Abstract

The TiO2 nano-crystals were synthesized on the HZSM-5 zeolite to facilitate the photocatalyst-water separation. The HZSM-5 surface was tightly coated with a TiO2 layer in the thickness of approximately 100 nm. The distinct boundaries of the TiO2 layer and the zeolite demonstrated the strong combination of the two materials. There was insignificant effect of this interaction on the properties of the TiO2-HZSM-5 (TOHZ) at a given titanium oxide content. The chemical environments of the two elements in the titanium dioxide were not influenced by the HZSM-5. The ECB (conduction band edge) and the EVB (valence band edge) were − 0.63 and 2.45 V for the TOHZ. The supported TOHZ photocatalyst had a promising activity on Acid Red 1 (AR1) degradation. 45.4% of the AR1 molecules were degraded in the solution using 300 mg/L of TOHZ after 30 min of reaction. Reusability test showed that 73.7% of the TOHZ’s activity was retained after five treatment cycles.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

The azo dye contaminated wastewater is produced in the dyeing and printing industries. The wastewater needs to be purified to remove the hazardous contaminates. If the wastewater contains toxic compounds, the bio-chemical technique cannot be applied to treat the wastewater [1,2,3,4]. The advanced oxidation techniques, e.g. photocatalytic oxidation, were applied to remove various organic pollutants in the wastewater [5,6,7,8]. Among the various kinds of photocatalytic materials, titanium dioxide was believed to be the most promising photocatalyst [9,10,11,12,13].

The expensive photocatalyst cannot be used only once in the wastewater treatment plant, so that the collection of the materials from the water is essential to the application of the photocatalytic technique. The collection of the fine photocatalyst powders from the water is difficult and inefficient [14, 15]. The titanium dioxide was deposited on different substrates or supports to facilitate the separation process. Nevertheless, the supported photocatalyst was normally not as powerful as the small TiO2 powders [16,17,18]. The interaction between the photocatalyst and the support was worthy of investigation, and the influences of the support on the activity of the TiO2 must be clarified.

The TiO2 in the supported form could be reused for water treatment due to the prompt separation of the photocatalyst and the water. Furthermore, if the activity of the supported TiO2 can be enhanced too, the supported TiO2 will inevitably find the wide application in the large-scale water treatment plant. The TiO2 nano-crystals were synthesized on the HZSM-5 zeolite to facilitate the photocatalyst-water separation in this work. The materials were characterized and were used to degrade the Acid Red 1 (AR1) dye. An interesting finding of this work was the promising activity of the supported photocatalyst, i.e. TiO2-HZSM-5 (TOHZ).

Experimental details

TOHZ preparation

The preparation of the TOHZ followed the general sol–gel procedure. The first solution was an ethanol aqueous solution (8 mL anhydrous ethanol + 3 g cetyltrimethyl ammonium bromide + 2 mL tetrabutyl titanate + 0.1 mL hydrochloric acid). The second solution was the mixture of anhydrous ethanol (4 mL) and water (0.9 mL). The HZSM-5 (Nankai Catalyst Corporation, China; SiO2/Al2O3 ratio = 25) was added in the solution A, and the mixture was stirred for 60 min. The solution B was mixed with the former mixture under stirring to form a gel. The gel was dried at 110 °C for 12 h, and then the gel was calcined for 3 h at 450 °C. The powders were gently ground before use. The TOHZ composite contained 30% titanium dioxide.

Characterization methods

The SEM observation was taken on a FEI QUANTA 250 scanning electron microscope. A transmittance electron microscope (FEI G2 20 TEM) was applied for the high-resolution observations. The FT-IR spectra were recorded using a Frontier spectrometer. The elemental analyses were obtained on an ESCALAB X-ray photoelectron spectroscopy (250Xi). A UV–Vis spectrometer (LAMBDA 35) was used to study the material’s band positions.

