Abstract

Nanocrystalline lanthanide oxide doped ZnO has been prepared by a simple and efficient technique for exhibiting an enhanced visible light photocatalytic activity. The prepared photocatalysts were characterized by SEM, XRD and UV–Vis DRS analysis. XRD data showed that the particles of samples were highly nanosized and crystalline. The sizes of Yb2O3/ZnO, Er2O3/ZnO and Pr6O11/ZnO nanoparticle were 40.97, 40.94 and 51.18 nm and found to be mixed morphology. Six factors such as dosage of photocatalysts, coupling ratio of lanthanide oxide and ZnO, initial concentration of diesel, concentration of H2O2, illumination time of visible light and pH value were changed in order to test the photocatalytic activity and efficiency of reaction. The enhanced photocatalytic activity was due to the presence of f shells in the lanthanide oxide crystal lattice which delays the process of recombination of electron hole pair. According to the results, diesel removal was < 30% without any catalyst (losses only by evaporation) and the optimized effects of Yb2O3/ZnO, Er2O3/ZnO and Pr6O11/ZnO occurred when the catalyst dose at 0.4, 0.6 and 0.4 g/L, catalyst-coupling ratio at 40, 30 and 10%, initial diesel concentration was 0.05, 0.10 and 0.20 g/L, H2O2 concentration at 4, 4 and 6 mg/L, illumination time at 1.5, 1.5, 2.5 h and pH at 7, 10 and 6 respectively, in which case the diesel removal rate reached 95.48, 98.60 and 90.81%. The experimental results clearly show that lanthanide oxide doped nanocrystalline semiconductor are highly active under visible light irradiation and may find wider applications in environmental remediation technologies.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

The preparation and application of ZnO photocatalysts have been widely investigated due to their excellent photocatalytic activity and stable chemical properties. However, ZnO needs ultraviolet light (UV) to produce photoinduced holes and photogenerated electron hole pairs because of its large band gap (Eg = 3.37 eV) [1]. In order to improve the photocatalytic activity of ZnO catalysts, this includes doping other elements into ZnO photocatalysts. The major doping methods include single metal doping [2], single nonmetallic doping [3], metal and metal co-doping [4], non-metallic and non-metallic co-doping [5, 6], metal and nonmetallic co-doping [7], multi-element doping [8] and composite oxide photocatalyst [9]. Using a simple process to prepare effective visible-light-activity ZnO photocatlysts is the purpose of this article.

Various elements doped TiO2 and ZnO have been exploited recently for the degradation of organic compounds but only few reports are available for rare earth metal ion doped ZnO and its visible photocatalytic activity. The zeolite fly ash bead (ZFAB) was used as a carrier doped TiO2 photocatalyst to improve the photocatalytic efficiency and the results showed that ZFAB/TiO2 samples performed better photocatalytic effects and long-term performance than that of samples prepared with pure TiO2 [10]. The photocatalytic activities of Fe–N–C–TiO2 nano-materials were examined under visible light illumination using Cr(VI) as target pollutant, which were higher than that of the other nano-materials under visible light irradiation [11]. The dopants in the composite not only provide a large adsorption capacity substrate, but also make TiO2 particles formed a well-dispersed monolayer to provide larger photocatalytic reaction surface area, resulting in the significantly increasing of photocatalytic activity [12]. MIP-TiO2/GR exhibited better adsorption capacity and adsorption selectivity towards the template molecule compared to NIP-TiO2/GR due to the imprinted cavities on the surface of MIP-TiO2/GR [13]. Complete mineralization has been achieved in the case of lanthanide oxide doped TiO2 photocatalysts in total contrast to the formation of intermediates in case of non-modified TiO2 [14]. Rare earth oxides turned a wide band gap metal oxide into in zirconium dioxide under visible light irradiation [15]. ZnO was doped on Dy2O3 in various proportions and the best ratio was finalized by the determination of photodegradation efficiency employing a model pollutant ORG under visible light irradiation [16]. Nanocrystalline semiconductor doped lanthanide oxides are highly active under visible light irradiations [17]. The catalysts prepared by co-precipitation exhibited a higher photocatalytic activity than those prepared by the usual sol–gel process [1].

