Abstract

Zirconia-supported vanadium catalysts were prepared by the wet impregnation of two different zirconia supports using ammonium metavanadate in aqueous hydrogen peroxide solution. The catalysts were characterized by N2 physisorption, X-ray fluorescence analysis (XRF), X-ray diffraction (XRD) and Raman spectroscopy to determine their textural properties, chemical composition and the nature of vanadium species. The partial oxidation of ethanol to acetaldehyde was carried out in a fixed bed reactor at atmospheric pressure varying the weight-hourly space velocity and temperature in the range 1–4 h−1 and 150–250 °C, respectively. In addition to acetaldehyde, a range of oxygenated and deoxygenated by-products was observed. Diethyl ether and ethyl acetate were detected in the reaction mixture with low and almost constant amount. These products are formed through a homogeneous reaction in the free volume of reactor or pre-heating zone irrespective of catalyst used. Vanadium species anchored on the zirconia surface are able to activate ethanol molecules already at 150 °C with the high selectivity to acetaldehyde. A comparison of vanadium speciation and catalytic results led to conclusion that oligomeric vanadium species and small oxide clusters have no deterioration effect on acetaldehyde selectivity.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Research and development of green routes to base chemicals attracts attention of academia as well as industry as it contributes to improving the sustainability of the chemical technologies. Acetaldehyde, produced by the classical Wacker process from ethylene, is an important intermediate for the production of various bulk chemicals such as acetic acid, acetate esters, pentaerythritol, pyridine bases and others [1]. Nonetheless, this well-established process suffers from the use of hazardous chemicals (such as chromate or permanganate), the need for the purification of waste air and the treatment of highly toxic wastewater and corrosion issues [2]. Consequently, acetaldehyde production via the oxidative dehydrogenation (ODH) of bio-ethanol, whose production has significantly increased [3, 4] over the past years resulting in a drop in its price and increased availability, eliminating most of the disadvantages of the Wacker process could be a promising alternative to it [5].

Apart from noble-metal based catalysts, supported vanadium catalysts have been investigated in selective oxidation of ethanol to acetaldehyde [5–13]. The dispersion and nature of the vanadium oxide species and the interaction with the support have been found essential for obtaining highly active catalysts for selective oxidation of ethanol [14]. In particular, ZrO2-supported vanadium catalysts have shown promising results for the partial oxidation or oxidative dehydrogenation reactions [14–20]. The previous studies of selective ethanol oxidation to acetaldehyde using ZrO2 were focused mainly on comparison of activity of catalyst with different supports and only minor attention was paid to the study of the influence of vanadium complex type and selectivity/reaction pathway of the reaction [10, 16–20]. For instance, Lin et al. [16] used highly dispersed vanadia supported on ZrO2/SiO2 and TiO2/SiO2 observing a better catalytic behavior for the selective oxidation of ethanol to acetaldehyde, when using the support containing ZrO2. Lakshmi et al. [20] studied a series of vanadium catalysts supported on ZrO2 and phosphorus modified ZrO2 materials for the partial oxidation of ethanol indicating that the activity of sites was related to number/strength of V–O–Zr bonds. Reddy et al. [18] used also ZrO2 in a vanadium oxide supported on TiO2–ZrO2, which resulted to be an active catalyst for the isobutyraldehyde production from ethanol and methanol.

Thus, the use of ZrO2 as support for the partial oxidation of ethanol is a promising option. However, the catalytic activity of each type of vanadium oxide present on the zirconia surface (monomers, oligomers, and bulk-like species) is still not clear. Therefore, the primary aim of this study is to elucidate the effect of zirconia support nature and preparation on the distribution of different types of vanadium species. To achieve this, the V/ZrO2 catalysts were prepared starting either from commercially available ZrO2 support or from Zr(OH)4 that were first impregnated and then calcined to yield V/ZrO2. Secondly, the goal of the research is to shed light on the reaction pathway of the selective oxidation of ethanol over V/ZrO2 catalysts.

Experimental

Materials

To study the role of vanadium loading in the oxidative dehydrogenation (ODH) of ethanol, two V/ZrO2 materials called V/Zr-com (5% wt of vanadium supported on zirconium oxide using commercial as ZrO2 a precursor material from the company Eurosupport Czechia) and V/Zr-lab (5% wt of vanadium supported on zirconium oxide using Zr(OH)4 from Sigma Aldrich as a precursor) were prepared by the wet impregnation of commercial zirconium oxide or zirconium hydroxide by a H2O2:H2O 1:4 molar ratio solution including an appropriate amount of ammonium metavanadate (Sigma-Aldrich). Impregnated samples were dried in a flow of air at 120 °C (temperature ramp: 5 °C/min) overnight. Calcination was done in flow of air at 450 °C for 6 h (temperature ramp 1 °C/min). Commercial zirconium oxide from Eurosupport Czechia was used as a catalyst without any modification. The final catalysts were prepared to obtain tablets with a size of 850–1120 µm.

