Abstract

A new benzoxazin derivative, namely methyl 3-(2-oxo-2H-1,4-benzoxazin-3-yl) propanoate (1,4-MBXP), was synthesized under mild conditions from 2-aminophenols and dimethyl-2-oxoglutarate. The prepared compound was identified by FT-IR, 1H NMR, 13C NMR spectroscopies, elementary analysis and MS. Its inhibitive action against the corrosion of carbon steel in 1M H2SO4 solution was investigated by weight-loss and hydrogen evolution measurements. 1,4-MBXP is a good corrosion inhibitor and its inhibition efficiency increases with the increase of concentration to attain 75.08 % at 180 ppm. The temperature effect on the corrosion behaviour of carbon steel in 1M H2SO4 with and without the inhibitor at 180 ppm was studied in the temperature range from 298 to 338 K. The synergistic action caused by iodide ions on the corrosion inhibition of carbon steel in 1M H2SO4 by 1,4-MBXP at 180 ppm was studied using weight methods at 298 K. The inhibition efficiency synergistically increased on addition of potassium iodide.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Carbon steel is widely used in the petrochemical, chemical and metallurgical industries. It is also used as a construction material owing to its excellent mechanical properties and cost-effectiveness. However, it easily undergoes corrosion in various environmental conditions. It is a lasting and a continuous problem, often difficult to eliminate completely.

Acid solutions are generally used in many industrial processes. Hydrochloric acid, phosphoric acid and sulfuric acid are aggressive solutions used for the pickling, cleaning, descaling, stimulation of oil wells, elimination of localized deposits and in many industrial synthesis processes [1, 2].

Because of the general aggressiveness of acid solutions, there are several methods available to protect metals from corrosion in this environment, such as the use of a protective barrier, electroplating. The use of solutions rust or corrosion inhibitors has been acknowledged as one of the best techniques, a very practical and most economical method to mitigate the corrosion rate, protect metal surfaces against corrosion and preserve industrial facilities [3–6]. It has been found to have widespread applications in many industries [7–14]. The existing data show that most organic inhibitors act by adsorption on the metal surface [1]. Most of the well-known acid inhibitors are organic compounds containing heteroatoms, such as N, P, S, and O, the unsaturated bonds (such as double bonds or triple bonds, etc.) and the plane conjugated systems including all kinds of aromatic cycles [15–18], and they show a significant inhibition efficiency [19].

Many N-heterocyclic compounds, such as Schiff’s bases [20, 21], quinolines derivatives [22, 23], oxadiazole [24, 25], diazole [26], pyrazole [27], triazole [28], tetrazole [29] and imidazole [30], have been reported to be effective organic inhibitors for the corrosion of carbon steel in acid media.

Also, synergistic effects describe an increase in effectiveness of the corrosion inhibitor in the presence of another substance in the corrosive medium. The role of synergism on the corrosion inhibition mechanism of steel in acidic solutions has been reported by several authors [31–33].

In the present work, the corrosion inhibition efficiency of a newly synthesized benzoxazin derivative, methyl 3-(2-oxo-2H-1,4-benzoxazin-3-yl)propanoate (1,4-MBXP), on carbon steel in sulfuric acid solution was investigated using weight-loss and hydrogen evolution measurements.

Experimental

Materials

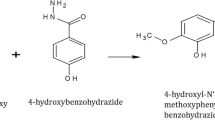

The tested inhibitor, namely methyl 3-(2-oxo-2H-1,4-benzoxazin-3-yl)-propanoate (1,4-MBXP), is shown in Fig. 1 and was synthesized according to a previously described experimental procedure [34].

A solution of dimethyl-2-oxoglutarate (1) (1.74 g, 0.01 mol) in 10 mL of dry methanol was added dropwise under stirring to a solution of 2-aminophenol (2) (0.01 mol) in 20 mL of dry methanol at 20 °C. After stirring for 1 h at 20 °C, the crystals formed were filtered off and recrystallized from methanol.

Weight loss measurements

The weight loss method as a means of evaluating corrosion rates of metals in corrosive environments and inhibiting potentials of studied inhibitors has been widely reported in the literature.

A metal plate of composition 0.13 % C, 0.32 % Si, 0.64 % Mn, 0.15 % Cu, 0.012 %S, 0.01 % P, 0.038 % Al, 0.081 % Cr, 0.011 % Mo, 0.083 % Ni, 0.01 % V, and Fe balance was cut into 2 × 2 × 0.2 cm pieces for weight loss measurements.

