Abstract

A novel Brønsted solid acid named poly(vinylpyrrolidonium) hydrogen phosphate ([PVP-H]H2PO4) has been prepared by using H3PO4 and poly(vinylpyrrolidone) as green and commercially available reagents. The prepared reagent was characterized using a series of techniques including Fourier-transform infrared (FT-IR) spectroscopy, thermogravimetric analysis (TGA), scanning electron microscopy (SEM), X-ray diffraction (XRD) analysis, energy-dispersive X-ray analysis (EDAX), pH analysis, and Hammett acidity function. The mentioned solid acid with wide acidic functional group sites can be utilized as a highly efficient, heterogeneous, and reusable catalyst for preparation of 2-amino-3-cyano-5-oxo-5,6,7,8-tetrahydro-4H-benzopyrans using aldehydes, dimedone, and malononitrile. Also, this catalyst can be reused for several times without loss of catalytic activity.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Mineral liquid acids such as H2SO4, HCl, H3PO4, HNO3, etc. have many applications in chemical industry for synthesis of organic and inorganic chemical materials. Large quantities of these acids, especially sulfuric acid, nitric acid, and hydrochloric acid, are manufactured for commercial use in vast plants. Furthermore, liquid acids have a degree of instability in the presence of air and moisture [1]. Also, H3PO4 is utilized in chemical production, metal treatment, refractories, ceramics, miscellaneous industries, and for food and beverages. In spite of the fact that phosphoric acid is an efficient green acid, its application suffers from various problems such as high cost, large consumption, and difficult recovery. Also separation of products and large-scale application are difficult with this reagent.

To avoid these problems, solid acids could be used as easily recyclable and ecofriendly catalysts. These materials have many other advantages such as operational simplicity, ease of recoverability, and noncorrosive nature, making them more efficient than traditional mineral liquid acids.

One of the most efficient heterogeneous and polymeric supports for numerous reagents and catalysts is cross-linked poly(vinylpyrrolidone) (PVP). This is because of its commercial availability, stability, reasonably high loading capacity, good physicochemical structure, and facile functionalization. PVP is also one of the most widely used excipients in pharmaceuticals, for example, as a binder in tablets, granules, and capsules. Other applications of this reagent include as a stabilizer for suspensions, ophthalmic preparations, sugar coating, film coating, and miscellaneous other applications [2]. In addition, it is an attractive support to immobilize mineral acids because of the basic nature of the pyrrolidonyl group. Therefore, various PVP-supported reagents have been designed to catalyze some organic reactions [3–7].

The 4H-pyran group and its derivatives belong to a major class of natural heterocyclic compounds used in cosmetics and pigments, and as potentially biodegradable agrochemicals [8–10]. Also, they may contribute to potential biological and pharmacological activities such as spasmolytic, diuretic, anticoagulant, anticancer, antianaphylactic, antioxidant, and anti-human immunodeficiency virus (HIV) effects [9, 11–16]. 2-Amino-4H-pyrans are a series of 4H-pyran derivatives with an improved structural scaffold and many biological activities [17, 18] as well as photochemical reactivity [19]. These derivatives of 4H-pyran can be synthesized via condensation of aromatic aldehydes, 1,3-cyclohexanedione derivatives, and malononitrile in a one-pot three-component condensation reaction.

In view of the biological, industrial, and synthetic applications of 4H-pyran and 2-amino-4H-pyran derivatives, a variety of catalysts such as nano-ZnO [20], NaBr [21], I2 [22], CeCl3·7H2O [23], tetrabutylammonium fluoride (TBAF) [24], 1,4-diazabicyclo[2.2.2]octane (DABCO) [25], hexadecyldimethylbenzyl ammonium bromide (HDMBAB) [26], PEG-1000-based dicationic acidic ionic liquid (PEG1000-DAIL) [27], MeCO2H [28], SiO2-Pr-SO3H [29], polyphosphoric acid (PPA–SiO2) [30], N(Et)4ClO4 [31], Caro’s acid–silica gel (CA-SiO2) [32], metformin-modified silica-coated magnetic nanoparticles (MNPs) (Fe3O4/SiO2−Met) [33], RuBr2(PPh3)4 [34], 2,2,2-trifluoroethanol (TFE) [35], SO 2−4 /MCM-41 [36], urea:choline chloride (as a deep eutectic solvent) [37], Fe3O4@SiO2/DABCO [38], potassium phthalimide-N-oxyl (POPINO) [39], and silica-bonded N-propylpiperazine sodium n-propionate (SBPPSP) [40] have been used to facilitate this reaction.

