinum on the acid cesium salt of phosphorus-tungsten heteropoly acid, Cs2.5H0.5PW12O40 (CsPW), gave 9% conversion of MIBK leading to 2MP with 62% selectivity. This result corresponded to the 0.5% Pt/CsPW catalyst relative to both activity and selectivity at 170 °C in the work of Eissa et al. [5]. Catalyst activity was markedly enhanced when Pt/25% HPW/SiO2 was used as the catalyst, which gave 52% MIBK conversion with 73% selectivity relative to 2MP. The catalytic selectivity for obtaining 2MP on these catalysts decreased in the following series: 1% Pt/25% HPW/SiO2 > 1% Pt/CsPW > 1% Pt/HPW. The variation in selectivity relative to 2MP can be attributed both to the large surface area of HPW and the small metallic platinum particle size on HPW/SiO2. Thus, the mesoporous Pt/HPW/SiO2 catalyst with large surface area and small platinum particle size displays considerable activity in the conversion of MIBK to give 2MP with high selectivity.

Thus, in the present work, we have demonstrated the effect of surface area and platinum particle size on the activity of bifunctional metal–acid Pt/HPW catalysts in the hydrodeoxygenation of MIBK. The catalyst selectivity for obtaining 2MP decreases in the following order: Pt/25% HPW/SiO2 > Pt/CsPW > Pt/HPW. The deposition of HPW onto SiO2 gives a corresponding increase in acid and metal functionality, which results from the large surface area of SiO2. The reaction proceeds through a series of steps including the hydrogenation of MIBK to give 4-methyl-2-pentanol on metallic platinum, subsequent dehydration of this alcohol to give 2-methylpentene on the acid sites, and, finally, hydrogenation of the alkene to give 2MP on the metal site. Hence, the large surface area of the heteropoly acid catalysts facilitates obtaining small platinum nanoparticles, leading to high conversion of MIBK and high selectivity relative to 2MP. In further investigations, we shall attempt to establish the effect of the interaction between HPW and various supports in order to improve Pt/heteropoly acid materials with large surface area for the liquid-phase hydrogenation of MIBK.

References

M. A. Alotaibi, E. F. Kozhevnikova, and I. V. Kozhevnikov, Chem. Commun., 48, 7194 (2012).

M. A. Alotaibi, E. F. Kozhevnikova, and I. V. Kozhevnikov, J. Catal., 293, 141 (2012).

O. Ellabban, H. Abu-Rub, and F. Blaabjerg, Renew. Sustain. Energy Rev., 39, 748 (2014).

P. McKendry, Biores. Technol., 83, 47-54 (2002).

M. Eissa, A. M. Alhanash, M. Benaissa, and M. S. Hamdy, Catal. Commun., 86, 27 (2016).

K. Alharbi, E. F. Kozhevnikova, and I. V. Kozhevnikov, Appl. Catal. A, 504, 457 (2015).

R. D. Hetterley, E. F. Kozhevnikova, and I. V. Kozhevnikov, Chem. Commun., 7, 782 (2006).

M. A. Alotaibi, E. F. Kozhevnikova, and I. V. Kozhevnikov, Appl. Catal. A, 447, 32 (2012).

T. Okuhara, N. Mizuno, and M. Misono, Adv. Catal., 41, 113 (1996).

I. V. Kozhevnikov, Catalysis by Polyoxometalates, Wiley & Sons, Chichester, England (2002).

Y. Izumi, Micropor. Mater., 5, 255 (1995).

J. E. Benson, H. S. Hwang, and M. Boudart, J. Catal., 30, 146 (1973).

O. Poole, Appl. Catal. B, 202, 446 (2017).

S. Itagaki, Chem. Lett., 43, 1086 (2014).

The author expresses his gratitude to the group of Prof. I. Kozhevnikov at the University of Liverpool and to Dr. Mohamed Hamdy for assistance with the experimental equipment.

This work was carried out with the financial support of the Deanship of Scientific Research at Prince Sattam bin Abdulaziz University in the framework of Research Project No. 2013/01/136.

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated from Teoreticheskaya i Éksperimental’naya Khimiya, Vol. 55, No. 2, pp. 129-132, March-April, 2019.

Rights and permissions

About this article

Cite this article

Alotaibi, M.A. Liquid-Phase Hydrodeoxygenation of Methyl Isobutyl Ketone on Bifunctional Catalysts Derived from Pt Nanoparticles and Phosphorus-Tungsten Heteropoly Acid. Theor Exp Chem 55, 143–146 (2019). https://doi.org/10.1007/s11237-019-09606-5

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11237-019-09606-5