Abstract

This research evaluated the profitability and nitrogen (N) efficiency of real time on-the-go optical sensing measurements (OPM) for variable-rate (VRT) N management for cotton. Two forms of OPM-based VRT N management and the existing farmer practice (FP) were used to determine N rates applied to cotton on 21 farm fields in the lower Mississippi River Basin states of Louisiana, Mississippi, Missouri and Tennessee, USA. A modified version of the Schabenberger and Pierce on-farm experimentation model was used to evaluate VRT N management and landscape, soil and weather factors on lint yields, N rates, N efficiency (lint yield divided by N rate) and net returns. Field level mean lint yields were not different between VRT and FP. VRT decreased N rates applied on four fields and increased N rates applied on four other fields. However, landscape, soil and weather attributes specific to fields influenced VRT N rates. VRT N rates were similar to FP N rates on the other fields in the study. N efficiency was not improved with VRT N management. N rates were not low enough to increase N efficiency. Changes in lint yields and N rates due to VRT coupled with USDA NRCS Environmental Quality Incentive Program cost-share payments were not sufficient to produce higher net returns relative to FP N management at the field level. In this multi-site, multi-year study, yields and net returns from VRT were not different from FPs which did not utilize variable rate N management.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Nitrogen (N) fertilizer is an important and expensive input in the production of upland cotton. Applying N uniformly across a field that has soil and landscape variability may result in sections of the field that are over- or under-fertilized. This variation could affect profit. In addition, the over application of N can increase excess N released into the environment from crop production (Butchee et al. 2011). Farmers can apply fertilizer more efficiently using precision agriculture (PA) technologies such as real time on-the-go optical sensing measurements (OPM) based variable rate (VRT) fertilizer application. This technology can reduce or eliminate over- or under-application of N (Boyer et al. 2011).

The N use efficiency (NUE) and profitability of OPM-based VRT has been evaluated in several North American locations for wheat and corn. Raun et al. (2002) analyzed optical sensing and VRT for Oklahoma, USA winter wheat production. The study examined four winter wheat experiments that compared these technologies with a uniform rate (URT) of N across the field. The NUE, defined in the Raun et al. (2002) study as yield times total N concentration in the grain divided by the N application rate, increased by more than 15% when comparing VRT to URT. Raun et al. (2002) found that the extra income due to an increase in NUE covered the expected costs of the technology and that OPM-based VRT would be most profitable in areas of high spatial variability. Raun et al. (2005) found N application rate reductions as well, measuring an increase of 15% in NUE via the use of optical sensing. Butchee et al. (2011) evaluated the same technologies to assess NUE compared to the farmer practice (FP) in Oklahoma. On average, using OPM to apply N produced similar wheat yields but reduced N by 22 kg ha−1 compared to the current FP. OPM-based VRT N application increased NUE and provided environmental benefits in the aforementioned Oklahoma studies.

Biermacher et al. (2006) estimated the profitability of OPM-based VRT for wheat production using 65 site-years of data from two long-term N management studies in Oklahoma. They used linear response plateau functions to evaluate the maximum economic value of sensor-based N management compared with uniform rate N management. Overall, the two sites showed average profitability of $23 to $24 ha−1 over conventional practices and reduced pre-plant N by 59–82%. In another study, Biermacher et al. (2009a) evaluated data from experiments conducted at nine Oklahoma locations. Results from the yield response to N showed that a ‘perfect information system’ (VRT application of N based on OPM and an optimization algorithm) generated $16 ha−1 more and the uniform top-dress-sensed system returned $9 more ha−1, respectively, compared to conventional practices. However, Boyer et al. (2011) found no statistical differences in net returns among 10 N treatments that included N applied using OPM-based VRT in a study conducted at seven experiment locations in Oklahoma. They concluded that OPM-based VRT did not apply enough N to maximize yields and profits relative to URT. The Oklahoma studies demonstrated mixed results about the economic benefits of OPM and VRT.

Ortiz-Monasterio and Raun (2007) determined N application efficiency in wheat utilizing OPM and VRT in Yaqui Valley, Mexico. Trials indicated an average savings of 69 kg ha−1 of N without a reduction in wheat yields. Across all field trials, OPM-based VRT N rates increased average profitability by $56 ha−1. Scharf et al. (2011) assessed OPM-based VRT N application versus current FP uniform N rates in corn production in Missouri, USA. Over 4 years, 55 replications were conducted to determine the profitability of PA. VRT N applications increased yields by 110 kg ha−1 and reduced N by 15 kg ha−1, increasing profits margins (value of corn grain less cost of N applied) by $42 ha−1 over producer chosen uniform N rates. OPM-based VRT increased NUE and provided environmental benefits in the aforementioned studies.

