Abstract

Water pollution is one of the major concerns over long-term sustainability of the environment. Effective and efficient treatment of polluted wastewater is still a serious challenge for global researchers. In the last 2–3 decades, due to the incessant emergence of micropollutants in surface and ground water bodies, several endeavors have been made to resolve the water pollution issues either through chemical, physical and biological degradation processes or through removal/separation processes using different adsorbents and membranes. It has been found that most of the studies are mainly limited to single or binary pollutant analysis in a pure water matrix. Therefore, in this novel investigation, a mixture of five different pollutants has been studied for UV/TiO2-based photocatalytic degradation. In the present study, a commercially available TiO2, an antibiotic, i.e. Ciprofloxacin and four different synthetic dyes, i.e. Rhodamine B, Methylene Blue, Methyl Orange and Amaranth have been used as a photocatalyst, a pharmaceutical and various industrial dyes, respectively, in a batch photocatalytic reactor system with a stirrer. It is important to note that the commercial TiO2 photocatalyst has also been characterized with the help of several characterization techniques. The present study is mainly focused on the degradation of different micropollutants present in the simulated wastewater matrix and their individual degradation kinetics. It is interesting to observe that MB and RhB have shown the maximum degradation followed by CIP (96.21, 96.15 and 89.62%, respectively). In addition, a microbiological assay has also been performed to check the toxicity variation in the degraded products. It is quite interesting to observe that the simulated wastewater matrix has completely lost its microbial toxicity within 120 min of UV/TiO2-based photocatalytic treatment. Finally, total organic carbon evaluations of various treated samples have also been performed and the obtained results substantiate the theory of assimilable organic carbon.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Pharmaceutical compounds are widely being used in hospitals, poultry farms, dispensaries and household medical treatments and applications. On the other hand, synthetic dyes are primarily used in dyeing application industries such as textile, cosmetic, leather, food, plastic, paint and pigments, etc. The versatile and broad level application of pharmaceuticals and dyes cause enormous contamination of discharged wastewater with these micropollutants [1,2,3,4]. These pollutants have some potential for direct and indirect effects on aquatic and terrestrial lives. The diversity of pharmaceuticals and synthetic dyes present in ground and surface water may contribute to several adverse effects or health issues for human and wildlife as some of these compounds/pollutants are allergic, carcinogenic or mutagenic in nature [2, 5,6,7,8]. In addition, the presence of antibiotics in the open environment may also lead to the emergence of multi-drug resistance [9, 10], which has been declared as the global risk of modern era by the World Health Organization [11]. Therefore, in many cases, the purification or removal or degradation or decomposition or treatment of these micropollutants present in wastewater streams is essential and an indelible necessity.

Some investigations have proclaimed that the elimination of pharmaceuticals and synthetic dyes through conventional or biological means is comparatively difficult since these compounds are more persistent in nature as compared to natural pollutants and have some bio-toxicity too [12, 13]. Therefore, it is inevitable and obligatory to eliminate these micropollutants through other means or processes from the wastewater streams before their release into natural water bodies. Recently, several studies have reported on the adsorption, coagulation, flocculation, chemical precipitation, electro-dialysis, membrane separation processes followed by oxidation or incineration, and advanced oxidation processes (AOPs) for removal of these pharmaceuticals and synthetic dyes present in wastewater streams. However, each of these methods has its own advantages and limitations as discussed in previous studies and also listed in Table 1 [7, 13, 14]. In addition to these methods, combinations of biological and chemical methods such as Fenton-Bioreactor [15] and the formulation of highly selective methods such as molecularly imprinted polymer-based adsorption [16] are examples of some innovative methods which are in the continuous development phase. Among the different AOPs, TiO2-based heterogeneous photocatalysis has its own advantages due to its remarkable oxidation potential, inertness, stability and reusability for the degradation of complex organic compounds without any further sludge formation [17,18,19,20,21,22,23]. Hence, it is a promising technique to cope with the current environmental situation of wastewater contamination.

Although many studies have already been performed and have reported on the photocatalytic degradation of synthetic dyes, pesticides, pharmaceuticals and other pollutants using different photocatalysts and combinations of photocatalysts [14, 24,25,26,27,28,29,30,31,32,33], the combined studies on different pollutants are yet to appear in the open literature and deserve holistic attention. These uncertainties have stimulated several researchers to re-examine the potential of existing treatment methods for the effective degradation of different combinations of pollutants present in a common matrix which is believed to be very similar to the actual environmental situation. In the present work, with the same impetus, a specific mixture of synthetic dyes and a pharmaceutical antibiotic (which are potent pollutants as mentioned in the supplementary information sheet: Section S4) in an aqueous matrix have been studied for commercial TiO2-based photocatalytic degradation using UV irradiation. In addition, the commercial TiO2 photocatalyst has also been characterized with the help of several characterization techniques to assure its properties and influence on the photocatalysis. Moreover, the degradation kinetics of the specific pollutant present in the simulated wastewater matrix have been studied. A brief mechanism of photocatalytic decomposition of pollutants present in simulated wastewater matrix has also been proposed. Finally, the microbiological toxicity, total organic carbon (TOC) and mass spectrometry analyses of the degraded simulated wastewater matrix have been performed for the competency assessments of the UV/TiO2-based photocatalysis.

