Abstract

During the gas phase oxidation of cyclohexane and its mixture with hydrogen peroxide in the presence of heterogeneous biomimetic catalysts per-FTPhPFe(III)OH/Al2O3 and PPFe(III)OH/Al2O3, it has been identified that a complex reaction consisting of parallel-consecutive reactions of cyclohexane monooxidation and cyclohexanol dehydration occurs on biomimetic catalyst. In addition, the selective action of these catalysts towards cyclohexane derivatives has been observed.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Studies related to the synthesis and development of biomimetic catalysts based on iron porphyrin complexes (which are the main active site of cytochrome P-450 enzyme) have been developed considerably in recent years [1,2,3,4,5]. There are studies [4, 5] on the oxidation of cyclohexane by peroxides in the presence of 5, 10, 15, 20 meso-tetraphenylporphyrinatechlorine, Fe3+ encapsulated in zeolite Y and chlorotetraphenylporphyrin Fe3+ biomimetic catalysts at the temperature of 140–150 °C and pressure of 2.5 MPa, where the high degree of cyclohexane conversion has not been achieved.

Studies of heterogeneous catalytic oxidation of substrates by hydrogen peroxide in the gas phase in the presence of biomimetic catalysts with iron-porphyrin active sites are a matter of concern [2, 3]. The coherent synchronized nature of the reactions proceeding in systems substrate—biomimetic catalyst—H2O2 has been demonstrated in these studies. It is demonstrated in [1] how coherent-synchronized reactions occur; how primary H2O2 decomposition reaction causes and accelerates secondary reaction of substrates oxidation; and at the same time, the secondary reaction slows down the flow of the primary reaction.

In the monooxidation of mixtures consisting of cyclohexane and its derivatives, biomimetic catalysts per-FTPhPFe(III)OH/Al2O3 and PPFe(III)OH/Al2O3 have shown high substrate (with respect to cyclohexane) selectivity [6].

Note that enzymes are highly selective towards the substrate, which is naturally found in a complex multi-component biochemical system. For enzyme systems, selectivity often means substrate specificity. However, in a biomimetic catalytic system, the substrate specificity and selectivity of the process are considered separately, since in the case of biomimetic and ordinary catalysis along with target reactions side reactions also often proceed [1]. Separation of mixtures consisting of cyclohexane and its derivatives requires certain costs, which can be avoided by using selectively functioning biomimetic catalysts.

Experimental part

Experimental study of the process of cyclohexane monooxidation has been carried out at the temperature of 130–230 °C and atmospheric pressure in a flowing quartz reactor with reaction zone of 3 cm3 (d = 1.8 cm). Its design has provided input of H2O2 into the reaction zone in non-decomposed form [9]. The raw feedstock consisted of two mixtures of cyclohexane and its derivatives: (1) 88.85% of C6H12, 6.25% of C6H11OH and 2.53% of CH3C6H11 and (2) 45.4% of C6H12, 1.91% of C6H11OH and 38.64% of CH3C6H11 as well as of various concentrations of H2O2 in aqueous solution.

Iron protoporphyrin (PPFe(III)OH/Al2O3) and iron perfluorotetraphenylporphyrin (per-FTPhPFe(III)OH/Al2O3) have been used as biomimetic catalysts. They have been synthesized by the adsorption of iron-porphyrin complexes onto the active carrier of Al2O3 from corresponding solvents. The neutral and basic form of Al2O3 with strong and weak acidic and basic active centers on the surface (identified by the method of programmed thermal desorption) has proven to be the most active sorbent [1].

During the synthesis of the PPFe(III)OH/Al2O3 catalyst, hemin was dissolved in a water-alcohol solution (pH 9) before adsorption, where it turned into hematin and was applied to the surface of Al2O3. The synthesis of another catalyst was carried out by adsorbing per-FTPhPFe(III)OH complex from dimethylformamide solvent to the surface of Al2O3. Concentrations of the active complexes PPFe(III)OH and per-FTPhPFe(III)OH were as 0.66 mg/g and 1.58 mg/g, respectively [1].

Based on the examination of resonance Raman spectra (Fig. 1) of PPFe3+OH/Al2O3 biomimetic catalyst, it was found out that ν4, ν3, ν2, ν37, ν10 frequencies correspond to 1372, 1492, 1574, 1593, 1631 cm−1, which are common for catalase iron protoporphyrin, and that Fe3+ high-spin heme ion is found in the fifth coordination position. A decrease in the ν4 frequency of the complex to 1361 cm−1 during the reduction of the complex indicates involvement of π-donor axial ligand of the iron ion, most likely Fe3+–O–Al. Thus, a considerable analogy with the fifth coordination high-spin heme ion Fe3+ associated with tyrosine in catalase has been revealed and the sixth coordination position of Fe3+ occupied by hydroxide has been established [1].