Although these procedures improve synthesis of these compounds, some of them suffer from disadvantages such as long reaction time, harsh reaction condition, need for excess amount of reagent, low product yield, and catalyst nonrecoverability. Therefore, introducing simple, efficient, and mild procedures with easily separable and reusable solid catalysts to overcome these problems is still in demand.

Experimental

Chemicals were purchased from Fluka, Merck, and Aldrich chemical companies. All yields refer to isolated products. Products were characterized by comparison of their physical constants, and infrared (IR) and nuclear magnetic resonance (NMR) spectra with authentic samples and those reported in literature. Purity determination of substrate and reaction monitoring were carried out by thin-layer chromatography (TLC) on silica gel poly gram SILG/UV 254 plates.

FT-IR spectra were obtained on a VERTEX 70 (Bruker, Germany). Thermogravimetric analysis (TGA) was performed on a Polymer Laboratories PL-TGA thermal analysis instrument (UK). Samples were heated from 25 to 600 °C at a ramp rate of 10 °C/min under N2 atmosphere. Scanning election microscopy (SEM) was carried out using a Philips XL30. X-ray diffraction (XRD) measurements were performed at room temperature on an XRD 6000 X’Pert Pro diffractometer (Philips) using Co Kα radiation (K = 1.7890 Å) with beam voltage and beam current of 40 kV and 30 mA, respectively.

Preparation of [PVP-H]H2PO4: Phosphoric acid (1.2 mL, 18 mmol) was added to a suspension of powdered poly(vinylpyrrolidone) (2.0 g) [cross-linked poly(vinylpyrrolidone) with MW > 1,000,000] in 10 mL dry CH2Cl2 over a period of 15 min. The mixture was stirred at room temperature for 5 h and then filtered. The solid residue was washed with ethyl acetate (20 mL) and dried at 80 °C to afford [H-PVP]H2PO4 as a pale-yellow powder (Scheme 1).

General procedure for preparation of 2-amino-3-cyano-5-oxo-5,6,7,8-tetrahydro-4H-benzopyrans: A mixture of aldehyde (1 mmol), dimedone and/or 1,3-cyclohexadione (1 mmol), malononitrile (1.1 mmol), and [PVP-H]H2PO4 (10 mg, 2.5 mol%) in EtOH:H2O (1:1) (4 mL) was heated at 80 °C. Progress of the reaction was monitored by TLC. Upon completion of the reaction, the solvent was evaporated, EtOH was added, and the catalyst was separated by filtration. The related product was purified by recrystallization from aqueous ethanol.

Spectral (1H and 13C NMR) data of new compounds are presented below:

4,4′-(1,3-Phenylene)bis(2-amino-7,7-dimethyl-5-oxo-5,6,7,8-tetrahydro-4H-chromene-3-carbonitrile) (s): m.p. 243–244 °C; IR (neat) ν = 3436, 3330, 3180, 2964, 2196, 1653, 1600, 1365, 1213, 1150, 1030 cm−1, 1H NMR (DMSO-d6, 400 MHz): δ = 0.955 (s, 6H, CH3), 1.057 (s, 6H, CH3), 2.045 (d, J AB = 17.4 Hz, 2H), 2.8 (d, J AB = 17.4 Hz, 2H), 2.38 (d, J AB = 17.4 Hz, 2H), 2.59 (d, J AB = 17.4 Hz, 2H), 4.113 (s, 2H), 6.08 (s, 1H, Ar), 6.921 (s, 4H, NH), 7.01 (2H, dd, J 1 = 7.6 Hz, J 2 = 1.6 Hz), 7.192 (t, 1H, J = 7.6, Ar) ppm; 13C NMR (DMSO-d6, 100 MHz): δ = 19, 26.9, 29.3, 32.1, 35.7, 50.3, 56.5, 58.6, 113.2, 120.1, 125.1, 126.2, 128.3, 145.5, 159, 162.9, 195.9.

