Abstract

Photocatalysts were prepared by the deposition of noble metal nanoparticles (Au, Pt, Rh or Ru) on different commercially available titanias. The photocatalytic performance of these catalysts was studied for the evolution of H2 during excitation with visible light. Experiments were carried out in irradiated suspensions containing various organic compounds. Noble metal nanoparticles can promote the lowering of the overvoltage of H+ reduction. The noble metal nanoparticles were deposited onto the TiO2 surface by in situ chemical reduction in a quantity of 1 wt%. Three aspects were considered: (i) the photocatalytic performance of different bare TiO2 deposited with Pt; (ii) the effect of the deposition of Au, Pt, Rh or Ru nanoparticles onto the TiO2 surface; and (iii) choosing the most suitable H2 production supporting organic compound. The rate of H2 evolution proved to be strongly dependent on the quality of TiO2 powder and the presence of different organics. The applied noble metal was also an efficiency determining factor during these photocatalytic reactions. With the best combination of the above mentioned circumstances, we achieved promising results to be able to effectively harvest the energy of sunlight.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

There is a steadily increasing demand for clean and environmentally friendly energy resources. The production of H2 is of great importance to meet future needs. The combustion of gaseous H2 results only in the formation of water (without CO2 emission), while relatively high energy becomes available. The use of heterogeneous photocatalysis may offer a sustainable solution for the indirect storage of solar energy via producing H2 gas from water [1, 2]. TiO2 photocatalysts can be excited with UV photons, though in most cases, bare TiO2 has low efficiency for direct photocatalytic water splitting when irradiating them with visible light. While natural sunlight contains only ~4% UV irradiation, the quantity of visible photons comprises nearly 40%. For practical purposes, this high-intensity photon flux should be harvested effectively. The overvoltage of H2 evolution and the recombination rate of electron-hole pairs can be lowered by depositing noble metal co-catalyst particles onto the TiO2 surface [3]. Numerous publications have reported on the use of Pd [4, 5], Pt [6–9], Ru [10], Rh [4], Au [11, 12] and Ag [13] to enhance the photocatalytic performance of TiO2. These nanoparticles can readily be synthesized and precipitated from their precursors through applying chemical reducing agents [14, 15]. From the aspect of cost-effectiveness, a noble metal content of 1 wt% [16–18] or below [5, 8, 19] is considered optimal and sufficient for a significant increase in photocatalytic activity. Higher quantities of noble metal particles on TiO2 can block the active sites. Several other factors also may influence the overall rate of H2 production, e.g. the surface properties and particle size of the catalyst and the reaction temperature. A noteworthy increase in reaction rate is observed in the presence of easily oxidizable organic compounds (especially water–alcohol mixtures) rather than using only pure water [6, 8, 20–27]. These electron donors (sacrificial reagents) react irreversibly with the photoinduced holes, resulting in suppressed electron-hole recombination and O2/H2 back-reaction rates. As the organic content of the suspension is completely mineralized, the H2 evolution rate falls back dramatically. In the study published by Yang et al. [4], different alcohols were compared for photocatalytic H2 production. Over Pt–TiO2, the evolution of molecular hydrogen showed the following trend: methanol ≈ ethanol > propanol ≈ isopropanol > n-butanol. Despite alcohols are the most investigated compounds in this area of photocatalysis, some carboxylic acids may serve as suitable hole scavengers, e.g. formic acid [28], chloroacetic acid [9] or oxalic acid [29].

In terms of environmental benefit, a combination of the disposal of organic industrial waste products with the production of gaseous H2 would be highly advantageous. Although huge efforts have been devoted to increasing the performance of noble metal deposited TiO2, the process still needs to be improved to make it suitable for industrial application. The aim of the present work was to find optimized reaction circumstances and developed photocatalytic processes through which to harvest the energy of sunlight efficiently. The main objective was to compare the H2 evolution rates of the photocatalysts during excitation with visible light. Three different factors that can be crucial in photocatalytic H2 evolution were considered: the roles of different TiO2 bare catalysts, the type of the noble metal nanoparticles on the TiO2 surface, and the nature of the organic sacrificial agent present during the photocatalytic reaction. Widely used titanias and common organic compounds were compared in an effort to optimize the reaction rates.