Catalyst characterization

The composition of the catalysts was ascertained by X-ray fluorescence analysis (XRF) of the catalyst powder using a S8 Tiger (Bruker AXS) with Rh cathode. The results were evaluated using the Spectra plus software. The crystallographic structures of the catalysts were determined by examining the X-ray diffraction (XRD) patterns of the powder samples obtained by using a D8 Advance ECO (Bruker) applying Cu Kα radiation (λ = 1.5406 Å). The step size of 0.02° and a step time of 0.5 s were used. The patterns were collected over the 2θ range from 5° to 70° and evaluated by using the Diffrac.Eva software.

The specific surface area (BET) of the catalysts was determined by N2 adsorption/desorption using an Autosorb iQ (Quantachrome) instrument. All samples were degassed before the analysis in a glass cell at 200 °C under vacuum for 16 h.

SEM images were obtained by using a scanning electron microscope (SEM) JSM-7500F (JEOL) with a cold cathode-field emission SEM (parameters of measurements: 1 kV, GB high mode).

All Raman spectra of dehydrated samples were measured in glass cuvette by Nicolet DXR Smart Raman spectrometer equipped with CCD detection. Spectra were excited by a Smart Excitation Laser (Thermo Scientific) with laser wavelength at 780 nm. The spectra were recorded by collecting of 2000 scans (scan time was 2 s with resolution 2 cm−1 in all cases). The laser power delivered to the sample varied depending on the sample concentration (max 50 mW). The spectrograph aperture was 50 µm slit (equivalent to laser spot size approximately 3.1 µm at the sample). All samples were granulated and sieved to the fraction of size of 0.25–0.5 mm, dehydrated before the spectral measurement and oxidized in the glass apparatus under static oxygen atmosphere (16–18 kPa) in two steps: 120 °C for 30 min and 450 °C for 60 min. Then, the sample was cooled down to 250 °C, evacuated for 30 min and sealed.

The reducibility of the vanadium species in the vanadium-containing catalysts was determined by H2-TPR using an AutoChem 2920 (Micromeritics) instrument. 100 mg of sample (50 mg for V/ZrO2) in a quartz U-tube were oxidized in oxygen flow at 450 °C (2 h) prior to the measurement. Reduction was carried out at T = 25–900 °C with a temperature ramp of 10 °C/min under reducing gas flow (5 vol% H2 in Ar). The changes of hydrogen concentration were monitored by a TCD detector.

TGA analyses were carried out using a TA Instruments Waters LLC instrument from 25 to 900 °C (10 °C/min) using nitrogen as gaseous carrier with the flow rate 20 ml/min.

Catalytic tests

ZrO2, V/Zr-com and V/Zr-lab catalysts were tested with the aim to determine their activity and selectivity in the oxidative dehydrogenation of ethanol. Moreover, a “blank” test without catalyst was carried out using the same conditions. Reaction tests conditions were selected taking previous experiments into account to optimize the yields of the partial oxidation of ethanol and according to the reactor design and possibilities. They were described previously [7]. A continuous flow reactor (stainless steel 316) with a length of 1000 mm was used. The reaction was carried out using 5 g of catalyst. The catalyst was prepared in a form of crushed pellets with a diameter of 850–1120 µm. The catalyst bed had a length of 301 mm and was located in the central part of the reactor. The catalyst and silicon carbide (1000–1500 µm) were mixed thoroughly (60 ml of SiC + catalyst together) and loaded into the reactor (two small amounts of quartz wool were put inside the reactor before and after introducing the mixture of SiC + catalyst). First, the catalyst was activated in air flow (50 NL/min) for 1 h at 400 °C; to reach the activation temperature, the temperature was increased by 5 °C/min from 25 °C). In catalytic tests, air was mixed with feedstock (ethanol 99.8% wt) before entering the reactor. Catalysts were tested at 150, 200 and 250 °C using a weight space velocity (WHSV) of 1, 2, 3 and 4 h−1 maintaining a constant ethanol/oxygen molar ratio equal to 2.4. The pressure was 1 bar. The products were collected at time on stream (TOS) = 4 (150 °C), 6 (200 °C) and 8 (250 °C) h. The scheme of the experimental setup is reported in Supplementary Information (SI) (see Fig. S1). The products were analyzed using a GC-FID “Agilent 7890A” and GC-OFID “Agilent-Wasson-ECE Instrumentation”. The gaseous products were analyzed off-line by the method “Refinery Gas Analysis” RGA (Agilent Technologies) with a GC 7890A Agilent (USA). The products were identified by using standard reference compounds along with GC–MS analyses using a Thermo Scientific ITQ 1100 unit. Details of analysis can be found in the SI.

