Abstract

A series of free radical photoinitiators with thioester bonds were synthesized by the nucleophilic substitution reaction of acyl chloride and thiol or thiophenol. These compounds could be efficiently obtained under mild reaction conditions and were fully characterized by 1H NMR, 13C NMR and high-resolution mass spectrometry. This kind of compounds exhibited a strong ultraviolet–visible light absorption spectrum with an extended absorption around 330 nm in DMSO. Moreover, these compounds were utilized as free radical photoinitiators in ultraviolet curing and the resulting films exhibited comparable mechanical properties in comparison with commercially available photoinitiators, such as 1-hydroxycyclohexyl phenyl ketone (Irgacure 184) and benzophenone. We also proposed a probable photoinitiated polymerization mechanism for S-benzoheterocycle thiobenzoates as photoinitiators.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

The ultraviolet (UV)-curing technology is a safe, green and friendly environmental technology [1,2,3]. Generally, the photopolymerization system is composed of a resin (oligomer), an active diluent (monomer), triethanolamine (auxiliary agent) and photoinitiator [4, 5]. It is worth noting that the photoinitiator plays an important role in the system as it determines the photopolymerization speed and affects the polymer properties, such as odor, yellowing and migration. Photoinitiators can be divided into cationic photoinitiators and free radical photoinitiators according to the photochemical mechanisms [6, 7]. Nowadays, BP and Irgacure 184 are the most commonly used free radical photoinitiators owing to their low cost and good solubility. However, owing to its small molecular weight, BP can easily migrate out of the polymer network and cause yellowing. These problems limit their applications in food and pharmaceutical packaging. On the other hand, Irgacure 184 whose maximum absorption wavelength is around 250 nm does not match the emission wavelength of high-pressure mercury lamp. To make them more widely used, there are two ways to improve their optical activity: One is to add the sensitizers, and the other is to extend conjugated degree [8, 9]. Therefore, developing long wavelength absorbed photoinitiators with low mobility and low benzene release is a growing area of interest for academic research and industrial applications [10, 11].

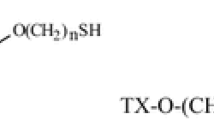

Historically, sulfur-containing materials have received significant interest both in academy and industry, optical lens materials [12], mucoadhesive materials [13], drug delivery systems [14], self-assembled monolayers (SAMs) [15,16,17] and thiol-containing biomolecules [18]. Thioesters are one of the most represented S-contained functional materials [19, 20]. Tomioka et al. [21] first reported the use of thioester-based materials as efficient photoinitiators. However, the short light absorption wavelength of S-phenyl thiobenzoate limited their practical applications. Herein, we designed and synthesized a series of S-benzoheterocycle thiobenzoates, which can be efficiently obtained by the nucleophilic substitution reaction of acyl chloride and thiol or thiophenol. The S-benzoheterocycle thiobenzoates exhibit a strong ultraviolet–visible light absorption with an extended absorption around 330 nm in DMSO. Moreover, these compounds can be applied as efficient photoinitiators with high photoactivity in a thiol/vinyl carbonate formulation.

Experimental section

Materials

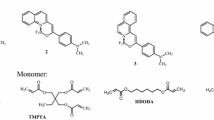

Unless otherwise stated, all chemicals were obtained from commercial suppliers and used without further purification. 1,6-Hexanediol diacrylate (HDDA) and polyurethane modified acrylate resin (UV 2100) were purchased from Sanmu chemical co., Ltd. 1-Hydroxycyclohexyl phenyl ketone (Irgacure 184) and BP were obtained from Beijing Yingli Technology co., Ltd (Scheme 1).

Instrumentation

1H NMR and 13C NMR spectra were recorded in CDCl3 with a Bruker AVANCE III 600 MHz spectrometer. High-resolution mass spectra were obtained on a Thermo Scientific Q Exactive mass spectrometer. UV–Vis absorption spectra were recorded in DMSO (1 × 10−5 M) on a Hitachi UH-5300 UV spectrophotometer (Hitachi High-Technologies, Tokyo, Japan). The cured films were performed on a UV-Curing machine (ZB-T150-UV1000), and the hardness of films was recorded by a portable pencil scratch hardness tester (QHQ-A).