Photocatalytic AR1 degradation

The AR1 (C18H13N3NaO8S2) was used to study the degradation efficiency on the TOHZ. The material was mixed with 50 mL AR1 solution (40 mg/L) in a quartz beaker. The material and AR1 solution were stirred in the dark until the dye concentration was stable. After that, the UV lamp irradiated at 253.7 nm to initiate the reaction. The dye concentration was determined by the absorption spectrum (721E).

Results and discussions

SEM and TEM morphologies

Fig. 1 gives the surface morphologies of the TiO2, TOHZ and HZSM-5. The nano-sized anatase TiO2 crystals aggregated to form large particles in the size more than 12 μm, as shown in Fig. 1a. Some small particle were also in the material as the result of grinding. The HZSM-5 was composed of regular-shaped particles and small fragments (Fig. 1b). The typical HZSM-5 particle was in the size of 2 × 3 × 6 μm3. As presented in Fig. 1c, the TiO2 and HZSM-5 were combined in the TOHZ. Although the zeolite particles could still be seen in the image, the surface of the zeolite particles was not as smooth as the surface in Fig. 1b. When the HZSM-5 particles were mixed in the sol, the tetrabutyl titanate was adhered on the zeolite particles. The hydrolysis of the tetrabutyl titanate took place on the HZSM-5 surface. Therefore, the zeolite provided the surface as the nucleation center for the sol–gel process. The formation of TiO2 crystals also originated on the zeolite’s surface, and there was a restrained aggregation of the TiO2 nano crystals [19].

The cross-section TEM image of TOHZ is shown in Fig. 2. The HZSM-5 surface was tightly coated with a TiO2 layer in the thickness of approximately 100 nm. The distinct boundaries of the TiO2 layer and the HZSM-5 surface demonstrated the strong combination of the two materials. The Ti–OH network was constructed on the HZSM-5 surface, and the crystallization of the anatase TiO2 crystals occurred on the HZSM-5 surface too. The nano-sized TiO2 crystals could be distinguished in the image, while the crystallite size was approximate the value calculated using the X-ray diffraction results.

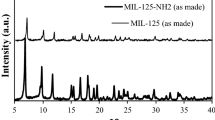

Material composition

Fig. 3 presents the infrared absorptions of the HZSM-5, TOHZ and TiO2 in the medium and far infrared spectra. The absorption of the stretching vibration of the hydroxyl group at 3429 cm−1 and the absorption of the bending vibration of the hydroxyl group at 1631 cm−1 were attributed to the surface adsorbed water. These two absorptions of the HZSM-5 and TOHZ had higher intensity than the absorptions of the TiO2, since the porous HZSM-5 zeolite was a good adsorbate of water. The HZSM-5 zeolite was composed of tetrahedral Al-O and Si–O, which had the antisymmetrical stretching vibrations at 796 and 1232 cm−1. The absorptions at 1064 and 439 cm−1 were also related to the stretching vibration of the Si(Al)-O bonds. The antisymmetrical stretching vibration of the penta-ring in the HZSM-5 led to the absorption at 545 cm−1. The strong absorption centered at 336 cm−1 was related to the stretching vibration of the Ti–O bond. The surface water was important to the photocatalyst since the photogenerated hydroxyl radicals were transformed from hydroxyl groups. The infrared spectra did not provide any proof for the interaction between the TiO2 and the HZSM-5.

The chemical environments of the TOHZ are presented in the XPS spectra, as shown in Fig. 4. Fig. 4a gives the XPS spectrum of titanium, including the Ti2p1/2 orbital and Ti2p3/2 orbital. The electron binding energies of these two orbitals were 464.4 and 458.7 eV. The titanium XPS spectrum represented the typical Ti4+ oxidation state in the TOHZ [20]. Fig. 4b gives the XPS spectrum of oxygen, including both the oxygen in the HZSM-5 and TiO2. The maximum absorption peak at 529.8 eV was attributed to the Ti–O bond in the TiO2. The binding energies of 530.5 and 531.9 eV were for the hydroxyl group. The Si(Al)-O bonds in the HZSM-5 were represented by the binding energy peaks at 532.6 and 533.2 eV. The chemical environments of TiO2 were not influenced by the HZSM-5.