Based on these studies, as well as on the data on the structure of catalytic sites of cytochrome P-450 and its mimics [1], design of catalytic domain of per-FTPhPFe(III)OH/Al2O3 biomimic is presented in Fig. 2. As can be seen from Fig. 2, inorganic support (Al2O3) of acid–base nature has terminal and bridge Brønsted acidic sites and corresponding basic sites necessary for the catalytic domain. The per-FTPhPFe(III)OH complex, which has a structure stabilized by matrix basement coordination (Al–O) with hematin functional groups, for example, due to axial ligands, is the redox site of the catalytic domain.

Qualitative and quantitative analysis of the reaction products have been carried out on chromatomass spectrometer 5975 MSD + 7820 GC System and gas–liquid chromatograph Agilent Technology 7820A GC System.

Chromatograms of the feedstock (a) and the reaction products (b) of cyclohexane conversion in monooxidation reactions are demonstrated in Fig. 3.

Chromatograms of the feedstock (a) and the reaction products (b) (\( c_{{{\text{H}}_{2} {\text{O}}_{2} }} \) = 25%, \( c_{{{\text{H}}_{2} {\text{O}}_{2} }} \) = 1.41 ml/h, \( V_{{{\text{C}}_{6} {\text{H}}_{12} }} \) = 0.9 ml/h, C6H12:H2O2 = 1:1.5) obtained on a chromatomass spectrometer 5975 MSD + 7820 GC system

When comparing the chromatograms (Fig. 3a, b), it can be seen that the reaction proceeds in the direction of cyclohexane monooxidation with the formation of cyclohexanol and cyclohexanone, as well as cyclohexene.

The mass spectra (Fig. 3b), confirming the presence of cyclohexanol, cyclohexanone and cyclohexene in the composition of the reaction products are shown in Fig. 4.

Mass spectra of the reaction products from the chromatogram of Fig. 3b: a cyclohexanol, b cyclohexanone, c cyclohexene

Results and discussion

Experimental studies of activity of per-FTPhPFe(III)OH/Al2O3 catalyst based on temperature, concentration of hydrogen peroxide and contact time made it possible to obtain data indicative of its high activity in cyclohexane monooxidation.

Kinetic regularities of cyclohexane conversion over per-FTPhPFe(III)OH/Al2O3 biomimetic catalyst as a function of temperature are presented in Fig. 3. As shown in the figure, oxidation of cyclohexane to cyclohexanol and cyclohexanone at the temperature range of 150–180 °C proceeds at the highest rate. With an increase in temperature, the yield of cyclohexene increases sharply while the yield of cyclohexadiene increases slightly, this is explained by increase of the reaction rate of cyclohexanol dehydration.

While the yield of cyclohexanol decreases with temperature, the yield of cyclohexanone at 180 °C reaches its maximum (10.34% at 180 °C).

It can be concluded from the nature of the experimental points 2 and 3 that the formation of cyclohexanone probably does not pass through the formation of an intermediate product of cyclohexanol. The temperature dependence of the experimental points shows that, starting from 200 °C H2O2 decomposition into molecular oxygen stabilizes. This indicates that the hydrogen peroxide in the system is completely consumed for carrying out of two interrelated reactions. This undoubtedly affects the processes of cyclohexane monooxidation to cyclohexanol and cyclohexanone and dehydration of cyclohexanol to cyclohexene. This experimental fact indicates that the monooxidation and oxidative dehydrogenation are interrelated with the reaction of H2O2 decomposition and proceed in a coherent with it manner. It is shown in [7] that such reaction system is effectively realized in a coherently synchronized regime. In this context, the kinetic data obtained in Fig. 5 are consistent with the theory and practice of coherently synchronized reactions [1].

Temperature dependence of the yield of oxidation products by hydrogen peroxide in a mixture with 6.25% of C6H11OH and 2.53% of CH3C6H11 on per-FTPhPFe(III)/Al2O3 biomimetic: \( c_{{{\text{H}}_{2} {\text{O}}_{2} }} \) = 25%, \( c_{{{\text{H}}_{2} {\text{O}}_{2} }} \) = 1.41 ml/h, \( V_{{{\text{C}}_{6} {\text{H}}_{12} }} \) = 0.9 ml/h, C6H12:H2O2 = 1:1.5, 1—conversion of C6H12; 2—cyclohexanol; 3—cyclohexanone; 4—cyclohexene; 5—cyclohexadiene; 6—O2

Since cyclohexanone (from Fig. 5) has been the dominant (target) product in our study, and its maximum yield (10%) has been observed at 180 °C, the effect of contact time on the cyclohexane oxidation has been investigated at this temperature.