Research indicates that OPM-based VRT N applications may provide higher NUE and profitability in corn and wheat production. Unknown though is how OPM-based VRT N fertilization rates affect cotton production in the lower Mississippi River Basin (MRB) of the United States. MRB cotton producers identified the need for information about using OPM-based VRT (Mooney et al. 2010). Managing N more efficiently on farm fields in the MRB is also an important USDA Natural Resources Conservation Service (NRCS) priority to reduce nutrient and sediment loading into local and regional water bodies (USDA 2017). If growers had access to information or studies specific to the MRB, they could make more informed decisions about the adoption of OPM-based VRT with regard to soil types, N costs, profitability and labor and application efficiency. This PA technology may benefit cotton farms in the MRB by increasing grower profits. The technology may also reduce the amount of N from cotton production released into the environment. The objective of this research was to determine the lint yields, N fertilization rates, N efficiency (lint yield divided by N rate) and profitability of OPM-based VRT in cotton production in the lower MRB.

Data and methods

Field demonstration trial data

N management data

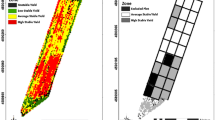

Farmer demonstration trials using OPM-based VRT to apply N on cotton were conducted on 21 farm fields in Louisiana, Mississippi, Missouri and Tennessee, USA from 2011 to 2014. Each farmer participating in the field demonstrations was eligible for USDA NRCS Environmental Quality Incentive Program (EQIP) payments to encourage adoption of PA technologies (USDA 2014a). Nine (9) of the trials occurred in Louisiana, four (4) in Mississippi, six (6) in Missouri and ten (10) in Tennessee (Fig. 1).

The field trials included the current FP for N management and two OPM-based VRT N management methods on each cotton field. The FP was a uniform rate of N applied across the field. VRT 1 was a VRT N rate calculated using normalized difference vegetation index (NDVI) readings from canopy optical-sensing. VRT 2 was a VRT N rate based on NDVI readings using canopy optical-sensing, but adjusted with combinations of historical yield productivity zones, soil imagery and/or aerial imagery of crop growth.

Canopy optical-sensing readings from study fields were collected using the Greenseeker™ Crop Sensing System (Trimble, Sunnyvale, CA, USA) or the Yara™ N-Sensor (Yara North America, Tampa, FL, USA). Sensor readings were obtained before VRT application of N at approximately the early bloom stage for each site-year of the field trial. Sensor configurations varied in each state where the field trials took place. For example, the Greenseeker™ RT200 System used in Tennessee consisted of six sensors covering 12 rows of cotton (11.58 m wide). The spacing between the sensors was about 1.93 m and the sensors were mounted at a height of about 0.76 m above the cotton canopy. About two data points s−1 were collected by the system at a field speed of 7.64 km h−1.

There are different methods to determine VRT N rates for cotton based on canopy optical-sensing readings. For example, Griffin et al. (2014) used data supplied by researchers across the U.S. cotton belt to develop an algorithm for VRT application of N based on NDVI readings of the growing cotton crop. Arnall et al. (2016) used data from cotton experiment plots in Oklahoma to develop an algorithm using NDVI readings. The two algorithms have not been validated in field trials in the four states where this study took place. At the time of the field study (2011–2014), each research institution participating in the project had different recommendations for VRT N rates using the canopy optical-sensing and other information to formulate VRT N prescriptions on the fields in each state.

Cotton was planted across 9 strip-plots (hereafter referred to as plots) containing 8–10 sub-plots, each measuring 30.5 m by 11.6 m, with the exception of Missouri. Cotton harvesters with yield monitors were unavailable to measure sub-plots in Missouri, where plot-level yields were determined using a weigh wagon. The three N management treatments were assigned to the plots following a randomized complete block design with three replicates per treatment. A uniform-rate of N was applied at (or before) planting to the entire field (covering all three treatment areas) that differed in the amount of N applied at (or before) planting depending on the farm field location. The second application of N for the VRT treatments was made after cotton emergence at approximately the early bloom stage. Data collected for each field location included harvested lint yields, N rates applied, type of N used and latitude and longitudes at the sub-plot or plot level for every participating year (Table 1).

