Abstract

Surfactant is a special kind of amphiphilic compound composed of water-loving and hating parts. The remarkable physical properties like interfacial tension, wettability, emulsifying and dispersing ability make the surfactant accessible for numerous applications from laboratory to commercial products. In recent years, the commercial applications of surfactant have led to greater relevance on account of the environmental concerns and market pressures of this compound. The utility of surfactants in global market increases steadily since its formulation with several beneficial aspects in pharmaceutical, detergent, cosmetic, paint, food science, gas hydrate, nanotechnology, petroleum recovery, bioremediation, chemical transformation and drug delivery. This review briefly discusses the applied aspect of surfactants in diverse area as well as catalytic effect of micelle in organic reactions from the recent literature survey. The trend of increasing use of bioderived surfactants in the modern field of research is also considered in this report. The recent advancement of surfactant-based organic transformations has been emphasized with the role of surfactant aggregates in course of different organic reactions.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

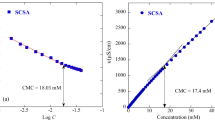

Surfactants are the unique class of organic compounds possessing the tendency to form a variety of aggregates owing to its amphiphilic nature. The term SURFACTANTS surprisingly exhibit the basic feature of this molecule, i.e., SURFace ACTive AgeNTS. Surfactant sometimes referred to a substance which adjusts energy relationships at interfaces; specifically, they can lower surface or interfacial tension between the two phases [1]. Concerning with the features of surfactants, they are characterized by some crucial properties such as critical micelle concentration (CMC), hydrophilic–lipophilic balance (HLB), chemical structure and charge on the hydrophilic head group, as well as the properties from their original source [2, 3]. Surface-activating property makes the surfactant excellent emulsifiers, dispersing and foaming agents [4]. As an active constituent of soaps and detergents, surfactants are commonly used for cleaning purpose to separate oily or greasy substance from a particular media.

A number of reviews and scientific reports depict the widespread applications of surfactant micelle in the fields of pharmaceutical, detergent, cosmetic, paint, food science, nanotechnology, optoelectronic, bioremediation, petroleum recovery, chemical transformation and drug delivery [5,6,7,8,9,10,11]. However, surfactants have been extensively used as adhesives, flocculating, wetting and foaming agents, deemulsifiers and penetrants in industries based on their abilities to lower surface tensions, increase solubility, detergency power, wetting ability and foaming capacity [12]. The petroleum industry has traditionally been the major users, as in enhanced oil removal applications [13]. Gemini surfactant, a special kind of surfactant molecules, is widely applied in numerous fields such as preparation of high-porosity materials, phase transfer catalysts, body care products, drug encapsulation/release, oil recovery, and antifungal and antibacterial agents [14, 15]. Currently with increasing market demand and environmental concerns, a new class of biodegradable surfactants from microbial origin known as biosurfactants is emerged as an excellent alternative to their chemical counterparts. Biosurfactants have been received much attention in pharmaceutical and industrial applications owing to their outstanding physicochemical property, harmless nature, biocompatibility and chemical diversity [16].

The applied aspects of surfactant have been growing day by day and simply lead to the development of chemical process following the conditions of green chemistry. In the context of green chemistry, nowadays the researchers great endeavor is to avoid waste from side products, along with execution of catalytic reactions, devoid of hazardous solvents and low energy costs in terms of supply and recycling [17]. Earlier, the application of surfactants in chemical transformation was primarily concentrated on aqueous phase catalysis reaction in laboratory scale; nevertheless, it is being rapidly escalated to the medicinal and industrial level in the present date. Nowadays, the use of surfactants is gradually increasing in the pharmaceutical formulations [13] since the surfactants in the pharmaceutical productions are successfully employed to solubilize the drugs and to provide them a reasonable stability. The particular nature of interactions between surfactant molecules and the drug molecules is highly significant with the viewpoint of stabilization and solubilization of drugs against degradation throughout its transportations in the biological systems [18,19,20].

The analysis of surfactant aggregation along with its potential application is a hot topic in association with the studies on the effect of organized assemblies during a number of chemical transformation [21,22,23]. The applicability of a particular surfactant in a reaction is mainly determined by the nature of forming aggregates [24]. The aggregated structural component of amphiphilic molecules is used as catalytic nanoreactor in a wide range of industrially important organic transformations. In addition, the surfactants are successfully employed to synthesize metal nanoparticles and thereby stabilize the nanoparticles. In most of the cases, monomeric surfactants are used as aggregates undergo catalysis with metal nanoparticles which are stabilized by amphiphiles, polymeric micelles or dendrimers [25].

The present review outlines the major applied aspect of surfactant aggregates from laboratory-based performance to the field-wide commercial applications highlighting especially pharmaceuticals, detergents, oil recovery, bioremediation, drug delivery systems and organic reactions.

Applications of surfactant in versatile fields

The utility of surfactants in global market experienced steady growth in the last few years. The global surfactant market is in a transitional phase: diversification or consolidation. Applications of different kind of surfactants in diverse fields have been reported as follows.

Market Report: Global surfactant market in personal care by type, 2015 [26]

Pharmaceuticals and cosmetics

In the past decades, an especially strong focus on the utilization of surfactants in pharmaceutical application has emerged. Surfactants have been explored as pharmaceutical adjuvant for many years owing to their unique functional properties. Synthetic surfactants have been commonly utilized in the petroleum, food and pharmaceutical industries as emulsifiers and wetting agents [27]. Surfactants are useful in the preparation of ointment, cold cream, cleansing cream, vanishing cream, shaving cream since it can be easily removable from skin when washing with water. So many reviews, book chapters and recently published articles are highlighted the pharmaceutical application of surfactants [12, 28, 29]. The fundamental information relating to synthesis and application of novel surfactant in cosmetic products was depicted by Lukic et al. [30]. Quaternary ammonium surfactants (N+ containing cationic surfactant, QAS) have been received much more attention in the biomedical field due to their antibacterial, antiviral and antifungal activity with broad spectrum since 1935 to date [31,32,33]. The QAS are not readily biodegradable and are toxic to aquatic organism. Hence increasing demand to synthesize the more environmentally benign surfactant has been knocking; at that time, amino acid-based surfactant appeared [34, 35] as the novel promising antibacterial agents used to hamper the development of bacteria resistance [36]. The HLB value of the molecule, cationic charge density and amino acid sequence on the polar head group directly influences the antimicrobial activity. The natural environment of proteins is a crowded environment as in cells. Many proteins, especially those used as therapeutics, are unstable to storage and shipping temperatures. Over the last decade, the biggest challenges in protein-based pharmaceutical products are maintaining the structural stability of proteins during purification, processing and storage. Surfactants can directly influence the protein stability by binding to them [37, 38]. Ionic surfactant mainly binds with protein molecules through both the electrostatic and hydrophobic interactions, whereas nonionic surfactants attach to proteins through only hydrophobic interactions. The nonionic surfactant plays a pivotal role in stabilizing the protein in commercial formulations over the ionic surfactants; however, the mechanism of this stabilization is not clearly established [39, 40]. Katz et al. [41] reported that the amino acid-based nonionic surfactants are promising one for stabilization of protein pharmaceuticals. Kishore and coworkers recently focused on the understanding of interactions of nonionic surfactants with proteins in biotherapeutic formulations [42]. Polysorbates (PS) are the most common surfactants in nonionic class, frequently used in biopharmaceutical products, particular to protect proteins against interfacial stress [43, 44]. Recent review article has been depicted the trends of polysorbates and their degradation products in biopharmaceutical formulations [45].