Materials and methods

Catalyst preparation

Six commercially available TiO2 photocatalysts were used as bare catalysts: Aeroxide P25 (TiO2–P25, Evonik Industries), Aldrich anatase (TiO2–AA, Sigma-Aldrich Co.), Aldrich rutile (TiO2–AR, Sigma-Aldrich Co.), Kronos vlp 7000 (TiO2–VLP7000, Kronos-Titan GmbH), Nanomaterials rutile (TiO2–NR, US Research Nanomaterials Inc.) and Sumitomo TP-S201 anatase (TiO2–TP-S201, Sumitomo Chemical Inc.) (Table 1). TiO2 photocatalysts modified with 1 wt% (\({\text{m}}_{\text{M}} / {\text{m}}_{{{\text{TiO}}_{ 2} }}\)) noble metal (Au, Pt, Rh or Ru) were prepared. This particular noble metal content was selected because photocatalytic activity is often optimal at around 1 wt% noble metal loading. Noble metal nanoparticles were deposited onto the TiO2 surface by in situ chemical reduction. The concentration of the TiO2 suspension was 5 g/L, while the quantity of noble metal precursor (HAuCl4, H2PtCl6, RhCl3 or RuCl3) was calculated to result in the desired noble metal loading on the photocatalyst. Trisodium citrate (ccitrate, final = 1.25 × 10−4 M) was utilized to stabilize the growth of the noble metal nanoparticles and to achieve a nearly monodisperse size distribution. Finally, freshly prepared, ice-cold NaBH4 solution was added as a reducing agent (\({\text{c}}_{{{\text{NaBH}}_{4},\;{\text{final}}}}\) = 3 × 10−3 M). The suspensions were thermostated at 20 °C during the reaction. The syntheses were carried out for 1 h in the dark. The catalysts were then washed by centrifugation, and the particles were resuspended in oxalic acid solution (1.0 × 10−3 M) to improve the sedimentation and to eliminate the residual chloride and sodium ions. The final suspensions were used fresh for the photocatalytic tests without any further purification.

All the syntheses and photocatalytic experiments were carried out in Millipore MilliQ ultrapure water as medium.

Characterization of the catalysts

Diffuse reflectance spectroscopy (DRS)

The UV–VIS reflection spectra (λ = 300–800 nm) of the photocatalyst powders were measured with a JASCO-V650 spectrophotometer equipped with an integration sphere (ILV-724). The possible electron transitions were evaluated by plotting dR/dλ vs. λ, where R is the reflectance and λ is the wavelength. DRS measurements were carried out with TiO2 powders in a cuvette.

Transmission electron microscopy (TEM)

The average size of the noble metal nanoparticles deposited on the TiO2 surface was calculated from TEM images recorded with a 100 kV Phillips CM 10 instrument. The catalyst samples were investigated immediately after preparation.

H2 production measurements

The freshly prepared, washed catalyst was suspended in a 50 mM solution of the hole scavenger organic compound, which was poured into a glass reactor (total volume: 150 mL). The VIS photoexcitation was achieved through the surrounding ten 15 W lamps (400–480 nm, λmax = 425 nm). The light emitted by the lamps contained a minimal amount of a 380–400 nm UV component, which was completely filtered out through the use of 0.1 M NaNO2 solution circulating in the reactor mantle. The well-stirred suspension (ccatalyst = 1 g/L) was purged with N2 carrier gas at a flow rate of 50 mL/min to ensure O2-free conditions. The reactor was connected through a PTFE tube to a Hewlett Packard 5890 gas chromatograph fitted with a 5 Å molecular sieve column and a thermal conductivity detector. Gas samples were taken with a 2 mL sampling valve to provide high fidelity for the measurements. The rate of H2 evolution was calculated with regard to the GC calibration (carried out with certified 5% H2:N2 gas) and the N2 flow rate.