Materials and methods

Materials and characterization

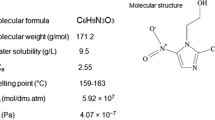

Different dyes such as Rhodamine B (RhB), Methylene Blue (MB), Methyl Orange (MO) and Amaranth (Ama) were procured from Sigma-Aldrich. Ciprofloxacin HCl (CIP), an antibiotic, LB (Luria–Bertani) broth and MHA (Mueller–Hinton Agar) media for the microbiological toxicity assay were purchased from Titan Biotech. A microbial strain of Escherichia coli DH5α (a kind gift from CCMB, Hyderabad) was used as test bacteria for microbiological toxicity assay. Titanium(IV) oxide (equivalent to Aeroxide® P25) nanopowder, a commercial TiO2 photocatalyst, was provided by Sigma-Aldrich. Ethanol (EtOH) and 1,4-benzoquinone (BQ) were purchased from Merck and TCI, respectively. Millipore water was used to produce simulated wastewater matrix and also for other dilution purposes.

The obtained commercial TiO2 photocatalyst was further characterized with the help of several characterization techniques such as FESEM (field emission scanning electron microscopy), EDX (energy dispersive X-ray), TEM (transmission electron microscopy)/HRTEM (high-resolution transmission electron microscopy), SAED (selected area electron diffraction), XRD (X-ray diffraction), PL (photoluminescence), UV–visible spectroscopy, Multipoint BET (Brunauer–Emmett–Teller)/N2 adsorption–desorption isotherm, CHNS elemental analysis, TGA (thermogravimetric analysis)/DTG (derivative thermogravimetric) analysis and electrical measurements like I–V (current–voltage) and I–T (current–time) characteristics. Instrumental details are given in the supplementary information sheet (S1).

Preparation of simulated wastewater matrix

For preparation of simulated wastewater matrix of synthetic dyes (RhB, MO, Ama and MB) and an antibiotic (CIP), separate stock solutions of 50 and 300 ppm concentration of each dye (RhB, MO, Ama and MB) and an antibiotic (CIP) were prepared, respectively, using Millipore water. After that, 5 mL from each stock were added together under dark and continuous stirring conditions. Now the concentrations of individual dye and antibiotic were obtained as 10 and 60 ppm, respectively.

Experimental design

The photocatalytic degradation of simulated wastewater matrix was carried out in a digital photocatalytic batch reactor at room temperature (25 ± 2 °C) with some customized modifications. This reactor basically had two parallel UV-rods (PHILIPS TUV 11 W G11 T5, a cylindrical low-pressure Hg lamp with irradiation area of about 96.94 cm2), one hot plate cum magnetic stirrer and a temperature probe inside a perfectly dark enclosure to avoid the surrounding lights and internal reflections. The UV fluence rate was around 0.542 mW/cm2 at ~5 cm distance from a single low-pressure Hg lamp. The reaction vessel used was a Petri plate with a top diameter and exposed area of 75 mm and ca. 44.18 cm2, respectively. The schematic of the reactor is given in Fig. S1. The reaction volume was 25 mL along with 25 mg of commercial TiO2 photocatalyst dose (equivalent to 1 g/L). The suspension was magnetically stirred under dark conditions at 200 rpm for a pre-initial 30 min to achieve the adsorption–desorption equilibrium. The stirring was continued for further 380 min under constant UV irradiation. One milliliter of test sample was taken out at different time intervals (0, 60, 120, 180, 240, and 380 min) and centrifuged, and 0.5 ml of each sample was diluted with 2.5 ml of Millipore water for UV–visible spectroscopic analysis. The remaining sample was used for the microbiological toxicity assay. In addition, TOC and mass spectrometry analyses were also performed to study the degraded sample products.

Analytical method and kinetic study

To discover the concentration of pollutants present in a simulated wastewater matrix, UV–visible spectroscopic analysis was performed using a Thermo Scientific UV–visible spectrophotometer (Evolution™ 200 series). For each sample, a full scan was recorded in the range of 200–700 nm with 2 nm bandwidth and data interval of 1 nm. The obtained data were further used for kinetic analysis in which absorbance at individual λmax had been calibrated as the concentration of the respective pollutant. Figure 1 represents the individual pollutant’s UV–visible absorption spectrum in the scan range of 200–800 nm. In this figure, the individual λmax has been identified and considered as 663, 553, 518, 466 and 275 nm for MB, RhB, Ama, MO and CIP, respectively. The absorbance at individual λmax had been considered as the residual concentration of the respective pollutant in the UV/TiO2 photocatalyzed simulated wastewater matrix. The individual pollutant’s absorbance data were further fitted with the pseudo-first-order reaction kinetics. The percentage degradation efficiency for individual pollutant was also calculated using the given formula:

where \(C_{0}\) is the initial concentration or absorbance at λmax of individual pollutant and \(C_{t}\) is the concentration or absorbance at λmax of individual pollutant at time ‘t’.