We report herein a process for the transformation of an insulator like LnxOy into a visible light active photocatalyst, by the process of coupling LnxOy onto ZnO. Nanocrystalline (NC) LnxOy doped ZnO have been synthesized and characterized by SEM and XRD techniques. The photocatalytic activities of the prepared catalyst have been carried out for the degradation of a model pollutant such as diesel.

Materials and methods

Materials

Zinc nitrate hexahydrate (AR, Zn(NO3)2·6H2O) was produced by Shenyang City Reagent Five Plant, China. Ytterbium nitrate (99.9%, Yb(NO3)3·5H2O) Erbium nitrate (99.9%, Er(NO3)3·5H2O) and praseodymium nitrate (99%, Pr(NO3)3·6H2O) were supplied by Aladdin Industrial Corporation, China. Cetyltrimethylammonium bromide (AR, CTMAB), sodium hydroxide (GR, NaOH) and absolute ethanol (AR, CH3CH2OH) were purchased from Tianjin Ke Miou Chemical Reagent Co., Ltd, China. The apparatus consisted of an ultrasonic cleaner (SB-5200D), a drying oven (101 type), a UV–visible spectrophotometer (752 type), an X-ray diffractometer (D/MAX-2500), UV–Vis diffuse reflectance spectrum (UV2600, Shimadzu, Japan) and some fluorescent lamps (YZ18RR26, 20 W, 400–700 nm).

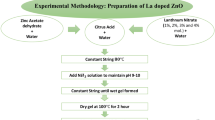

Preparation of the doped photocatalysts

The non-modified ZnO, ytterbium(Yb3+)-, erbium(Er3+)- and praseodymium(Pr3+)- doped ZnO were prepared. A solution contained Zn(NO3)3, Ln(NO3)3 and CTAB was mixed by ultrasonic dispersion for about 2 h. Then, the NaOH solution was slowly added to the mixture solution and the precipitation was slowly generated. The resulting precipitation was dried at 105 °C for 12 h. The resulting powder was calcined by heating to 550 °C for 2 h in air. The Yb2O3/ZnO, Er2O3/ZnO and Pr6O11/ZnO were prepared by a similar method. The molar ratios of lanthanide oxide and ZnO were 0, 10, 20, 30, 40 and 50%. The Yb2O3/ZnO, Er2O3/ZnO and Pr6O11/ZnO catalysts showed white, pink and black, respectively.

Preparation of diesel pollutant solutions

The diesel pollutant solutions were prepared by dissolving the required amount of diesel in seawater (The seawater was taken from the sea area of Heishijiao, Dalian, China) in the required pH. A 200 mg/L solution of the diesel pollutant sample was prepared by taking 10 mg of diesel in 50 mL of seawater. Then the required concentrations were prepared by diluting accordingly.

Methods

The prepared photocatalysts were characterized by Quanta 200 FEG field emission environmental scanning electron microscopy (SEM), X-ray diffraction (XRD) and UV–Vis diffuse reflectance spectrum (UV–Vis DRS). A certain concentration of seawater polluted by diesel was added in a 100 mL beaker. The pH value of the wastewater was adjusted by HCl or NaOH. Different coupling ratios of homemade nano photocatalysts LnxOy/ZnO were added and irradiated by visible light for 2 h. The content of residual diesel fuel could then be estimated by spectrophotometer after reaction. Finally, the degradation efficiency of catalysts could be calculated from following equation:

Here C0 and C i are the initial and final concentrations of diesel in the seawater (g/L).