Soil variability, landscape, and weather data

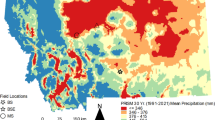

The field demonstration dataset was augmented with landscape, soil and weather data for each field location. Presuming spatial variability increases the profitability of PA (Raun et al. 2002; Scharf et al. 2011), one would expect field-specific features to be correlated with site-specific profitability. Field-level landscape, soil and weather characteristics were collected from the National Elevation dataset (U.S. Geological Survey 2014), the SSURGO database (USDA 2014b), and the PRISM dataset (PRISM 2014) using the center point of each sub-plot (plot for Missouri locations). Geospatial data were processed in ArcGIS 10.1 (ESRI, Redlands, CA, USA). Data collected included field elevation (m), soil texture, soil erosion factors, available water capacity (volume fraction), soil organic matter (%), soil depth (cm) and temperature (°C) (Table 2).

The percent sand, silt and clay from SSURGO (USDA 2014b) were used to classify general soil texture with the USDA soil texture calculator (USDA 2014c). Textures were then narrowed down to four major categories ranked by coarseness: clay (finest), silt, loam and sand (coarsest). A soil erosion index (SEI) was calculated using physical soil erosion factors from the SSURGO database (USDA 2014b) to account for topographic influences on field soils:

where KF is an erodibility factor caused by water; LS is a soil length (L) and slope steepness (S) factor; R is the rainfall and runoff factor from USDA RUSLE2 version 2.5.2.11 (USDA 2014d); and TF is a soil tolerance factor (USDA 2014b). Weather was measured by temperature (PRISM 2014) and expressed as growing degree days (April 1–October 31) (Wright et al. 2015). The daily average temperature minus 15.6 °C was summed over April 1 through October 31 per location-year for daily calculations greater than zero.

N use efficiency

VRT NUE has been measured in several ways, most of which require a zero-N application plot (omission plot) or an N-rich plot for comparison purposes. Butchee et al. (2011) calculated NUE from the following equation used to find the N rate:

where YP0 is yield potential for zero N applied; RI is a N response index measured by OPM; and the grain crop is winter wheat. Cassman et al. (1998, 1996) employed partial factor productivity (PFP) as a measure of NUE: PFPi = (Y0 + ΔYi)/Ni, where ∆Y is change in yields from zero-N applied; and Ni is the N rate applied per treatment i. Raun et al. (2002) measured NUE by subtracting N removed (grain yield times total N concentration in grain) in the grain yield in the zero-N applied plots from the N removed in the grain yield found in the plots receiving added fertilizer N, divided by the rate of fertilizer N applied.

An N fertilizer efficiency measure was used in this study to approximate NUE of the OPM-based VRT treatments (NEFF). N efficiency was calculated by dividing the lint yield (Y) for a given technology by the corresponding N rate applied (N):

where i is N treatment 1 (FP), 2 (VRT 1), and 3 (VRT 2). The mean N for each field site and year are presented in Table 2.

Profitability

Net returns were calculated using lint yields and N rates for the three N treatments. Price and budget data used to calculate net returns are in real 2013 dollars, indexed to the Bureau of Economic Analysis Annual Gross Domestic Product Price Deflator Index (U.S. Department of Commerce 2014). Price data included the national average marketing year (August 1–July 31) cotton lint prices received for 2011 through 2014 (USDA 2014e), adjusted to real 2013 dollars of $1.84 kg−1. National prices paid for N were collected for the 2011 through 2014 marketing years (USDA 2014f), adjusted to real 2013 dollars of $0.91 N kg−1. EQIP cost-share payments were collected for each participating state for precision nutrient management payment code 590 for 2011 through 2014. The EQIP cost-share payments were adjusted to real 2013 $ ha−1. Payments were $68.21 ha−1 in Mississippi, $68.46 ha−1 in Louisiana, $65.85 ha−1 in Tennessee, and $32.64 ha−1 in Missouri. The payments were added to crop revenue for VRT 1 and VRT 2 (personal communication with Patricia Turman, Tennessee State Agronomist, 2014, Chris Coreil, Louisiana NRCS Conservation Agronomist, 2014 and Jodie Reisner, Missouri NRCS Conservation Agronomist, 2014; USDA 2014g).

Information and application costs, including technology, labor and other costs for the FP, VRT 1 and VRT 2 N treatments were estimated using partial budgeting techniques (Agricultural and Applied Economics Association (AAEA) 2000). Two budgets were developed to account for information and application costs of the VRT treatments: (1) OPM-based VRT N application (VRT 1) and (2) OPM adjusted with other information based VRT N application (VRT 2). For VRT 2, yield productivity zones were assumed to be identified using yield monitor information and to adjust the OPM data. VRT N rate recommendations were assumed to be made using these data. Therefore, information and application costs for VRT 2 included the estimated costs for OPM and yield monitor information, the cost of a computer to manage information and a technical consulting fee.

