The possibility is considered of using a hot-wire method (cross-array method) for determining heat insulation material thermal conductivity at high temperature. These tests show that different indices obtained by the hot-wire method and the steady-state standard do not exceed 12 – 15%.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

In recent years instead of steady-state methods for determining thermophysical properties (in particular thermal conductivity) for ceramic refractory materials of different designation there is more frequent use of transient methods, i.e., a probe method (heated thread), a method of uniform heating, and a thermal wave method. A hot-wire method is a version of the probe method, and it has been used extensively for determining refractory thermophysical properties over a significant temperature range.

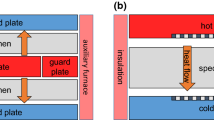

The hot-wire method is based on features of heating inorganic material within which a thin thread is placed, heated by a direct electric current. Advantages of the method in determining refractory thermal conductivity are the simple specimen shape (brick or part of it in the form of a parallelepiped), absence of limitations for test material thermal conductivity, and the possibility of limiting to one temperature sensor. It is also important that in a test the working change temperature and material thermal conductivity is determined under conditions similar to those during refractory object operation in a furnace. The measurement error is low (5 – 10% for heat insulation materials) and depends on quality of specimen temperature control, its thermal conductivity, and measurement precision. The hot-wire method may with satisfactory accuracy determine thermal conductivity with low values, i.e., from 0.05 to 2.5 W/(m·K); by the GOST 12170 procedure the lower limit for hot-wire method determination of refractories is 0.18 W/(m·K). This method is convenient for determining thermal conductivity of granular and powder refractories. Inadequacies of the method limiting its application are significant (up to 15 – 20%) measurement error in testing dense refractories with high thermal conductivity (more than 2.5 W/(m·K)), and increase in requirement for operator qualification and also the complexity of precise control of specimen temperature during isothermal exposure. It is difficult to use this method for determining the thermal conductivity of anisotropic material [1]. At the same time, an advantage of the method is its use in testing heat insulation refractories and this has made it possible to recommend it as an international standard (ISO 8894).

Within the D. I. Mendeleev RKhTU faculty of chemical technology of ceramics and refractories a test unit has been developed in which one version of the hot-wire method is implemented, i.e., a cross-array method with the possibility of performing tests up to 1200°C. Previously by means of this unit research was carried out for heat insulation chamotte refractories [2]. Satisfactory convergence has been obtained for values of effective thermal conductivity with indices for materials of this type determined in a steady state regime, and the measurement error is not more than 10%. Recently the cross-array method has been used for determining the effective thermal conductivity of heat insulation materials of two different forms: fiber, based on mullite-silica fiber, and unmolded heat insulation (ceramic concrete) with density of 96 – 300 and 600 – 1000 kg/m3 respectively.

Preparation of heat insulation material specimens and performance of the test have been performed as described in an article [2]; tests were carried out in the range 300 – 1200°C. Results of determining the temperature dependence of effective thermal conductivity for the test materials are provided in Tables 1 and 2.

The difference in experimental results from those in available data for thermal conductivity of the test materials obtained at the temperatures indicated by a steady state regime does not exceed 12 – 15%, and this makes the hot-wire method promising for determining thermal conductivity of insulating materials at higher (up to 1200°C) temperature.

References

J. H. Lienhard IV and J. H. Lienhard V, A Heat Transfer Textbook. 4th ed., Phlogiston Press, Cambridge (2012).

B. S. Skidan and S. A. Borisov, “High-temperature testing of heat insulation materials for thermal conductivity,” Ogneupor. Tekhn. Keram., No. 4, 38 – 41 (1999).

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated from Novye Ogneupory, No. 6, pp. 67 – 68, June, 2016.

Rights and permissions

About this article

Cite this article

Vartanyan, M.A., Gerasimov, R.I., Pyren’kin, O.V. et al. Study of Heat Insulation Material Thermal Conductivity by a Hot-Wire Method. Refract Ind Ceram 57, 332–333 (2016). https://doi.org/10.1007/s11148-016-9979-5

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11148-016-9979-5