Band positions

Fig. 5 schematically illustrates of the band positions of the TOHZ. The band positions were calculated using the equations, ECB = X—EC − 1/2Eg and EVB = ECB + Eg [21, 22]. The band gap Eg of the TOHZ was 3.08 eV, which was obtained using the UV–Vis diffuse reflectance spectrum. The ECB (conduction band edge) and the EVB (valence band edge) were − 0.63 and 2.45 V, respectively. Since the OH−/·OH oxidation potential was 1.89 V and the O2/O2−· reduction potential was O2 − 0.13 V, the ·OH and O2−· were produced on the excited TOHZ.

AR1 removal.

Fig. 6 illustrates the influences of the TOHZ dosage on AR1 decoloration, including both adsorption and degradation. The adsorption of the dye constantly increased with rising TOHZ dosage. Nearly 20% of the AR1 molecules could be removed by adsorption in the presence of 500 mg/L TOHZ. The adsorption of the dye was the initial step for the subsequent degradation reaction, and the adsorbed AR1 molecules could eventually be degraded as well. Besides the dye removal by adsorption, the degradation of the AR1 molecules was the key character of the photocatalyst. The AR1 degradation efficiency steadily increased when the TOHZ dosage was less than 300 mg/L. After 30 min of reaction, 45.4% of the AR1 molecules were degraded in the solution using 300 mg/L of TOHZ. If the TOHZ dosage was raised further, the AR1 degradation efficiency increased quite slowly.

Fig. 7 shows the reusability of the TOHZ on AR1 degradation. The reaction time was 30 min and the TOHZ dosage was 300 mg/L. 5 mL of the AR1 solution was taken to determine the AR1 concentration after each treatment cycle. Subsequently, another 5 mL AR1 stock solution was added to restore the initial concentration. The degradation efficiency slightly decreased after each cycle, and 73.7% of the TOHZ’s activity was retained after five cycles.

Conclusions

The TiO2 nano-crystals were synthesized on the HZSM-5 zeolite to prepare the TOHZ. The distinct boundaries of the TiO2 layer and the HZSM-5 surface demonstrated the strong combination of the two materials. The size of the crystallites of titanium oxide in TOHZ decreased in comparison with pure titanium oxide. The infrared spectra and the XPS spectra did not provide any proof for the chemical interaction between the TiO2 and the HZSM-5. The •OH and O2−• could be produced on the excited TOHZ due to the conduction band and valence band positions. The AR1 degradation efficiency steadily increased with rising TOHZ dosage below 300 mg/L. The degradation efficiency slightly decreased after each treating cycle, and 73.7% of the TOHZ’s activity was retained after five cycles.

References

Barceló D, Žonja B, Ginebreda A (2020) Toxicity tests in wastewater and drinking water treatment processes: A complementary assessment tool to be on your radar. J Environ Chem Eng 8:104262

Lu HB, Yu Y, Zhou YX, Xing F (2019) A quantitative evaluation method for wastewater toxicity based on a microbial fuel cell. Ecotoxicol Environ Saf 183:109589

Zhao WT, Sui Q, Huang X (2018) Removal and fate of polycyclic aromatic hydrocarbons in a hybrid anaerobic–anoxic–oxic process for highly toxic coke wastewater treatment. Sci Total Environ 635:716–724

Zan J, Song H, Zuo SY, Chen XR, Xia DS, Li DY (2020) MIL-53(Fe)-derived Fe2O3 with oxygen vacancy as Fenton-like photocatalysts for the elimination of toxic organics in wastewater. J Clean Prod 246:118971

Martín-Sómer M, Pablos C, de Diego A, van Grieken R, Encinas Á, Monsalvo VM, Marugán J (2019) Novel macroporous 3D photocatalytic foams for simultaneous wastewater disinfection and removal of contaminants of emerging concern. Chem Eng J 366:449–459