Microbiological toxicity assay

The microbiological toxicity of simulated wastewater matrix was assessed with the help of the disk diffusion assay [9]. In brief, from the centrifuged samples that were taken out at different time intervals (0, 60, 120, 180, 240, and 380 min) of UV/TiO2-based photocatalysis of simulated wastewater matrix, 7-μL aliquots were used for the impregnation of filter paper discs having a diameter of 6 mm. The test microorganism (E. coli DH5α) was cultured in LB broth and adjusted to the concentration of the 0.5 McFarland standard that contains approximately 1.5 × 108 CFU/mL. After this, the dried surface of MHA agar plate was inoculated with the test microorganism using a gentle swab over the entire sterile surface. The antibiotic-impregnated discs were dispensed onto the surface of the inoculated agar plate. In addition, a positive growth control was also used. The plate was incubated at 37 °C for 12 h. After the completion of the incubation period, the zones of inhibition were measured with the help of a digital vernier caliper.

Results and discussion

Detailed characterization of commercial TiO2 photocatalyst

FESEM, TEM/HRTEM, SAED and EDX analysis

The morphology, particle size, and crystallinity of commercial TiO2 photocatalyst were examined with the help of FESEM and TEM micrographs, and SAED patterns, respectively (Fig. 2). It can be seen from the FESEM and TEM images (Fig. 2a–c) that the commercial TiO2 photocatalyst used for this study possess sphere like shapes with substantial agglomeration. The TEM image was used to calculate the distribution of particle size and nearly spherical-shaped particles ranging from 15 to 30 nm are observed (Fig. 2c inset). The corresponding SAED patterns of commercial TiO2 photocatalyst are shown in Fig. 2d. The SAED patterns show bright and intense polymorphic rings that confirm fine crystallinity and non-amorphous nature of the commercial TiO2 photocatalyst. These SAED patterns are in good agreement with the bulk XRD data of commercial TiO2 photocatalyst which is discussed later. The HRTEM image of commercial TiO2 photocatalyst (Fig. 2e) shows the inter-planar spacing (d-spacing) of 0.351 nm that corresponds to the (101) plane of the anatase phase.

The surface elemental composition of the commercial TiO2 photocatalyst was further explored from EDX analysis (Fig. 3). The obtained EDX spectrum (Fig. 3a) confirms that the commercial TiO2 photocatalyst consists of titanium (Ti) and oxygen (O) atoms. The existence of oxygen is mainly due to the oxides of titanium. The EDX mapping (Fig. 3b) shows the uniform distribution of titanium dioxide.

X-ray powder diffraction analysis

The XRD pattern of commercial TiO2 photocatalyst is shown in Fig. 4, in which several diffraction peaks can be observed which are indexed for their respective crystal phases with the help of JCPDS card no. 21-1272 (anatase TiO2) and JCPDS card no. 21-1276 (rutile TiO2) (as marked in Fig. 4). This suggests the polycrystalline nature of the bulk commercial TiO2 photocatalyst. Moreover, the intense diffraction peaks at 25.25° (101) and 27.43° (110) of 2θ confirm the coexistence of anatase and rutile phases, respectively. In addition, the weight percentage of the anatase phase was also calculated with the help of the given formula [34]:

where W A is the weight percentage of anatase phase, I R and I A are the reflection intensities of the R(110) and A(101) peaks, respectively. This formula gives the weight fraction of the anatase phase as ca. 77.97%, which is very close to the standard composition (75% anatase, 25% rutile) of the TiO2 nanopowder required for its better synergistic performance during the photocatalysis [35, 36].

Room-temperature PL analysis

The room-temperature PL emission spectrum has been used to study the coherence between charge carrier trapping and radiative recombination of commercial TiO2 photocatalyst that also helps to understand the fate of e−/h+ pairs in this TiO2 semiconductor material. An excitation wavelength of 200 nm at room temperature was used to produce PL and the emission was recorded in the wavelength range of 300–650 nm. The commercial TiO2 photocatalyst has shown a broad PL emission band (Fig. 5). The emission band corresponding to the peak positions of about 436.5, 486 and 530.5 nm is due to the charge transfer transition near the defects of the rutile and anatase phases and oxygen vacancies [37]. However, there is no differential emission peak observed due to the exact band gap transition (410 nm for rutile and/or 390 nm for anatase) of the probed TiO2 sample.

UV–visible spectroscopic analysis

The UV–visible absorption spectroscopy was used to check the light absorption properties of the commercial TiO2 photocatalyst. Figure 6 (inset) shows the UV–visible absorption spectrum of the commercial TiO2 photocatalyst over the wavelength range of 200–900 nm. The same data have been used to calculate the band gap of the commercial TiO2 photocatalyst with the help of the Tauc plot method [38], as shown in Fig. 6, which was found to be around 3.08 eV.

