Abstract

Electrochemical oxidation (EO) of organic compounds is an outstanding technology capable of oxidizing organic pollutants to simple inorganic compounds such as H2O and CO2. Moreover, EO can be attributed to an energy-efficient process, since it requires only insignificant amount of energy in the form of an applied current or a potential to activate the electrodes. There is a vast variety of electrodes used in EO processes for organic compounds degradation. They are noble metal electrodes, such as Pt and Au, boron-doped diamond (BDD) electrodes, mixed metal oxide (MMO), graphite and carbon electrode, etc. In this regard, it becomes difficult to focus on existing electrode properties and characteristics and choose an anode material for a particular application. The aim of this study was to review information on existing anodes used in EO processes, their advantages and disadvantages, performance and application area. Thus far, MMO electrodes along with BDD electrodes are leading materials used in the processes of EO of dyes, pesticides, pharmaceuticals, industrial wastewaters, etc. This is due to their excellent catalytic properties and resistance to both corrosion and dissolution. The catalytic activity of MMO electrodes strongly depends not only on their composition but also on fabrication methods. Thus, a correlation was made between the methods of manufacturing, efficiency and cost in the MMO electrodes. Despite the wide variety of anodes, most of them are either relatively expensive to be used for large volumes of wastewater, or they consist of potentially toxic metals. Moreover, none of them are sufficiently efficient and stable. Therefore, cost-effective, efficient and “green” anodic materials are still under development.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

1 Introduction

Electrochemical oxidation (EO) of organic compounds is an advanced oxidation method (AOP), which allows to completely mineralize organic pollutants. EO has a number of advantages over traditional and other AOP water treatment methods. They are elimination of secondary waste production, such as spent adsorbents, contaminated retentate, waste activated sludge or ferric hydroxide sludge that occurs during adsorption, nanofiltration, biological treatment and Fenton reactions, respectively. Moreover, EO can easily oxidize highly toxic pollutants, which are refractory to microorganisms, and requires significantly smaller working areas compared to biological treatment. EO has the advantage of easy control through automation and the absence of additional chemicals necessary to conduct the process, such as in the Fenton process. This is due to the high electric conductivity of industrial wastewaters, which usually exceeds 10 mS/cm. In addition, electric energy is the main driving force of the EO process. EO is applicable for the treatment of turbid and coloured wastewater, which is difficult to treat by photocatalysis and photodegradation. However, similarly to other processes, EO has some drawbacks. They are polarization, passivation and corrosion of electrodes. Polarization of the electrodes is caused by poor mass transfer and the accumulation of gases on the electrode surface, which leads to the depletion of electroactive species in the boundary layer of the electrode (Lee et al. 2016). Passivation of electrodes is often caused by polymeric and oligomeric compounds, which are formed during electrode reactions. However, polarization and passivation can be suppressed by powerful agitation, generated, for example, by rapid stirrers, pumps or turbulence promoters (Pletcher and Walsh 1990). Another disadvantage of EO is the corrosion of the electrodes caused by oxidation reactions of the anode material and the formation of corrosive products on the surface of electrode, such as, for example, chlorine gas. This problem can be solved by choosing properly the electrode materials, or by developing new electrode materials.

There is a wide variety of electrodes used in EO of organic pollutants in water. They are noble metal electrodes, metal alloys electrodes, mixed metal oxide electrodes (MMO, commercial name is dimensionally stable anodes DSA®), carbon and graphite electrodes, boron-doped diamond (BDD) electrodes, etc. (ElMekawy et al. 2016). However, the most common ones are BDD and MMO electrodes, such as Ti/Ta2O5–IrO2, Ti/SnO2–IrO2, Ti/RuO2–IrO2, Ti/Sb–SnO2, Ti/SnO2–Sb2O5–RuO2 and Ti/TiO2–IrO2, etc. (Yahiaoui et al. 2013; Bogdanovskii et al. 2001; Pereira et al. 2012; da Silva et al. 2013; Kong et al. 2007). This is explained by their long service life, corrosion resistance and high overpotential towards oxygen evolution reactions. Despite the variety of electrodes, most of them contain either expensive platinum-group materials, such as Ir and Ru, or toxic compounds such as Sb and Pb. Therefore, the search for novel, non-expensive and non-toxic materials continues. The aim of this work was to briefly summarize the information on existing electrodes used in EO of organic compounds and identify their advantages and disadvantages, as well as the field of application.

The process of oxidation of organic compounds in microbial fuel cells (MFC) can be partially attributed to the processes of EO. This is explained by the fact that the driving force of the oxidation process is not the electrical energy, but the metabolism of bacteria and their ability to oxidize electron-donor compounds. Microorganisms attached to the surface of the anode and the enzymes produced by these microorganisms serve as biocatalysts for the oxidation of organic compounds. The principle of MFC operation is the detachment of electrons from nutrients by microorganisms and the transfer of detached electron to the anode. The anode is connected to the cathode by a wire/electric circuit. Because of the difference in redox potentials, the electrons start to move towards the cathode. Electrons moving from the negative electrode to the positive electrode generate an electric current that can be recovered. Electrode materials with high specific surface area, such as for example graphite brush, carbon felt, cloth and foam, are used as anodes in MFCs (Pasupuleti et al. 2015a, b). Since the processes taking place in the MFCs are bioelectrochemical in nature, they will not be considered in this article. Attention will be concentrated on the true electrochemical oxidation processes and electrodes used in these processes.