The OPM-based VRT technology (Greenseeker™) had an estimated cost of $60,684, including installation (adjusted to real 2013 dollars), and was assumed to be retrofitted to a boom sprayer measuring 24.7 m wide (Larson et al. 2010). The yield monitor (estimated cost of $14,421 including installation and adjusted to 2013 real dollars), was assumed to be retrofitted to a 6-row cotton picker (Larson et al. 2010). Ownership and operating costs of equipment for VRT 1 and VRT 2 were estimated using the standards of the American Society of Agricultural and Biological Engineers (ASABE) (ASABE 2011), similar to Biermacher et al. (2009b) and equipment costs calculation techniques outlined on the AAEA Commodity Costs and Returns Estimation Handbook (AAEA 2000). Capital recovery was estimated using a 5-year useful life, zero salvage value and 4% real interest. The applicator was assumed to be used 300 h year−1 and operated at a field speed of 10.5 km h−1 at a field efficiency of 65%. Skilled operator labor for the applicator was assumed to be $2.14 h−1 (adjusted 2013 real dollars) more with VRT (Biermacher et al. 2009b). To account for the cost of a nitrogen rich strip with OPM-based VRT, applicator ownership and operating costs were multiplied by 1.02 (Biermacher et al. 2009b). The additional ownership, operating and labor cost was estimated to be $2.45 ha−1 for OPM-based VRT and $2.73 ha−1 for yield monitoring. In addition, the costs of a computer to manage yield monitor data and technical advice for incorporating yield monitor with sensing information were included in the total cost for VRT 2. Computer equipment costs (from an informal survey conducted by the authors) were estimated to be $0.31 ha−1 of cotton based on average cotton area of 274 ha for cotton farms in the four states (USDA 2012). An average of 2009 cotton PA technical advice fees (Mooney et al. 2010) was normalized to real 2013 dollars ($12.63 ha−1) and added to all years of available data.

Statistical analysis

The methods and procedures used to compare the OPM-based VRT to the FP were based on a modified version of the Schabenberger and Pierce (2002, pp. 474–479) on-farm experimentation model. The dependent variables cotton lint yield (kg ha−1), N rate applied (kg ha−1), N efficiency (and index) and net returns ($ ha−1) are regressed on field-level variables and FP and VRT treatments with the general linear model presented in Eq. (4):

where i = 1 (FP), 2 (VRT 1), 3 (VRT 2) N rates; j = 1,…, 21 farm field locations; k is the replications on fields; l is the indices replication subplots; t = 2011, 2012, 2013, 2014; \(Y_{ijklt}\) is a response variable [cotton lint yield (kg ha−1), N rate applied (kg ha−1), N efficiency (index), and net returns ($ ha−1)]; \(\mu\) is the mean of the response variable; \(\tau\) is a treatment effect; X includes field elevation (m), soil texture, SEI, available water capacity (volume fraction), soil organic matter (%), soil depth (cm) and growing degree days (°C) associated with each subplot; \(\beta\) are the average effects of soil edaphic features, growing conditions and topography on the response variable; \(\varphi_{t} \sim G(0,\sigma_{{\varphi_{t} }}^{2} )\) is a year random effect; \(\varphi_{j} \sim G(0,\sigma_{{\varphi_{j} }}^{2} )\) is a location random effect; \(\varphi_{k(j)} \sim G(0,\sigma_{{\varphi_{k(j)} }}^{2} )\) are nested random effects from replications in field locations; \((\varphi \cdot \tau )_{ij} \sim G(0,\sigma_{\varphi \tau }^{2} )\) is a location × treatment random effect and \(e_{ijkt} \sim G(0,\sigma_{e}^{2} )\) is the model error.

The variance components are Gaussian with an expected value of zero and a constant variance. The model was estimated using the MIXED model procedure and restricted maximum likelihood in SAS 9.2 (Littell et al. 2006).

The variables in Eq. (4) were hypothesized to affect the dependent variables as follows: location because the farm fields are physically different, time because the demonstration trials extend across more than 1 year, treatment because the treatments differ within a field and among fields and sub-plot because sub-plots physically differ within a field and among fields. The location × treatment random effect was expected to affect the dependent variables but to mask treatment differences (Schabenberger and Pierce 2002). VRT N applications were expected to reduce N use compared to the FP. In the special case that the yields are not significantly different across treatments per location-year, revenues from yield differences will not be a factor in net returns; N rates become the driver. The null hypothesis that VRT is not different from the FP was tested for lint yields, N rates, N efficiency and net returns averaged across the 21 fields and for each individual field in the project.