Detergents and cleaning agents

Every year, more than 50 million tons of detergent is used in the world in any form (powder, liquid, bar, paste, cake, shape, molded piece, etc.) for household laundry products, domestic and industrial cleaners and cosmetic products. Surfactant is one of the most fundamental ingredients for formulation of detergent and other cleaning agents. The primary function of all cleaning agents is to cleanse the surface of matter by removing hydrophobic oily molecules such as non-covalently bound lipids and dust particles, as water alone cannot remove the oily or greasy soil blurred on cloth [46]. The removal of these greasy materials from the surface of cloth is typically achieved using surfactants, as they can effectively solubilize these molecules by forming micelles. Surfactant molecules composed by two parts: hydrophobic tail and hydrophilic head able to form a bridge between water and oil. The hydrophobic tails of the surfactant tightly entrap the oily soil and adsorb onto it while their hydrophilic head groups oriented toward the water. The oil or grease material is thus dispersed into the water as such as the oil-in-water emulsion formed. In this form, it can be rinsed away. The exploitation of surfactant in production of soaps and detergent (personal cleansing, laundry, dishwashing, household cleaners) has been moved up to a great extent on or after the beginning. Anionic surfactants are frequently used as wetting agents in industrial applications, particularly where the wetting liquid is applied on a waxy or “waxlike” surface [47]. Two major surfactants currently use in detergent industry are the linear alkylbenzene sulfonates (LAS) and the alkyl phenol ethoxylates (APE). Since anionic surfactant is the most important components of laundry detergents [48, 49] while cationic surfactants are commonly used in hair care products as it makes the hair softer, silky and glossy when treated with hair as well, the wetting aptitude of cationic surfactants has found applications as oil-wetting agents in dry cleaning fluids. Dialkyl quaternary ammonium compounds with long alkyl chain are the common class of cationic surfactants used in detergents as fabric softeners. Most of the nonionic surfactants consist of a series of ethylene oxide groups (EO) in the form of an ethoxylate chain which creates hydrophilicity in the molecule. It should be pointed out that synthetic nonionic surfactants with 7–12 mol of ethylene oxide content exhibited excellent detergent property [50]. Polyethoxylated surfactants are widely applied in the formulation of different cleaning agents such as shampoo, dish washing and hand washing products and lotion formulation [51]. The cleansing agents are mainly four types: soap, synthetic detergents, lipid-free lotions and prescription antimicrobials [52].

Recently, considerable attention has been focused on the production of environmental friendly, low-cost modern synthetic cleaning agents owing to environmental risks associated with their manufacture, use and disposal. Binici et al. [53] recently reported sunflower stalk powder as non-harmful natural detergents which can remove a high percentage of difficult stains. Because of the amphipathy nature, surfactants are able to lower the surface tension, disrupting the cohesive energy at the water surface and thus considered as a viscosity builder and foam booster. The highly surface active fatty acid salt compounds, containing at least eight carbon atoms, are used as a detergent abundantly. The following list gives some of the more common surfactants with their potential application in pharmaceutical and cleaning performance (Table 1) [54].

Bioremediation

Bioremediation is a process of biological transformation of organic compounds by living microorganism, widely employed novel waste management technique to remove or neutralize the environmental pollutants from a contaminated site. Surfactant-assisted bioremediation process can be used as an effective and convenient method over earlier established chemical processes for the elimination of toxic heavy metal species. The highly toxic Cr(VI) was effectively reduced to relatively less toxic Cr(III) in the presence of SDS and TX-100 through the oxidation of bio-organic compounds present in the water extract of wall algae [55]. Water extract of mango leaves in the presence of these surfactants also has strong bioremediation property for Cr(VI) detoxification from the contaminated effluents [56]. Recently, a natural surfactant, saponin, was successfully extracted from Soapnut (Sapindus mukorossi) for utilization in the bioremediation of greater percentage of hexavalent chromium from contaminated water [57]. An another report exhibited that TX-100 and SDS surfactants were used to accelerate the bioremediation rate of hexavalent chromium by the aqueous extract of sugar cane bagasse [58]. In most of the cases, SDS was found to be the best accelerator for efficient and maximum reduction of higher valent metal ions from contaminated water [59]. The application of surfactant or micellar aggregates for isolating heavy metal ions from water is now gaining popularity depending on micellar-enhanced ultrafiltration process where the surfactant selected as charge opposite to the target toxic ions [60]. Biosorption of Cr(VI) by water extract of Siris (Albizia lebbeck) sawdust was appeared as a very cost-effective alternative for decontamination of higher valent chromium-bearing effluents. SDS and TX-100 micellar aggregates were able to assist the bioremediation process efficiently and increased the removal rate by the phenomena of micellar catalysis [61].

In the perspective of sustainable management, the applications of biosurfactant in the environmental industries are very promising on account of their biodegradability, low toxicity and effectiveness in accelerating biodegradation and solubilization of low-solubility compounds [15]. The rhamnolipid biosurfactant can enhance the in situ bioremediation process both effectively and economically. Furthermore, biosurfactants are equally effective for remediation of hydrocarbons and related polluting organic compounds. Over the last few years, many studies have addressed on the biosurfactant-enhanced desorption of organic contaminants adsorbed onto soil and organic pollutants on their desorption in soil–water-surfactant systems [62]. Yang et al. established bioavailability of hydrophobic volatile organic compounds (VOCs), n-hexane by introducing SDS into a biofilter in batch mode. Here the anionic surfactant was proved excellent for enhancing the degradation of n-hexane from contaminated air streams [63]. Surfactants have the great potential to boost the biodegradation rate of hydrophobic organic compounds in unhygienic environments by increasing the total aqueous solubility of these compounds. The use of nonionic surfactants, e.g., Brij 35, Tween 81, Tween 20, Triton X-100, in biofilters for improving volatile organic compounds (VOC) removal has attracted more concern [64]. The most abundant biosurfactants rhamnolipids and saponins have many advantages in biodegradation of VOCs since they are less toxic, environmental friendly compounds and more biodegradable [65]. The upcoming success of biosurfactant in bioremediation technique will involve the precise targeting of the biosurfactant system to the physical conditions and chemical nature of the polluted environment [66].