2 History of application of electrodes for water treatment from organic compounds

The first studies on electrodes testing for EO of organic compounds began in the early 1970s with the degradation of phenolic compounds at PbO2 anodes (Nilsson et al. 1973). However intense research on EO began in the late 1980s and early 1990s from the testing of PbO2 and SnO2 electrodes (Comninellis and Plattner 1988; Kötz et al. 1991). Thus, phenol was removed with an efficiency of 72–100% in a packed bed reactor filled with PbO2 pellets after 1.5–2.5 h of electrolysis in an acidic medium. The initial concentration of phenol was 1.4 × 10−4 M, and the current applied varied from 1 to 3 A (Sharifian and Kirk 1986). The main degradation products of phenol oxidation included benzoquinone, maleic acid and CO2. Oxidation of phenol on the Pt electrode followed two mechanisms: either direct oxidation of the adsorbed phenol and its intermediates, such as maleic, fumaric and oxalic acids to CO2, or chemical oxidation through the generation of hydroxyl radicals (Comninellis 1991). Another study showed complete degradation of phenol (93–1100 mg/L) after 1.5–2 h of electrolysis at an applied current of 10 A and pH 2.5 (Smith de Sucre and Watkinson 1981). Increase of pH reduced the efficiency of phenol degradation. Electrolysis at PbO2 anodes at an applied current of 526 A/m2 provided 57, 18 and 22% removal of TOC, COD and BOD respectively in a mixture of five monohydric phenols (phenol, p-cresol, o-cresol, 2,3-xylenol and 3,4-xylenol) within 3 h (Chettiar and Watkinson 1983). Development of mixed metal oxide (MMO) electrodes in the late 1960s paved the way for their further testing in the water treatment processes from organic pollutant (Beer 1966). In the early 1990s it as discovered that MMO electrodes have high efficiency towards organic compounds oxidation and a better corrosion resistance than PbO2 and noble Pt anodes. It was shown that Ti/SnO2 anodes doped with Sb performed about 5 times better than Ti/PbO2 and Ti/Pt anodes (Stucki et al. 1991). The removal efficiency of benzoic acid exceeded 90% at the Ti/SnO2 anode at an applied current density of 30 mA/cm2, while the maximum removal efficiency of benzoic acid on Ti/PbO2 and Ti/Pt anodes was below 30% (Stucki et al. 1991). Another study showed a complete mineralization of 1000 mg/L phenol at the Ti/SnO2–Sb2O5 anode in alkaline media at an applied current density of 300 A/m2, whereas the Ti/PbO2 electrode provided a 40% TOC reduction (Kötz et al. 1991).

3 Types of electrodes materials used in EO

Different electrode materials were tested and used for electrochemical water treatment. They are noble metal electrodes, carbon and graphite electrodes, metal oxide and MMO, BDD and mixed type of electrodes. In general, all electrodes are divided into active and non-active (Comninellis 1994). The activity of electrodes is related to the interactions between hydroxyl radicals and anodes. At potentials that exceed the potential for oxygen evolution reactions (OER), water molecules undergo electrolytic discharge followed by physical adsorption of reactive ·OH radicals on the anode surface (Eq. 1).

Hydroxyl radicals adsorbed strongly on active electrodes can interact with anode material forming higher oxides (MO), which then react with pollutant forming pollutant oxidation products, or release free oxygen (Martínez-Huitle and Ferro 2006).

This behavior is typical for anodes with a lower OER overpotential (Pt, carbon, IrO2, RuO2) and, as a result, lower activity towards organic oxidation.

Non-active electrodes, such as PbO2, SnO2–SbO2 or BDD, have a high overpotential toward OER and weakly adsorb the ·OH radicals. This contributes to a decrease in OER, direct mineralization of organic compounds through reaction 5 and, as a result, a higher pollutant degradation rates.

However, in the case of both active and non-active anodes, pollutant degradation reactions are constantly competing with OER described in Eqs. 4 and 6. Equations 4 and 6 also occur in the absence of organic pollutants. The implementation of each particular reaction is associated with minimal energy consumption.

Along with useful electrochemical reactions leading to the organic pollutant oxidation, there are unwanted side reactions, which can cause the corrosion of electrodes. They are, for example, dissolution of the anode metal (Eq. 7), anodic oxygen evolution (Eqs. 8, 9) or toxic chlorine gas evolution (Eq. 10) in the presence of chloride ions in the working solution (Sequeira 1994). Therefore, to improve the efficiency of EO, corrosion-resistant electrode materials are needed.