Results

Characterization

XRF, XRD, SEM and nitrogen physisorption

The elemental composition of the supported vanadium catalysts obtained by XRF. The vanadium content in V/Zr-com and V/Zr-lab was 3.44 and 3.63 wt%, respectively. The main difference between the catalysts is presence of some silica (ca. 3.4 wt%) and alumina (0.2 wt%) in the catalyst prepared from commercial ZrO2 support. The V/Zr-lab contained only 0.1 and 0.0 wt% of SiO2 and Al2O3, respectively. It is also noteworthy that both catalysts contained ca. 2.5 wt% of HfO2. The presence of other impurities was insignificant. Complete chemical analysis is summarized in Table S1 in Supplementary information section.

The XRD patterns of both catalysts exhibit set of diffraction lines at 28–32, 34–36, 49–52 and 58–62° (see Fig. S2), which belong to zirconium oxide (tetragonal and monoclinic phases). V/Zr-com presented 43% of monoclinic and 57% of tetragonal phase, whereas V/Zr-lab 45% monoclinic and 55% tetragonal phase, based on the results of Rietveld refinement made by MAUD software. No diffraction lines of other crystalline compound were detected in the XRD patterns.

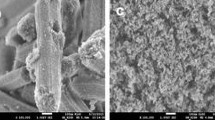

The SEM images for V/Zr-com catalyst show large particles of several micrometers in size (3–14 μm). On the contrary, V/Zr-lab catalyst consists of micrometer size agglomerates of irregular particles with a size of 20–30 nm. No separate vanadium pentoxide particles (typically needle- or platy-shaped particles) are visible, evidencing good dispersion of vanadium on the zirconia surface.

The BET surface area of catalysts was 115 and 124 m2/g for V/Zr-com and V/Zr-lab, respectively. The isotherms exhibit hysteresis loops proving mesoporosity of the material (Fig. 1a). The shapes of the hysteresis loops and their positions on the x axis differ significantly indicating a difference in the pore shape and size distribution (Fig. 1b). The isotherm of V/Zr-com catalyst exhibit a hysteresis loop of H2 type ascribed usually to a system of interconnected cylindrical pores or to so called ink-bottle pores (cylindrical pores with some narrowing at the pore mouth. The isotherm of V/Zr-lab catalyst exhibits two hysteresis loops, one at higher relative pressures of H3 type and the second of H2 type at relative pressures ca. 0.45). The H2 hysteresis loop is related to the existence intraparticle mesopores, whereas the H3 loop is caused by condensation of adsorptive in the interparticle void space. The differences in adsorption isotherms are in good agreement with the significantly smaller particle size of V/Zr-lab catalyst evidenced by SEM images (see Fig. S3) and the existence of agglomerates with plausible interparticle void space. The pore size distributions calculated by application BJH methodology to adsorption branches of the isotherms exhibit main distribution peak in the mesoporosity with maximum at 4.4 nm for V/Zr-com and 2.3 nm for V/Zr-lab catalysts. The total pore volume of both catalysts is very similar (approximately 0.15 cm3/g).

Raman spectroscopy

The Raman spectra of dehydrated V/Zr catalysts are shown in the Fig. 2. Both catalysts exhibit the presence of Raman band at 1033 cm−1 evidencing the presence of well-dispersed VO x species with tetrahedral coordination. However, another Raman band at 995 cm−1 was found for catalyst V/Zr-com indicating some small amount of octahedrally coordinated oxidic species. Thus, the samples contained mainly tetrahedrally coordinated surface species of vanadium. The Raman signal at 995 cm−1 indicates the presence of V2O5 microcrystallites in the V/Zr-com catalyst. It is well known that Raman spectroscopy is highly sensitive to V2O5 species due to the Raman resonance enhancing effect. Thus, the content of oxidic species is expected to be relatively low, under the detection limit of XRD (no diffraction lines of V2O5 crystallites were detected). The better dispersion of vanadium on the Zr(OH)4 support can be explained by the presence of a larger amount of surface Zr–OH species, which facilitate the dispersion of vanadium due to easy bond formation during the calcination Zr–OH + (NH4)+···−O–VO2 mixture forming the Zr–O–V bonds species. In addition, no Raman bands belonging to ZrV2O7 compound (988, 955, 777, 511, 369, 262 and 190 cm−1) were detected in the spectra.