4,4′-(1,4-Phenylene)bis(2-amino-7,7-dimethyl-5-oxo-5,6,7,8-tetrahydro-4H-chromene-3-carbonitrile) (t): m.p. 266–268 °C; IR (neat) ν = 3448, 3327, 3189, 2960, 2194, 1655, 1602, 1363, 1210, 1148, 1029 cm−1, 1H NMR (DMSO-d6, 400 MHz): δ = 0.985 (s, 3H, CH3), 1.035 (s, 3H, CH3), 2.16 (d, J AB = 16.4 Hz, 1H), 2.23 (d, J AB = 16.4 Hz, 1H), 2.50 (s, 2H), 4.14 (s, 1H), 6.98 (s, 2H), 7.04 (s, 2H) ppm; 13C NMR (DMSO-d6, 100 MHz): δ = 27.4, 27.6, 28.6, 32.3, 35.4, 50.4, 58.8, 113.1, 120.2, 127.4, 143.3, 159.0, 163.1, 196.1 ppm.

Results and discussion

Catalyst characterization

The FT-IR spectra of H3PO4, PVP, and [PVP-H]H2PO4 are presented in Fig. 1. Successful loading of H3PO4 onto the surface of PVP led to an increased number of vibration modes. The overlap of some peaks results in broadening of the [PVP-H]H2PO4 spectrum. In the case of [PVP-H]H2PO4, the broad band between 2700 and 3750 cm−1, centered at 3410 cm−1, can be attributed to OH stretching of H2PO4 group. The bands appearing at 1170, 1105, 992, and 822 cm−1 can be assigned to P=O stretching, P–O bending, and stretching vibrations, respectively [41]. Furthermore, in this spectrum, the bands at 1429 (C–N) and 650 cm−1 (N–C=O) disappeared and a moderate absorption at 1648 cm−1 corresponding to internal imine groups present in the pendant rings of the polymer appeared [7].

The samples of PVP and [PVP-H]H2PO4 were also analyzed by scanning electron microscopy (SEM) at various magnifications to determine the size distribution, particle shape, surface morphology, and diagram of surface, as presented in Fig. 2. These images show that, with chemical modification, the primary morphology of PVP changed completely and particles were localized by the modification process. Both size reduction and increased aggregation resulted in swelling of the surface area of the catalyst. This increased the catalytic activity of the catalyst in the reaction [42]. As seen in the diagram of surface (Fig. 2c, d), PVP showed an almost smooth surface, but after modification the surface became uneven.

EDAX spectra were recorded to analyze the elemental constitution qualitatively for the modified PVP. Figure 3 depicts the EDAX spectra for [PVP-H]H2PO4. The presence of phosphor peak confirms the presence of P in the lattice of [PVP-H]H2PO4.

To gain insight into the thermal changes in the PVP and [PVP-H]H2PO4 system, the thermal stability was probed by thermogravimetric analysis. Figures 4 and 5 display typical TGA and differential TGA (DTGA) spectra for native PVP and [PVP-H]H2PO4, using weight percent for the TGA curve and differential weight for the DTGA curve.

As can be seen from these figures, both PVP and [PVP-H]H2PO4 showed one-step thermal decomposition below 120 °C, corresponding to loss of moisture. Furthermore, the surfaces of PVP almost loaded with H3PO4 because [PVP-H]H2PO4 have a completely different curves rather than PVP [43]. For PVP, the maximum weight loss occurred at 350–470 °C (T max = 428 °C), corresponding to degradation of the polymer backbone, but in the case of [PVP-H]H2PO4 the maximum weight loss (due to decomposition of the backbone) occurred at lower temperature of 230–315 °C (T max = 282.5 °C).

Figure 6 presents the X-ray diffraction (XRD) patterns of the PVP and [PVP-H]H2PO4 samples. Incorporation of H3PO4 led to reduced intensity and some changes in the diffractogram of PVP. The XRD pattern of PVP reveals a couple of broad bands located at 2θ = 13.5° and 23.5°, clearly indicating the amorphous nature of the host PVP [44]. After modification of PVP by H3PO4, the first peak (2θ around 13.5°) disappeared whereas the broad peak at 2θ around 23.5° increased slightly. These observations imply that PVP lost its primal structure after reaction with H3PO4.

To 25 mL of an aqueous solution of NaCl (1 M) with a primary pH 5.2, [PVP-H]H2PO4 (0.5 g) was added and the resulting mixture was stirred for 2 h at room temperature. The pH of the solution decreased to 1.3. This is equal to a loading of 2.5 mmol H+/g [45].