Results and discussion

Photocatalytic H2 production using different types of TiO2

There are numerous types of commercially available TiO2 catalysts on market. As a consequence of the differences in the production methods, these catalysts differ considerably in particle size, crystalline phase, specific surface area and other specific surface properties, all features which may influence the photocatalytic performance appreciably. We investigated six widely used TiO2 catalysts from the aspect of their suitability for photocatalytic H2 production during irradiation with visible light. Under the reaction circumstances described above, the photocatalytic activity of pure TiO2 is negligible, whereas the photocatalytic properties of Pt deposited TiO2 is emphasized frequently. Thus, Pt nanoparticles were chemically reduced onto the TiO2 surface at a level of 1 wt% to enhance the rate of H2 evolution. The syntheses were carried out in a similar way for all the TiO2 catalysts. During the photocatalytic tests, the reaction mixture contained an initial concentration of 50 mM oxalic acid as sacrificial reagent. In the case of Pt–TiO2–AR, substantially higher initial rates of H2 production were detected, which had diminished to a steady-state level after the first 2 h of irradiation (Fig. 1a). According to our previous measurements, this significant decrease also can be observed in H2 production rates when the Pt–TiO2 catalyst is irradiated with UV light [30]. It was confirmed by TEM measurements that the average particle diameter and size distribution of platinum does not change considerably during irradiation. Furthermore, it was proven by ICP measurements that the detachment and dissolution of Pt from the TiO2 surface is negligible (below 2 ppb in the solution phase from the total concentration of 10,000 ppb). Raising the carrier gas flow rate causes an elongated maximum of H2 production, while low N2 flow rate (25 mL/min) resulted in the complete disappearance of the initial maximum values in the investigated time frame. At the later stages of the experiments (t > 50 min), the steady state H2 evolution rates were nearly identical. A possible explanation of the phenomenon can be that in the first period of irradiation, the hydrogen generation is regulated by the varying potential of H-electrode established by the dissolution of hydrogen in Pt [31]. At higher carrier gas flow rates, this process is limited. Therefore, the overpotential of hydrogen evolution can remain in an optimal range for a longer timeframe, while with lower N2 flow the equilibrium redox potential can be achieved faster.

a H2 evolution from oxalic acid solution (cinitial = 50 mM) using Pt deposited on (filled square) TiO2–AR, (filled circle) TiO2–P25, (plus) TiO2–NR, (filled triangle) TiO2–VLP7000, (times) TiO2–TP-S201 or (filled diamond) TiO2–AA catalysts (1 g/L)—VIS irradiation (400–480 nm, λmax = 425 nm). b Average H2 evolution rates (120–240 min of irradiation) on the use of different commercially available bare TiO2 photocatalysts deposited with 1 wt% Pt (1 g/L) in the presence of 50 mM oxalic acid—VIS irradiation (400–480 nm, λmax = 425 nm)

In view of the shape of the H2 evolution curves, the steady-state results were averaged and compared for the 120–240 min period of the measurements (Fig. 1b). The H2 evolution rate was appreciably better using Pt–TiO2–AR than with the other commercially available TiO2 based samples.

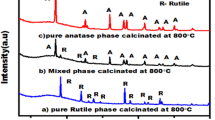

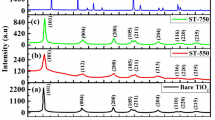

During visible light excitation, considerable H2 evolution was observed only in the cases of the rutile-containing catalysts. The DRS spectra of these catalysts clearly reveal that Pt–TiO2–AR is more easily excited with photons above 400 nm, while Pt–TiO2–NR and Pt–TiO2–P25 are more likely to absorb photons in the near UV (<400 nm) according to the dR/λ vs. λ plots (Fig. 2). The effect is possibly due to that the size reduction of a semiconductor crystal is accompanied with band gap widening—in the literature, the so called blue shift. When having semiconductor crystals with lower particle size (but the same crystalline phase), higher absorbed quantum energy is required to excite electrons from the valence band into the conduction band, and this results in absorption edge shift [32].

Effect of different noble metal nanoparticles deposited on TiO2–AR

For further photocatalytic experiments, TiO2–AR was chosen as bare catalyst and 1 wt% Au, Pt, Rh or Ru nanoparticles were deposited onto the TiO2 surface by the identical chemical reduction synthesis method. The average diameters of the resulting noble metal nanoparticles (determined using TEM) were 5.7, 5.4, 8.1 and 9.2 nm, i.e. almost two orders of magnitudes smaller than the average TiO2–AR particles (Fig. 3). This means that several noble metal islands are situated on each rutile particle, and this can greatly enhance the charge separation during the photoreactions. The dispersion of the noble metal nanoparticles on the TiO2 surface was nearly consistent.