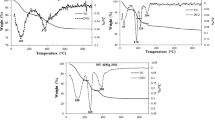

Temperature programmed reduction (TPR)

The H2-TPR patterns (Fig. S4 in SI) of V/Zr-com and V/Zr-lab catalysts showed a single reduction peak with maximum of the reduction peak at 580 and 609 °C, respectively. The presence of only one reduction peak indicates the presence of VO X units with similar degree of polymerization and/or coordination environment. The character and reduction temperatures for these catalysts are typical and attributable to the reduction of tetrahedrally coordinated VO x surface species. The reducibility of vanadium species on V/Zr-com catalyst is slightly higher compare to V/Zr-lab as evidenced by temperature shift from 580 to 609 °C. It is noteworthy that no reduction peak at temperature around 700 °C typical for bulk vanadium pentoxide species is visible on both TPR patterns. It indicates that V2O5 crystallites visible in Raman spectrum of V/Zr-com at 995 cm−1 are really infrequent.

Thermal gravimetric analysis (TGA)

TGA analysis showed that the main weight loss occurred between 50 and 500 °C (see Fig. S5). Commercial zirconium oxide ZrO2, used as support of the catalyst V/Zr-com, presented a weight loss during heating in the flow of nitrogen of only 5 rel. %. The zirconium hydroxide precursor used for the synthesis of V/Zr-lab catalyst presented a weight loss of 22 rel. %. These weight losses can be ascribed to the dehydroxylation on the surface and desorption of adsorbed species on the surface (especially water). A much more distinct change of weight in the case of Zr(OH)4 precursor is caused by a high amount of hydroxyl groups on the surface and its dehydroxylation leading to conversion of Zr(OH)4 to ZrO2. However, the final catalyst presented similar and relatively low weight loss (3 rel. %) indicating that the surface hydroxyl groups were largely consumed.

Catalytic tests

Low conversion of ethanol (<2%) (see Fig. 3) was observed in experiments when no catalyst (reactor filled just with SiC) or only the catalyst supports were used at temperatures up to 200 °C. This proves that at these low temperatures ethanol was converted thermally only at a marginal extent. When the temperature was increased to 250 °C, the conversion increased slightly. In the absence of catalyst or support, the conversion reached about 4% while over the support the conversion reached about 8%. This suggests that ZrO2 already possesses some catalytic activity at 250 °C. A similar behavior was observed and reported also by other researchers [10, 21–25] and the production of acetaldehyde over bare ZrO2 could be explained due to the presence of active sites of zirconium(IV), which could be reduced to zirconium(III) during the process according to a similar pathway as explained by Idriss et al. [24]. On the other hand, when V/Zr catalysts were used, a dramatic increase in conversion was obtained. The conversion increased over both catalysts 3–4 times (from 10 to 15% to about 45%) upon increasing the reaction temperature from 150 to 200 °C. This clearly evidences that vanadium species are the active sites. This is in line with previous studies using vanadium catalysts on various supports [7, 10]. Both, laboratory and commercial V/Zr catalysts exhibited similar activity in the reaction, as will be discussed in detail below.

The main products of the oxidative dehydrogenation of ethanol are acetaldehyde, diethyl ether, ethyl acetate and carbon dioxide. The distribution of individual product depends on the type of catalyst and temperature/conversion level. The selectivity to acetaldehyde (Fig. 4) in the blank test and in the test using only the support presented a similar tendency: the selectivity to acetaldehyde increased (surprisingly) with the increase in conversion of ethanol. This suggests that other reactions occur under thermal transformation of ethanol more easily than ethanol oxidation to acetaldehyde at low temperatures and formation of acetaldehyde is more probable at higher temperatures. On the contrary, acetaldehyde selectivity over V/Zr catalysts reached highest values (approx. 80%) at the lowest conversion degree and decrease with conversion increase as consequence of consecutive oxidation of acetaldehyde to carbon dioxide. The decline of acetaldehyde selectivity is more distinct for the V/Zr-lab catalyst.