Experimental points in Fig. 6 show that the increase in the contact time (τ) in cyclohexane monooxidation reaction up to 10 s increases the yield of cyclohexanone and cyclohexanol, and then the yield varies insignificantly. The rate of the conversion of cyclohexanol to cyclohexene increases, while the yield of cyclohexanone increases insignificantly. In this case, conversion of cyclohexane increases with increasing contact time. Kinetic regularities in Fig. 6 lead us to the conclusion that cyclohexanone is probably formed not from cyclohexanol. It should be noted that in the absence of cyclohexane, H2O2 at these contact times has been completely decomposed.

Dependence of the yields of cyclohexane oxidation in a mixture of 6.25% of C6H11OH and 2.53% of CH3C6H11 on per-FTPhPFe(III)/Al2O3 biomimetic by hydrogen peroxide on contact time: \( c_{{{\text{H}}_{2} {\text{O}}_{2} }} \) = 25%, t = 180 °C, C6H12:H2O2 = 1:1, 1—conversion of C6H12; 2—cyclohexanol; 3—cyclohexanone; 4—cyclohexene; 5—O2

The effect of the concentration of hydrogen peroxide in aqueous solution on monooxidation and oxidative dehydrogenation of cyclohexane is presented in Fig. 7. There is a rather interesting fact observed here: an increase in H2O2 concentration has an insignificant effect on cyclohexane conversion, while O2 formation (catalase reaction), although very high in character, also varies insignificantly throughout the concentration range of H2O2. Nevertheless, the change in H2O2 concentration leads to significant decrease in the rate of cyclohexane oxidative dehydrogenation and significant increase in the yield of cyclohexanone. The experimental points indicating formation of monooxidation products which are cyclohexanone and cyclohexanol, show that the yield of cyclohexanone increases from 10 to 14%, while the yield of cyclohexanol passes through a maximum of 7.6%. The complex character of these experimental points in Figs. 5 and 6 does not give an unambiguous answer to the key question: whether cyclohexanone is formed from cyclohexanol or not. In this regard, the reaction of cyclohexanol oxidation (97.52% of C6H11OH in raw material) by hydrogen peroxide has been studied under identical conditions.

Dependence of the yields of cyclohexane oxidation on per-FTPhPFe(III)/Al2O3 bioimitator on the concentration of H2O2 in aqueous solution: t = 200 °C, \( V_{{{\text{H}}_{2} {\text{O}}_{2} }} \) = 1.41 ml/h, \( V_{{{\text{C}}_{6} {\text{H}}_{12} }} \) = 0.9 ml/h, 1—conversion; 2—cyclohexanol; 3—cyclohexanone; 4—cyclohexene; 5—cyclohexadiene; 6—O2

The experimental points in Fig. 8 show that peroxidase reaction of cyclohexanol, that is, the formation of cyclohexanone, is hardly observed. The dehydration of cyclohexanol to cyclohexene mainly proceeds here.

The yield of cyclohexanol conversion on per-FTPhPFe(III)/Al2O3 biomimetic by hydrogen peroxide depending on the temperature: \( c_{{{\text{H}}_{2} {\text{O}}_{2} }} \) = 20%, \( V_{{{\text{H}}_{2} {\text{O}}_{2} }} \) = 1.41 ml/h, \( V_{{{\text{C}}_{6} {\text{H}}_{11} {\text{OH}}}} \) = 0.9 ml/h, 1—conversion of C6H11OH; 2—cyclohexene; 3—1, 2 cyclohexanediol; 4—1,3 cyclohexadiene; 5—other oxygen-containing compound; 6—O2

It should be noted that an increase in temperature from 150 to 230 °C sharply increases the conversion of cyclohexanol towards the formation of cyclohexene. At the same time, the rate of molecular oxygen formation increases, which undoubtedly indicates that these processes proceed coherently through a common highly active intermediate compound (intermediate) [1].