The experiment uses self-made photocatalytic reaction chamber (Fig. S2) with a fluorescent lamp as a light source. The reaction was placed in a beaker put on a magnetic stirrer. The reaction was stirred continuously to simulate the waves and to bring the photocatalyst into full contact with the substrate.

Fig. S3 shows the absorbance spectra of diesel solution at time intervals of irradiation with the Er2O3/ZnO photocatalyst (coupling ratio = 0.2). A substantial decrease in the absorbance of the substrate at all the wavelengths is observed indicating its degradation and mineralization. It can be seen that the absorption peak is obvious when the wavelength at 225 nm, so the determination of diesel at a wavelength of 225 nm.

Scanning electron microscopy analysis

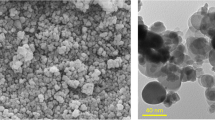

The surface morphology of photocatalysts and size of particle were analyzed by SEM. The Scanning electron microscopy images of 20% coupling ratios of three samples are shown in Fig. 1. They were in the nano range from 40 to 60 nm for all the three composite samples. The surface morphology of ZnO is nearly spherical. The morphology of Yb2O3 (Fig. 1a) and Er2O3 (Fig. 1b) is irregular ellipsoid and the morphology of Pr6O11 (Fig. 1c) is long stripe. In Yb2O3/ZnO, Er2O3/ZnO and Pr6O11/ZnO catalysts, it is obvious that there are two morphologies existing.

X-ray diffraction analysis

X’Pert High-Score software was used for data handling. The composition of the sample can be determined by multiphase analysis. Finally, the grain size of the material is calculated by the Scherrer equation:

Here D is the average size of the crystallite; β is the full width at half maximum; θ is Bragg angle (taking radian calculation); λ represents the wavelength of X-ray (Å); K is taken as a constant related to the degree of broadening.

The composition of the catalyst material and particles sizes were determined by X-ray diffraction (XRD, Fig. 2). The ZnO peaks (Fig. 2a) were obvious when 2θ was 31.7348°, 34.3994°, 36.2102°, 56.5351°, 61.7981°, or 47.4826°. The average photocatalyst crystallite size was calculated using the Scherrer formula. The lattice constants of a, b, and c for ZnO were 3.2539, 3.2539, and 5.2098 Å, and the average photocatalyst crystallite size was 34.14 nm from calculations of the (111) diffraction peak, which were similar to ZnO’s XRD pattern. Comparing these results from the XRD pattern with the Joint Committee on Powder Diffraction Standards (JCPDS) card, it was obvious that the sample was a form of ZnO (ZnO-JCPDS No. 36-1451).

The Y20 peaks (Fig. 2b) were apparent when 2θ was 29.6110°, 34.3406°, 36.2388°, 49.3215°, 31.7536°, or 58.5863°. The lattice constants of a, b, and c for Y20 were 5.3580, 5.3580, and 5.3580 Å, and the average photocatalyst crystallite size was 40.97 nm, according to calculations of the (111) diffraction peak. Comparing the XRD pattern with the JCPDS card, the composite photocatalyst was concluded to be a mixture of Yb2O3 and ZnO.

E20 photocatalyst (Fig. 2c) has obvious peaks when 2θ is 36.2429°, 29.2834°, 31.7572°, 34.4099°, or 56.5498°. The diffraction peaks of Er2O3 is similar to the standard patterns (Er2O3-JCPDS 01-077-0459). The lattice constants of a, b, and c of Er2O3 are 10.5500, 10.5500, and 10.5500 Å. The average crystallite sizes of Er2O3 are and 40.94 nm, which are calculated by Scherrer equation according to the diffraction peaks (111). Thus, the prepared photocatalysts are pure ZnO and Er3+–ZnO.

The P20 peaks (Fig. 2d) were apparent when 2θ was 28.2910°, 36.2977°, 31.8088°, 46.9969° or 32.7761°. The lattice constants of a, b, and c for P20 were 5.4678, 5.4678, and 5.4678, respectively, and the average photocatalyst crystallite size was 51.18 nm, according to calculations of the (111) diffraction peak. The diffraction peaks of Pr6O11 are similar to the standard patterns (Pr6O11-JCPDS 00-042-1121).