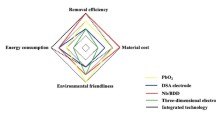

Figure 1 shows the activity of different electrodes towards OER in acidic media, which can serve as an indicator of the efficiency of these electrodes for the oxidation of organic compounds. As can be seen in Fig. 1, the BDD anode along with Ti/SnO2–Sb2O5 have the highest OER overpotential, and they are the most effective in terms of mineralization of organic pollutants, followed by Ti/PbO2 and Ti/Ta2O5–SnO2 electrodes (Shestakova et al. 2016). As mentioned above, the higher OER overpotential the weaker bonding of ·OH radicals on the anode material and less energy is consumed for the side reaction of water oxidation. Pt, IrO2–Ta2O5 and RuO2–TiO2 anodes have a high activity for OER and are less efficient in the mineralization of pollutants.

Over the past 10 years EO treatment has been recognized as effective in discoloring wastewater, removing pesticides, pharmaceuticals, and complex industrial effluents (Un et al. 2008; Zayas et al. 2011). A summary on the performance of different active and non-active electrode materials for the oxidation of organic pollutants is given in Table 1.

3.1 Noble metal electrodes

Noble metal electrodes, in particular Pt anodes, have the longest history of use in electrochemical processes due to their excellent electrocatalytic properties, corrosion resistance and long-service life. Pt is widely used in electroplating and fuel cells processes however, but has limited application in water treatment because of its high cost and low activity towards organic compound oxidation. Nevertheless, pure Pt anodes or, more often, platinized metal electrodes are intensively used on a laboratory scale to study new processes due to their excellent repeatability properties. It was found that Pt can completely degrade phenol to chlororganic compounds while applying only 1 mA/cm2 current (Bogdanovskii et al. 2001). The degradation of organic pollutants on Pt occurs through two mechanisms. The first one is controlled by direct slow electron transfer between the adsorbed organic pollutant (R) and the anode, which leads to the formation of pollutant oxidation products (Eq. 11) (Li et al. 2005).

The direct oxidation via electron transfer reactions usually takes place at high electrode potentials. Indirect pathway involves the reaction of organics oxidation by ·OH radicals (Eqs. 1, 5) and is prone to occur at low electrode potentials (Martínez-Huitle 2004).

The indirect mineralization pathway of phenol on the Pt anode consists of intermediate reactions of formation of hydroquinone and benzoquinone with their subsequent conversion into maleic and succinic or oxalic acids. Maleic and succinic acids are directly oxidized to CO2 and H2O, while succinic acid undergoes transformation through the formation of malonic and acetic acids with a final oxidation to CO2 and H2O (Li et al. 2005). Galvanostatic (100 A/m2) oxidation of oxalic acid at Pt anode provided complete removal of the pollutant after consumption of the charge of 12 Ah/dm3. For comparison, the Au electrode showed the same efficiency upon consuming 11 Ah/dm3 charge (Martínez-Huitle 2004). The Pt anode provided 96–98% malachite green oxalate dye decolourisation in 6 h of electrolysis while applying 66.7 mA/cm2 current (El-Ghenymy et al. 2015). However, the mineralization efficiency after 6 h was only 22%. As mentioned above, Pt anodes are not effective in the complete oxidation of organic compounds, since they have a low overpotential toward the OER. To enhance their mineralization activity, Pt electrodes are usually used in indirect oxidation processes in combination with other strong oxidants and their intermediates, such as, for example, H2O2 or electro-Fenton. In the case of the malachite green oxalate dye, coupling of EO on Pt anode with electro-Fenton process increased mineralization efficiency of the dye to about 97% after 3 h of the degradation process at same working parameters (El-Ghenymy et al. 2015). Moreover, the mineralization of the dye reached almost 85% after 2 h of the degradation process while coupling Pt anodic oxidation with the photo electron-Fenton process.

Another group of catalysts used in wastewater treatment application are metal alloys (Pt–Au, Ru–Pd, Pt–Ru). The activity of these catalysts depends on the ratio of components, as well as on the surface properties. They are widely used in fuel cell applications and rarely find application in water treatment technologies.

3.2 PbO2 electrodes

The second most studied anode material for the oxidation of organic compounds is PbO2. According to Fig. 1 the onset potential of the OER on PbO2 electrodes is in the range between 1.8 and 2 V versus SHE, which determines the high efficiency of these materials towards organic pollutants oxidation. Moreover, the electrodes are cost-effective compared to noble metal electrodes. It was shown that 55% of the mineralization efficiency was achieved after 2 h of electrolysis in a 0.25 mM solution of methyl orange dye at an applied current of 1 A and pH 3 while controlling TOC reduction values (Recio et al. 2011). The removal efficiency of tetracycline reached 78% within 1 h of electrolysis at Pb/PbO2 anode with applied current density of 25 mA/cm2 (Yahiaoui et al. 2013). A filter-press reactor with a β-PbO2 anode operating at 30 mA/cm2 and pH 10 provided 50% mineralization of the picloram herbicide (100 mg/L) (Pereira et al. 2015). The removal of TOC from the treated phenol solution (50 mg/L) reached 90% at the PbO2 anodes when conducting electrolysis at an applied current of 50 mA/cm2 for 3 h (Duan et al. 2013). Nevertheless the high activity of PbO2 anodes towards the EO of organic compounds, there is a risk of Pb leaching from the electrodes during their operation. Therefore, the wide use of these electrodes in industrial water treatment applications is still limited.