Synthesis

The substitution reaction of acyl chloride and mercapto reagent was carried out under mild conditions, and the general procedure is as follows: Acyl chloride (2.0 mmol), mercapto reagent (1.0 mmol) and base (2.0 mmol) were dissolved in THF. The reaction mixture was stirred at 60 °C for 12 h. After cooling to room temperature, the precipitates were filtered off. The crude products were purified by silica gel chromatography using dichloromethane and petroleum ether as the eluent to afford compound 3.

S-(1-benzoyl-6-methoxy-1H-benzo[d]imidazol-2-yl) benzothioate 3e

Pale yellow crystals (75%), mp: 152–156 °C. 1H NMR (600 MHz, CDCl3) δ 7.97–7.90 (m, ArH, 4H), 7.66 (dd, J = 16.3, 7.5 Hz, ArH, 2H), 7.55–7.48 (m, ArH, 4H), 7.33 (dd, J = 10.6, 5.7 Hz, ArH, 1H), 6.92 (d, J = 2.4 Hz, ArH, 1H), 6.88 (dd, J = 8.9, 2.4 Hz, ArH, 1H), 3.85–3.79 (m, -OCH3,3H). 13C NMR (151 MHz, CDCl3) δ 170.15, 169.00, 168.92, 157.91, 134.62, 134.38, 132.48, 132.31, 132.26, 130.72, 130.63, 128.93, 128.83, 125.41, 112.85, 112.10, 97.07, 77.25, 77.04, 76.83, 55.98. HRMS (ESI) m/z: calcd for C22H16N2O3S: 389.0915, found: 389.0950.

S-(6-methoxy-1-(4-methylbenzoyl)-1H-benzo[d]imidazol-2-yl) 4-methylbenzothioate 3f

Pale yellow crystals (76%), mp: 239–241 °C. 1H NMR (600 MHz, CDCl3) δ 7.85 (dd, J = 10.6, 8.3 Hz, ArH, 4H), 7.32 (t, J = 7.4 Hz, ArH, 4H), 7.27–7.24 (d, J = 8.7 Hz, ArH, 1H), 6.86 (dt, J = 8.7, 2.2 Hz, ArH, 2H), 3.81 (s, OCH3, 3H), 2.50–2.40 (d, J = 3.1 Hz, CH3, 6H). 13C NMR (151 MHz, CDCl3) δ 169.87, 168.66, 168.58, 157.79, 146.18, 145.90, 132.35, 131.08, 131.00, 129.73, 129.63, 129.58, 129.44, 125.57, 112.60, 111.95, 96.86, 55.97, 21.99, 21.97. HRMS (ESI) m/z: calcd for C24H20N2O3S{[M + H]+}: 417.1195, found: 417.1262.

S-(6-nitro-1H-benzo[d]imidazol-2-yl) benzothioate 3g

Colorless oil liquid (62%), 1H NMR (600 MHz, CDCl3) δ 8.22–8.17 (m, ArH, 3H), 7.71 (t, J = 7.5 Hz, ArH, 2H), 7.56 (t, J = 7.9 Hz, ArH, 4H).

S, S’-(thiobis(4,1-phenylene)) dibenzothioate 3h

White Crystals (81%), mp: 112–114 °C. 1H NMR (600 MHz, CDCl3) δ 8.05 (t, J = 8.6 Hz, ArH, 2H), 7.64 (t, J = 7.3 Hz, ArH, 1H), 7.49 (d, ArH, 6H). 13C NMR (151 MHz, CDCl3) δ 189.86, 137.24, 136.47, 135.78, 133.83, 131.52, 128.82, 127.5, 126.45, 77.26, 77.05, 76.83.