Thus, the kinetic data from Figs. 5 and 8 shed light on the mechanism of cyclohexanol and cyclohexene formation. Indeed, it can be seen from the kinetic data of Fig. 5 that at temperatures up to 150–180 °C, the reaction of cyclohexane monooxidation proceeds, and when the temperature goes above 180 °C the reaction of cyclohexanol dehydration to cyclohexene (curve 4, Fig. 5) is accelerated, and respectively the yield of cyclohexanol and cyclohexanone decreases. A sharp increase in the yield of cyclohexene in parallel with a decrease in the yield of formed cyclohexanol indicates that at 230 °C and at lower H2O2 concentrations in the reaction system, cyclohexanol is converted to cyclohexene. This conclusion is unambiguously confirmed by the experimental data of C6H11OH oxidation on the biomimetic catalyst at 200–230 °C: cyclohexanol is completely dehydrated (Fig. 8) and high yields of cyclohexene are obtained (16–30%).

Thus, from the experimental data from Figs. 5, 6, 7, and 8 it can be concluded that the process of cyclohexene formation proceeds along a sequential-parallel mechanism, which can be represented as the following scheme:

Comparing the experimental data on the formation of cyclohexene in Figs. 5, 6, 7, and 8, it can be concluded that at a temperature above 180 °C and at the lowest concentration of H2O2, the major part of cyclohexene is formed by the sequential reaction 2 and 3 (from Scheme 1).

The next stage of our research has been the study of biomimetic catalytic system with regard to the selective nature of its influence when mixtures of cyclohexane with some of its derivatives are used.

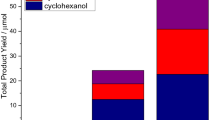

The results of studies using raw materials with 88.85% of C6H12, 6.25% of C6H11OH and 2.53% of CH3C6H11 have demonstrated that during the oxidation process, cyclohexane is mainly being converted, and the amount of methylcyclohexane in the raw material remains practically unchanged.

In order to define the selective effect of the iron-phosphorene-containing biomimetic catalysts an artificially prepared mixture containing 45.4% of C6H12, 38.64% of CH3C6H11, and 1.91% of C6H11OH has been used as the raw material in the oxidation of complex mixtures. Results of the study of oxidation of this mixture by 20% hydrogen peroxide at different feed rates and different temperatures on PPFe(III)/Al2O3 biomimetic are shown in Table 1. According to the data in Table 1, there is an unequivocal conclusion about selective effect of the catalytic biomimetic on the oxidation of cyclohexane in the mixture with significant amount of methylcyclohexane (38.6%).

Thus, the investigated catalytic biomimetic has been not just highly selective, but also selective towards the oxidizable substrate. As a rule, this is typical of only monooxygenase enzymes.

High selectivity and catalytic activity of the biomimetic catalyst can be explained by the fact that the cyclohexane-biomimetic complex formed during the reaction (unlike methyl cyclohexane) may simulate the cyclohexane-enzyme complex of monooxygenase.

Coherently synchronized reactions of cyclohexane monooxidation by hydrogen peroxide are described by the following generalized scheme [1]:

It follows from this scheme that the primary H2O2 decomposition reaction forms highly active hydroperoxide active site, which by interacting with cyclohexane leads to the formation of desired products (secondary reactions), according to the mechanism based on CBR principle (3) [1]:

Here ImtOH/Al2O3 is a catalytic biomimic (simulator); ImtOOH/Al2O3 is an intermediate;

and ··· are, respectively, the gap and the formation of links.

and ··· are, respectively, the gap and the formation of links.

Scheme 3 shows the principle of constructing of ImtOOH/Al2O3 complex on per-FTPhPFe3+OH/Al2O3 biomimic, which is analogous to the formation of the Chance complex (PPFe3+OOH) under the effect of the catalase enzyme [1, 8, 9]. In our case, Al2O3 is used as the matrix of acid–base nature.

The presented scheme of the mechanism of catalase reaction demonstrates that under the influence of the axial group of Fe3+OH ligand and with the “assistance” of the acid–base support centers, the H2O2 molecule is transformed into the active intermediate (ImtOOH) by abstraction of two protons from the acid center and the hydroxyl group of the ligand simultaneously with the opening and formation of chemical bonds according to the principle of chain of bond rearrangement (CBR). As known the interaction of the formed intermediate with the second H2O2 molecule leads to the formation of final products of catalase reaction [1].

The probable mechanism of monooxidation of cyclohexane to cyclohexanol on a biomimetic catalyst, according to [1], can be represented in the following form:

Here A and B are respectively the acid and base centers.

The unity of the acid–base and oxidation–reduction mechanism according to the CBR principle (Scheme 4) is also traced in the schemes of the mechanism of cyclohexane conversion to cyclohexanol. Two or more protons are transferred under the effect of acid–base centers of the carrier from the substrate and the acid center of the carrier through various stages of cyclohexane oxidation with the formation of cyclohexanol.