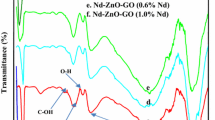

UV–Vis diffuse reflectance spectrum analysis

The UV–Vis DRS result positively predicts the photocatalytic activity of the photocatalysts. Fig. 2ii shows the diffuse reflectance spectra of all the prepared photocatalysts. The spectrum of ZnO is dominated by the band gap transition occurring at about 250 nm that is due to the electrons excitation from the valence band (VB) to the conduction band (CB). A very weak absorption between 250 and 350 nm is also present, which is due to traces of point defects always present in the bare material [15]. No absorption is observed in the visible region. ZnO has the maximum absorbance in the far UV region, when the coupling ratios of lanthanide oxide increase, a shift in absorbance is observed from UV to the visible region (red shift). To evaluate the entity of the red shift, we calculated the energy gap (Eg) value for all the samples. The band gaps of pristine ZnO, Y20, E20 and P20 are found to be 3.4, 3.0, 3.1 and 2.4 eV.

Results and discussion

Variation of catalysts’ dosage

The dosage of photocatalyst is one of the deciding factors in the examination of degradation efficiency of the target pollutants. The effect of photocatalyst dosage on degradation of diesel was studied with varied catalytic amount from 0 to 1.2 g/L for a diesel concentration of 0.2 g/L and the results are shown in Fig. 3a. It was found that at 0.6 g/L (Yb2O3/ZnO) and 0.8 g/L (Er2O3/ZnO, Pr6O11/ZnO) of catalysts the degradation efficiency was optimum and further addition of catalyst into the system did not enhance the efficiency of diesel degradation. The optimum removal rates of the prepared photocatalysts are 97.04, 94.70 and 84.58% (Er2O3/ZnO, Pr6O11/ZnO and Yb2O3/ZnO). The photocatalytic activity of composite photocatalysts was far higher when compared to pristine ZnO (26.95%) under similar conditions. As the dosage of photocatalysts increase there is a decrease in the removal rate of diesel pollutant. The addition of too much photocatalyst could cause the scattering and reflection of ultraviolet light, which affects the excitation of the partial photocatalyst by ultraviolet light and affects the generation of photogenerated electron–hole pairs.

Effects in diesel removal of a photocatalyst dosage, b catalyst coupling ratio, c initial diesel concentration, d H2O2 concentration, e reaction time, and f pH value. (Standard experimental conditions: dosage 0.2 g/L, coupling ratio 20%, diesel initial concentration 0.2 g/L, hydrogen peroxide concentration 6 mg/L, illumination time 2 h and pH value 8. Each experiment changes one of the conditions as a variable.)

Variation of coupling ratios

Different coupling ratios determine the different absorption rate of energy. The removal rate of diesel pollutant was studied with varied coupling ratio from 0 to 50% in visible light irradiation with standard experimental conditions. The results are shown in Fig. 3b. The optimum degradation rate of diesel exists when the coupling ratio is 20% for the three kinds of photocatalysts. Thus, the experiment employs 20% coupling ratio of the photocatalysts as a standard condition. When the lanthanide oxide coupling ratio is high, the lanthanide oxide particles may cover the surface of ZnO, thus hindering the excitation of ultraviolet light on the catalyst. It will affect the generation of photogenerated electron hole pairs and affect the photocatalytic effect of diesel. In addition, when the amount of lanthanide oxide coupling ratio is too large, the lanthanide oxide particles can also be referred to as the composite centers of electrons and holes, which also affect the oxidation of photogenerated holes. Then the amount of hydroxyl radicals decrease and the photocatalytic effect is weakened.