S, S’-(thiobis(4,1-phenylene)) bis(4-methylbenzothioate) 3i

White crystals (71%), mp: 147–149 °C. 1H NMR (600 MHz, CDCl3) δ 2.50 (s, CH3, 3H), 7.28–7.30 (m, ArH, 2H), 7.43–7.49(m, ArH, 4H)), 7.91–7.93 (m, ArH, 2H). 13C NMR (75 MHz, CDCl3) δ: 22.7, 77.5, 77.9, 78.3, 127.5, 128.5, 130.3, 132.4, 134.8, 136.7, 138.0, 145.7, 190.3; HRMS (ESI) m/z: calcd for C28H22O2S3: 487.0815, found 487.0852.

The preparation of cured films

The polymeric formulation is composed of 45 wt% monomer (HDDA), 50 wt% polyurethane modified acrylate resin (UV 2100), 2 wt% triethanolamine and 3 wt% photoinitiator. The photoinitiator and HDDA were mixed at room temperature under stirring, and then, triethanolamine and resin were successively added. A thin layer (ca. 75 um) of the resulting mixture was coated on the pre-cleaned glass substrates and exposed to UV irradiation for a certain time to afford cured films.

The gel content was determined by solvent extraction method. The cured films baked at 50 °C for 3 h and weighed M1. After soaking in acetone solution for 24 h, the filtrated solids were dried and weighted M2. The gel content was calculated by the equation:

Results and discussion

Optimization of the reaction conditions

Firstly, taking the reaction of 2-mercapto imidazole (1a) and benzoyl chloride (2a) as an example, we carefully studied the reaction conditions, including the reaction solvent, temperature, time and base. All the detailed results are summarized in Table 1. Initial investigations focused on the reaction of 1a with 2.0 equiv of 2a in the presence of NaOH (2.0 equiv) as base in DMF at room temperature for 6 h. It was found that the expected product 2-phenylthiobenzimidazole 3a was obtained in a low isolated yield (35%) (Table 1, entry 1). Further investigations revealed that the most efficient temperature was 60 °C (Table 1, entries 1–5). In addition, when the reaction time was increased from 6 h to 12 h, the yield of the product 3a increased from 43 to 52%. To further optimize the reaction conditions, various bases and solvents were examined (Table 1, entries 6–10). Finally, 3a can be obtained with a high yield of 75% in THF at 60 °C for 12 h in the presence of Et3N as base (Table 1, entry 10).

With the optimized conditions in hand, we further examined the scope of the substrates for the reaction of 2-mercaptoheterocycles (1b–1h) with chloride (2a–2b) (Table 2).

As shown in Table 2, the reactions of acyl chlorides with 2-mercaptobenzoxazole and 2-mercaptobenzothiazole exhibited moderate yields (< 70%), compared to 2-mercaptobenzimidazole (78%, Table 2, entries 1–3). In addition, we found that methoxy-substituted 2-mercaptobenzimidazole gave the disubstituted products in high yields (> 70%), while 2-mercaptobenzimidazole with an electron-withdrawing group (nitro) on the benzene ring only gave S-benzimidazole thiobenzoate, which may ascribe to the activation of the N–H bond by the methoxy group (Table 2, entries 4–5). On the other hand, we also synthesized other thioester compounds from the corresponding substrates (Table 2, entries 7–9). Note that the reaction of 4-methoxybenzenethiol and benzoyl chloride gave the corresponding product S-(4-methoxyphenyl) benzothioate (3j) with the highest isolated yield of 98%.

UV–Vis absorption studies

Figure 1 depicts the UV absorption spectra of compounds 3 in DMSO solution. These spectra were measured at an identical molar concentration (1 × 10−5 M), so that a direct comparison of absorbance could be made. As shown in Fig. 1, compounds 3 exhibit stronger ultraviolet absorption intensity due to the introduction of benzoheterocycles and sulfur atoms in comparison with BP, and the maximum absorption wavelength has a significant redshift.