Since (4) the peroxidase reaction does not proceed according to our experimental data, probable mechanism for the formation of cyclohexanone from cyclohexane can be represented in the following form:

According to the results of studies and schemes presented (5 and 6), the direct conversion of cyclohexane to cyclohexanone occurs through formation of Imt–O–C6H11 intermediate biomimetic-substrate complex, which is formed as a result of the interaction of intermediate (ImtOOH) with cyclohexane (5). The interaction of this complex with another H2O2 molecule leads to oxidation–reduction transformation of the complex into cyclohexanone, water and original biomimic (6). This mechanism fits in well with the fact that cyclohexanone is formed precisely by using the most concentrated H2O2 (30% or more) and at a lower temperature (150–180 °C).

The above monooxygenase reactions are coherently related to the primary H2O2 decomposition reaction and this factor is measured using determinant equation [1]:

As can be seen from Scheme 2, hydrogen peroxide is consumed as an intermediate in two coherently synchronized reactions: in the primary (1) catalase in the amount of f1 and in the secondary (2) monooxygenase in the amount of f2, cyclohexane (acceptor) consumption of is referred to as facc. Here ν is stoichiometric coefficient of the actor

The coherent-synchronized reactions of H2O2 decomposition and cyclohexane monooxidation in terms of conjugate reactions can be represented as following:

Here the actor is H2O2, which is consumed in both gross reactions (7) and (8), and the second H2O2 molecule is an inducer, and cyclohexane is an acceptor, the interaction of which with hydrogen peroxide leads to the formation of products of the secondary reaction 8.

A more visual scheme of these reactions in the presence of a biomimetic catalyst can be represented as following:

Calculated values of the determinant, as well as data on the coherence ratio are given in Table 2 according to equation

This unambiguously indicates that considered reactions are coherently synchronized.

Thus, the coherent synchronization of these reactions (values of D < 1) [1] allows us to consciously control the rates and direction of these complex target reactions. So, if we, for example, mainly need to obtain products of cyclohexanol and cyclohexanone monooxidation, knowing that they correspond to low determinant values, then by keeping it low and, accordingly, manipulating reaction conditions, the process will be effectively directed toward monooxidation. Thus, using the D factor, we determine the best conditions for the production of cyclohexanol and cyclohexanone. According to the data in Table 2, the conditions are as following: at D = 0.28: T = 150 °C, τ = 5.92 s, molar C6H12:H2O2 = 1:1, the yield of monooxidation products is 18.46%. The D factor makes it possible to determine the potential for obtaining the best yield of a given product by the target—secondary reaction. The solution of the determinant equation in the framework of the kinetic equations of the rates of two coherently synchronized reactions with determination of constants and activation energies will make it possible to develop a kinetic model of cyclohexane conversion process based on the general scheme:

Conclusions

In conclusion, it should be noted that the determinant equation for a chemical system with coherently synchronized [primary and two secondary (target)] reactions adequately describes the experimental results.

The selective effect of iron-porphyrin-containing biomimetic catalyst on cyclohexane during the oxidation of cyclohexane in the mixture with its derivatives has also been determined by experimental study.

References

Nagiev TM (2007) Coherent synchronized oxidation reactions by hydrogen peroxide. Elsevier, Amsterdam

Nagiev TM, Gasanova LM, Zulfugarova SZ, Mustafaeva ChA, Abbasov AA (2003) Chem Eng Commun 190(5–8):726–748

Karasevich EI, Karasevich YuK (2000) Kinet Catal 41(4):535–542 (in Russian)

Olsen MHN, Salomao GC, Drago V et al (2005) J Supercrit Fluids 34(2):119–124

Yuan Y, Ji H, Chen Y et al (2004) Org Proc Res Dev 8(3):418–420

Aghamammadova S, Nagieva I, Gasanova L, Nagiev T (2017) Int J Eng Res Appl 7(2):36–40, www.ijera.com, ISSN: 2248-9622

Aghamammadova S, Nagieva I, Gasanova L, Nagiev T (2017) EUROPACAT 2017. In: 13th European congress on catalysis: a bridge to the future. Book of Abstracts. Florence, Italy. August 27–31, 2017

Poltorak OM, Chukhray ES, Vestnik MSU (1971) Chemistry 2 12(6):656

Poltorak OM, Vestnik MSU (1991) Chemistry 2 12(6):639

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Aghamammadova, S., Nagieva, I., Gasanova, L. et al. Catalytic monooxidation of cyclohexane by hydrogen peroxide in the gas phase. Reac Kinet Mech Cat 126, 701–715 (2019). https://doi.org/10.1007/s11144-018-01525-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11144-018-01525-1