Before all measurements, the exposed area was mechanically abraded with emery paper of 280, 400, 600, 800, and 1200 grades. The specimens are washed thoroughly with bidistilled water, degreased with ethanol and dried before being weighed and immersed in 60 mL of 1M H2SO4. The immersion time for the weight loss measurements was 6 h at 298 K. Gravimetric measurements were carried out in a double-walled glass cell equipped with a thermostated cooling condenser. The value of the inhibitory efficacy data is the average of three tests under the same conditions for each concentration.

Hydrogen evolution measurements

For the hydrogen evolution reaction, the cathodic reaction may have three different steps. First, the water molecule or hydronium ion is discharged on the electrode surface to produce a hydrogen atom in acidic solution and an adsorbed hydrogen atom is generated (Volmer reaction). Second, one electron is transferred to a hydronium ion and the hydrogen evolution reaction occurs on the metal surface (Heyrowsky reaction) or a pure chemical reaction subsequently takes place (Tafel reaction) [35]. In spite of three states for the formulation of the mechanism, no one of the three reactions occurs as a single step but combines with another, i.e. it must be a Volmer reaction (slow) with the following Heyrowsky (faster) or Tafel (faster) reaction. If the Volmer reaction is fast, the Tafel and/or Heyrowsky reaction must be slow. The step of a slow reaction follows a fast step.

The progress of the corrosion reaction was determined by volumetric measurement of the evolved hydrogen gas. The corrosion rate was taken as the slope of the straight line representing the variation of hydrogen volume and time of exposure at 298 K. The procedure has been described elsewhere [36]. The material used for constructing the working electrode was the same as used for the gravimetric measurements.

Results and discussion

Spectrum analysis of 1,4-MBXP

The molecular structure of 1,4-MBXP is shown in Fig. 1.

This compound was obtained as orange crystals; 1.39 g (yield 60 %); m.p. = 134–135 °C.

The structure of the 1,4-MBXP was confirmed by FT-IR, 1H- and 13C-NMR, mass spectroscopy and elemental analysis:

FT-IR (KBr): (v cm−1) 1740 (C=O), 1612 (N=C); 1H-NMR (300 MHz, DMSO-d6): δ (ppm) = 2,76 (t, 2H, CH2, J = 7.2 Hz); 3.03 (t, 2H, CH2, J = 7.2 Hz); 3.59 (s, 3H, OCH3); 7.36 (dd, 1H, Harom, J = 8.6 Hz, J = 7.5 Hz); 7.38 (d, 1H, Harom, J = 8.5 Hz); 7.51 (dd, 1H, Harom, J = 8.5 Hz, 7.5 Hz); 7.67 (d, 1H, Harom, J = 8.6 Hz); 13 C-NMR (75,44 MHz, DMSO-d6): δ (ppm) = 28,14 (CH2); 29,11 (CH2); 51,48 (OMe); 116,23 (C-8); 125,31 (C-6); 128,24 (C-5); 130,49 (C-7); 130,57 (C-4a); 146,10 (C-8a); 152,28 (C = O); 156,60 (N = C); 172,67 (COO). MS: m/z 233 (M+, 58 %), 202 (M+ − OCH3, 37 %), 174 (M+− CO2CH3, 35 %), 146 (M+− CH2CH2CO2CH3, 100 %); Anal. Calcd for C12H11NO4 (M = 233 g/mol): C, 61.80; H, 4.75; N, 6.01 %, Found: C, 61.63; H, 4.74; N, 5.91 %.

Gravimetric technique and inhibition efficiency

The effect of the addition of 1,4-MBXP tested at different concentrations on the corrosion of steel in 1M H2SO4 solution was studied by using weight-loss at 298 K after 6 h of immersion period.

Table 1 gives values of the rate of corrosion (mg cm−2 h−1) and inhibition efficiency (E %) for corrosion of carbon steel in 1M H2SO4 and in the presence of 1,4-MBXP as inhibitor at different concentrations. Inhibition efficiency E (%) is calculated as follows:

where W corr and W′corr are the corrosion rate of steel in 1M H2SO4 in absence and presence of inhibitor, respectively.

Figure 2 shows the plot of inhibition efficiency against inhibitor concentration for steel corrosion in 1M H2SO4.

As shown in Fig. 2, the inhibition efficiency increases with the increase in inhibitor concentration, tending to saturate at higher values of inhibitor concentration. This indicates that the effectiveness of the 1,4-MBXP in retarding the corrosion rate of carbon steel in the test solutions does not improve indefinitely with an increase in inhibitor concentration.

As can be seen from Table 1, the 1,4-MBXP has the ability to inhibit the corrosion of steel in the acid solution and acted as a good inhibitor.