Compared with BP, it can be seen that 3a, 3c and 3d possess higher ultraviolet absorption intensity and redshift of maximum absorption wavelength due to the introduction of benzoheterocycles. In addition, the absorption wavelengths of compounds 3 with different benzoheterocycles are quite different. When connected with benzoxazole, compound 3a presents the most significant red-shifted absorption spectrum with a maximum peak at 325 nm. As shown in Fig. 1b, the absorption wavelength of compounds 3e and 3f has a strong redshift with the increase in carbonyl structure and benzene ring, which is attributed to n–π* or π–π* electron transition. As shown in Fig. 1c, compounds 3h, 3i and 3j have better ultraviolet absorption properties than BP due to the introduction of sulfur atoms. The chemical structures and absorption spectra of 3h and 3i are similar. Compared with BP, 3j exhibited stronger light absorption intensity and red-shifted spectrum due to the formation of n-π* transition between heteroatoms and benzene ring structure, which leads to the enhancement of the conjugation degree.

Photopolymerization studies

To evaluate the photopolymerization properties, all the synthesized thioester compounds were utilized as free radical photoinitiators in polyurethane modified acrylate resin (UV 2100) and the activated monomer hexane-1,6-diyl diacrylate (HDDA) with triethanolamine as additive. The experiments of UV-curable surface coating were realized under commercially available UV-lamp (main peak at 365 nm) illumination. All the mechanical properties of the cured film are summarized in Table 3.

As shown in Table 3, compounds 3a, 3b, 3c, 3e, 3h, 3j have been transformed into smooth and transparent films, indicating that they can be used as efficient radical photoinitiators in the ultraviolet curing system. Moreover, we found that compounds 3e, 3f, 3h and 3i need shorter curing time to transform into films. Compared with BP and Irgacure 184, all the UV-cured coating films show better adhesion. We also found that some films (3e, 3f, 3g and 3h) exhibited a better pencil hardness. Gel content is an important parameter of photoinitiators, and 3e and 3h give the highest gel content. Accordingly, compounds 3e and 3h are the most efficient photoinitiators, which may ascribe to the introduction of multi-ketone segments in the chemical structures.

Photoinitiation mechanism

Generally, the free radical photoinitiators [22,23,24] can be divided into pyrolytic free radical photoinitiators and hydrogen-scavenging free radical photoinitiators. Tomioka et al. considered that homolytic α-cleavage of C-S bond in S-phenyl thiobenzoates is the initiation mechanism of photopolymerization under UV irradiation. [21, 25,26,27] However, we found that the resulting films without triethanolamine as additive needed repeated UV-lamp illumination under the same curing conditions. Thus, as shown in Scheme 2, we took the compound 3a as a model molecular and proposed the possible photoinitiation mechanism [28,29,30,31,32]. Under UV illumination, the sensitized 3a and the coinitiator triethanolamine can form an exciplex, and then, two radical sources are produced through a photoinduced electron transfer process. Both of them can participate in the following polymerization, thus accelerating the curing process.

Conclusion

A series of S-benzoheterocycle thiobenzoate photoinitiators have been synthesized, and their chemical structures were characterized by 1H NMR and 13C NMR, and high-resolution mass spectrometry (HRMS). By introducing the benzoheterocycle into the backbone, S-benzoheterocycle thiobenzoate photoinitiators exhibited strong and red-shifted ultraviolet–visible light absorption spectrum. Moreover, these compounds could be utilized as efficient free radical photoinitiators. They exhibited excellent photoinitiating activity. The resulting films possessed comparable/better mechanical properties in comparison with BP and Irgacure 184, implying potential applications in industrial production.

References

S. Gaidukovs, A. Medvids, P. Onufrijevs, L. Grase, Express Polym. Lett. 12, 10 (2018)

Y. Lee, S. Lee, X.G. Zhao, D. Lee, T. Kim, H. Jung, N. Kim, Smart. Struct. Syst. 22, 2 (2018)

B. Cesur, O. Karahan, S. Agopcan, T.N. Eren, N. Okte, D. Avci, Prog. Org. Coat. 86, 71 (2015)

J.V. Crivello, E. Reichmanis, Chem. Mat. 26, 1 (2014)

Y. Liu, X. Huang, K.-C. Han, ACS Sustai. Chem. Eng. 7, 1 (2019)

B.-X. Zhang, T. Li, Y. Kang, Res. Chem. Intermed. 43, 11 (2017)