Multipoint BET and N2 physisorption analysis

N2 physical adsorption–desorption isotherm study has been used to determine the BET surface area, average pore diameter and pore size distribution of the commercial TiO2 photocatalyst. The BET isotherm and its relative Barret–Joyner–Halender (BJH) pore size distribution was obtained from the adsorption and desorption branches of the N2 adsorption–desorption isotherm, respectively, as shown in Fig. 7. The specific surface area of the commercial TiO2 photocatalyst was calculated by multi-point BET transforms and was ca. 54.64 m2/g (in relative pressure, P/PO range of 0.05–0.35). It can also be seen that the commercial TiO2 photocatalyst possesses a mesoporous surface as the isotherm of Type IV with the average pore diameter of ca. 6.63 nm. The BJH pore size distribution curve of commercial TiO2 photocatalyst confirms a narrow pore size distribution (inset Fig. 7).

CHNS analysis

CHNS elemental analysis had been performed to assess the purity of commercial TiO2 photocatalyst. This analysis basically gives information about the carbon (C), hydrogen (H), nitrogen (N) and sulfur (S) content present in the commercial TiO2 photocatalyst. The C, H, N and S contents of the commercial TiO2 photocatalyst were found about 0.1090, 0.7004, 0.0000, and 0.1323%, respectively. Here, the nitrogen content is nil, which indicates that the commercial TiO2 photocatalyst is completely free of biological impurities. However, the minute impurity of C, H and S is possibly due to the contamination of chemicals or solvents used during the synthesis of the commercial TiO2 photocatalyst.

TGA/DTG analysis

TGA analysis had been used to study the thermal stability of the commercial TiO2 photocatalyst. Moreover, it was also used to compare the used and recovered TiO2 photocatalyst with the pristine one (after a single degradation cycle). Figure 8 shows the results of the TGA analysis of the pristine and used commercial TiO2 photocatalysts. It shows no significant weight loss at room temperature. However, when the temperature was gradually increased above 75 °C, a monotonic decrease in weight was observed in both cases due to the continuous removal of moisture (intact and loosely bound water), which has a very low heat of vaporization. When the temperature was increased further (up to 500 °C), the release of hydrated or structural water was observed, also contributing to a continuous weight loss. In addition, the DTG patterns of the pristine and used commercial TiO2 photocatalysts have shown some deviation in first-order derivative weight loss between the temperature range of 400–500 °C (inset Fig. 8). This is most likely due to the presence of more hydrated water on the surface of the used TiO2 photocatalyst in comparison to the pristine one.

I–V and I–T characteristics

The I–V characteristics of the commercial TiO2 photocatalyst were investigated with the help of two probe measurements using the Keithley’s Source Meter (Model 2420) operated through the LabVIEW program. In brief, the commercial TiO2 photocatalyst was first pelleted (without any binder) with the top exposure area of 0.75 cm2 and the contacts were made with the help of crocodile clamps. Different light sources such as a Solar Simulator (Xenon Lamp with AM 1.5G), UV LED (8 mW bright UV-A, 365–375 nm), UV lamp (cylindrical low-pressure Hg lamp) were used to observe the change in I–V characteristic of the commercial TiO2 photocatalyst pellet. The obtained results confirm that the overall increase in total current is mainly due to the generation of additional charge carriers under the UV lamp and UV LED exposures, respectively, followed by the Solar Simulator’s Xenon Lamp (Fig. 9). However, during both dark conditions and Xenon Lamp exposure, it is showing a non-Ohmic or Schottky behavior; and, for the UV lamp and UV LED exposures, it is showing a near-Ohmic behavior. The deviation from the origin of the obtained results are mainly due to the metal–semiconductor contacts.

In addition, the I–T characteristic of the same TiO2 pellet was also analyzed for 500 s exposure duration under UV LED irradiation. The obtained results indicate the presence of electronic defects in commercial TiO2 photocatalysts which are mainly responsible for trapping of electrons, as the photocurrent response produces a trough in the initial 100 s exposure of UV LED irradiation (Fig. 9, inset). However, after this, the photocurrent was increased and made to approach the saturation value.

Photocatalytic degradation of simulated wastewater matrix

The overall degradation profiles of the simulated wastewater matrix containing synthetic dye mixtures (RhB, MO, Ama, and MB) and an antibiotic (CIP) using the commercial TiO2 photocatalyst are shown in Fig. 10 (in the form of absorbance spectra) and also on the supplementary information sheet (Section S3, Fig. S2). It indicates that the concentrations of pollutants present in a simulated wastewater matrix are continuously decreasing with UV irradiation time. In this figure, an indivisible overlapping of the individual signature spectrum of MO, Ama and RhB dye have also been observed (in the wavelength range of around 450–530 nm). This overlapping makes it difficult or less reliable to consider further interpretations about the presence of MO and Ama in a photocatalyzed simulated wastewater matrix. Therefore, in this study, the degradation data of MO and Ama dyes have not been considered for further kinetic analysis of the shown degradation profiles. Figure 11 indicates the degradation rate of the individual pollutants (CIP, RhB and MB) in a photocatalyzed simulated wastewater matrix (based on the absorbance at individual λmax). From this figure, it can also be seen that the degradation of MB was quite fast, followed by RhB and CIP, respectively, over the UV irradiation period of 380 min.