The Hammett acidity function can efficiently express the acid strength of an acid in organic solvents [46, 47]. It can be calculated by the equation below:

where “I” depicts the indicator base (mainly substituted dinitroanilines), and [IH+]s and [I]s are the molar concentrations of the protonated and unprotonated forms of the indicator, respectively. The pK(I)aq values are already known [for example, the pK(I)aq value of 4-nitroaniline is 0.99] and can be obtained from literature. According to the Lambert–Beer law, the value of [I]s/[IH+]s can be determined and calculated from UV–Vis spectra. In our experiment, 4-nitroaniline was chosen as the basic indicator and CCl4 as the solvent. The maximal absorbance of the unprotonated form of 4-nitroaniline was observed at 330 nm in CCl4. Figure 7 compares the absorbance of [PVP-H]H2PO4 and also recovered catalyst after five runs.

As shown in Fig. 7, in comparison with blank solution, the absorbance of the unprotonated form of the indicator in [H-PVP]H2PO4 was weak compared with the sample of the indicator in CCl4, showing that the indicator was partially in the form of [IH+]. The obtained results are listed in Table 1, which shows the acid strength of [PVP-H]H2PO4.

Catalytic activity

On the basis of the information obtained from the studies on [PVP-H]H2PO4, we anticipated that this reagent could be used as a solid acid catalyst for promotion of reactions requiring an acidic catalyst for speed-up. So, we were interested in investigating the applicability of this reagent for promotion of synthesis of 2-amino-4H-pyran derivatives.

First and for optimization of the reaction conditions, the reaction of 4-chlorobenzaldehyde, dimedone (5,5-dimethyl-1,3-cyclohexanedione), and malononitrile to obtain corresponding product was selected as a model reaction under various conditions (Table 2). Different solvents such as EtOH, H2O, and EtOH:H2O were used to choose the reaction medium, the best results being obtained in EtOH:H2O (1:1). Having optimized the reaction medium, further experiments were performed to delineate the best reaction. Finally, the best result was obtained using 10 mg [PVP-H]H2PO4 in EtOH:H2O (1:1) at 80 °C (Scheme 2).

After optimization of the reaction conditions and to establish the effectiveness and suitability of this method, we explored the protocol with a variety of simple, readily available substrates under the optimal conditions (Table 3). Under the determined conditions, it was observed that a wide range of aromatic aldehydes containing electron-withdrawing as well as electron-donating groups such as Cl, Br, CH3, OCH3, NO2, and OH in ortho, meta, and para positions of the benzene ring easily converted to corresponding 2-amino-4H-pyrans in short reaction time with good to excellent isolated yield (Table 3, entries 1–10). Cinnamaldehyde, 2-naphthaldehyde, and isatin, as α,β-unsaturated, polycyclic aromatic, and heterocyclic substrates, respectively, also provided the desired products in good yields (Table 3, entries 11–13). Furthermore, when 1,3-cyclohexadione was employed in place of dimedone, the corresponding products were also obtained during short reaction times in high yields (Table 3, entries 14–18).

This method was also found to be useful for dialdehydes (Table 3, entry 19 and 20). In this reaction, 2 equivalents of dimedone and malononitrile successfully condensed with 1 equivalent of isophthalaldehyde and terephthalaldehyde with high yield at short time, showing the practical synthetic efficiency of this reaction (Scheme 3).

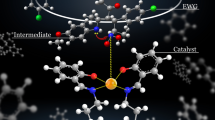

The proposed mechanism for synthesis of 2-amino-3-cyano-5-oxo-5,6,7,8-tetrahydro-4H-benzopyrans in the presence of [PVP-H]H2PO4 as catalyst is shown in Scheme 4. At the first step in this mechanism, α-cyanocinnamonitrile (III) forms initially by Knoevenagel condensation between aldehyde and malononitrile in the presence of [PVP-H]H2PO4. Then, Michael addition of enolizable dimedone (IV) on intermediate (III), followed by intramolecular cyclization and final tautomerization of intermediates, affords the desired product.

To check the reusability of the catalyst, the reaction of 4-chlorobenzaldehyde, dimedone, and malononitrile under the optimized reaction conditions was studied again. When the reaction completed, the solid was filtered off, ethanol was added, and the catalyst was separated by filtration. The recovered catalyst was washed with ethyl acetate, dried, and reused for the same reaction. This process was carried out over five runs, and all reactions led to the desired products without significant change in reaction time or yield, clearly demonstrating the practical recyclability of this catalyst (Fig. 8).