The analytical steps to test the aforementioned hypothesis about the FP, VRT 1 and VRT 2 treatments using Eq. (4) follow. First, the cotton lint yield, N rate, N efficiency and net return equations were estimated including only treatment (τi) as the explanatory variable and then again with the landscape, soil and weather explanatory variables. The better fitting models were chosen based on Akaike’s information criterion (AIC) and Bayesian information criterion (BIC) (Littell et al. 2006). Multi-collinearity was checked by calculating the variance inflation factors (VIF).

Second, the hypothesis that treatment effects may be masked was tested by estimating the regression models for lint yields, N rates, N efficiency and net returns with and without the location × treatment random effect \((\varphi \cdot \tau )_{ij}\) in Eq. (4). Rejection of the null hypothesis (\(H_{0} : \sigma_{\varphi \cdot \tau }^{2} = 0\)) indicates that the variance between fields was larger than the variation within the fields and treatment effects were masked (Schabenberger and Pierce 2002). The better fitting models (with or without the location × treatment random effect) were chosen using the AIC and BIC criterion.

Third, average treatment differences across the 21 project fields were evaluated if the regression model with the location × treatment random effect was the better fitting model based on AIC and BIC criterion. The null hypothesis was no difference in the response variable for VRT versus the FP. Dunnett’s tests were performed to determine if the VRT treatments produced significantly different lint yields, N rates, N efficiency and net returns than the FP (Letner and Bishop 1993). The test performs multiple comparisons, while holding the familywise error rate at or below a specified Type I error rate. Satterthwaite’s approximation was used to adjust the degrees of freedom for those tests (Casella and Berger 1990).

Fourth, contrasts between farm fields were estimated using the Best Linear Unbiased Predictions if the regression model with the location × treatment random effect was the better fitting model (Schabenberger and Pierce 2002). The contrasts were used to measure treatment effects for each project field. Both VRT treatments were compared with the FP. The null hypothesis of this comparison is that VRT treatments do not differ from the FP at the field level. A Bonferroni correction is a conservative way to handle multiple comparisons and deal with the familywise error rate (Casella and Berger 1990). Because there are 21 farm fields, there are 21 separate hypotheses to test for VRT 1 versus the FP and VRT 2 versus the FP. At a Type I error rate of 10%, the Bonferroni correction is calculated as α = 0.10/21 = 0.0047. The Type I error rate becomes 0.0047 for each field-level contrast.

Finally, it is expected that variation in the field-level landscape, soil and weather variables help explain the observed variability of the response variables using \(X_{lt} \beta\) in Eq. (4). The null hypotheses that mean yields, N rates, N efficiency and net returns do not differ between VRT and the FP due to variability in these physical factors were tested.

Results and discussion

All of the variables in the estimated models for lint yields, N rates, N efficiency and net returns had VIF values of less than five. Thus, the standard errors of the estimates are unlikely affected by multi-collinearity. The four statistical models were first estimated with only the N management treatments as covariates. Adding the landscape, soil and weather explanatory variables generated better fitting models. Notably, the treatment effects for the base and augmented interaction models were unchanged when these additional covariates were included.

Lint yields

The lint yield regression had a better fit based on the AIC and BIC criterion when the location × treatment random effect was included (Table 3). However, the model with the interaction random effect did not indicate significant treatment effects. There were no differences in either VRT 1 or VRT 2 versus the FP when lint yields for each treatment were averaged across the 21 fields (Table 4). A contrast comparison of the treatment performance across farms also indicated that VRT 1 or VRT 2 lint yields were not significantly different from the FP on any of the 21 fields in the project (Table 5). Results indicate that lower N rates relative to the FP would need to be the driver of the profitability of VRT rather than lint yields for the 21 project fields.

Soil and weather attributes significantly affected lint yield (Table 6). All else equal, soils with coarser soil textures, greater available water capacity, more organic matter or a deeper profile were positively correlated with lint yields. Layers of soil below the surface are typically more fertile, with more organic matter and N available to the plant (Tiessen et al. 1994), thereby potentially increasing yields. Field locations with higher elevations and fields in locations accumulating more growing degree days were negatively associated with lint yields.

N rates

The N rate regression that included the location × treatment random effect had lower AIC and BIC scores than the model without the interaction random effect (Table 3). Dunnett’s tests from the model that included the interaction random effect indicated that the two VRT treatments were not significantly different from the FP treatment (Table 4). However, contrast results indicated that VRT N rates relative to the FP were lower on four fields and higher on four fields (Table 3). The VRT 1 and VRT 2 treatments produced significantly lower applied N rates in Middle Tensas Parish, Louisiana, Gibson County, Tennessee and Lauderdale County, Tennessee. The Northern Leflore County, Mississippi, location had lower N rates than the FP for only VRT 1. The northern and southern locations in Tensas Parish, Louisiana and Northern Madison County, Tennessee had estimated N rates that were significantly lower using the FP than either VRT 1 or VRT 2. Adams County, Mississippi, experienced lower N rates with FP than VRT 2 (Table 5).