Variation of initial diesel concentration

The effects of initial concentration of diesel on photodegradation of diesel pollutant were studied from 0.05 to 0.30 g/L at fixed amount of the photocatalyst with the pH of seawater. The results are shown in Fig. 3c. It is observed that as the concentration of diesel increases there is an increase and a decrease in the photocatalytic activity of the photocatalyst. When the concentration is lower than the optimum diesel concentration, the photocatalytic power may be insufficient. When the concentration of diesel is higher than that of the optimum diesel oil, the catalyst will be coated with the diesel, which is not conducive to the excitation of the surface electrons of the catalyst and the generation of hydroxyl radicals. Under similar reaction conditions, Pr6O11/ZnO and Yb2O3/ZnO are suitable for the treatment of lower concentrations of wastewater while Er2O3/ZnO is suitable for the treatment of higher concentrations of wastewater contaminants.

Variation of hydrogen peroxide concentration

Hydrogen peroxide promotes the photocatalytic reaction as a co-oxidant role under certain conditions. Hydrogen peroxide plays the role of electron acceptor, which can capture the photogenerated electrons on the surface of ZnO catalyst. It can effectively hinder the recombination of photogenerated electron holes, which is beneficial to the photocatalytic oxidation reaction. As shown in Fig. 3d, the optimum removal rate of three kinds of photocatalysts are 92.37, 92.37 and 83.02% (Er2O3/ZnO, Pr6O11/ZnO and Yb2O3/ZnO). When the concentration of hydrogen peroxide exceeds a certain value, the removal rates decrease under three conditions because hydrogen peroxide is a superoxide scavenger. Excessive hydrogen peroxide removes the superoxide radicals produced by the photocatalytic reaction, which inhibits the progress of the photocatalytic reaction, so the removal rate decreases.

Variation of illumination time

The removal rate of diesel was studied with various illumination times in visible light irradiation with standard experimental conditions. As shown in Fig. 3e, the results prove that Er2O3/ZnO possessed a better photoactivity compared to the other two photocatalysts after 2.0 h irradiation of visible light. After 1.5 h, Er2O3/ZnO has a faster growth rate for diesel removal than the other two photocatalyst. From 1.5 to 2.0 h, three kinds of photocatalysts has the fastest growth rate for the degradation of diesel, and after that, the degradation rate tends to be gentle. This is due to the fact that the residual diesel concentration is very low after a certain period of time, and the photocatalytic power will be reduced under low concentration contaminants, which is not conducive to the continuation of the photocatalytic reaction.

Variation of pH values

Aqueous phase pH value of seawater greatly influences the degradation efficiency of the diesel pollutant under visible light irradiation. The pH value of the aqueous phase was varied between 5 and 10 by the addition of required amounts of equimolar HCl and NaOH solution before irradiation. If a particular photocatalyst is capable of exhibiting photocatalytic activity in a wide range of pH value, it may be a major benefit in the treatment of industrial wastewater as they are not always present at a particular pH value. The results are shown in Fig. 3f. The optimum results exist when the pH value is 8.0, which suggests that the photocatalyst is better for diesel removal in seawater (pH value is about 8.0).

Optimization of LnxOy/ZnO photocatalytic conditions

The experiment included Yb2O3/ZnO, Er2O3/ZnO and Pr6O11/ZnOat 0.2–1.0 g/L, catalyst coupling ratios from 10–50%, initial diesel concentration at 0.05–0.25 g/L, H2O2 at 2–10 mg/L, illumination time at 0.5–2.5 h, and pH from 6 to 10 to study the interaction of key factors with the photocatalyst. Six factors and five concentrations were designed into an orthogonal table to document 25 experiments (Table 1).