3.3 Mixed metal oxide electrodes

MMO electrodes are a wide group of electrocatalysts, both noble, which can adsorb oxygen on their structure, and base metals. The invention of MMO anodes was a breakthrough in electrocatalysis and allowed new cell engineering solutions with stable, inexpensive and long service life lasting electrodes (up to 10 years) (Trasatti 2000). Material oxides are prone to complete or partial reduction at the cathode and unstable in acidic media. Therefore, they are usually used for the anodic oxidation of organic pollutants in neutral and alkaline pH values. The most common MMO electrodes are Ti/TiO2–RuO2 (Pereira et al. 2012), Ti/Ta2O5–IrO2 (da Silva et al. 2013), Ti/TiO2–RuO2–IrO2 (Rajkumar et al. 2001), Ti/IrO2–RuO2 (Zhou et al. 2011), Ti/SnO2–Sb2O5 (Kong et al. 2007), etc. The oxide layers of these anodes are mainly deposited on Ti substrates. This due to the stability, good conductivity properties and cost-efficiency of Ti metal. MMO anodes have high corrosion-resistant properties and are resistant to dissolution. The commercial name for MMO anodes is dimensionally stable anodes (DSA). It was given to the anodes because of their excellent properties. Taking into account the possibility of regenerating the catalytic surface oxide coating, MMO anodes are considered stable in preserving structural integrity. They have a much slower rate of degradation compared to graphite and PbO2 electrodes. DSA have been found effective in mineralization of dyes, pesticides, herbicides, phenols and other toxic organic compounds (Feng and Li 2003; Aquino Neto and de Andrad 2009; Panakoulias et al. 2010; Motheo et al. 2000). IrO2 and RuO2-doped Ti substrates are the most studied DSA electrodes.

While studying the EO of the glyphosate herbicide (1000 mg/L) in an acidic medium of 2662 mg/L NaCl at pH = 3 and an applied current of 50 mA/cm2, different MMO electrodes such as Ti/Ru0.30Pb0.70O2, Ti/Ru0.30Ti0.70O2, Ti/Ir0.30Sn0.70O2, Ti/Ru0.30Sn0.70O2 and Ti/0.3(RuO2)0.7(Ta2O5) provided 75, 50, 35, 32 and 30% of pollutant removal respectively after 4 h of electrolysis. The highest mineralization efficiency of 24% was obtained using the Ti/Ir0.30Sn0.70O2 anode (Aquino Neto and de Andrad 2009).

The SnO2 anode with a small amount of dopant elements, for example, Sb, has a catalytic behaviour of the semiconductor. The Ti/SnO2–Sb2O5 electrode provided complete mineralization of the 1000 mg/L phenol to CO2 at pH = 12, while applying 300 A/m2 current (Kötz et al. 1991). Another MMO electrodes showed good performance towards mineralization of dyes. The rhodamine B mineralization efficiency reached 71.7, 61.7, 50.1 and 15.2% after 30 min of electrolysis with an applied current of 20 mA on Ti/TiO2–PdO–RuO2 Ti/TiO2–PdO Ti/RuO2 and Ti/TiO2 electrodes, respectively. Ti/TiO2–PdO–RuO2 electrode was also the most effective among the above-described electrodes for decolourisation of treated solution providing a colour removal efficiency of 90.4% after 30 min (Du et al. 2012).

Electrodes preparation methods

The efficiency of MMO anodes depends not only the composition of electrodes but also on the effect of manufacturing technology. All methods of MMO electrode preparation can be divided into two groups, depending on the ease of implementation and quality of the film. The first group includes sol–gel, spray pyrolysis, thermal decomposition and Pechini methods. These methods are inexpensive, simple in operation, and allow the preparation of a multicomponent precursor solution and film deposition in a single coating. The electrodeposition method can also be attributed to this group due to its wide application. Thin films produced by these methods can be morphologically and structurally uneven, have a cracking surface, lack of porosity and transparency. This can lead to a lack of accurate reproducibility of pollutant removal efficiency while using electrodes prepared at different time. However, the efficiency of the electrodes is still sufficient for most of industrial wastewater treatment applications. In the case of laboratory studies or the need for secondary use of treated wastewater in precise technological processes, such as, for example, microelectronics, electrodes with high quality properties are required. The second group of methods, which can be used to obtain MMO electrodes with high quality catalytic coatings are physical and chemical vapour deposition (PVD and CVD respectively) methods. These methods are relatively expensive and require professional staff to carry out the coating process. The essence of the methods of MMO electrodes preparation, as well as their advantages and disadvantages are given in Table 2.

3.4 Graphite and carbon electrodes

Carbon and graphite electrodes are effective in a range of small potentials and currents, which is explained by high corrosion rates at potential higher than 1.7–1.9 V versus SCE (Gattrell and Kirk 1990). Corrosion of carbon-based anodes is a major disadvantage since it leads to electrode deterioration, material loss, increase of electrode resistance and loss of stability. It was found that the removal efficiency of phenol at carbon electrodes reached 50% after 8 h of potentiostatic electrolysis at a constant voltage of 1.7 V (Gattrell and Kirk 1990). Graphite rod anodes packed into a square packed/bed reactor provided 95% TOC removal during EO treatment of textile effluents after 1 h of electrolysis at an applied current density of 28 mA/cm2 (Radha et al. 2009). Graphite carbon electrodes enabled 68% of COD and 84% of colour removal from the landfill leachate wastewater within 4 h of the EO process at an applied current density of 79 mA/cm2 (Bashir et al. 2009).