Kinetics of photocatalytic degradation of simulated wastewater matrix

For the study of the degradation kinetics of the TiO2 photocatalyzed simulated wastewater matrix, data have been used from Fig. 11. These data have been fitted for the pseudo-first-order reaction kinetics, which have been rigorously studied and reported for the photocatalytic degradation of several pollutants [9, 23, 30, 32, 39, 40]. This kinetic model was proposed by Langmuir–Hinshelwood and is as follows:

where C represents the concentration of individual pollutants in a simulated wastewater matrix at time ‘t’, and ‘k’ is the apparent degradation rate constant. Noting C 0 as the initial concentration of individual pollutants in a simulated wastewater matrix, the integration of the above equation yields:

Plotting ln(C 0/C) as a function of time (t) yields the ‘k’ value. A linear relationship between ln(C 0/C) and ‘t’ can be observed in Fig. 12. Then, the individual pollutant’s ‘k’ value for the photocatalytic degradation of the simulated wastewater matrix using the TiO2 photocatalyst was determined graphically. The agreement between the experimental data and the results obtained using the pseudo-first-order kinetic model was evaluated from the coefficients of determination (R 2). The nearest unity value of R 2 basically indicates that the photocatalytic degradation of individual pollutants present in a simulated wastewater matrix using commercial TiO2 photocatalyst obeyed the pseudo-first-order kinetic model. Furthermore, the half-life of an individual pollutant was also calculated with the help of the given formula:

The calculated kinetic parameters of the pseudo-first-order reaction kinetic model fittings are presented in Table 2, which indicate that the rate of degradation was the highest for MB followed by RhB and CIP, respectively, for UV/TiO2-based photocatalysis of the simulated wastewater matrix. Hence, MB corresponds to the highest rate constant and the lowest half-life value, followed by RhB and CIP, respectively.

In addition to this, it has also been observed that most of the MB dye decomposed in the first hour of UV/TiO2 treatment. Therefore, an additional experiment has been conducted with 15 min time intervals to study more accurate degradation kinetics of MB in the mixed pollutant matrix (Fig. 13). The obtained results have shown a considerable improvement in the previously calculated MB degradation kinetic parameters. Now, the revised rate constant (k) and half-life (t 1/2) value for the MB degradation are 0.01402 min−1 and 49.43 min, respectively, with an improved coefficient of determination (R 2 = 0.99053).

Figure 14 represents the individual pollutant-based degradation efficiency (%) of UV/TiO2-based photocatalysis of a simulated wastewater matrix containing synthetic dye mixtures (RhB, MO, Ama, and MB) and an antibiotic (CIP) as pollutants. This figure demonstrates that MB and RhB have the maximum degradation potential followed by CIP (96.21, 96.15 and 89.62%, respectively) in the simulated wastewater matrix.

The obtained results have also been ascertained with the help of mass spectroscopy (ESI–MS). In this regard, TOF MS ES+ mode has been used to trace the parent pollutant molecules present in the initial, 120 and 380 min UV/TiO2-treated simulated wastewater matrix. Figure 15a–d shows the obtained mass spectra of different samples. Here, Fig. 15a shows the presence of inherent impurities in the aqueous medium used for the preparation of the simulated wastewater matrix as it shows the presence of some intact mass peaks (m/z = 102.04, 125.99, 167.02, 202.19, etc.). Figure 15b shows the intense molecular ion peaks of MB, CIP and RhB at m/z = 284.13, 332.16 and 443.25, respectively, whereas the relative intensity of these peaks has been notably reduced after 120 min of UV/TiO2 treatment (Fig. 15c). However, the molecular ion peaks of these parent pollutants have almost disappeared in the 380 min UV/TiO2-treated simulated wastewater matrix (Fig. 15d). These observations are in better agreement with the UV–vis spectroscopy-based results.