Optimization ofphotocatalytic conditions (Table 2) indicated the best conditions for Yb2O3/ZnO to be: initial diesel at 0.05 g/L, catalyst dose at 0.4 g/L, catalyst coupling ratio at 40%, pH 7, H2O2 at 4 mg/L, and illumination time at 1.5 h. The best conditions for Er2O3/ZnO to be: initial diesel at 0.10 g/L, catalyst dose at 0.6 g/L, catalyst coupling ratio at 30%, pH 10, H2O2 at 4 mg/L, and illumination time at 1.5 h. The best conditions for Pr6O11/ZnO to be: initial diesel at 0.20 g/L, catalyst dose at 0.4 g/L, catalyst coupling ratio at 10%, pH 6, H2O2 at 6 mg/L, and illumination time at 2.5 h. Verification tests under the above conditions were carried out, which produced diesel removal rates that reached 95.48, 98.60 and 90.81%. The order of these factors magnitude of effects on the removal rate was the following: illumination time > H2O2 concentration > pH > coupling ratio > catalyst dosage > initial diesel (Yb2O3/ZnO), coupling ratio > catalyst dosage > H2O2 concentration > initial diesel > illumination time > pH (Er2O3/ZnO), illumination time > initial diesel > catalyst dosage > H2O2 concentration > coupling ratio > pH (Pr6O11/ZnO).

Conclusions

In conclusion, three kinds of new visible photocatalyst were developed based on the use of NC ZnO doped by lanthanide oxide. In the present study lanthanide was doped on NC ZnO in various ratios examined for their photocatalytic activity by performing the photocatalytic degradation studies by taking diesel as a model pollutant. The lower band gap (3.4 eV), the f orbitals present in LnxOy and the red shift are responsible for the enhanced visible light photocatalytic activity compared to pristine ZnO. The characterization of the photocatalysts clearly confirmed the nano crystallinity. The enhanced photocatalytic activity of lanthanide oxide doped ZnO is due to the delayed recombination of electron hole pair, which leads to the enhanced production of hydroxyl radicals. According to the results, diesel removal was < 30% without any catalyst (losses only by evaporation) and greatest effects of Yb2O3/ZnO, Er2O3/ZnO and Pr6O11/ZnO occurred when the catalyst dose at 0.4, 0.6 and 0.4 g/L, catalyst-coupling ratio at 40, 30 and 10%, initial diesel concentration was 0.05, 0.10 and 0.20 g/L, H2O2 concentration at 4, 4 and 6 mg/L, illumination time at 1.5, 1.5 and 2.5 h and pH at 7, 10 and 6 respectively, in which case the diesel removal rate reached 95.48, 98.60 and 90.81%. It indicates that Yb2O3/ZnO phtotcatalyst applies to neutral low concentration of diesel pollutant, Er2O3/ZnO phtotcatalyst applies to alkaline low concentration of diesel pollutant and Pr6O11/ZnO photocatalyst applies to acidic high concentration of diesel pollutants. The experimental results clearly show that lanthanide oxide doped nanocrystalline semiconductor are highly active under visible light irradiation and may find wider applications in environmental remediation technologies.

References

Quan X, Zhao Q, Tan H, Sang X, Wang F, Dai Y (2009) Comparative study of lanthanide oxide doped titanium dioxide photocatalysts prepared by coprecipitation and sol-gel process. Mater Chem Phys 114:90–98

Changlin Y, Yang K, Shu Q, Yu JC, Cao F, Liu X, Zhao X (2012) Preparation, characterization and photocatalytic performance of Mo-doped ZnO photocatalysts. Sci China Chem 55(9):1802–1810

Wang X, Zhu F, Linfeng H (2012) Preparation and photocatalytic activity of N-doped ZnO. Journal of the Chinese Ceramic Society 40(9):1300–1304

Guo S, Liwen Y, Shixiang L et al (2012) Study on photocatalytic degradation of isocarbazide wastewater by europium aluminum co-doped nano-ZnO. J Inner Mong Polytech Univ (Nat Sci Edit) 31(1):24–28