All of the photocatalytic measurements in this series were carried out in the presence of 50 mM oxalic acid. Our results demonstrated that all of the above-mentioned noble metals on TiO2–AR are suitable for the promotion of H2 evolution from oxalic acid during visible light excitation (Fig. 4). The photon absorption properties were almost the same for each catalyst (Fig. 5), although the best-performing 1 wt% Pt–TiO2–AR resulted in nearly three times more evolved H2 than in the case of Au–TiO2–AR. The reduction of the hydrogen ions is strongly dependent on the material quality of the deposited noble metal. Using different noble metals results in different overvoltage for hydrogen generation. Platinum group metals such as Pt, Rh, and Ru reduce this overvoltage to near 0 V. This phenomenon can explain why using Au deposited samples resulted in three times less evolved H2 [33].

Photocatalytic H2 production in the presence of various organics

Pt–TiO2–AR exhibited pronounced photocatalytic activity in the presence of oxalic acid. We examined the possibility of finding an even more suitable organic sacrificial reagent with which to enhance the rate of H2 evolution. Seven common, readily oxidizable organic compounds (Table 2) were compared under identical reaction conditions. The steady-state H2 evolution rates are presented in Fig. 6. The use of lactic acid as a sacrificial electron donor in the reaction mixture instead of oxalic acid resulted in an outstanding H2 production, nearly four times higher. The presence of formic acid also led to a marked enhancement of the photocatalytic formation of H2. It appears that the application of substances with an acidic character as sacrificial agents instead of the alcohols mostly studied in the literature may be favorable. Our concept was to increase the amount of H+ in water by decreasing the pH. However, the oxidational step also means a speed limiting factor for H2 generation. By using organic acids as a model component, we ensured the higher amount of H+ in water and the presence of an easily oxidizable reaction partner.

Conclusions

Commercially available TiO2 photocatalysts deposited with noble metal nanoparticles were examined for their applicability in photocatalytic H2 production during visible light irradiation. An effective set of reaction conditions were identified: considerable H2 generation was observed when catalysts were used with rutile content. Pt-modified Aldrich rutile demonstrated outstanding efficiency due to its ability to be excited with photons in the range of 400–425 nm. Of the noble metals used, Pt proved most appropriate in enhancing the H2 evolution rates. However, Rh on TiO2 also appears to be a good choice for harvesting the energy of photons >400 nm, especially in view of the recent fall in price and its ability to produce high amount of gaseous hydrogen relative to Pt–TiO2. As concerns the effect of various organic compounds, carboxylic acids seem to have huge potential in this field of photocatalysis, especially lactic acid which can be easily produced through biotechnological processes. With Pt–TiO2–AR in the presence of lactic acid, we observed a 6-fold higher level of H2 production than in the case of using methanol.

References

Carp O, Huisman CL, Reller A (2004) Photoinduced reactivity of titanium dioxide. Prog Solid State Chem 32(1–2):33–177. doi:10.1016/j.progsolidstchem.2004.08.001

Bolton JR (1996) Solar photoreduction of hydrogen: a review. Sol Energy 57:37–50

Rosseler O, Shankar MV, Du MK-L, Schmidlin L, Keller N, Keller V (2010) Solar light photocatalytic hydrogen production from water over Pt and Au/TiO2(anatase/rutile) photocatalysts: influence of noble metal and porogen promotion. J Catal 269(1):179–190. doi:10.1016/j.jcat.2009.11.006

Yang Y, Chang C, Idriss H (2006) Photo-catalytic production of hydrogen form ethanol over M/TiO2 catalysts (M = Pd, Pt or Rh). Appl Catal B 67(3–4):217–222. doi:10.1016/j.apcatb.2006.05.007

Sakthivel S, Shankar MV, Palanichamy M, Arabindoo B, Bahnemann DW, Murugesan V (2004) Enhancement of photocatalytic activity by metal deposition: characterisation and photonic efficiency of Pt, Au and Pd deposited on TiO2 catalyst. Water Res 38(13):3001–3008. doi:10.1016/j.watres.2004.04.046