Mechanism of photocatalytic degradation of simulated wastewater matrix

Figure 16 illustrates the mechanism for the photocatalytic degradation of the simulated wastewater matrix containing a mixture of 4 different synthetic dyes (RhB, MO, Ama, and MB) and an antibiotic (CIP) using the commercial TiO2 photocatalyst and a low-pressure Hg lamp as the UV source. The first step in TiO2 photocatalytic reaction is the generation of excitons (electron–hole pairs) in the conduction and valence bands. After this, the series of chemical reactions lead to the production of hydroxyl radicals (OH·) and superoxide radical anions (\(\text{O}_{2}^{ \cdot - }\)) as shown in Fig. 16. The presence of these active free radicals has also been confirmed through the observed effects of EtOH and BQ as OH· and \(\text{O}_{2}^{ \cdot - }\) scavengers, respectively [41], on the UV/TiO2-based photocatalytic degradation of MB. The obtained results have shown that the OH· radicals have more influence over the UV/TiO2-based photocatalytic degradation of pollutant in comparison to that with the \(\text{O}_{2}^{ \cdot - }\) radicals (Fig. 17). These radicals readily oxidize the organic pollutant molecules into some intermediates which are finally converted into simple products such as CO2 and H2O [37, 42,43,44,45,46,47]. The presented mechanism is primarily based on some assumptions, such as:

-

No chemical interaction between pollutants.

-

No lateral interaction between adsorbed pollutants/species on the TiO2 surface.

-

Non-competitive adsorption–desorption of pollutants/intermediates/product species on the TiO2 surface.

-

Only temporal monolayer adsorption of different pollutant/species is present.

-

Cyclic process.

Major steps of the overall degradation mechanism are given below:

The overall photocatalytic degradation process involves several cycles of pollutant adsorption on the TiO2 surface followed by its decomposition and desorption from the TiO2 surface to the bulk matrix, respectively. Hence, the mineralization level of the photocatalysis process is always going to be uncertain and unpredictable.

Microbiological toxicity assessment of simulated wastewater matrix

The microbiological toxicity or antibacterial activity of the simulated wastewater matrix at different time intervals (0, 60, 120, 180, 240, and 380 min) of UV-irradiated photocatalysis has been studied with the help of the disk diffusion assay (results shown in Fig. S3). It is interesting to observe that the initial (0 min) and 60 min treated simulated wastewater matrix have a perceptible zone of inhibition with a diameter of ca. 2.1 cm and ca. 1.4 cm, respectively. However, a further treated simulated wastewater matrix did not show any zone of inhibition. This indicates that the simulated wastewater matrix containing a mixture of synthetic dyes (RhB, MO, Ama, and MB) and an antibiotic (CIP) has completely lost its antibacterial activity during 60–120 min of UV/TiO2-based photocatalysis.

In addition, to determine the organic content of the treated samples stored in a low metabolic activity environment, TOC measurements were carried out for all 0, 60, 120, 180, 240 and 380 min treated aliquots (referred as MixC-0, 1, 2, 3, 4 and 5, respectively) using an O-I-Analytical Aurora 1030 W Total Organic Carbon analyzer. For this, 300 µL of the original sample was diluted with Millipore water to 10 mL. Then, the average TOC value was calculated using three repetitions of the same sample with 2 mL injection volume. The TOC measurements have shown an interesting pattern (Fig. 18) which seemed to be quite unusual at the first stage of observation/interpretation. However, after correlating the obtained TOC pattern with the microbiological toxicity data, it has been found that the obtained TOC results are in good agreement with the UV/TiO2-treated samples. Here, the TOC has been significantly reduced during the initial 120 min of UV/TiO2 treatment. However, it subsequently showed a gradual increment in the TOC. That increment is primarily due to the reduced and ineffective concentration of the CIP antibiotic in the UV/TiO2-treated simulated wastewater matrix which favors/promotes the growth of microflora whose metabolites and biomass could be major sources for the increased TOC. The present study substantiates the previously reported theory of the assimilable organic carbon (AOC) which was investigated by Bazri and Mohseni [48]. According to this theory, the microflora such as bacteria and other single cell organisms would readily prefer to consume these AOCs over the parent/inceptive micropollutants. Consequently, this causes a comprehensive increment in the TOC value and validates the results obtained in the present study.

Conclusions

In the present study, the effectiveness of UV/TiO2-based photocatalytic degradation of the simulated wastewater matrix (containing a specific combination of RhB, MO, Ama and MB dyes, and CIP antibiotic) has been thoroughly investigated. This study confirms its photocatalytic potential for a specific mixture of synthetic dyes (RhB, MO, Ama, and MB) and an antibiotic (CIP) and ensures that the UV/TiO2 photocatalysis could be successfully applied to degrade all four synthetic dyes and the antibiotic. It is interesting to observe that MB and RhB have shown the maximum degradation followed by CIP (96.21, 96.15 and 89.62%, respectively). In addition, the rigorous characterizations of the commercially available TiO2 photocatalyst are also reported in the present article and have revealed the morphological, optical, physical, purity/compositional, thermal and electrical properties of the used photocatalyst. The present study also confirms that some pollutants require additional treatment time for their complete decomposition in a mixed pollutants matrix which mainly depends on their concentration and the persistence of those specific compounds. It is interesting to observe that the CIP present in the simulated wastewater matrix has certainly been reduced to less than its minimal inhibitory concentration within 120 min of UV/TiO2-based photocatalytic treatment. Moreover, TOC evaluations of various treated samples have also been performed and the results substantiate the theory of AOC [48]. Overall, the present comprehensive study provides important guidelines for degradation studies of multiple pollutants present in a common aqueous matrix, and it can also be benchmarked as a reference for comparison with other multicomponent degradation studies.