Liu W, Wang M, Xu C et al (2012) Facile synthesis of g-C3N4/ZnO composite with enhanced visible light photooxidation and photoreduction properties. Chem Eng J 209:386–393

Gao F, Cheng Y, An L, Tan R, Li X, Wang G (2015) Polyaniline nanotube-ZnO composite materials: facile synthesis and application. J Wuhan Univ Technol-Mater Sci Ed 11:1147–1151

Liu Y, Song H, Zhang Q et al (2012) A Preliminary study of the preparation of a KBr-doped ZnO nanoparticle and its photocatalytic performance on the removal of oil from oily sewage. Ind Eng Chem Res 51(13):4779–4782

Ma H, Han J, Fu Y et al (2011) Synthesis of visible light responsive ZnO-ZnS/C photocatalyst by simple carbothermal reduction. Appl Catal B 102(3/4):417–423

Hua Q (2012) Photocatalytic degradation of NPE-10 by SnO2 modified nano-ZnO. J Lanzhou Univ (Nat Sci Ed) 48(5):139–144

Yang L, Wang F, Dan D, Liu P, Zhang W, Shuguang H (2016) Enhanced photocatalytic efficiency and long-term performance of TiO2 in cementitious materials by activated zeolite fly ash bead carrier. Constr Build Mater 126:886–893

Lei XF, Zhang ZN, Wu ZX, Piao YJ, Chen C, Li X, Xue XX, Yang H (2017) Synthesis and characterization of Fe, N and C tri-doped polymorphic TiO2 and the visible light photocatalytic reduction of Cr(VI). Sep Purif Technol 174:66–74

Tang X, Feng Q, Liu K, Tan Y (2016) Synthesis and characterization of a novel nanofibrous TiO2/SiO2 composite with enhanced photocatalytic activity. Mater Lett 183:175–178

Lai C, Wang M-M, Zeng G-M, Liu Y-G, Huang D-L, Zhang C, Wang R-Z, Piao X, Cheng M, Huang C, Hai-Peng W, Qin L (2016) Synthesis of surface molecular imprinted TiO2/grapheme photocatalyst and its highly efficient photocatalytic degradation of target pollutant under visible light irradiation. Appl Surf Sci 390:368–376

Ranjit KT, Willner I, Bossmann SH, Braun AM (2001) Lanthanide oxide doped titanium dioxide photocatalysts: effective photocatalysts for the enhanced degradation of salicylic acid and t-cinnamic acid. J Catal 204:305–313

Gionco C, Paganini MC, Giamello E, Sacco O, Vaiano V (2016) Rare earth oxides in zirconium dioxide: how to turn a wide band gap metal oxide into a visible light active photocatalyst. J Energy Chem 000:1–7

Suganya Josephine GA, Sivasamy A (2014) Nanocrystalline ZnO doped Dy2O3 a highly active visible photocatalyst: the role of characteristic f orbital’s of lanthanides for visible photoactivity. Appl Catal B 150–151:288–297

Suganya Josephine GA, Ramachandran S, Sivasamy A (2015) Nanocrystalline ZnO doped lanthanide oxide: an efficient photocatalyst for the degradation of malachite green dye under visible light irradiation. J Saudi Chem Soc 19:549–556

Acknowledgments

This work has been supported by a grant from marine research and special funds public service sectors of the State Oceanic Administration People’s Republic of China (201305002), Liaoning Province large equipment and equipment sharing service platform capacity building funds, Department of Science and Technology of Liaoning (2016LD0105),and Science Foundation of Department of Ocean and Fisheries of Liaoning Province (201733).

Author information

Authors and Affiliations

Corresponding author

Electronic supplementary material

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Ji, Q., Yu, X., Nie, Z. et al. Lanthanide oxide doped zinc oxide: effective photocatalysts for the degradation of diesel in seawater under visible light irradiation. Reac Kinet Mech Cat 124, 305–316 (2018). https://doi.org/10.1007/s11144-018-1352-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11144-018-1352-x