The highest inhibition efficiency of 75.08 % was obtained at 180 ppm 1,4-MBXP at 298 K. This result suggests that an increase in inhibitor concentration increases the number of inhibitor molecules adsorbed onto the steel surface and reduces the surface area that is available for the direct acid attack on the metal surface [37].

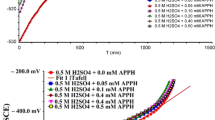

Hydrogen gas evolution

Figure 3 shows the volume of hydrogen evolved during the corrosion reaction of carbon steel in 1M H2SO4 with and without 180 ppm of 1,4-MBXP at 298 K. The plots in Fig. 2 illustrate the decrease of the hydrogen gas evolution rate on the introduction of 180 ppm of inhibitor into the corrodent, indicating that the 1,4-MBXP actually affords corrosion inhibition of steel in the acidic environments when compared to the blank.

Further inspection of Fig. 3 reveals a relationship between the time of reaction and the volume of hydrogen gas evolved in both inhibited and uninhibited solutions. However, the presence of the extract markedly decreases the slope of the straight line. Since the slope of the line represents the corrosion reaction rate, it can be concluded that the 180 ppm of 1,4-MBXP has an ability to inhibit the corrosion of carbon steel in the 1M H2SO4.

We note the results obtained from weight loss are in good agreement with the hydrogen gas evolution studies.

Effect of temperature

The effect of temperature on the corrosion rate of steel in 1M H2SO4 containing the inhibitor at a optimal concentration (180 ppm) was studied in the temperature range 298–338 K using weight-loss measurements, and the corresponding results are summarised in Table 2.

The increase in corrosion rate is more pronounced with the rise of temperature for the uninhibited acid solution. The presence of the inhibitor leads to a decrease of the corrosion rate. On the other hand, the inhibition efficiency (E %) depends upon the temperature and decreases with the increase in temperature.

The activation energy of the corrosion process in free and inhibited acid can be calculated using the equation.

Figure 4 also shows that the corrosion reaction can be regarded as an Arrhenius-type process [Eq. (2)]. The activation parameters for the studied system (E a, \(\Delta H_{\text{a}}^{*}\) and \(\Delta S_{\text{a}}^{*}\)) were estimated from the Arrhenius equation and transition state equation [Eq. (3)]:

where A is the Arrhenius factor, E a is the apparent activation corrosion energy, N is Avogadro’s number, h is Plank’s constant, and \(\Delta H_{\text{a}}^{*}\) and \(\Delta S_{\text{a}}^{*}\) are the enthalpy and the entropy changes of activation corrosion energies for the transition state complex, respectively. R is the perfect gas constant.

The apparent activation energy was determined from the slopes of the Ln W versus 1000/T graph depicted in Fig. 4

The slope of the linear plots obtained by ln W (corrosion rate) and 1/T leads to the determination of the activation energies, \(E_{\text{a}}^{\text{o}}\) and Ea, for the corrosion in the absence and the presence of 180 ppm of inhibitor at different concentrations, respectively. In this case, \(E_{\text{a}}^{\text{o}}\) = 53.28 kJ/mol and E a = 55.52 kJ/mol. We note that the apparent activation energy is almost the same in the presence and absence of the inhibitor. Also, it can be seen from Table 2 that the inhibition efficiency decreased with the rise in temperature.

The unchanged value of E a of the corrosion process in the presence of the inhibitor, when compared to that in the absence of inhibitor, can be attributed to the physisorption of the inhibitor on the surface of the steel [37].

Figure 5 shows a plot of Ln (W/T) against 1/T of the leaves extract. Straight lines are obtained with a slope of (−\(\Delta H_{\text{a}}^{*}\)/R) and an intercept of (Ln R/Nh + ∆S *a /R) from which the values of \(\Delta H_{\text{a}}^{*}\) and \(\Delta S_{\text{a}}^{*}\) are calculated, respectively.

Values obtained of \(\Delta H_{\text{a}}^{*}\) are 50.64 and 52.89 kJ/mol for free acid and 180 ppm 1,4-MBXP, respectively. We note that the presence of the inhibitor causes a low change in the values of activation enthalpy. Furthermore, the positive values of \(\Delta H_{\text{a}}^{*}\) show that the corrosion process is an endothermic phenomenon. We note that the E a and \(\Delta H_{\text{a}}^{*}\) values vary in the same way with the inhibitor concentration.

On the other hand, the values calculated of activation entropy \(\Delta S_{\text{a}}^{*}\) are 265.30 and 262.30 J/mol K for the corrosion in the absence and the presence of 180 ppm of inhibitor, respectively.