However, there are still some challenges or issues such as the exact identification of the stable intermediates and/or degraded products, followed by their degradation pathway, the influence of various environmental factors on the degradation feasibility and kinetics, the possible regulatory effect of specific pollutants, the mineralization limit for different pollutant combinations, the immobilization of heavy metals on the catalyst surface for additional benefits [49], etc. Taking these pertinent factors into account, the authors remain positive about the future research prospects in these given directions. Suitable development in mixed pollutant degradation technologies may help in the emergence of frugal and competitive wastewater treatment processes.

References

H. Ali, Water Air Soil Pollut. (2010). doi:10.1007/s11270-010-0382-4

S.K. Khetan, T.J. Collins, Chem. Rev. (2007). doi:10.1021/cr020441w

I. Michael, L. Rizzo, C.S. Mcardell, C.M. Manaia, C. Merlin, T. Schwartz, C. Dagot, D. Fatta-Kassinos, Water Res. (2012). doi:10.1016/j.watres.2012.11.027

A.J. Watkinson, E.J. Murby, S.D. Costanzo, Water Res. (2007). doi:10.1016/j.watres.2007.04.005

J. Corcoran, M.J. Winter, C.R. Tyler, Crit. Rev. Toxicol. (2010). doi:10.3109/10408440903373590

V.L. Cunningham, S.P. Binks, M.J. Olson, Regul. Toxicol. Pharmacol. (2009). doi:10.1016/j.yrtph.2008.10.006

M.A.M. Salleh, D.K. Mahmoud, W.A.W.A. Karim, A. Idris, Desalination (2011). doi:10.1016/j.desal.2011.07.019

M. Vakili, M. Rafatullah, B. Salamatinia, A.Z. Abdullah, M.H. Ibrahim, K.B. Tan, Z. Gholami, P. Amouzgar, Carbohydr. Polym. (2014). doi:10.1016/j.carbpol.2014.07.007

P. Verma, J. Kumar, Int. J. Eng. Res. Appl. 4(7), 58–65 (2014)

P. Verma, S.K. Samanta, Comp. Clin. Pathol. (2016). doi:10.1007/s00580-016-2321-2

Antimicrobial resistance: global report on surveillance. World Health Organization (2014). www.who.int/iris/bitstream/10665/112642/1/9789241564748_eng.pdf

V.K. Gupta, Suhas. J. Environ. Manage. (2009). doi:10.1016/j.jenvman.2008.11.017

T. Robinson, G. McMullan, R. Marchant, P. Nigam, Bioresour. Technol. (2001). doi:10.1016/S0960-8524(00)00080-8

V. Homem, L. Santos, J. Environ. Manag. (2011). doi:10.1016/j.jenvman.2011.05.023

D. Huang, C. Hu, G. Zeng, M. Cheng, P. Xu, X. Gong, R. Wang, W. Xue, Sci. Total Environ. (2017). doi:10.1016/j.scitotenv.2016.08.199

D. Huang, R. Wang, Y. Liu, G. Zeng, C. Lai, P. Xu, B. Lu, J. Xu, C. Wang, C. Huang, Environ. Sci. Pollut. Res. (2015). doi:10.1007/s11356-014-3599-8

M.G. Alalm, A. Tawfik, S. Ookawara, J. Environ. Chem. Eng. (2016). doi:10.1016/j.jece.2016.03.023

U.G. Akpan, B.H. Hameed, J. Hazard. Mater. (2009). doi:10.1016/j.jhazmat.2009.05.039

A.R. Khataee, M.B. Kasiri, J. Mol. Catal. A Chem. (2010). doi:10.1016/j.molcata.2010.05.023

J. Schneider, M. Matsuoka, M. Takeuchi, J. Zhang, Y. Horiuchi, M. Anpo, D.W. Bahnemann, Chem. Rev. (2014). doi:10.1021/cr5001892

R. Shetty, V.B. Chavan, P.S. Kulkarni, B.D. Kulkarni, S.P. Kamble, Indian Chem. Eng. (2016). doi:10.1080/00194506.2016.1150794

L. Zhou, L. Wang, J. Zhang, J. Lei, Y. Liu, Res. Chem. Intermed. (2016). doi:10.1007/s11164-016-2748-8

H. Zhang, D. Liu, S. Ren, H. Zhang, Res. Chem. Intermed. (2017). doi:10.1007/s11164-016-2713-6

M.N. Chong, B. Jin, C.W.K. Chow, C. Saint, Water Res. (2010). doi:10.1016/j.watres.2010.02.039