Drug delivery systems

Over the last several decades, a number of phase organization produced by surfactants have been of prime concern to the pharmaceutical scientist, either as drug carriers/vehicles or as targeting systems [67]. The most serious problem with formulating drugs in surfactant systems is the scarcity of suitable and commercially available biodegradable surfactants. Keeping the target in mind, Leonard and coworkers chemically tailored the selected polysaccharide, dextran by the covalent attachment of hydrocarbon groups via the generation of ether links [68]. The hydrophobically modified dextrans are proved to be good candidates for a potential use as in drug delivery particular systems. The dextran was also effective to facilitate the hydrophilic polysaccharide to be used for the preparation of nanoparticles.

Dendrimer–surfactant aggregates are of great potential significant in the design of new drug discoveries/establishment, particularly in transdermal delivery pathways [69]. The dendrimer–surfactant aggregates were evaluated as carriers of hydrophobic drugs, e.g., nonsteroidal antiinflammatory drug phenylbutazone (PBZ), the antibacterial drug sulfamethoxazole (SMZ) and the anticancer drug methotrexate (MTX). Recent studies by Kumar et al. explored the interactions between sodium salt of ibuprofen (SIBU) and conventional surfactant hexadecyltrimethylammonium bromide (HTAB) in addition to gemini surfactant 1,6-bis(N-hexadecyl-N,N-dimethylammonium)hexane dibromide (16-6-16) usually recommended in pharmaceutical formulations. The sodium salt of ibuprofen (NaIBU) drug encloses a carboxylate group and also facing numerous side effects, whereas most of the side effects can be reduced by employing proper drug carriers [70]. Nieder et al. reported the in vitro performance of vesicles based on cationic and anionic serine-based surfactants using a cancer cell model for the delivery of the anticancer drug doxorubicin (DOX). These serine-based surfactant vesicles are investigated as nanocarriers for DOX, a well-known agent among the anthracycline antibiotic drugs [71]. Micellar clusterization (MC) method supported on TX-100 and TX-114 had been applied to obtain MCs loaded by toxic hydrophobic compounds such as bilirubin and coumarin 6. The systems were encapsulated by the newly synthesized anticancer PTR-58-CLBCAMP peptide drug. The study showed that MCs encapsulated by the anticancer drug, which is naturally highly hydrophobic, demonstrated significant antitumor activity against HeLa cells [72].

Span and Tween surfactants are composed of sugar structure and acyl chain which have been reported as a substance of drug carrier [73]. Hayashi and coworkers investigated the function of Span 20, Span 40 and Tween 20 and Tween 40 aggregates as drug carriers by using 8-anilino-1-naphthalenesulfonic acid (ANS) as a model drug [74]. Shoichet et al. designed a stable, targeted colloidal formulation with the ionizable chemotherapeutic lapatinib. The work corresponds to the selective, stimulus-responsive release of drugs from colloidal aggregates, thus laying the framework for controlled release from a colloid that is inactive until its target is reached [75]. The research groups of Zhang have successfully represented the grafting of β-cyclodextrin (β-CD) onto cellulose nanocrystal (CNC) in a stepwise manner using cyanuric chloride as the linker. The process can efficiently describe the complex formation between CNC-CD and surfactants. In this case, an improved understanding of CD interactions with surfactants and lipids would enable better strategies for drug encapsulation with CDs [76].

The properties of surfactants are such that they can modify the diffusion, solubility, disintegration, thermodynamic activity and dissolution rate of a drug. Furthermore, surfactants can apply direct effects on biological membranes, thereby altering drug transport across the membrane. Very recently lysine-based novel bola surfactant exhibited as an excellent pH-sensitize drug carrier for targeting tumor tissues [77]. PEG-based neutral amphiphilic random copolymer micelles have been expansively used as drug delivery agents in recent time [78]. Molecular self-assembly of surfactant-based materials are used to construct well-organized carriers for targeted delivery and release of bioactive molecules in a number of important purposes ranging from pharmaceutical to cosmetics [79].

In oxidative transformations

In the angle of organic transformation, several metal-mediated oxidative reactions were investigated in aqueous micellar medium. In most of the cases, micelles play a crucial role to influence the kinetics of the oxidation pathways. The most prominent role of surfactant micelles is the improvement of reaction velocity for a particular bimolecular reaction by concentrating both the reactants at their surfaces. Many works have been reported on the higher valent metal-based oxidation of organic molecules catalyzed by numerous surfactant micelles. The catalytic enhancement of the micelle-mediated organic transformation is due to the higher collision frequency among the reactant molecules in the small volume of micelle-like confined environment, the phenomenon termed as localization effect (Schemes 1 and 2). However, micellar catalysis critically depends on the interactions of the micellar aggregates with the substrate(s) and the activated complex (Schemes 3 and 4). Surfactant micelle plays as a confined nanoreactor in homogeneous medium for all the different reactions [80] by enhancing the velocity of the reaction up to kilo fold or even more in magnitude depending on the substrate molecules and reaction parameters. Besides, there are a number of significant factors (ascribed below) involved which governed the rate enhancement for a particular oxidation reaction examined under the specific micellar environment.

Localization of the cationic vanadium(V) species and propanol in the Stern layer region of anionic SDS micellar surface. Reproduced with permission from Ref. [87]

Schematic model showing reaction site for the micelle-mediated oxidation reaction for a [Ce(IV)] species, valeraldehyde and proton; b [Ce(IV)] species, Ru(III)-valeraldehyde and proton. Reproduced with permission from Ref. [86]

Representation of 1-pentanol oxidation by Cr(VI) and reactant molecules encapsulated in a micelle-like aggregate. Reproduced with permission from Ref. [81]

Schematic model showing probable reaction site for CPC micelle-mediated oxidation reaction between [MnO4−] and 2-butanol. Reproduced with permission from ref. [91]

- (a)

A strong electrostatic or Coulombic interactions between the oppositely charged micelles and the accumulated active oxidant species at stern layer of micelle is another one forceful factor behind the micellar catalysis [81,82,83,84,85,86,87,88,89,90].

- (b)

The distribution of reactants between water and “pseudo-micellar phase” in the micellar media also endorsed for acceleration of reaction kinetic [91, 92].

- (c)

The hydrogen bonding or hydrophobic interaction between the nonionic micelles and anionic form of amino acid (in alkali medium) plays an important role [93].

- (d)

A greater attractive interaction between reverse micelle and the cationic head group of lipopathic oxidant established for the rate enhancement [94].

- (e)

The partitioning mode leads to higher local concentration of both the reactants at the micelle water surface for which preferential rate enhancement in the micellar phase was noticed [95].