The results were ambiguous with respect to N rates determined with VRT or the FP. This finding suggests that optical sensing of the plant canopy is associated with landscape, soils and weather attributes of fields. Organic matter significantly explained N rates (P < 0.10) (Table 6), supporting the proposition that optical sensing of the plant canopy was associated with low (high) organic matter areas in the field and applied more (less) N to the soil. All else equal, soils that were more erodible or field locations that had warmer temperatures were positively associated with N rates. Warmer temperatures may be associated with higher applied N losses to the environment (Alva et al. 2006) and therefore may require more applied N. Soils more susceptible to erosion and may also require more applied N. Holding other factors constant, field elevation and soil texture were negatively related to N rates.

On average, farm fields requiring significantly higher VRT N rates relative to FP were located at lower elevations, had higher SEI, higher percentages of organic matter, deeper soils and warmer temperatures (Table 7). Fields requiring significantly lower N rates using VRT compared to the FP were, on average, situated at higher elevations, had lower SEI indexes, lower available water capacity, lower organic matter, shallower soils and cooler temperatures.

N efficiency

As with the lint yield and N rate regressions, including the location × treatment random effect improved model fit (Table 3). Dunnett’s tests from the model with the interaction random effect indicated that N efficiency averaged across the 21 fields was not significantly different between the VRT treatments and the FP (Table 4). Contrast results for the mean treatment differences at the field level indicated significantly higher N efficiency for the FP than either of the VRT treatments in northern Tensas Parish, Louisiana, Adams County, Mississippi and northern Madison County, Tennessee (Table 5). These three fields had increased N efficiency with the FP than with VRT. No farm fields exhibited a higher N efficiency with VRT when compared to the FP.

Elevation, soil texture, available water capacity, organic matter, soil depth and growing degree days significantly affected N efficiency (Table 6). Fields located at higher elevations, with greater available water capacity, or had warmer temperatures, ceteris paribus, were negatively associated with lower N efficiency scores. Fields with a coarser soil texture, a higher organic matter or deeper soils had higher positive effects on N efficiency. All else equal, coarser soils in reference to sand promoted more efficient use of N. Soils with relatively more organic matter, coarser soil textures or deeper soils were associated with N rates low enough to increase N efficiency. Holding other factors constant, high elevation fields with greater available water capacity or warmer average days had lower calculated N efficiency. Soils with these conditions may have higher tendencies for erosion, and therefore may require more N fertilizer.

Profitability

The best fitting net returns model based on the AIC and BIC scores included the location × treatment random effect (Table 3). Results from the model estimated with the interaction random effect indicated that average net returns across the 21 project fields were different between VRT treatments and the FP (P < 0.10; Table 4). Estimating the difference between treatments at the field level, however, indicated no treatment differences (Table 5). The above-mentioned lint yield results indicated no yield gain with VRT and that lower N rates determine profitability of VRT. On the four fields where VRT N rates were lower than the FP, cost-share payments from USDA NRCS EQIP, coupled with N rate reductions ranging from 14 kg ha−1 (Middle Tensas Parish, Louisiana) to 31 kg ha−1 (Northern Leflore County, Mississippi), were insufficient to cover the additional information and application costs and provide higher net returns. VRT N rates were unchanged or higher relative to the FP on the other 17 fields in the project.

All else equal, coarser soil textures, soils with higher organic matter and deeper soils were positively associated with yields and, in turn, net returns (Table 6). The significant and positive soil texture estimates indicates that coarser soil textures had a positive effect on net returns. Greater available water capacity was negatively associated with net returns. In the same respect, fields at higher elevations or that were warmer had lower lint yields and profits.

Conclusions

This research determined the lint yields, N fertilization rates, N efficiency and profitability of using OPM-based VRT to manage spatial variability in cotton production using data from 21 farm field trials in Louisiana, Mississippi, Missouri and Tennessee. OPM and VRT N management indicated some potential for N savings but were not more profitable at the field level than existing FP N management. Three additional inferred conclusions may aid in farmers’ decisions about precision N management. First, VRT may not apply enough N to significantly increase yields relative to the FP. Second, changes in the N rate for VRT relative to the FP were field/farm specific. Four locations (Tensas Middle, LA, Gibson, TN, Lauderdale, TN and Leflore, MS) realized lower N rates applied in at least one form of VRT N application. Four locations had higher N rates with OPM and VRT (Madison North, TN, Adams, MS, Tensas North, LA and Tensas South, LA). Finally, the N rates across the 21 project fields were not low enough to increase N efficiency. Even though the fields in the project represented a range of soils, landscapes and weather, there was likely not enough spatial variability within the fields that VRT N management did not make a difference in field level net returns.