Other detected liquid products of ethanol conversion were diethyl ether and ethyl acetate. The diethyl ether is formed by the reaction of two molecules of ethanol and a water molecule is released at the same time. The presence of ethyl acetate proves the oxidation of ethanol to acetic acid and a consecutive reaction of the acid with the alcohol. The dependence of selectivity toward these two products on the conversion degree/temperature can be found in supplementary information (Figs. S6 and S7). Both vanadium catalysts exhibited very low, and rather constant, selectivity towards these products (less than 5%). On the other hand, the selectivity to both products was high in the case of blank catalytic tests and over pure Zr-com support and strongly decreased with the increasing conversion of ethanol. Since the yields of both products in the blank test and test with catalysts were almost constant (1.0% for diethyl ether and 0.6% for ethyl acetate), we can speculate that these products are formed via homogeneous reaction in the free volume of reactor or pre-heating zone irrespective of catalyst used.

The conversion and selectivity over the zirconia-supported vanadium catalysts was studied over a wide range of experimental conditions (reaction temperature 150–250 °C and WHSV 1–4 h−1). Ethanol conversion versus space time is depicted in Fig. 5. At low temperature (150 °C), the conversion is linearly increasing with space time for both catalysts. It can be noted that the slope of this linear dependence is slightly higher for V/Zr-lab catalyst having slightly higher vanadium content. For the reaction temperatures of 200 and 250 °C, the situation is different. The dependences for both catalysts deviate from linear dependence and tend to level off at conversion close to 50%. It is caused by a significant decrease of oxygen concentration in the reaction system. In addition, the conversion degree at small space time values is significantly higher for V/Zr-com catalyst, which can be attributed to an enhanced activity of vanadium species on V/Zr-com catalyst.

At low conversion, the selectivity to acetaldehyde reached values around 80–90%, but it decreased with increasing conversion (Fig. 6) due to the growing importance of consecutive reactions, such as over-oxidation. Another interesting fact is that the increasing importance of consecutive oxidation of acetaldehyde occurs more significantly over V/Zr-lab catalyst than over the V/Zr-com catalysts and takes place mainly at lower temperatures. We can speculate that this effect can be ascribed to the prolonged retention time of adsorbed acetaldehyde on the acid–base sites of V/Zr-lab catalysts at lower temperatures. This decline of acetaldehyde selectivity is accompanied by a significant increase in the selectivity to carbon dioxide (Fig. 7) as a product of the consecutive over-oxidation of acetaldehyde which is a consequence of the prolonged retention of acetaldehyde on the catalyst surface. Considering the characterization data of both catalysts, it can be inferred that the vanadium located in smaller pores of V/Zr-lab retain acetaldehyde more strongly allowing the over-oxidation to take place. This effect is pronounced the most at 150 °C and is the cause of higher conversion of acetaldehyde to CO2. With increasing reaction temperature, the adsorption/desorption equilibrium shifts in favor of acetaldehyde, thus suppressing its over-oxidation at low ethanol conversions, i.e. low acetaldehyde yields.

A clear tendency to lower selectivities to diethyl ether and ethyl acetate (Figs. S8 and S9) was found when the conversion increased. As suggested above, the high selectivity to these products as low conversions (and at low temperature) is the consequence of reactions outside the catalytic zone that are highly unselective. The formation of acetaldehyde is significantly suppressed in the thermal conversion route as implied by the ethanol transformation results in presence of only ZrO2 (the support) or inert (SiC). As soon as the vanadium containing catalyst started showing significant catalytic activity, i.e. at temperatures above 150 °C, the conversion achieved in the catalytic zone exceeded the one obtained in the thermal zone and as a consequence, the selectivity to by-products characteristic for the thermal conversion dropped and remained low (selectivity about 2%).

Conclusions

Two catalysts (vanadium oxide supported on ZrO2 with similar vanadium concentration), called V/Zr-com and V/Zr-lab, were characterized and tested in the ODH of ethanol. Acetaldehyde was the main product at 200 and 250 °C. The samples contained mainly tetrahedrally coordinated surface species of vanadium as proved by Raman spectroscopy. The Raman signal at 995 cm−1 also indicates the presence of V2O5 microcrystallites in the V/Zr-com catalyst or very small amounts of octahedral species on its surface. No formation of ZrV2O7 compound during impregnation and pre-treatment was detected.