3.5 BDD electrodes

According to Fig. 1, the BDD anodes have the highest overpotential for the OER among existing electrodes used in the EO. This implies a high electrocatalytic activity and a high efficiency of the electrodes towards different organic compounds oxidation (Table 1), which was confirmed by a significant number of studies (Santana et al. 2005; Kisacik et al. 2013; Zhao et al. 2008; Cruz et al. 2012; Urtiaga et al. 2014; Haidar et al. 2013; Labiadh et al. 2016). BDD anodes are electrochemically stable, corrosion-resistant, have excellent conducting properties in a wide range of temperatures and low operation costs (Panizza et al. 2008). Despite the high mineralization rates supported by the reactions of ·OH radicals with pollutants, BDD anodes are expensive because of the high diamond and boron dopant contents (boron: 1019–1021 atoms/cm3) (Patel et al. 2013; Martínez-Huitle 2004). It has been found that the ability to mineralize pollutants using BDD electrodes is more pronounced in concentrated solutions and at lower current densities (Patel et al. 2013). The latter is due to side reactions (Eqs. 12–14) that occur with ·OH radicals (Panizza and Cerisola 2009).

Summarizing the above review, advantages and disadvantages of different electrode materials used for EO of organic pollutants are listed in Table 3.

4 Conclusions

The activity of different electrodes with respect to the mineralization of organic compounds can be estimated on the basis of OER overpotentials. The higher the OER overpotential, the more efficient the electrode in the complete oxidation of pollutants. Higher OER overpotentials facilitate the indirect pathway for pollutants oxidation through reactions with the ·OH radical. An example is BDD anodes. On the contrary, lower OER overpotentials induce direct oxidation of organics through the electron transfer between adsorbed pollutants and the anode (for example, RuO2, IrO2 and Pt electrodes), which leads to the formation of oxidation products and, as a result, lower mineralization efficiencies. All electrodes have their own advantages and disadvantages, therefore an optimal choice of electrode types should be made in each case. Such, for example, Pt electrodes and Pt-based electrodes have excellent stability in a wide range of potentials and pH. However, the low mineralization efficiency and high price of these electrodes significantly limit the field of application of the anodes. The BDD anode is the most effective in terms of complete oxidation of organic compounds, however they are relatively expensive. PbO2 and carbon-based anodes are the most cost-effective, but have low corrosion resistance properties. Depending on the composition and preparation method, the MMO electrodes can be relatively inexpensive. Sol–gel, Pechini and spray pyrolysis electrodes fabrication methods, as well as partial or complete substitution of noble metals by base metals in the structure of MMO anodes can significantly reduce their cost and make them available for large volume water treatment applications.

References

Alaoui A, El Kacemi K, El Ass K, Kitane S, El Bouzidi S (2015) Activity of Pt/MnO2 electrode in the electrochemical degradation of methylene blue in aqueous solution. Sep Purif Technol 154:281–289

Aquino Neto S, de Andrad A (2009) Electrooxidation of glyphosate herbicide at different DSA® compositions: pH, concentration and supporting electrolyte effect. Electrochim Acta 54:2039–2045

Attia SM, Wang J, Wu G, Shen J, Ma J (2002) Review on sol–gel derived coatings: process, technique and optical applications. J Mater Sci Technol 18:211–218

Baker P, Sanderson R, Crouch A (2007) Sol–gel preparation and characterisation of mixed metal tin oxide thin films. Thin Solid Films 515:6691–6697

Bashir MJK, Isa MH, Kutty SRM, Awang ZB, Aziz HA, Mohajeri S, Farooqi IH (2009) Landfill leachate treatment by electrochemical oxidation. Waste Manag 29:2534–2541

Beer BH (1966) Electrolysis with precious metalcoated titanium anode. Patent No. US3236756 A

Bogdanovskii G, Savel’eva T, Saburova T (2001) Phenol conversions during electrochemical generation of active chlorine. Russ J Electrochem 37:865–869

Chellammal S, Kalaiselvi P, Ganapathy P, Subramanian G (2016) Anodic incineration of phthalic anhydride using RuO2–IrO2–SnO2–TiO2 coated on Ti anode. Arabian J Chem 9:S1690–S1699

Chettiar M, Watkinson A (1983) Anodic oxidation of phenolics found in coal conversion effluents. Can J Chem Eng 61:568–574

Chu YY, Wang WJ, Wang M (2010) Anodic oxidation process for the degradation of 2, 4-dichlorophenol in aqueous solution and the enhancement of biodegradability. J Hazard Mater 180:247–252

Comninellis C (1991) Anodic oxidation of phenol for waste water treatment. J Appl Electrochem 21:703–708

Comninellis C (1994) Electrocatalysis in the electrochemical conversion/combustion of organic pollutants for waste water treatment. Electrochim Acta 39:1857–1862

Comninellis C, Plattner E (1988) Electrochemical wastewater treatment. Chimia 42:250–252