References

AAEA. (2000). Commodity costs and returns estimation handbook: A report of the AAEA task force on commodity costs and returns. Ames, IA, USA.

Alva, A. K., Paramasivam, S., Fares, A., Delgado, J. A., Mattos, D., Jr., & Sajwan, K. (2006). Nitrogen and irrigation management practices to improve nitrogen uptake efficiency and minimize leaching losses. Journal of Crop Improvement, 15, 369–420.

Arnall, D. B., Abit, M. J. M., Taylor, R. K., & Raun, W. R. (2016). Development of an NDVI-based nitrogen rate calculator for cotton. Crop Science, 56, 3263–3271.

ASABE. (2011). Agricultural machinery management data. ASAE D497.7. St. Joseph, MI, USA: American Society of Agricultural and Biological Engineers.

Biermacher, J. T., Brorsen, B. W., Epplin, F. M., Solie, J. B., & Raun, W. R. (2009a). The economic potential of precision nitrogen application with wheat based on plant sensing. Agricultural Economics, 40, 397–407.

Biermacher, J. T., Brorsen, B. W., Epplin, F. M., Solie, J. B., & Raun, W. R. (2009b). Economic feasibility of site-specific optical sensing for managing nitrogen fertilizer for growing wheat. Precision Agriculture, 10, 213–230.

Biermacher, J. T., Epplin, F. M., Brorsen, B. W., Solie, J. B., & Raun, W. R. (2006). Maximum benefit of a precise nitrogen application system for wheat. Precision Agriculture, 7, 193–204.

Boyer, C. N., Brorsen, B. W., Solie, J. B., & Raun, W. R. (2011). Profitability of variable rate nitrogen application in wheat production. Precision Agriculture, 12, 473–487.

Butchee, K. S., May, J., & Arnall, B. (2011). Sensor based nitrogen management reduced nitrogen and maintained yield. Crop Management, 10(1).

Casella, G., & Berger, R. L. (1990). Statistical inference. Pacific Grove, CA, USA: Duxbury.

Cassman, K. G., Gines, G. C., Dizon, M. A., Samson, M. I., & Alcantara, J. M. (1996). Nitrogen-use efficiency in tropical lowland rice systems: Contributions from indigenous and applied nitrogen. Field Crops Research, 47, 1–12.

Cassman, K. G., Peng, S., Olk, D. C., Ladha, J. K., Reichardt, W., Dobermann, A., et al. (1998). Opportunities for increased nitrogen-use efficiency from improved resource management in irrigated rice systems. Field Crops Research, 56, 7–39.

Griffin, T. W., Barnes, E. M., Allen, P. A., Andrade-Sánchez, P., Arnall, D. B., Balkcom, K., et al. (2014). Pooled analysis of combined primary data across multiple states and investigators for the development of a NDVI-based on-the-go nitrogen application algorithm for cotton. ASABE Paper No. 141900279. St Joseph, MI, USA: American Society of Agricultural and Biological Engineers.

Larson, J. A., Mooney, D. F., Roberts, R. K., & English, B. C. (2010). A computer decision aid for the cotton precision agriculture investment decision. In R. Khosla (Ed.), Proceedings of the 10th international conference on precision agriculture. Monticello, IL, USA: ISPA. Retrieved August 15, 2018, from https://www.ispag.org/proceedings/?action=year_abstracts.

Letner, M., & Bishop, T. (1993). Experimental design and analysis. Blacksburg, VA, USA: Valley Book Company.

Littell, R. C., Milliken, G. A., Stroup, W. W., Wolfinger, R. D., & Schabenberger, O. (2006). SAS ® for mixed models (2nd ed.). Cary, NC, USA: SAS Institute Inc.

Mooney, D. F., Roberts, R. K., English, B. C., Lambert, D. M., Larson, J. A., Velandia, M., et al. (2010). Precision farming by cotton producers in twelve southern states: Results from the 2009 southern cotton precision farming survey. Research Report 10-02. Department of Agricultural & Resource Economics, The University of Tennessee, Knoxville, USA.

Ortiz-Monasterio, J. I., & Raun, W. R. (2007). Reduced nitrogen and improved farm income for irrigated spring wheat in the Yaqui Valley, Mexico, using sensor based nitrogen management. Journal of Agricultural Science, 145, 1–8.

PRISM, Climate Group. (2014). Northwest alliance for computational science & engineering. Oregon State University. Retrieved August 15, 2018, from http://www.prism.oregonstate.edu/recent/.