The decrease of the values of \(\Delta S_{\text{a}}^{*}\) show that the activated complex in the rate-determining step represents an association rather than a dissociation step, meaning that a decrease in disordering takes place on going from reactants to the activated complex [38, 39].

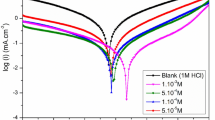

Study of synergism phenomenon

Synergism is a combined action of a compound greater in total effect than the sum of the individual effects. It has become one of the most important factors in the inhibition process and serves as a basis for all modern corrosion inhibitor formulation. Synergism of corrosion inhibitors is either due to interaction between components of the inhibitors or to the interaction between the inhibitor and one of the ions present in the aqueous solution [40].

It has also been reported that the inhibitive effect increases in the order Cl− < Br− < I−, which seems to indicate that the radii of halide ions may have an important role to play [41].

Synergistic studies were carried out on the combination of the 180 ppm of 1,4-MBXP with different concentrations of KI.

From Table 3, it can be seen that the inhibition efficiency of 180 ppm 1,4-MBXP alone attains a maximum value of 75.08 % at 298 K. However, the addition of KI to the 180 ppm of 1,4-MBXP shows a significantly different trend for all the different concentrations of KI added to the highest concentration of inhibitor (180 ppm) inhibition efficiency. The increase in inhibition efficiency with an increase in concentration of the additives compounds (KI) studied can be attributed to a synergistic inhibition between 1,4-MBXP and KI for carbon steel corrosion in the 1M H2SO4 medium.

The highest inhibition efficiency of 96.02 % was obtained in the presence of a mixture of 180 ppm 1,4-MBXP and 3 mM KI.

Conclusion

On the basis of the results, it can be seen that:

-

1.

This present study provides new information on the inhibiting characteristics of methyl 3-(2-oxo-2H-1,4-benzoxazin-3-yl) propanoate (1,4-MBXP) on carbon steel in acidic solution.

-

2.

(1,4-MBXP) is a good inhibitor for carbon steel in 1M H2SO4.

-

3.

The inhibition efficiency increases with the increase of inhibitor concentration and attains a maximum value of 74.08 %, at 180 ppm. The inhibition efficiencies of the tested inhibitors obtained from the gravimetric measurements are in good agreement with the values obtained from the hydrogen evolution measurements.

-

4.

The inhibition efficiency of (1,4-MBXP) decreased with rise of temperature.

-

5.

Activation energies were almost the same in the absence or the presence of 180 ppm (1,4-MBXP), suggesting a physisorption. On the other hand, inhibition efficiency synergistically increased on addition of potassium iodide.

References

F. Bentiss, M. Lebrini, H. Vezin, M. Lagrenée, Mater. Chem. Phys. 87, 18 (2004)

D. Benmessaoud Left, M. Zertoubi, A. Irhzo, M. Azzi, J. Mater. Environ. Sci. 4, 855 (2013)

C.M. Goulart, A. Esteves-Souza, C.A. Martinez-Huitle, C.J.F. Rodrigues, M.A.M. Maciel, A. Echevarria, Corros. Sci. 67, 281 (2013)

A. Khadraoui, A. Khelifa, Res. Chem. Intermed. 39, 3937 (2013)

E.S. Meresht, T.S. Farahani, J. Neshati, Corros. Sci. 54, 36 (2012)

A. Khadraoui, A. Khelifa, H. Boutoumi, B. Mettai, Y. Karzazi, B. Hammouti, Port. Electrochim. Acta. 32, 271 (2014)

A. Lalitha, S. Ramesh, S. Rajeswari, Electrochim. Acta 51, 47 (2005)

Fouad Bentiss, Mounim Lebrini, Michel Traisnel, Michel Lagrenée, J. Appl. Electrochem. 39, 1399 (2009)

K.F. Khaled, Appl. Surf. Sci. 230, 307 (2004)

V. Branzoi, F. Golgovici, F. Branzoi, Mater. Chem. Phys. 78, 122 (2002)

A.S. Algaber, E.M. El-Nemma, M.M. Saleh, Mater. Chem. Phys. 86, 26 (2004)

M.A. Migahed, H.M. Mohamed, A.M. Al-Sabagh, Mater. Chem. Phys. 80, 169 (2003)