Micellar catalysis and organic reaction in micellar media

The employment of aqueous solutions of surfactants to promote chemical transformations and to control substrate and product selectivity is no more a curiosity, but a common practice to cope with the raising request to limit the use of organic solvents. This is not just a trendy green option, but a desired option thanks to the fact that micelles in many cases improve yields, selectivity (chemo, regio, enantio) as well as favor product separation, and very importantly, they promote catalyst recycling. The confinement of apolar substrates within the micelles implies a higher local concentration for the substrates with respect to the same reaction in an ordinary organic medium leading to increase in reactivity, and if the products are sufficiently apolar, these can be extracted with limited amounts of water-immiscible organic solvents with possible catalyst recycling with evident economic advantages and better perspectives for practical applications. Micellar catalysis as reactions promoted by micelles and the use of catalysts in micellar media is a field of research that has been reviewed several times over the last decade [96,97,98,99,100], recently focusing on new emerging trends like the application to multicomponent reactions [101], the use metal nanoparticles associated with micellar media [102, 103], the synthesis and applications of chelating surfactants for metal cations [104], the combination of micellar media with visible light photo-redox catalysis [105], the development of new surfactants endowed with new catalytic head groups [106]. Because of this, the present contribution will focus specifically on application of micellar media in chemical transformations in the presence or absence of catalysts for the period 2018 until the publication of the present review paper. Specifically, due to the large amount of papers present in the literature, a critical selection of the most important results has been carried out, classifying the contribution as function of the role of the surfactant and of the micellar aggregates as true catalysts or nanoreactors and then detailing the differences in terms of the nature of the surfactant, often specifically designed for the catalytic performance described. In fact, some chemical transformations can be accelerated in water by the presence of just the surfactant above the CMC due to compartmentalization; in other cases, a catalyst (organocatalyst, transition metal complex as catalyst or metal nanoparticle is requested) and the micellar media have the role to promote the intimate contact between substrates and the catalyst (metal complex or metal nanoparticle), imparting specific selectivity both for the substrate and the product.

Catalysis by micelles

A recent example of the combination of hydrogen peroxide with formic acid for the in situ formation of performic acid in aqueous solution was reported for the oxidation of aromatic amines to nitro compounds with good selectivity and activity in the presence of the cationic surfactant CTAB [107]. The oxidation reaction was optimized enabling the synthesis of a series of nitroaromatic compounds with yields in the range 39–92% in just 15 min with no use of metal complexes through a ecofriendly and economically viable protocol.

Another pair of examples from the group of Saha were related to the kinetic study of the oxidation of cyclohexanol to cyclohexanone with chromic acid in aqueous medium and the oxidation of lipophilic alcohol like octanols observing the beneficial effect of the combination of the presence of SDS as surfactant with 2,2‘-bipyridine [108, 109]. After optimization of several reaction parameters, it was possible to achieve several hundred-fold accelerations of the rate of the reaction with complete conversion in few minutes.

Micelles obtained with cationic surfactants have the ability to concentrate on the surface (Stern layer) a large amount of counter-anions, thus favoring the interaction of the latter with apolar substrates dissolved in the apolar core of the micelles. This effect is a common strategy observed, for instance, in the recently reported synthesis of 3-hydroxy-3-(nitroalkyl)indolin-2-one by reaction of isatins with nitromethane with the anionic surfactant SDS that forms anionic micelles. On the surface of the micelles, 1-butyl-3-methyl imidazolium hydroxide (BMIm[OH]) is attracted favoring the reaction of the hydroxyl anion with the nitroalkane forming the nucleophilic species that finally attacks the isatins leading to the final products [110].

Transition metal catalysts

An important group of reactions widely investigated in micellar media is the cross-coupling reactions. Recently, the Sonogashira coupling between aryl halides and alkynes was further investigated with the aid of surfactants in water observing that for the reaction with Pd(II) catalyst coordinated to diamines, triethylamine as base, CuI and SDS in aqueous media, a key role was played by the ligand of the metal. In particular, the smaller N,N,N′,N′-tetramethylethylenediamine turned out to favor the reaction, [111] leading in the presence of the substrates to the formation of micelles characterized by smaller size than with other complexes bearing more hydrophobic ligands.

A further important advantage of the use of micellar media with transition metal catalysis consists in a simplified catalyst recycling. An important example was recently reported for the stereoselective hydrogenation of itaconic acid and ester derivatives mediated by Rh/BPPM catalyst. The chiral metal catalyst was efficiently recycled through cloud point extraction (CPE) from aqueous micellar solutions of the nonionic surfactant NP8 and reused in subsequent reactions [112]. While for substrate with free acid moieties the activity was severely affected, for itaconic esters the reaction was very efficient and recycling was almost quantitative with ~ 96% of metal recovered.

Metal nanoparticle catalysis

Micellar media has also the great effect to stabilize metal nanoparticles, and a recent general example was reported by Scarso and collaborators dealing with the selective hydrogenations and dechlorination reactions in water with Pd nanoparticles stabilized by anionic surfactants like sodium 1-dodecanesulfonate, sodium dodecylbenzene sulfonate, dioctyl sulfosuccinate sodium salt and poly(ethylene glycol) 4-nonylphenyl-3-sulfopropyl ether potassium salt (Scheme 5) [113]. The Pd nanoparticles micellar solutions were simply obtained stirring Pd(OAc)2 with the commercial anionic surfactants further treated under hydrogen atmosphere for variable amounts of time and then were successfully tested for a wide series of hydrogenation reactions, in most cases overperforming with respect to Pd/C as a benchmark catalyst. In particular, efficient hydrogenation of aryl-alcohols, aldehydes and ketones as well as controlled semi-hydrogenation of alkynes leading to alkenes and in the efficient hydro-dechlorination of aromatic substrates were achieved.

Metallo-micelles

In some cases, specific coordination units are connected to the surfactant in order to obtain metallo-micelles and metallo-nanoparticles. An example of this approach is related to the synthesis of PEG-grafted nitrogen ligands that once coordinated to copper led to the formation of metallo-micellar nanoreactors for the aerobic tandem desilylation/glaser coupling of TMS-protected alkynes in water and for the base-free homocoupling of terminal alkynes [114], with the important advantage of good recyclability.

When the surfactant unit is directly bound to the catalytic metal center, for instance through coordination, metallo-micelles are present. An example of this approach applied to polyoxometalate (POM) catalyzed reaction was recently proposed for the oxidation of alcohols where the apolar portion was covalently grafted to the POM unit through an alkoxysilane group [115]. The metallo-micelle catalyst was employed in a biphasic catalytic system forming efficient emulsions that could be simply solved increasing the temperature leading to isolation of the catalyst for many times with no apparent decrease in catalytic activity.