Raun, W. R., Solie, J. B., Johnson, G. V., Stone, M. L., Mullen, R. W., Freeman, K. W., et al. (2002). Improving nitrogen use efficiency in cereal grain production with optical sensing and variable rate application. Agronomy Journal, 94, 815–820.

Raun, W. R., Solie, J. B., Stone, M. L., Martin, K. L., Freeman, K. W., Mullen, R. W., et al. (2005). Optical sensor-based algorithm for crop nitrogen fertilization. Communications in Soil Science and Plant Analysis, 36, 2759–2781.

Schabenberger, O., & Pierce, F. J. (2002). Contemporary statistical models for the plant and soil sciences. Boca Raton, FL, USA: CRC Press LLCC.

Scharf, P. C., Shannon, D. K., Palm, H. L., Sudduth, K. A., Drummond, S. T., Kitchen, N. R., et al. (2011). Sensor-based nitrogen applications out-performed producer-chosen rates for corn in on-farm demonstrations. Agronomy Journal, 103, 1683–1691.

Tiessen, H., Cuevas, E., & Chacon, P. (1994). The role of soil organic matter in sustaining soil fertility. Nature, 371, 783–785.

U.S. Department of Agriculture (USDA). (2012). Census of agriculture. 2012 Census Volume 1, Chapter 1: State level data. Retrieved August 15, 2018, from https://www.agcensus.usda.gov/Publications/2012/Full_Report/Census_by_State/.

U.S. Department of Agriculture (USDA). (2014a). Natural resources conservation service (NRCS). Environmental quality incentives program. Retrieved August 15, 2018, from http://www.nrcs.usda.gov/wps/portal/nrcs/main/national/programs/financial/eqip/.

U.S. Department of Agriculture (USDA). (2014b). Natural resources conservation service: Soils. SSURGO database. Retrieved August 15, 2018, from http://www.nrcs.usda.gov/wps/portal/nrcs/detail/soils/survey/?cid=nrcs142p2_053627.

U.S. Department of Agriculture (USDA). (2014c). National resources conservation service: Soils. Soil texture calculator. Retrieved August 15, 2018, from http://www.nrcs.usda.gov/wps/portal/nrcs/detail/soils/survey/?cid=nrcs142p2_054167.

U.S. Department of Agriculture (USDA). (2014d). Agricultural research service. Revised universal soil loss equation, version 2. Retrieved August 15, 2018, from http://fargo.nserl.purdue.edu/rusle2_dataweb/RUSLE2_Index.htm.

U.S. Department of Agriculture (USDA). (2014e). National agriculture statistics service. Cotton, price received, measured in $/lb. Retrieved August 15, 2018, from http://quickstats.nass.usda.gov/.

U.S. Department of Agriculture (USDA). (2014f). National agriculture statistics service. Nitrogen, price paid, measured in $/ton. Retrieved August 15, 2018, from http://quickstats.nass.usda.gov/.

U.S. Department of Agriculture (USDA). (2014g). National agriculture statistics service: Mississippi. 2014 Statewide EQIP practice, ranking and rate information. Retrieved August 15, 2018, from https://www.nrcs.usda.gov/wps/portal/nrcs/detail/ms/programs/financial/eqip/?cid=stelprdb1193441.

U.S. Department of Agriculture (USDA). (2017). Natural resources conservation service. Mississippi River Basin healthy watersheds initiative. Retrieved August 15, 2018, from http://www.nrcs.usda.gov/wps/portal/nrcs/detailfull/national/programs/initiatives/?cid=stelprdb1048200.

U.S. Department of Commerce. (2014). Bureau of economic analysis. Implicit price deflators for gross domestic product. NIPA Table 1.1.9.

U.S. Geological Survey. (2014). National elevation dataset: Metadata. Retrieved August 15, 2018, from https://nationalmap.gov/elevation.html.

Wright, D. L., Sprenkel, R. K., & Marois, J. J. (2015). Cotton growth and development. University of Florida IFAS extension. Retrieved August 15, 2018, from http://edis.ifas.ufl.edu/ag235.

Acknowledgements

This research was made possible with funding from USDA NRCS Conservation Innovation Grant Project No. 69-3A75-11-177, USDA Hatch Project TN TEN00442, and agricultural research institutions at Louisiana State University, Mississippi State University, University of Missouri, and University of Tennessee.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Stefanini, M., Larson, J.A., Lambert, D.M. et al. Effects of optical sensing based variable rate nitrogen management on yields, nitrogen use and profitability for cotton. Precision Agric 20, 591–610 (2019). https://doi.org/10.1007/s11119-018-9599-9

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11119-018-9599-9