Cruz J, Ramos Hernandez A, Guerra-Balcazar M, Arriaga LG (2012) Electrochemical evaluation of a Ir–Ru binary oxide for oxygen evolution reaction. Int J Electrochem Sci 7:7866–7876

da Silva AJC, dos Santos EV, de Oliveira Morais CC, Martínez-Huitle CA, Leal Castro SS (2013) Electrochemical treatment of fresh, brine and saline produced water generated by petrochemical industry using Ti/IrO2–Ta2O5 and BDD in flow reactor. Chem Eng J 233:47–55

Ding HY, Feng YJ, Liu JF (2007) Preparation and properties of Ti/SnO2–Sb2O5 electrodes by electrodeposition. Mater Lett 61:4920–4923

Du L, Wu J, Hu C (2012) Electrochemical oxidation of Rhodamine B on RuO2–PdO–TiO2/Ti electrode. Electrochim Acta 68:69–73

Duan X, Ma F, Yuan Z, Chang L, Jin X (2013) Electrochemical degradation of phenol in aqueous solution using PbO2 anode. J Taiwan Inst Chem Eng 44:95–102

El-Ghenymy A, Centellas F, Rodriguez RM, Cabot PL, Garrido JA, Sires I, Brillas E (2015) Comparative use of anodic oxidation, electro-Fenton and photoelectro-Fenton with Pt or boron-doped diamond anode to decolorize and mineralize Malachite Green oxalate dye. Electrochim Acta 18:247–256

ElMekawy A, Hegab HM, Losic D, Saint CP, Pant D (2016) Applications of graphene in microbial fuel cells: the gap between promise and reality. Renew Sust Energy Rev. doi:10.1016/j.rser.2016.10.044

Feng Y, Li X (2003) Electro-catalytic oxidation of phenol on several metal-oxide electrodes in aqueous solution. Water Res 37:2399–2407

Fernandes A, Santos D, Pachero MJ, Ciriaco L, Lopes A (2014) Nitrogen and organic load removal from sanitary landfill leachates by anodic oxidation at Ti/Pt/PbO2, Ti/Pt/SnO2–Sb2O4 and Si/BDD. Appl Catal B 148–149:288–294

Freitas R, Oliveira RTS, Santos MC, Bulhões LOS, Pereira EC (2006) Preparation of Pt thin film electrodes using the Pechini method. Mater Lett 60:1906–1910

Gattrell M, Kirk D (1990) The electrochemical oxidation of aqueous phenol at a glassy carbon electrode. Can J Chem Eng 68:997–1003

Haidar M, Dirany A, Sirés I, Oturan N, Oturan MA (2013) Electrochemical degradation of the antibiotic sulfachloropyridazine by hydroxyl radicals generated at a BDD anode. Chemosphere 91:1304–1309

Kirk D, Sharifian H, Foulkes F (1985) Anodic oxidation of aniline for waste water treatment. J Appl Electrochem 15:285–292

Kisacik I, Stefanova A, Ernst S, Baltruschat H (2013) Oxidation of carbon monoxide, hydrogen peroxide and water at a boron doped diamond electrode: the competition for hydroxyl radicals. Phys Chem Chem Phys 15:4616–4624

Klamklang S, Vergnes H, Senocq F et al (2010) Deposition of tin oxide, iridium and iridium oxide films by metal-organic chemical vapor deposition for electrochemical wastewater treatment. J Appl Electrochem 40:997–1004

Kong JT, Shi SY, Zhu XP, Ni JR (2007) Effect of Sb dopant amount on the structure and electrocatalytic capability of Ti/Sb–SnO2 electrodes in the oxidation of 4-chlorophenol. J Environ Sci 19:1380–1386

Kötz R, Stucki S, Carcer B (1991) Electrochemical waste water treatment using high overvoltage anodes. Part I: physical and electrochemical properties of SnO2 anodes. J Appl Electrochem 21:14–20

Labiadh L, Barbucci A, Carpanese MP, Gadri A, Ammar S, Panizza M (2016) Comparative depollution of Methyl Orange aqueous solutions by electrochemical incineration using TiRuSnO2, BDD and PbO2 as high oxidation power anodes. J Electroanal Chem 766:94–99

Lee BS, Parl HY, Choi I, Cho MK, Kim HJ, Yoo SJ, Henkensmeier D, Kim JY, Nam SW, Park S, Lee KY, Jang JH (2016) Polarization characteristics of a low catalyst loading PEM water electrolyzer operating at elevated temperature. J Power Sources 309:127–134

Li XY, Cui YH, Feng YJ, Xie ZM, Gu JD (2005) Reaction pathways and mechanisms of the electrochemical degradation of phenol on different electrodes. Water Res 39:1972–1981

Li H, Zhu X, Jiang Y, Ni J (2010) Comparative electrochemical degradation of phthalic acid esters using boron-doped diamond and Pt anodes. Chemosphere 80:845–851

Li D, Tang J, Zhou X, Li J, Sun X, Shen J, Wang L, Han W (2016a) Electrochemical degradation of pyridine by Ti/SnO2–Sb tubular porous electrode. Chemosphere 149:49–56