P. Gauss, M. Griesser, M. Markovic, Macromolecules. 52, 2629 (2019)

J. Wang, J. Yang, M. Atif, R. Bongiovanni, G. Li, Z. Xue, X. Yang, Polym. Adv. Technol. 29, 8 (2018)

T.N. Eren, B. Graff, J. Lalevee, D. Avci, Prog. Org. Coat. 128, 148 (2019)

P. Sautrot-Ba, N. Bogliotti, A. Brosseau, J. Bourgon, P.-E. Mazeran, J. Lalevee, F. Morlet-Savary, D.-L. Versace, Mater. Eng. 303, 8 (2018)

M.A. Tasdelen, Y. Yagci, ACS Macro Lett. 6, 12 (2017)

T. Matsuda, Y. Funae, M. Yoshida, T. Yamamoto, T. Takaya, J. Appl. Polym. Sci. 76, 1 (2000)

C.E. Kast, A. Bernkop-Schnürch, Biomaterials 22, 17 (2001)

F. Driessen, F.E. Du Prez, P. Espeel, ACS Macro Lett. 4, 6 (2015)

Y. Xue, X. Li, H. Li, W. Zhang, Nat. Commun. 5, 4348 (2014)

H. Häkkinen, Nat. Chem. 4, 6 (2012)

J.C. Love, L.A. Estroff, J.K. Kriebel, R.G. Nuzzo, G.M. Whitesides, Chem. Rev. 105, 4 (2005)

M.H. Stenzel, ACS Macro Lett. 2, 1 (2013)

S. Aksakal, R. Aksakal, C.R. Becer, Polymer Chem. 9, 36 (2018)

N.H. Jabarullah, K. Jermsittiparset, P.A. Melnikov, A. Madeleno, A. Hosseinian, E. Vessally, J. Sulfur Chem. 41, 1 (2019)

H. Tamioka, Y. Takimoto, M. Kawabata, M. Harada, J.-P. Fouassier, D. Ruhlmann, J. Photochem. Photobiol. A Chem. 53, 3 (1990)

N.D. Carbone, M. Ene, J.R. Lancaster, J.T. Koberstein, Macromolecules 46, 14 (2013)

J. Christmann, X. Allonas, C. Ley, A. Ibrahim, C. Croutxe-Barghorn, Macromol. Chem. Phys. 218, 18 (2017)

X. Wu, M. Jin, J.-P. Malval, D. Wan, H. Pu, J. Polym. Sci., Part A: Polym. Chem 55, 24 (2017)

F. Morlet-Savary, J.P. Fouassier, H. Tomioka, Polymer 33, 19 (1992)

M. Yamaji, X. Cai, M. Sakamoto, M. Fujitsuka, T. Majima, J. Phys. Chem. A 113, 9 (2009)

M. Yamaji, F. Kazmierczak, B. Marciniak, J. Phys. Chem. A 113, 46 (2009)

W.A. Green, Industrial Photoinitiators: A Technical Guide (CRC Press, Boca Raton, 2010)

C.S.H. Chen, J. Polym. Sci. Part A 3, 3 (1965)

B. Orellana, A.M. Rufs, M.V. Encinas, C.M. Previtali, S. Bertolotti, Macromolecules 32, 20 (1999)

Z. Kecici, S. Babaoglu, G. Temel, Prog. Org. Coat. 115, 1 (2018)

X. Qin, G. Ding, Y. Gong, C. Jing, G. Peng, S. Liu, L. Niu, S. Zhang, Z. Luo, H. Li, F. Gao, Dyes Pigm. 132, 1 (2016)

Acknowledgements

We thank the National Natural Science Foundation of China (No. 21971154) and the Shanxi Province Talent Project (No. 2018043) for financial support. We are also grateful for the platform provided by the Scientific Instrument Center of Shanxi University.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Electronic supplementary material

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Zhao, Z., Wang, C., Liu, F. et al. Synthesis and application of new S-benzoheterocycle thiobenzoates photoinitiators. Res Chem Intermed 46, 3717–3726 (2020). https://doi.org/10.1007/s11164-020-04170-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11164-020-04170-3