The experiments with supported vanadium catalysts, on the one hand, and zirconia support and inert, on the other hand, clearly demonstrate that vanadium plays a pivotal role in the catalyst activity and selectivity. Without vanadium, ethanol was converted either thermally or, at 250 °C, due to the presence of some active sites present on the zirconia support. Nonetheless, the conversion was <10%. Moreover, the transformation of ethanol in presence of ZrO2 or the inert (SiC) afforded significant amounts of side-products, such as diethyl ether. Only when vanadium was introduced, high conversions exceeding 40% were achieved. At the same time, acetaldehyde became the main product with selectivity in the range 80–90%. Comparison of vanadium speciation and catalytic results led to conclusion that oligomeric vanadium species and small oxide clusters have no deterioration effect on acetaldehyde selectivity. Vanadium species anchored on zirconia surface are able to activate ethanol molecules already at 150 °C.

References

Stirling A, Nair NN, Lledo A, Ujaque G (2014) Chem Soc Rev 43:4940–4952

Redina EA, Greish AA, Mishin IV, Kapustin GI, Tkachenko OP, Kirichenko OA, Kustov LM (2015) Catal Today 241:246–254

Renewable Fuels Association (2016) Fueling a high octane future: Ethanol Industry Outlook. http://ethanolrfa.org/wp-content/uploads/2016/02/RFA_2016_full_final.pdf

Baier S, Clements M, Griffiths C, Ihrig J (2009) Biofuels impact on crop and food prices: using an interactive spreadsheet, Board of Governors of the Federal Reserve System, International. Finance Discussion Papers Number 967. http://www.federalreserve.gov/pubs/ifdp/2009/967/ifdp967.htm

Oyama ST, Somorjai GA (1990) J Phys Chem-Us 94:5022–5028

Lakshmi J (2001) J Mol Catal A-Chem 165:199–209

Hidalgo JM, Tišler Z, Kubička D, Raabova K, Bulanek R (2016) J Mol Catal A 420:178–189

Santacesaria E, Sorrentino A, Tesser R, Serio MD, Ruggiero A (2003) J Mol Catal A 204:617–627

Kilos B, Bell AT, Iglesia E (2009) J Phys Chem C 113:2830–2836

Nair H, Baertsch CD (2008) J Catal 258:1–4

Nair H, Gatt JE, Miller JT, Baertsch CD (2011) J Catal 279:144–154

Gucbilmez Y, Dogu T, Balci S (2006) Ind Eng Chem Res 45:3496–3502

Quaranta NE, Martino R, Gambaro L, Thomas H (1994) Stud Surf Sci Catal 82:811–818

Du G, Lim S, Pinault M, Wang C, Fang F, Pfefferle L, Haller GL (2008) J Catal 253:74–90

Beck B, Harth M, Hamilton NG, Carrero C, Uhlrich JJ, Trunschke A, Shaikhutdinov S, Schubert H, Freund H, Schlogl R, Sauer J, Schomacker R (2012) J Catal 296:120–131

Lin Y, Chang C, Chen C, Jehng J, Shyu S (2008) Cat Commun 9:675–679

Lakshmi LJ, Ihasz NJ, Miller JM (2001) J Mol Catal A-Chem 165:199–209

Reddy BM, Ganesh I, Chowdhury B (1999) Catal Today 49:115–121

Huuhtanen J, Sanati M, Andersson A, Andersson SLT (1993) App Catal A-Gen 97:197–221

Lakshmi LJ, Ju Z, Alyea EC (1999) Langmuir 15:3521

He X, Liu H (2014) Catal Today 233:133–139

Dejoz A, López-Nieto JM, Melo F, Vázquez I (1997) Ind Eng Chem Res 36:2588

Carrero CA, Keturakis CJ, Orrego A, Schomäcker R, Wachs IE (2013) Dalton Trans 42:12644–12653

Idriss H, Seebauer EG (2000) J Mol Catal A 152:201–212

Tarek T, Al-Thabaiti SA, Alyoubi AO, Mokhtar M (2010) J Alloy Compd 496:553–559

Acknowledgements

The publication is a result of the Project Reg. No. P106/15-19780S which was financially supported by the Czech Science Foundation GA ČR. The project has been integrated into the National Programme for Sustainability I of the Ministry of Education, Youth and Sports of the Czech Republic through the project Development of the UniCRE Centre, Project Code LO1606.

Author information

Authors and Affiliations

Corresponding author

Electronic supplementary material

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Hidalgo, J.M., Tišler, Z., Bulánek, R. et al. Partial oxidation of ethanol over ZrO2-supported vanadium catalysts. Reac Kinet Mech Cat 121, 161–173 (2017). https://doi.org/10.1007/s11144-017-1159-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11144-017-1159-1