Li X, Shao D, Xu H, Lv W, Yan W (2016b) Fabrication of a stable Ti/TiOxHy/Sb–SnO2 anode for aniline degradation in different electrolytes. Chem Eng J 285:1–10

Liang J, Geng C, Li D, Cui L, Wang X (2015) Preparation and degradation phenol characterization of Ti/SnO2–Sb–Mo electrode doped with different contents of molybdenum. J Mater Sci Technol 31:473–478

Lin H, Niu J, Ding S, Zhang L (2012) Electrochemical degradation of perfluorooctanoic acid (PFOA) by Ti/SnO2–Sb, Ti/SnO2–Sb/PbO2 and Ti/SnO2–Sb/MnO2 anodes. Water Res 46:2281–2289

Liu M, Wang D (1995) Preparation of La1−zSrzCo1−yFeyO3−x thin films, membranes, and coatings on dense and porous substrates. J Mater Res 10:3210–3221

Lv J, Feng Y, Liu J, Qu Y, Cui F (2013) Comparison of electrocatalytic characterization of boron-doped diamond and SnO2 electrodes. Appl Surf Sci 283:900–905

Makgae M, Klink M, Crouch A (2008) Performance of sol–gel titanium mixed metal oxide electrodes for electro-catalytic oxidation of phenol. Appl Catal B Environ 84:659–666

Martin N, Rousselot C, Savall C, Palmino F (1996) Characterizations of titanium oxide films prepared by radio frequency magnetron sputtering. Thin Solid Films 287:154–163

Martínez-Huitle C (2004) Direct and indirect electrochemical oxidation of organic pollutants, Dissertation thesis. University of Ferrara

Martínez-Huitle C, Ferro S (2006) Electrochemical oxidation of organic pollutants for the wastewater treatment: direct and indirect processes. Chem Soc Rev 35:1324–1340

Meaney K, Omanovic S (2007) Sn0.86–Sb0.03–Mn0.10–Pt0.01-oxide/Ti anode for the electro-oxidation of aqueous organic wastes. Mater Chem Phys 105:143–147

Mooney J, Radding S (1982) Spray pyrolysis processing. Ann Rev Mater Sci 12:81–101

Moraes P, Bertazzoli R (2005) Electrodegradation of landfill leachate in a flow electrochemical reactor. Chemosphere 58:41–46

Motheo A, Gonzalez ER, Tremiliosi-Filho G, Olivi P, de Andrade AR, Kokoh B, Léger JM, Belgsir EM, Lamy C (2000) The oxidation of formaldehyde on high overvoltage DSA type electrodes. J Braz Chem Soc 11:16–21

Natishan PM, O’Grady WE, Martin FJ, Hagans PL, Martin H, Stoner BR (2013) Electrochemical oxidation of organic compounds using boron-doped diamond electrodes. ECS Trans 45:19–30

Nilsson A, Ronlán A, Parker V (1973) Anodic oxidation of phenolic compounds. Part III. Anodic hydroxylation of phenols. A simple general synthesis of 4-alkyl-4-hydroxycyclo-hexa-2,5-dienones from 4-alkylphenols. J Chem Soc Perkin Trans 1:2337–2345

Nordin N, Amir F, Riyanto Othman M (2013) Textile Industries wastewater treatment by electrochemical oxidation technique using metal plate. Int J Electrochem Sci 8:11403–11415

Okimura K (2001) Low temperature growth of rutile TiO films in modified rf magnetron sputtering. Surf Coat Technol 135:286–290

Panakoulias T, Kalatzis P, Kalderis D, Katsaounis A (2010) Electrochemical degradation of Reactive Red 120 using DSA and BDD anodes. J Appl Electrochem 40:1759–1765

Panizza M, Cerisola G (2009) Direct and mediated anodic oxidation of organic pollutants. Chem Rev 109:6541–6569

Panizza M, Brillas E, Comninellis C (2008) Application of boron-doped diamond electrodes for wastewater treatment. J Environ Eng Manag 18:139–153

Pasupuleti SB, Srikanth S, Mohan SV, Pant D (2015a) Continuous mode operation of microbial fuel cell (MFC) stack with dual gas diffusion cathode design for the treatment of dark fermentation effluent. Int J Hydrog Energy 40:12424–12435

Pasupuleti SB, Srikanth S, Mohan SV, Pant D (2015b) Development of exoelectrogenic bioanode and study on feasibility of hydrogen production using abiotic VITO-CoRE™ and VITO-CASE™ electrodes in a single chamber microbial electrolysis cell (MEC) at low current densities. Bioresour Technol 195:131–138

Patel P, Bandre N, Saraf A, Ruparelia JP (2013) Electro-catalytic materials (electrode materials) in electrochemical wastewater treatment. Proc Eng 51:430–435

Pechini M (1967). Method of preparing lead and alkaline earth titanates and niobates and coating method using the same to form a capacitor. USA, Patent No. US 3330697 A

Pereira G, Rocha-Filho R, Bocchi N, Biaggio S (2012) Electrochemical degradation of bisphenol A using a flow reactor with a boron-doped diamond anode. Chem Eng J 198–199:282–288

Pereira G, Rocha-Filho R, Bocchi N, Biaggio S (2015) Electrochemical degradation of the herbicide picloram using a filter-press flow reactor with a boron-doped diamond or β-PbO2 anode. Electrochim Acta 179:588–598