Designer surfactants

The field of micellar catalysis received a boosting improvement by the works of Lipshutz and collaborators dedicated to the development of new surfactants specifically designed and synthesized for catalytic applications. The group disclosed a series of new sustainable amphiphiles based on α-tocopherol (vitamin E) as the apolar portion connected through different bis-carboxylic spacers to different polyethylene glycol derivatives. Such new surfactants, in particular TPGS-750-M, demonstrated impressive properties for a wide range of chemical transformations often enabling much milder experimental conditions.

Further extensions of the already rich chemistry of TPGS-750-M were provided by Ackermann that described an important example of C–H activation of an aryl thioketone substrate using 10 mol% of ruthenium(II) precursors in combination with TPGS-750-M surfactant in water at 100 °C (Scheme 6) [116]. The reaction occurred on thioketone ferrocene derivatives thanks to the weak chelation assistance of the sulfur atom to the metal center leading to C–H arylated ferrocenes with wide functional group tolerance and possible catalyst recycling up to four times, with a general 50% decrease in the E-factor of the reaction with respect to the same transformation in toluene.

The use of TPGS-750-M was further extended to the amide coupling reaction for peptide synthesis enabling the preparation of polypeptides using 1-cyano-2-ethoxy-2-oxoethylidenaminooxy)dimethylamino-morpholino-carbenium hexafluorophosphate (COMU) as coupling agents with no problems related to the presence of water as solvent [117]. Each coupling reaction could be carried out in few hours and 8 h for a two-step deprotection/coupling process, on gram scale with no racemization issues.

Since biocatalysis with enzymes ensures very high activity and stereoselectivity, the group of Lipshutz demonstrated its compatibility with traditional metal-catalyzed transformations using TPGS-750-M as surfactant in water as sole medium [118]. Specifically, they reported about the synthesis of ketone-containing products through transition metal-catalyzed reactions based on Pd, Cu, Rh, Fe and Au that was followed by enzymatic reductions mediated by alcohol dehydrogenases in the same solution system. The nanomicelles provided by the aggregation properties of the surfactant acted as substrate reservoir and favored also the enzymatic reduction of more lipophilic substrates, while being completely compatible with the enzymatic chemical transformations.

The designer surfactant TPGS-750-M turned out to greatly affect the yields for reactions involving metal nanoparticle catalysts. One example was related to the synthesis of Fe nanoparticles doped with ppm levels of other metals (Pd + Ni) that were efficiently tested for the reduction of nitroaromatic compounds to the corresponding anilines with borohydride reducing agents in water [119]. The very low noble metal content was possible thanks to a synergistic effect with the Fe nanoparticles and the micellar media. The reaction turned out to be characterized by a broad substrate scope, low catalyst loading with possible in-flask product isolation and recycling of the catalyst.

Other designer surfactants

The impressive potentialities of designer surfactants developed by Lipshutz spurred several other research groups to design, synthesize and test new surfactants for catalytic applications. An interesting new surfactant based on the dehydroabietinol–polyethyleneglycol–succinate monomethyl ether structure called DAPGS-750-M, as a potential alternative to the commercially available TPGS-750-M, was proposed based on the hydrophobic core of rosin functionalized with a PEG unit to be employed for the oxidation of tertiary alcohols with β-scission mediated by AgNO3, K2S2O8 and Bi(OTf)3 leading to ketones in water (Scheme 7) [120]. The reaction was possible under mild experimental conditions, for a wide range of substrates with the simple in-flask recycling of the aqueous phase after product isolation.

Another neutral surfactant recently proposed is FI-750-M [121] comprising a long alkyl chain connected through a proline unit to a PEG hydrophilic portion that showed good results in the Suzuki–Miyaura cross-couplings of 2-and 4-quinoline and isoquinoline substrates with gram-scale product formation. Peculiar features of the micellar catalytic method were the low catalyst loading, the good compatibility with other functional groups and the good recyclability directly in the flask.

The group of Lipshutz pursued on the development of new surfactants for micellar catalysis. With this aim, to improve peptide synthesis in water and taking inspiration from the reactions in DMSO as common polar aprotic solvent, Lipshutz and collaborators disclosed the synthesis of MC-1 as new surfactant comprising a sulfone unit in the apolar core of the structure while for the polar hydrophilic portion a traditional PEG fragment was used [122]. The implementation of the sulfone unit led to a series of advantages like high yields, ease of handling of the reaction mixtures and gram-scale syntheses.

To address a common problem encountered in reactions performed in water in which gas evolution takes place, like, for instance, reduction reactions, a specifically designed surfactant was proposed named Coolade characterized by good anti-frothing properties in order to greatly mitigate the foaming effect during organic synthesis in water. The synthesis of Coolade was specifically designed in order to easily isolate the product without requiring column chromatography. Typical examples of successful applications of Coolade were the reduction of nitroaromatic compounds to the corresponding anilines or the reduction of organic azides to the corresponding amines [123].

An interesting example of the application of SPGS-550-M as one designer surfactant developed by Lipshutz based on β-sitosterol methoxyethyleneglycol succinate commonly known as Nok [124] was the Pd-catalyzed arylation of indoles with aryl bromides in water under mild experimental conditions. The reaction turned out to enable the efficient synthesis of the C-arylated (C-3 and C-2) indole products depending on the chelating phosphine ligand employed for the metal center, enabling multigram scale with relatively low catalyst loading.

Conclusions

The chemistry behind the surfactant aggregation and the application of micellar aggregates is an interesting topic that merits further research. In connection with the usefulness of surfactants, the application of cationic, anionic, nonionic or amphoteric surfactants in many industrial processes is very well known. The important properties such as increase solubility, detergency power, wetting ability, foaming capacity and abilities to lower the surface tension make their application in broader sense in terms of commercial and biomedical perspective. In spite of the above applications, surfactants serve as dissolving hydrophobic molecules, vehicle for drugs and protecting agent (from degradation) as well. This review discusses about the application of surfactants in various industrial, medicinal and chemical fields. In addition, we reveal the applications of polymeric surfactants are not only restricted to laboratory purpose rather it is being consumed in miscellaneous industrial as well as biological productions.

Due to their high availability, low-cost, self-assembling properties and wide chemical variability, surfactants in water provide unique chemical environments for chemical transformations. Moreover, the recent efforts of several research teams further boosted the field proposing a wide range of new surfactant, mostly neutral, specifically designed to address a wide range of organic synthesis needs. Micellar catalysis is strongly dependent on the correct choice of the surfactant and for the optimization of several issues of the entire chemical processes; therefore, more input is necessary in this direction. New emerging ideas for catalysis in micellar media have been reported in this section, with the hope that thanks to the many advantages, and the much lower environmental impact, micellar catalysis and micellar media one day not too far will surpass traditional organic solvents for chemical transformations.