Chen T, Feng Z, Wu G, Shi J, Ma G, Ying P, Li C (2007) Mechanistic studies of photocatalytic reaction of methanol for hydrogen production on Pt/TiO2 by in situ Fourier Transform IR and Time-Resolved IR Spectroscopy. J Phys Chem C 111:8005–8014

Patsoura A, Kondarides DI, Verykios XE (2006) Enhancement of photoinduced hydrogen production from irradiated Pt/TiO2 suspensions with simultaneous degradation of azo-dyes. Appl Catal B 64(3–4):171–179. doi:10.1016/j.apcatb.2005.11.015

Ikuma Y, Bessho H (2007) Effect of Pt concentration on the production of hydrogen by a TiO2TiO2 photocatalyst. Int J Hydrog Energy 32(14):2689–2692. doi:10.1016/j.ijhydene.2006.09.024

Li Y, Xie Y, Peng S, Lu G, Li S (2006) Photocatalytic hydrogen generation in the presence of chloroacetic acids over Pt/TiO2. Chemosphere 63(8):1312–1318. doi:10.1016/j.chemosphere.2005.09.004

Nada A, Barakat M, Hamed H, Mohamed N, Veziroglu T (2005) Studies on the photocatalytic hydrogen production using suspended modified photocatalysts. Int J Hydrog Energy 30(7):687–691. doi:10.1016/j.ijhydene.2004.06.007

Wu G, Chen T, Su W, Zhou G, Zong X, Lei Z, Li C (2008) H2 production with ultra-low CO selectivity via photocatalytic reforming of methanol on Au/TiO2 catalyst. Int J Hydrog Energy 33(4):1243–1251. doi:10.1016/j.ijhydene.2007.12.020

Dawson A, Kamat PV (2001) Semiconductor-metal nanocomposites. Photoinduced fusion and photocatalysis of gold-capped TiO2 (TiO2/gold) nanoparticles. J Phys Chem B 105:960–966

Park J, Kang M (2007) Synthesis and characterization of AgxOAgxO, and hydrogen production from methanol photodecomposition over the mixture of AgxOAgxO and TiO2TiO2. Int J Hydrog Energy 32(18):4840–4846. doi:10.1016/j.ijhydene.2007.07.045

He P, Zhu X (2007) Phospholipid-assisted synthesis of size-controlled gold nanoparticles. Mater Res Bull 42(7):1310–1315. doi:10.1016/j.materresbull.2006.10.014

Singh SK, Iizuka Y, Xu Q (2011) Nickel-palladium nanoparticle catalyzed hydrogen generation from hydrous hydrazine for chemical hydrogen storage. Int J Hydrog Energy 36(18):11794–11801. doi:10.1016/j.ijhydene.2011.06.069

Yi H, Peng T, Ke D, Ke D, Zan L, Yan C (2008) Photocatalytic H2 production from methanol aqueous solution over titania nanoparticles with mesostructures. Int J Hydrog Energy 33(2):672–678. doi:10.1016/j.ijhydene.2007.10.034

Zheng X-J, Wei L-F, Zhang Z-H, Jiang Q-J, Wei Y-J, Xie B, Wei M-B (2009) Research on photocatalytic H2 production from acetic acid solution by Pt/TiO2 nanoparticles under UV irradiation. Int J Hydrog Energy 34(22):9033–9041. doi:10.1016/j.ijhydene.2009.09.019

Iliev V, Tomova D, Bilyarska L, Tyuliev G (2007) Influence of the size of gold nanoparticles deposited on TiO2 upon the photocatalytic destruction of oxalic acid. J Mol Catal A 263(1–2):32–38. doi:10.1016/j.molcata.2006.08.019

Iliev V, Tomova D, Todorovska R, Oliver D, Petrov L, Todorovsky D, Uzunova-Bujnova M (2006) Photocatalytic properties of TiO2 modified with gold nanoparticles in the degradation of oxalic acid in aqueous solution. Appl Catal A 313(2):115–121. doi:10.1016/j.apcata.2006.06.039

Bamwenda GR, Tsubota S, Nakamura T, Haruta M (1995) Photoassisted hydrogen production from a water–ethanol solution: a comparison of activities of Au–TiO2 and Pt–TiO2. J Photochem Photobiol A 89:177–189