K. Ikehata, N.J. Naghashkar, M.G. El-Din, Ozone Sci. Eng. (2006). doi:10.1080/01919510600985937

R. Ameta, S. Benjamin, A. Ameta, S.C. Ameta, Mater. Sci. Forum (2013). doi:10.4028/www.scientific.net/MSF.734.247

M. Umar, H.A. Aziz, InTech (2013) doi:10.5772/53699. http://www.intechopen.com/books/organic-pollutants-monitoring-risk-and-treatment/photocatalytic-degradation-of-organic-pollutants-in-water

C.C. Wang, J.R. Li, X.L. Lv, Y.Q. Zhang, G. Guo, Energy Environ. Sci. (2014). doi:10.1039/C4EE01299B

M. Pirilä, M. Saouabe, S. Ojala, B. Rathnayake, F. Drault, A. Valtanen, M. Huuhtanen, R. Brahmi, R.L. Keiski, Top. Catal. (2015). doi:10.1007/s11244-015-0477-7

X. Zhu, D. Zhou, L. Cang, Y. Wang, J. Soils Sediments (2012). doi:10.1007/s11368-011-0464-y

X. Zhu, Y. Wang, D. Zhou, J. Soils Sediments (2014). doi:10.1007/s11368-014-0883-7

B. Xiong, A. Zhou, G. Zheng, J. Zhang, W. Xu, J. Soils Sediments (2015). doi:10.1007/s11368-015-1139-x

S. Rahimi, B. Ayati, A. Rezaee, Res. Chem. Intermed. (2017). doi:10.1007/s11164-016-2740-3

D. Mardare, M. Tasca, M. Delibas, G.I. Rusu, Appl. Surf. Sci. (2000). doi:10.1016/S0169-4332(99)00508-5

S. Bakardjieva, J. Šubrt, V. Štengl, M.J. Dianez, M.J. Sayagues, Appl. Catal. B. (2005). doi:10.1016/j.apcatb.2004.06.019

A. Kafizas, X. Wang, S.R. Pendlebury, P. Barnes, M. Ling, C. Sotelo-Vazquez, R. Quesada-Cabrera, C. Li, I.P. Parkin, J.R. Durrant, J. Phys. Chem. A (2016). doi:10.1021/acs.jpca.5b11567

A. Kaur, A. Umar, S.K. Kansal, J. Colloid Interface Sci. (2015). doi:10.1016/j.jcis.2015.08.010

I. Karabay, S.A. Yüksel, F. Ongül, S. Öztürk, M. Asli, Acta Phys. Pol. A 121, 265–267 (2012)

S.K. Kansal, M. Chopra, Engineering (2012). doi:10.4236/eng.2012.48055

C.C. Lin, Y.J. Chiang, Chem. Eng. J. (2012). doi:10.1016/j.cej.2011.11.062

Y. Ye, H. Yang, R. Li, X. Wang, J. Sol–Gel. Sci. Technol. (2017). doi:10.1007/s10971-017-4332-0

Y.A. Attia, T.A. Altalhi, Res. Chem. Intermed. (2017). doi:10.1007/s11164-017-2862-2

A. Eshaghi, S. Hayeripour, A. Eshaghi, Res. Chem. Intermed. (2016). doi:10.1007/s11164-015-2161-8

R. Lakshmipathy, M.K. Kesarla, A.R. Nimmala, S. Godavarthi, C.M. Kukkambakam, L.M. Gomez, N.C. Sarada, Res. Chem. Intermed. (2017). doi:10.1007/s11164-016-2700-y

X. Lü, J. Shen, D. Fan, J. Wang, Z. Cui, J. Xie, Res. Chem. Intermed. (2015). doi:10.1007/s11164-015-1953-1

E. Safaralizadeh, S.J. Darzi, A.R. Mahjoub, R. Abazari, Res. Chem. Intermed. (2017). doi:10.1007/s11164-016-2692-7

Y. Wu, L. Tao, J. Zhao, X. Yue, W. Deng, Y. Li, C. Wang, Res. Chem. Intermed. (2016). doi:10.1007/s11164-015-2234-8

M. Bazri, M. Mohseni, Environ. Sci. Water Res. Technol. (2016). doi:10.1039/c5ew00235d

D. Huang, W. Xue, G. Zeng, J. Wan, G. Chen, C. Huang, C. Zhang, M. Cheng, P. Xu, Water Res. (2016). doi:10.1016/j.watres.2016.09.050

Acknowledgements

The authors would like to thank Dr. Sushant Kumar, Dr. Subrata Hait and Dr. A. K. Thakur from IIT Patna for their help, support and cooperation. The authors would also like to thank the anonymous reviewers for their critical comments and suggestions that improved the quality of the revised manuscript.

Author information

Authors and Affiliations

Corresponding author

Electronic supplementary material

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Verma, P., Samanta, S.K. Degradation kinetics of pollutants present in a simulated wastewater matrix using UV/TiO2 photocatalysis and its microbiological toxicity assessment. Res Chem Intermed 43, 6317–6341 (2017). https://doi.org/10.1007/s11164-017-2992-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11164-017-2992-6