Furthermore, the FT-IR spectra of 2-amino-3-cyano-4-(4-chlorophenyl)-7,7-dimethyl-5-oxo-5,6,7,8-tetrahydro-4H-benzopyran using fresh (a) and recovered (b) (after five runs) [PVP-H]H2PO4 are shown in Fig. 9. The presence of typical absorption bands in the FT-IR spectra of products demonstrates that, in the course of recovery, the quality of the products was retained.

To highlight the merits of our newly developed procedure, we compared our results for synthesis of 2-amino-3-cyano-4-(4-nitrophenyl)-7,7-dimethyl-5-oxo-5,6,7,8-tetrahydro-4H-benzopyran using the [PVP-H]H2PO4 catalyst with other results reported in literature for the same transformation. As shown in Table 4, the obtained results show that the catalytic activity of [PVP-H]H2PO4 is convincingly superior to other reported procedures in terms of catalyst loading, reaction time, and yield.

Conclusions

We have demonstrated an efficient procedure for synthesis of 2-amino-tetrahydro-4H-pyrans as biologically and pharmacologically active products using a new heterogeneous polymeric catalyst [PVP-H]H2PO4. Moreover, this functionalized solid acid catalyst can be readily synthesized and easily used as an efficient and recyclable catalyst in the desired reactions. In addition, this methodology offers significant improvements with regard to product yield and reaction time.

References

GhH Mahdavinia, M.A. Bigdeli, M.M. Heravi, Chin. Chem. Lett. 19, 1171 (2008)

H. Folttmann, A. Quadir, Drug Deliv. Technol. 8, 22 (2008)

G. Chehardoli, M.A. Zolfigol, S.B. Azimi, E. Alizadeh, Chin. Chem. Lett. 22, 827 (2011)

P. Veerakumar, Z. Lu, M. Velayudham, K. Lu, S. Rajagopal, J. Mol. Catal. A Chem. 332, 128 (2010)

S. Khaksar, M. Tajbakhsh, M. Gholami, Comptes Rendus Chim. 17, 30 (2014)

N. Soltani, E. Saion, M.Z. Hussein, M. Erfani, K. Rezaee, G. Bahmanrokh, J. Inorg. Organomet. Polym. 22, 830 (2012)

F. Shirini, P. NajafiMoghadam, S. Moayedi, M. Seddighi, RSC Adv. 4, 38581 (2014)

Y. Morinaka, K. Takahashi, Jpn Patent JP52017498 (1977)

R.S. Keri, S. Budagumpi, R.K. Pai, R.G. Balakrishna, Eur. J. Med. Chem. 78, 340 (2014)

E.A. Hafez, M.H. Elnagdi, A.A. Elagamey, F.A. El-Taweel, Heterocycles 26, 903 (1987)

L.L. Andreani, E. Lapi, Boll. Chim. Farm. 99, 583 (1960)

Y.L. Zhang, B.Z. Chen, K.Q. Zheng, M.L. Xu, X.H. Lei, Yao Xue Xue Bao 17, 17 (1982)

Y.L. Zhang, B.Z. Chen, K.Q. Zheng, M.L. Xu, X.H. Lei, Chem. Abstr. 96, 135383e (1982)

L. Bonsignore, G. Loy, D. Secci, A. Calignano, Eur. J. Med. Chem. 28, 517 (1993)

E.C. Witte, P. Neubert, A. Roesch, Chem. Abstr. 104, 224915f (1986)

J.Z. Deng, D.A. Sun, S.R. Starck, S.M. Hecht, R.L. Cerny, J.R. Engen, J. Chem. Soc. Perkin Trans. 1, 1147 (1999)

D. Kumar, V.B. Reddy, S. Sharad, U. Dube, S. Kapur, Eur. J. Med. Chem. 44, 3805 (2009)

X. Fan, D. Feng, Y. Qu, X. Zhang, J. Wang, P.M. Loiseau, G. Andrei, R. Snoeck, E.D. Clercq, Bioorg. Med. Chem. Lett. 20, 809 (2010)

D. Armesto, W.M. Horspool, N. Martin, A. Ramos, C. Seoane, J. Org. Chem. 54, 3069 (1989)

P. Bhattacharyya, K. Pradhan, S. Paul, A.R. Das, Tetrahedron Lett. 53, 4687 (2012)

I. Devi, P.J. Bhuyan, Tetrahedron Lett. 45, 8625 (2004)

R.S. Bhosale, C.V. Magar, K.S. Solanke, S.B. Mnae, S.S. Choudhary, R.P. Pawar, Synth. Commun. 24, 4353 (2007)