Concerning the environmental impact, thanks to the self-assembling properties of surfactants for their crucial role in different branches as discussed earlier. Currently, importance of the surfactant and micelle-like confined environment is so emerging that more and more researchers will move toward the direction of unveiling new aspect of surfactant for better tomorrow.

Abbreviations

- CTADC:

-

Cetyltrimethylammonium dichromate

- CTAB:

-

Cetyltrimethylammonium bromide

- SDS:

-

Sodium dodecyl sulfate

- TTAB:

-

Tetradecyltrimethylammonium bromide

- CHAPS:

-

3-[(3-Cholamidopropyl)dimethylammonio]-1-propanesulfonate

- CPC:

-

N-cetylpyridinium chloride

- Brij 35:

-

Dodecyltricosaethylene glycol ether

- Tween-80:

-

Polyethylene oxide sorbitan monooleate

- Span 20:

-

Sorbitan monolaurate

- Span 40:

-

Sorbitan monopalmitate

- SDBS:

-

Sodium dodecylbenzenesulfonate

- CMC:

-

Critical micellar concentration

- DODAB:

-

Dioctadecyldimethylammonium bromide

- DMPC:

-

Dimyristoylphosphatidylcholine

- CD:

-

Cyclodextrin

References

P.J. Reeve, H.J. Fallowfield, J. Environ. Manag. 205, 253 (2018)

V. Hamme, J.D. Singh, A. Ward, Biotechnol. Adv. 24, 604 (2006)

M. Bustamante, N. Duran, M.C. Diez, J. Soil Sci. Plant Nutr. 12, 667 (2012)

J. Zhao, X. Liu, Y. Wu, D.-S. Li, Q. Zhang, Coord. Chem. Rev. 391, 30 (2019)

M. Ramanathan, L.K. Shrestha, T. Mori, Q. Ji, J.P. Hill, K. Ariga, Phys. Chem. Chem. Phys. 15, 10580 (2013)

A. Spernath, A. Aserin, Adv. Colloid Interface Sci. 128–130, 47 (2006)

M. Fanun, Curr. Opin. Colloid Interface Sci. 17, 306 (2012)

S. Chowdhury, A. Rakshit, A. Acharjee, B. Saha, ChemistrySelect 4, 6978 (2019)

J. Eastoe, M.J. Hollamby, L. Hudson, Adv. Colloid Interface Sci. 128–130, 5 (2006)

A.S. Narang, D. Delmarre, D. Gao, Int. J. Pharm. 345, 9 (2007)

M. Mishra, P. Muthuprasanna, K. Surya Prabha, P. Sobhitarani, I.A. Satishbabu, I.S. Chandiran, G. Arunachalam, S. Shalini, Int. J. PharmTech Res. 1, 1354 (2009)

M.H. Mondal, S. Malik, A. Roy, R. Saha, B. Saha, RSC Adv. 5, 92707 (2015)

C.N. Mulligan, Environ. Pollut. 133, 183 (2005)

Z. Huang, C. Cheng, L. Li, Z. Guo, G. He, X. Yu, R. Liu, H. Han, L. Deng, W. Fu, J. Agric. Food Chem. 66, 13126 (2018)

M.H. Mondal, A. Roy, S. Malik, A. Ghosh, B. Saha, Res. Chem. Intermed. 42, 1913 (2016)

S. De, S. Malik, A. Ghosh, R. Saha, B. Saha, RSC Adv. 5, 65757 (2015)

M. Schwarze, T. Pogrzeba, I. Volovych, R. Schomacker, Catal. Sci. Technol. 5, 24 (2015)

C.H. Hsu, Z. Cui, R.J. Mumper, M. Jay, AAPS PharmSciTech 9, 939 (2008)

A. Al-Lohedan, H.F.F. Al-Blewi, M.Z.A. Rafiquee, Z.A. Issa, J. Mol. Liq. 206, 321 (2015)

A.S. Al-Ayed, M. Ali, H.A. Al-Lohedan, A.M. Al-Sulaim, Z.A. Issa, J. Colloid Interface Sci. 361, 205 (2011)

C. De, R. Saha, S.K. Ghosh, A. Ghosh, K. Mukherjee, S.S. Bhattacharyya, B. Saha, Res. Chem. Intermed. 39, 3463 (2013)

S. Mandal, S. Mandal, S. Biswas, S. Banerjee, B. Saha, Res. Chem. Intermed. 44, 2169 (2017)

P. Sar, A. Ghosh, S. Malik, B. Saha, J. Carbohydr. Chem. 35, 86 (2016)

M. Ishiguro, L.K. Koopal, Adv. Colloid Interface Sci. 23, 59 (2016)

T. Dwars, E. Paetzold, G. Oehme, Angew. Chem. Int. Ed. 44, 7174 (2005)

Market Report: Global Surfactant Market, 4th edition

B.S. Sekhon, J. Pharm. Technol. Res. Manag. 1, 11 (2013)

N. Kumar, R. Tyagi, Cosmetics 1, 3 (2014)

C. Zhou, F. Wang, H. Chen, M. Li, F. Qiao, Z. Liu, Y. Hou, C. Wu, Y. Fan, L. Liu, S. Wang, Y. Wang, A.C.S. Appl, Mater. Interfaces 8, 4242 (2016)

M. Lukic, I. Pantelic, S. Savic, Tenside Surfactant Det. 53, 7 (2016)

M. Jadhav, R.S. Kalhapure, S. Rambharose, C. Mocktar, T. Govender, J. Ind. Eng. Chem. 47, 405 (2016)

R. Herbert, D. Tom, S. Anja, G. Silke, B. Harald, Am. J. Rhinol. 18, 291 (2004)

R. Enomoto, C. Suzuki, M. Ohno, T. Ohasi, R. Futagami, K. Ishikawa, M. Komae, T. Nishino, Y. Konishi, E. Lee, Ann. N. Y. Acad. Sci. 1095, 1 (2007)

M.C. Moran, A. Pinazo, L. Perez, P. Clapes, M. Angelet, M.T. Garcia, M.P. Vinardell, M.R. Infante, Green Chem. 6, 233 (2004)

A. Pinazo, R. Pons, L. Perez, M.R. Infante, Ind. Eng. Chem. Res. 50, 4805 (2011)

A. Pinazo, M.A. Manresa, A.M. Marques, M. Bustelo, M.J. Espuny, L. Perez, Adv. Colloid Interface Sci. 228, 17 (2016)

L.S. Jones, N.B. Bam, T.W. Randolph, ACS Symp. Ser. 675, 206 (1997)

T.W. Randolph, L.S. Jones, Surfactant-protein interactions, in Pharmaceutical Biotechnology, Rational Design of Stable Protein Formulations, vol. 13, ed. by J.F. Carpenter, M.C. Manning (Plenum, New York, 2002), p. 159