Yin S, Sato T (2005) Photocatalytic activity of platinum loaded fibrous titania prepared by solvothermal process. J Photochem Photobiol A 169(1):89–94. doi:10.1016/j.jphotochem.2004.05.038

Chiarello GL, Aguirre MH, Selli E (2010) Hydrogen production by photocatalytic steam reforming of methanol on noble metal-modified TiO2. J Catal 273(2):182–190. doi:10.1016/j.jcat.2010.05.012

Cui W, Feng L, Xu C, Lü S, Qiu F (2004) Hydrogen production by photocatalytic decomposition of methanol gas on Pt/TiO2 nano-film. Catal Commun 5(9):533–536. doi:10.1016/j.catcom.2004.06.011

Choi H, Kang M (2007) Hydrogen production from methanol/water decomposition in a liquid photosystem using the anatase structure of Cu loaded TiO2TiO2. Int J Hydrog Energy 32(16):3841–3848. doi:10.1016/j.ijhydene.2007.05.011

Ikeda M, Kusumoto Y, Yakushijin Y, Somekawa S, Ngweniform P, Ahmmad B (2007) Hybridized synergy effect among TiO2, Pt and graphite silica on photocatalytic hydrogen production from water–methanol solution. Catal Commun 8(12):1943–1946. doi:10.1016/j.catcom.2007.03.015

Mizukoshi Y, Makise Y, Shuto T, Hu J, Tominaga A, Shironita S, Tanabe S (2007) Immobilization of noble metal nanoparticles on the surface of TiO2 by the sonochemical method: photocatalytic production of hydrogen from an aqueous solution of ethanol. Ultrason Sonochem 14(3):387–392. doi:10.1016/j.ultsonch.2006.08.001

Sreethawong T, Suzuki Y, Yoshikawa S (2006) Platinum-loaded mesoporous titania by single-step sol–gel process with surfactant template: photocatalytic activity for hydrogen evolution. C R Chim 9(2):307–314. doi:10.1016/j.crci.2005.05.015

Chen T, Wu G, Feng Z, Hu G, Su W, Ying P, Li C (2008) In situ FT-IR study of photocatalytic decomposition of formic acid to hydrogen on Pt/TiO2 catalyst. Chin J Catal 29(2):105–107. doi:10.1016/s1872-2067(08)60019-4

Mogyorósi K, Kmetykó Á, Czirbus N, Veréb G, Sipos P, Dombi A (2009) Comparison of the substrate dependent performance of Pt-, Au- and Ag-doped TiO2 photocatalysts in H2-production and in decomposition of various organics. React Kinet Catal Lett 98(2):215–225. doi:10.1007/s11144-009-0052-y

Kmetykó A, Mogyorósi K, Gerse V, Kónya Z, Pusztai P, Dombi A, Hernádi K (2014) Photocatalytic H2 production using Pt–TiO2 in the presence of oxalic acid: influence of the noble metal size and the carrier gas flow rate. Materials 7(10):7022–7038

De Luca L, Donato A, Santangelo S, Faggio G, Messina G, Donato N, Neri G (2012) Int J Hydrog Energy 37:1842–1851

Weller H (1993) Colloidal semiconductor Q-particles: chemistry in the transition region between solid state. Angew Chem Int Ed Engl 5(32):41–53

Gratzel M (2012) Energy resources through photochemistry and catalysis. Elsevier, Amsterdam

Acknowledgments

This research was supported by the European Union and the State of Hungary, co-financed by the European Social Fund in the framework of TÁMOP-4.2.4.A/2-11/1-2012-0001 ‘National Excellence Program’. The work was supported by the Swiss Contribution SH/7/2/20. The authors would express their gratitude to the fund received from the Greek-Hungarian bilateral project nr. TÉT_10-1-2011-0536. Part of the research was co-funded by the European Regional Development Fund of European Commission and the General Secretariat for Research and Technology under a Greek-Hungarian Joint Research and Technology Programme.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Kmetykó, Á., Szániel, Á., Tsakiroglou, C. et al. Enhanced photocatalytic H2 generation on noble metal modified TiO2 catalysts excited with visible light irradiation. Reac Kinet Mech Cat 117, 379–390 (2016). https://doi.org/10.1007/s11144-015-0923-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11144-015-0923-3