Rani SEGD, Kumar AG, Steplinpaulselvin S, Rajaram R, Silambarasan TS, Lydia IS, Chen Y (2020) Survival assessment of simple food webs for dye wastewater after photocatalytic degradation using SnO2/GO nanocomposites under sunlight irradiation. Sci Total Environ 721:137805

Ambigadevi J, Senthil Kumar P, Vo DVN, Hari Haran S, Srinivasa Raghavan TN (2021) Recent developments in photocatalytic remediation of textile effluent using semiconductor based nanostructured catalyst: A Review. J Environ Chem Eng 9:104881

Deepracha S, Ayral A, Ogawa M (2021) Acceleration of the photocatalytic degradation of organics by in-situ removal of the products of degradation. Appl Catal B: Environ 284:119705

Fujishima A, Honda K (1972) Electrochemical photolysis of water at a semiconductor electrode. Nat 238:37–38

Fujishima A, Rao TN, Tryk DA (2000) Titanium dioxide photocatalysis. J Photochem Photobio C 1:1–21

Hendrix Y, Lazaro A, Yu QL, Brouwers HJH (2019) Influence of synthesis conditions on the properties of photocatalytic titania-silica composites. J Photochem Photobio A: Chem 371:25–32

Rasheed T, Adeel M, Nabeel F, Bilal M, Iqbal HMN (2019) TiO2/SiO2 decorated carbon nanostructured materials as a multifunctional platform for emerging pollutants removal. Sci Total Environ 688:299–311

Wang SL, Lin SH, Zhang DQ, Li GS, Leung MKH (2017) Controlling charge transfer in quantum-size titania for photocatalytic applications. Appl Catal B: Environ 215:85–92

Zhang XL, Yuan JL, Zhu J, Fan L, Chen HT, He H, Wang Q (2019) Visible light photocatalytic performance of laser-modified TiO2/SnO2 powders decorated with SiC nanocrystals. Ceram Int 45:12449–12454

Elsellami L, Dappozze F, Fessi N, Houas A, Guillard C (2018) Highly photocatalytic activity of nanocrystalline TiO2 (anatase, rutile) powders prepared from TiCl4 by sol–gel method in aqueous solutions. Process Saf Environ Prot 113:109–121

Al-Mamun MR, Kader S, Islam MS, Khan MZH (2019) Photocatalytic activity improvement and application of UV-TiO2 photocatalysis in textile wastewater treatment: A review. J Environ Chem Eng 7:103248

He XH, Wang AZ, Wu PA, Tang SB, Zhang Y, Li L, Ding P (2020) Photocatalytic degradation of microcystin-LR by modified TiO2 photocatalysis: A review. Sci Total Environ 743:140694

Ng KH, Yuan LS, Cheng CK, Chen KJ, Fang C (2019) TiO2 and ZnO photocatalytic treatment of palm oil mill effluent (POME) and feasibility of renewable energy generation: A short review. J Clean Prod 233:209–225

Li HL, Zhang WJ, Liu YX (2020) HZSM-5 zeolite supported boron-doped TiO2 for photocatalytic degradation of ofloxacin. J Mater Res Technol 9:2557–2567

Zhang WJ, Bi FF, Yu Y, He HB (2013) Phosphoric acid treating of ZSM-5 zeolite for the enhanced photocatalytic activity of TiO2/HZSM-5. J Mole Catal A: Chem 372:6–12

Arthur H, Nethercot J (1974) Prediction of Fermi energies and photoelectric thresholds based on electronegativity concepts. Phys Rev Lett 33:1088–1091

Zhang GS, Zhang W, Crittenden JC, Chen YS, Minakata D, Wang P (2013) Photocatalytic hydrogen production under visible-light irradiation on (CuAg)0.15In0.3Zn1.4S2 synthesized by precipitation and calcination. Chin J Catal 34:1926–1935

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Lv, Z., Tao, Y. & Zhang, W. Titanium dioxide supported on HZSM-5 for acid red 1 photocatalytic degradation. Reac Kinet Mech Cat 133, 531–539 (2021). https://doi.org/10.1007/s11144-021-01971-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11144-021-01971-4