M.S. Singh, G.C. Nandi, S. Samai, Green Chem. 14, 447 (2012)

S. Gao, C.H. Tsai, C. Tseng, C. Yao, Tetrahedron 64, 9143 (2008)

D. Tahmassebi, J.A. Bryson, S.I. Binz, Synth. Commun. 41, 2701 (2011)

T. Jin, A. Wang, F. Shi, L. Han, L. Liu, T. Li, Arkivoc 78, xiv (2006)

H. Zhi, C. Lu, Q. Zhang, J. Luo, Chem. Commun. 2878 (2009)

K. Singh, J. Singh, H. Singh, Tetrahedron 52, 14273 (1996)

G.M. Ziarani, A. Abbasi, A. Badiei, Z. Aslani, Eur. J. Chem. 8, 293 (2011)

A. Davoodnia, S. Allameh, S. Fazli, N. Tavakoli-Hoseini, Chem. Pap. 65, 714 (2011)

K.T. Abu, L. Mohan, A. Shahzad, KMd Musawwer, Tetrahedron Lett. 52, 5327 (2011)

H.A. Oskooie, M.M. Heravi, N. Karimi, M.E. Zadeh, Synth. Commun. 41, 436 (2011)

A. Alizadeh, M.M. Khodaei, M. Beygzadeh, D. Kordestani, M. Feyzi, Bull. Korean Chem. Soc. 33, 2546 (2012)

K. Tabatabaeian, H. Heidari, M. Mamaghani, N.O. Mahmoodi, Appl. Org. Chem. 26, 56 (2012)

S. Khaksar, A. Rouhollahpour, S.M. Talesh, J. Fluor. Chem. 141, 11 (2012)

M. Abdollahi-Alibeik, F. Nezampour, React. Kinet. Mech. Catal. 108, 213 (2013)

N. Azizi, S. Dezfooli, M. Khajeh, M.M. Hashemi, J. Mol. Liq. 186, 76 (2013)

J. Davarpanah, A.R. Kiasat, S. Noorizadeh, M. Ghahremani, J. Mol. Catal. A Chem. 376, 78 (2013)

M.G. Dekamin, M. Eslami, A. Maleki, Tetrahedron 69, 1074 (2013)

K. Niknam, N. Borazjani, R. Rashidian, A. Jamali, Chin. J. Catal. 34, 2245 (2013)

A. Bamoniri, B.F. Mirjalilib, S. Nazemiana, J. Nanostruct. 2, 101 (2012)

F. Shirini, O.G. Jolodar, J. Mol. Catal. A Chem. 356, 61 (2012)

X. Li, X. Wang, D. Yu, S. Ye, Q. Kuang, Q. Yi and X. Yao, J. Nanomater. 1 (2012)

D. Zareyee, B. Karimi, Tetrahedron Lett. 48, 1277 (2007)

Z.Y. Duan, Y.L. Gu, J. Zhang, L.Y. Zhu, Y.Q. Deng, J. Mol. Catal. A Chem. 250, 163 (2006)

H. Xing, T. Wang, Z. Zhou, Y. Dai, J. Mol. Catal. A Chem. 264, 53 (2007)

C. Thomazeau, H. Olivier-Bourbigou, L. Magna, S. Luts, B. Gilbert, J. Am. Chem. Soc. 125, 5264 (2003)

A. Hasaninejad, M. Shekouhy, N. Golzar, A. Zare, M.M. Doroodmand, Appl. Catal. A 402, 11 (2011)

M. Khoobi, L. Mamani, F. Rezazadeh, Z. Zareie, A. Foroumadi, A. Ramazani, A. Shafiee, J. Mol. Catal. A Chem. 359, 74 (2012)

Acknowledgments

The authors are grateful to the Guilan University Research Council for partial support of this work.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Shirini, F., Goli-Jolodar, O., Akbari, M. et al. Preparation, characterization, and use of poly(vinylpyrrolidonium) hydrogen phosphate ([PVP-H]H2PO4) as a new heterogeneous catalyst for efficient synthesis of 2-amino-tetrahydro-4H-pyrans. Res Chem Intermed 42, 4733–4749 (2016). https://doi.org/10.1007/s11164-015-2312-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11164-015-2312-y