H.L. Kim, A. Mcauley, J. Mcguire, J. Pharm. Sci. 103, 1337 (2014)

P.K. Chang, C.A. Prestidge, T.J. Barnes, K.E. Bremmell, RSC Adv. 6, 78970 (2016)

J.S. Katz, Y. Tan, K. Kuppannan, Y. Song, D.J. Brennan, T. Young, L. Yao, S. Jordan, A.C.S. Biomater, Sci. Eng. 2, 1093 (2016)

T.A. Khan, H.-C. Mahler, R.S.K. Kishore, Eur. J. Pharm. Biopharm. 97, 60 (2015)

B.A. Kerwin, J. Pharm. Sci. 97, 2924 (2008)

M. Agarkhed, C. O’Dell, M.-C. Hsieh, J. Zhang, J. Goldstein, A. Srivastava, AAPS PharmSciTech 14, 1 (2013)

A. Martos, W. Koch, W. Jiskoot, K. Wuchner, G. Winter, W. Friess, A. Hawe, J. Pharm. Sci. 106, 1722 (2017)

L. Landeck, L.A. Baden, S.-M. John, Detergents, in Kanervas Occupational Dermatology, vol. 2, 2nd edn., ed. by T. Rustemeyer, P. Elsner, S.M. John, H. Maibach (Springer, Berlin, 2012), p. 847

L.L. Schramm, E.N. Stasiuk, D.G. Marangoni, Annu. Rep. Prog. Chem. Sect. C Phys. Chem. 99, 3 (2003)

D. Bajpai, V.K. Tyagi, J. Oleo Sci. 56, 327 (2007)

J.J. Scheibel, J. Surfactants Deterg. 7, 319 (2004)

Chemical Formulation: An Overview of Surfactant-based Preparations Used in Everyday Life, Chapter 2: Surfactants in Action, RSC (2003) Cambridge University Press, Cambridge, UK, p. 71

M. Saraji, N. Shirvani, Int. J. Cosmet. Sci. 39, 36 (2017)

C.M.S. Reis, E. Reis-Filho, Cleanser, in Clinical Approaches and Procedures in Cosmetic Dermatology, ed. by M.C.A. Issa, B. Tamura (Springer, New York, 2016), p. 1

H. Biniciet, Res. Civil Environ. Eng. 1, 169 (2013)

M.I. Levison, in Handbook of Detergents Part E: Applications, ed., Taylor & Francis Group, LLC, 2009

R. Nandi, S. Laskar, B. Saha, Res. Chem. Intermed. 43, 1619 (2017)

K. Mukherjee, D. Ghosh, B. Saha, Des. Water Treat. 57, 169219 (2016)

M.H. Mondal, S. Malik, A. Garain, S. Mandal, B. Saha, Tenside Surfactant Det. 54, 519 (2017)

K. Mukherjee, R. Saha, A. Ghosh, S.K. Ghosh, P.K. Maji, B. Saha, Res. Chem. Intermed. 40, 1727 (2014)

K. Mukherjee, R. Nandi, D. Saha, B. Saha, Des. Water Treat. 54, 525 (2015)

K. Mukherjee, R. Saha, A. Ghosh, B. Saha, Res. Chem. Intermed. 39, 2267 (2013)

K. Mukherjee, D. Ghosh, B. Saha, Tenside Surfactant Det. 51, 521 (2014)

F. Fava, S. Berselli, P. Conte, A. Piccolo, L. Marchetti, Biotechnol. Bioeng. 88, 214 (2004)

Y. Cheng, H. He, C. Yang, Z. Yan, G. Zeng, H. Qian, Chemosphere 150, 248 (2016)

W.C. Chan, H.Z. You, Afr. J. Biotechnol. 9, 5914 (2010)

W.J. Zhou, J.J. Yang, L.Z. Zhu, Environ. Pollut. 159, 1198 (2011)

S.S. Cameotra, R.S. Makkar, J. Kaur, S.K. Mehta, Biosurfactants, vol. 20 (Springer, New York, 2010), p. 261

F. Bassyouni, N. ElHalwany, M.A. Rehim, M. Neyfeh, Res. Chem. Intermed. 41, 2165 (2015)

A. Aumelas, A. Serrero, A. Durand, E. Dellacherie, M. Leonard, Colloids Surf. B 59, 74 (2007)

Y. Cheng, Q. Wu, Y. Li, J. Hu, T. Xu, J. Phys. Chem. B 113, 8339 (2009)

D. Kumar, N. Azum, M.A. Rub, A.M. Asiri, J. Mol. Liq. 262, 86 (2018)

R.C.F.G. Lopes, O.F. Silvestre, A.R. Faria, M.L.C. do Vale, E.F. Marques, J.B. Nieder, Nanoscale 11, 5932 (2019)

A.V. Solomonov, Y.S. Marfin, E.V. Rumyantsev, E. Ragozin, T. Shekhter, Z.G. Gellerman, A.B. Tesler, F. Muench, A. Kumagai, A. Miyawak, Mat. Sci. Eng. C 99, 794 (2019)

P. Balakrishnan, S. Shanmugam, W.S. Lee, W.M. Lee, J.O. Kim, D.H. Oh, D.-D. Kim, J.S. Kim, B.K. Yoo, H.-G. Choi, J.S. Woo, C.S. Yong, Int. J. Pharm. 377, 1 (2009)

K. Hayashi, H. Iwai, T. Kamei, K. Iwamoto, T. Shimanouchi, S. Fujita, H. Nakamura, H. Umakoshi, Colloids Surf. B 152, 269 (2017)

E.N. Donders, A.N. Ganesh, H. Torosyan, P. Lak, B.K. Shoichet, M.S. Shoichet, ACS Chem. Biol. 14, 1507 (2019)