Petit M, Plichon V (1998) Anodic electrodeposition of iridium oxide films. J Electroanal Chem 444:247–252

Pletcher D, Walsh F (1990) Industrial electrochemistry. Springer, New York

Radha K, Sridevi V, Kalaivani K (2009) Electrochemical oxidation for the treatment of textile industry wastewater. Bioresour Technol 100:987–990

Rajkumar D, Palanivelu K, Mohan N (2001) Electrochemical oxidation of resorcinol for wastewater treatment using Ti/TiO2–RuO2-IrO2 electrode. J Environ Sci Health A Tox Hazard Subst Environ Eng 36:1997–2010

Recio FJ, Herrasti P, Sirés I, Kulak AN, Bavykin DV, Ponce-de-León C, Walsh FC (2011) The preparation of PbO2 coatings on reticulated vitreous carbon for the electro-oxidation of organic pollutants. Electrochim Acta 56:5158–5165

Santana M, de Faria L, Boodts J (2005) Electrochemical characterisation and oxygen evolution at a heavily boron doped diamond electrode. Electrochim Acta 50:2017–2027

Sequeira C (1994) Studies in environmental science 59. Environmental oriented electrochemistry. Elsevier Science BV, Amsterdam

Sharifian H, Kirk D (1986) Electrochemical oxidation of phenol. J Electrochem Soc 133:921–924

Shestakova M, Bonet P, Gómez R, Sillanpää M, Tang WZ (2014) Novel Ti/Ta2O5–SnO2 electrodes for water electrolysis and electrocatalytic oxidation of organics. Electrochim Acta 120:302–307

Shestakova M, Vinatoru M, Mason T, Sillanpää M (2015) Sonoelectrocatalytic decomposition of methylene blue using Ti/Ta2O5–SnO2 electrodes. Ultrason Sonochem 23:135–141

Shestakova M, Graves J, Sitarz M, Sillanpää M (2016) Optimization of Ti/Ta2O5–SnO2 electrodes and reaction parameters for electrocatalytic oxidation of methylene blue. J Appl Electrochem 46:349–358

Smith de Sucre V, Watkinson A (1981) Anodic oxidation of phenol for waste water treatment. Can J Chem Eng 59:52–59

Stucki S, Kötz R, Carcer B, Suter W (1991) Electrochemical wastewater treatment using high overvoltage anodes. Part II: anode performance and applications. J Appl Electrochem 21:99–104

Trasatti S (2000) Electrocatalysis: understanding the success of DSA®. Electrochim Acta 45:2377–2385

Un U, Altay U, Koparal A, Ogutveren U (2008) Complete treatment of olive mill wastewaters by electrooxidation. Chem Eng J 139:445–452

Urtiaga A, Fernandez-Castro P, Gómez P, Ortiz I (2014) Remediation of wastewaters containing tetrahydrofuran. Study of the electrochemical mineralization on BDD electrodes. Chem Eng J 239:341–350

Wang H, Wang J (2007) Electrochemical degradation of 4-chlorophenol using a novel Pd/C gas-diffusion electrode. Appl Catal B Environ 7:58–65

Wei J, Feng Y, Sun XLJ, Zhu L (2011) Effectiveness and pathways of electrochemical degradation of pretilachlor herbicides. J Hazard Mater 189:84–91

Xu L, Guo Z, Du L, He J (2013) Decolourization and degradation of C.I. Acid Red 73 by anodic oxidation and the synergy technology of anodic oxidation coupling nanofiltration. Electrochim Acta 97:150–159

Yahiaoui I, Aissani-Benissad F, Fourcade F, Amran A (2013) Removal of tetracycline hydrochloride from water based on direct anodic oxidation (Pb/PbO2 electrode) coupled to activated sludge culture. Chem Eng J 221:418–425

Yao Y, Zhao C, Zhao M, Wang X (2013) Electrocatalytic degradation of methylene blue on PbO2–ZrO2 nanocomposite electrodes prepared by pulse electrodeposition. J Hazard Mater 263:726–734

Zayas T, Picazo M, Salgado L (2011) Removal of organic matter from paper mill effluent by electrochemical oxidation. J Water Resour Prot 3:32–40

Zhang J, Wei Y, Jin G, Wei G (2010) Active stainless steel/SnO2–CeO2 anodes for pollutants oxidation prepared by thermal decomposition. J Mater Sci Technol 26:187–192

Zhao G, Shen S, Li M, Li D (2008) The mechanism and kinetics of ultrasound-enhanced electrochemical oxidation of phenol on boron-doped diamond and Pt electrodes. Chemosphere 73:1407–1413

Zhou M, Liu L, Jiao Y, Wang Q, tan Q (2011) Treatment of high-salinity reverse osmosis concentrate by electrochemical oxidation on BDD and DSA electrodes. Desalination 277:201–206

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Shestakova, M., Sillanpää, M. Electrode materials used for electrochemical oxidation of organic compounds in wastewater. Rev Environ Sci Biotechnol 16, 223–238 (2017). https://doi.org/10.1007/s11157-017-9426-1

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11157-017-9426-1