M. Lashkari, M.R. Arshadi, Chem. Phys. 299, 131 (2004)

A. Popova, M. Christov, S. Raicheva, E. Sokolova, Corros. Sci. 46, 1333 (2004)

M. Gopiraman, N. Selvakumaran, D. Kesavan, R. Karvembu, Prog. Org. Coat. 73, 104 (2012)

A.M. Al-Sabagh, N.M. Nasser, A.A. Farag, M.A. Migahed, A.M.F. Eissa, Egypt. J. Pet. 22, 101 (2013)

S.M. Abd El Haleem, S. Abd El Wanees, E.E. Abd El Aal, A. Farouk, Corros. Sci. 68, 1 (2013)

A. Doner, E.A. Şahin, G. Kardaş, O. Serindağ, Corros. Sci. 66, 278 (2013)

E.A. Noor, Corros. Sci. 47, 33 (2005)

A.B. da Silva, E. D’Elia, J.A.C.P. Gomes, Corros. Sci. 52, 788 (2010)

N. Soltani, M. Behpour, S.M. Ghoreishi, H. Naeimi, Corros. Sci. 52, 1351 (2010)

G. Achary, H.P. Sachin, Y. Arthoba Naik, T.V. Venkatesha, Mater. Chem. Phys. 107, 44 (2008)

V.R. Saliyan, A.V. Adhikari, Corros. Sci. 50, 55 (2008)

M. Outirite, M. Lagrenée, M. Lebrini, M. Traisnel, C. Jama, H. Vezin, F. Bentiss, Electrochim. Acta 55, 1670 (2010)

M.Z.A. Rafiquee, N. Saxena, S. Khan, M.A. Quraishi, Mater. Chem. Phys. 107, 528 (2008)

J. Aljourani, K. Raeissi, M.A. Golozar, Corros. Sci. 51, 1836 (2009)

A. El-Ouafi, B. Hammouti, H. Oudda, S. Kertit, R. Touzani, A. Ramdani, Anti-Corros. Meth. Mater. 49, 199 (2002)

B. Hammouti, A. Aouniti, M. Taleb, M. Brighli, S. Kertit, Corrosion 51, 411 (1995)

F. Chaouket, B. Hammouti, S. Kertit, K. Elkacemi, Bull. Electrochem. 17, 311 (2001)

A. Dafali, B. Hammouti, A. Aouniti, R. Mokhlisse, S. Kertit, K. El-kacemi, Ann. Chim. Sci. Mat. 25, 437 (2000)

A.A. Farag, M.A. Hegazy, Corro. Sci. 74, 168 (2013)

S. Muralidharan, S. Syed Azim, L. John Berchmans, S.V.K. Iyer, Anti-Corros. Methods Mater. 44, 30 (1997)

A. Khadraoui, A. Khelifa, K. Hachama, H. Boutoumi, B. Hammouti, Res. Chem. Intermed. (2014). doi:10.1007/s11164-014-1870-8

K. Hachama, M. Khodja, S. Moulay, H. Boutoumi, L. Hennig, D. Sicker, J. Heterocyclic. Chem. 50, 413 (2013)

M. Bhardwaj, R. Balasubramaniam, Int. J. Hydrogen Energy 33, 2178 (2008)

A. Khadraoui, A. Khelifa, L. Touafri, H. Hamitouche, R. Mehdaoui, J. Mater. Environ. Sci. 4, 663 (2013)

A. Khadraoui, A. Khelifa, H. Boutoumi, H. Hamitouche, R. Mehdaoui, B. Hammouti, S.S. Al-Deyab, Int. J. Electrochem. Sci. 9, 3334 (2014)

A. Khadraoui, A. Khelifa, H. Boutoumi, B. Hammouti, Nat. Prod. Res. 28, 1206 (2014)

A. Khadraoui, A. Khelifa, H. Hamitouche, R. Mehdaoui, Res. Chem. Intermed. 40, 961 (2014)

S.A. Umoren, E.E. Ebenso, Pigment Resin Technol. 37, 173 (2008)

S.A. Umoren, U.F. Ekanem, Chem. Eng. Commun. 197, 1339 (2010)

Acknowledgments

The authors extend their sincere gratitude to the Institute of Organic Chemistry of the University of Leipzig, Germany, in which we analyzed and identified the organic inhibitor and the Laboratory of the valorization of natural substances, University Djilali Bounaȃma, Khemis-Miliana, Algeria, for its contribution in further work.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Hachama, K., Khadraoui, A., Zouikri, M. et al. Synthesis, characterization and study of methyl 3-(2-oxo-2H-1,4-benzoxazin-3-yl) propanoate as new corrosion inhibitor for carbon steel in 1M H2SO4 solution. Res Chem Intermed 42, 987–996 (2016). https://doi.org/10.1007/s11164-015-2068-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11164-015-2068-4