F. Zhang, M.S. Islam, R.M. Berry, K.C. Tam, ACS Omega 4, 2102 (2019)

B. Hu, Y. Yuan, Y. Yan, X. Zhou, Y. Li, Q. Kan, S. Li, Mater. Sci. Eng. C 75, 637 (2017)

P. Laskar, B. Saha, S.K. Ghosh, J. Dey, RSC Adv. 5, 16265 (2015)

M. Salim, H. Minamikawa, A. Sugimura, R. Hashim, Med. Chem. Commun. 5, 1602 (2014)

S. Mandal, S. Mandal, S.K. Ghosh, P. Sar, A. Ghosh, R. Saha, B. Saha, RSC Adv. 6, 69605 (2016)

P. Sar, A. Ghosh, S. Malik, D. Ray, B. Das, B. Saha, J. Ind. Eng. Chem. 42, 53 (2016)

R. Saha, A. Ghosh, P. Sar, I. Saha, S.K. Ghosh, K. Mukherjee, B. Saha, Spectrochim. Acta Part A 116, 524 (2013)

P. Sar, A. Ghosh, R. Saha, B. Saha, Res. Chem. Intermed. 41, 5331 (2015)

P. Sar, A. Ghosh, D. Ghosh, B. Saha, Res. Chem. Intermed. 41, 5565 (2015)

A. Ghosh, R. Saha, K. Mukherjee, S.K. Ghosh, P. Sar, S. Malik, B. Saha, Res. Chem. Intermed. 41, 3057 (2015)

A. Ghosh, P. Sar, S. Malik, B. Saha, J. Mol. Liq. 211, 48 (2015)

P. Sar, A. Ghosh, B. Saha, Res. Chem. Intermed. 41, 7775 (2015)

S. Chowdhury, A. Rakshit, A. Acharjee, A. Ghosh, K. Mahali, B. Saha, J. Mol. Liq. 290, 111247 (2019)

P. Sar, A. Ghosh, S. Malik, B. Saha, Res. Chem. Intermed. 41, 10151 (2015)

A. Ghosh, P. Das, D. Saha, P. Sar, S.K. Ghosh, B. Saha, Res. Chem. Intermed. 42, 2619 (2016)

A. Ghosh, K. Sengupta, R. Saha, B. Saha, J. Mol. Liq. 198, 369 (2014)

P.K. Sen, N. Gani, J.K. Midya, B. Pal, Int. J. Chem. Kinet. 44, 482 (2012)

R. Shukla, S.K. Upadhyay, Colloids Surf. A 331, 245 (2008)

S. Garnayak, S. Patel, Int. J. Chem. Kinet. 48, 32 (2016)

Y.R. Katre, S. Nayak, D.N. Sharma, A.K. Singh, Res. Chem. Intermed. 38, 179 (2012)

G.L. Sorella, G. Strukul, A. Scarso, Green Chem. 17, 644 (2015)

T. Kitanosono, K. Masuda, P. Xu, S. Kobayashi, Chem. Rev. 118, 679 (2018)

B.H. Lipshutz, S. Ghorai, M. Cortes-Clerget, Chem. Eur. J. 24, 6672 (2018)

A. Scarso, Micellar nanoreactors, in Encyclopedia of Inorganic and Bioinorganic Chemistry, 1–16 edn., ed. by D.A. Atwood (Wiley, Chichester, 2016)

A. Scarso, G. Strukul, Transition metal catalysis in micellar media: much more than a simple green chemistry promise, in Green Synthetic Processes and Procedures, ed. by R. Ballini (RSC, New York, 2019), p. 268

D. Paprocki, A. Madej, D. Koszelewski, A. Brodzka, R. Ostaszewski, Front. Chem. 6, 502 (2018)

B.H. Lipshutz, Curr. Opin. Green Sust. Chem. 11, 1 (2018)

M. Bihani, T.N. Ansari, J.D. Smith, S. Handa, Curr. Opin. Green Sust. Chem. 11, 45 (2018)

A. Eivazihollagh, I. Svanedal, H. Edlund, M. Norgren, J. Mol. Liq. 278, 688 (2019)

M.-J. Bu, G.-P. Lu, J. Jiang, C. Cai, Catal. Sci. Technol. 8, 3728 (2018)

S. Polarz, M. Kunkel, A. Donner, M. Schlotter, Chem. Eur. J. 24, 18842 (2018)

K. Ravi, B.D. Bankar, S. Jindani, A.V. Biradar, ACS Omega 4, 9453 (2019)

A. Acharjee, A. Rakshit, S. Chowdhury, S. Malik, M.K. Barman, M. Ali, B. Saha, J. Mol. Liq. 277, 360 (2019)

A. Acharjee, A. Rakshit, S. Chowdhury, I. Datta, M.K. Barman, M. Ali, B. Saha, J. Mol. Liq. 293, 111475 (2019)

A. Chakraborty, T. Ghosh, D.K. Maiti, S. Majumdar, ChemistrySelect 4, 1841 (2019)

Y. Suzaki, Y. Kobayashi, Y. Tsuchido, K. Osakada, Mol. Catal. 466, 106 (2019)

M. Schmidt, S. Schreiber, L. Franz, H. Langhoff, A. Farhang, M. Horstmann, H.-J. Drexler, D. Heller, M. Schwarze, Ind. Eng. Chem. Res. 58, 2445 (2019)

G.L. Sorella, L. Sperni, P. Canton, L. Coletti, F. Fabris, G. Strukul, A. Scarso, J. Org. Chem. 14, 7438 (2018)

S. Tang, L. Li, X. Ren, J. Li, G. Yang, H. Li, B. Yuan, Green Chem. 21, 2899 (2019)

X. Bai, X. Huang, L. Wen, N. Song, J. Zhang, Y. Zhang, Y. Zhao, Chem. Commun. 55, 3598 (2019)

S.R. Yetra, T. Rogge, S. Warratz, J. Struwe, W. Peng, P. Vana, L. Ackermann, Angew. Chem. Int. Ed. 58, 7490 (2019)

M. Cortes-Clerget, N.R. Lee, B.H. Lipshutz, Nat. Protoc. 14, 1108 (2019)

M. Cortes-Clerget, N. Akporji, J. Zhou, F. Gao, P. Guo, M. Parmentier, F. Gallou, J.-Y. Berthon, B.H. Lipshutz, Nat. Commun. 10, 2169 (2019)

H. Pang, F. Gallou, H. Sohn, J. Camacho-Bunquin, M. Delferro, B.H. Lipshutz, Green Chem. 20, 130 (2018)

D. Chen, Y. Zhang, X. Pan, F. Wang, S. Huanga, Adv. Synth. Catal. 360, 3607 (2018)

S. Handa, F. Ibrahim, T.N. Ansari, F. Gallou, ChemCatChem 10, 4229 (2018)

M. Cortes-Clerget, S.E. Spink, G.P. Gallagher, L. Chaisemartin, E. Filaire, J.-Y. Berthonb, B.H. Lipshutz, Green Chem. 21, 2610 (2019)

N.R. Lee, M. Cortes-Clerget, A.B. Wood, D.J. Lippincott, H. Pang, F.A. Moghadam, F. Gallou, B.H. Lipshutz, ChemSusChem 12, 3159 (2019)

G. NikhilVaidya, S. Fiske, H. Verma, S.K. Lokhande, D. Kumar, Green Chem. 21, 1448 (2019)

Author information

Authors and Affiliations

Corresponding authors

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Sar, P., Ghosh, A., Scarso, A. et al. Surfactant for better tomorrow: applied aspect of surfactant aggregates from laboratory to industry. Res Chem Intermed 45, 6021–6041 (2019). https://doi.org/10.1007/s11164-019-04017-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11164-019-04017-6