Abstract

Purpose

Although the mechanical properties of paracetamol and MCC are extensively described in literature, there still is a need for a better understanding of the material properties impacting them. Thus, this study systematically analyzed material properties of paracetamol-MCC blends to elucidate their influence on the mechanical tablet properties in roller compaction and direct compression with special focus on surface properties.

Methods

Multiple material characteristics of binary mixtures of paracetamol and MCC with varying drug loads were analyzed, with particular emphasis on specific surface area and surface energy. Subsequently, mechanical tablet properties of the materials in direct compression and after roller compaction were examined.

Results

It was demonstrated that the impact of the initial material properties on mechanical tablet properties prevailed over the impact of processing route for paracetamol-MCC blends, underlining the importance of material characterization for tabletability of oral solid dosage forms. By applying bivariate as well as multivariate analysis, key material properties influencing the tabletability of paracetamol, MCC and its mixtures such as surface area, surface energy, effective angle of internal friction and density descriptors were identified.

Conclusions

This study highlighted the importance of comprehensive assessment of different material characteristics leading to a deeper understanding of underlying factors impacting mechanical tablet properties in direct compression and after roller compaction by the example of paracetamol-MCC mixtures with varying drug loads. Furthermore, it was shown that multivariate analysis could be a valuable extension to common bivariate analysis to reveal underlying correlations of material properties.

Graphical Abstract

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

In order to accelerate the drug product development, it is essential to understand the properties of the API and their impact on the processability of a formulation already at an early stage, as this enables a suitable formulation and a robust process to be established faster with lower API quantities. For oral solid dosage forms (OSD), a Manufacturing Classification System (MCS) was proposed as a tool to select feasible processing routes for an API depending on its powder and particle properties. It was illustrated how the systematic characterization of powder properties and identifying critical material attributes (CMAs) can lower the experimental burden and lead to robust formulation and process development in a time- and cost-efficient manner [1].

In the MCS, only the API’s properties are considered for the processability assessment, but the formulation of OSD drug products commonly consists to a large extent of excipients such as fillers, binders, flow additives or disintegrants, which impact the formulations’ processability as well. In this study, a systematic analysis of powder and particle characteristics of binary mixtures with varying drug load of paracetamol and microcrystalline cellulose (MCC) is presented to elucidate the impact of initial material properties on tabletability.

Paracetamol and MCC were explicitly chosen as they both exhibit a very different mechanical compression behavior which is representative for many pharmaceutical materials as paracetamol is a rather brittle and elastically deforming API with weak compression properties and MCC is as plastically deforming filler with strong tabletability.

According to the MCS, direct compression and roller compaction are the two processing routes with the lowest process complexity, yet with the highest requirements for the material characteristics compared to the other classes. In both, the material is exposed to mechanical stress, yet to a different extent. Furthermore, direct compression and roller compaction are both important processes for the continuous manufacturing of oral solid dosage forms [2,3,4,5]. For continuous manufacturing, a controlled process and thus a deep knowledge of the process and its critical impact factors is essential. In order to identify these impact factors and maintain a controlled process, it is therefore especially important for continuous manufacturing to acquire a thorough understanding of the properties of the materials in the process. Comparing the paracetamol-MCC powder system in direct compression and roller compaction in this study enabled a detailed analysis of the impact of the process on material properties and consequently how that affects the mechanical properties during tableting.

A study by Jeon and Betz demonstrated less tableting speed dependency but a decreased tablet tensile strength of paracetamol-MCC blends after roller compaction compared to direct compression, most likely due to loss in plasticity after roller compaction [6]. These results were partially opposed by a study from Tay, Han, Liew et al. where better tableting properties of neat paracetamol after roller compaction were attributed to a pre-breakage and partial amorphization during the roller compaction process [7]. Another study by Paul and Sun correlated a high capping tendency with increasing paracetamol drug load to its higher in-die elastic recovery and low tensile strength [8]. Although the mechanical properties of MCC and paracetamol are well described in literature, there still is a scientific gap in understanding the relationship between mechanical tablet properties in roller compaction and direct compression and initial powder properties. This has proven to be a complex topic as multiple powder and particle properties interact with each other and simultaneously impact mechanical tablet properties [9, 10]. Surface properties such as the specific surface area and surface energy are known to strongly impact processability as the mechanical properties are dependent on interparticle interactions during tableting [11,12,13]. Therefore, it is essential to analyze individual contributions of different powder properties, and especially surface properties, on tabletability to identify potential critical powder properties for mechanical tablet properties of PCM and MCC.

Thus, to the best of our knowledge, the present work is the first systematic analysis of material properties of paracetamol-MCC blends with focus on surface properties to elucidate their influence on the mechanical tablet properties in direct compression and roller compaction. By combination of bivariate and multivariate analysis of the impact of initial material properties on the tabletability of paracetamol-MCC powders and roller compacted materials, underlying correlations were revealed and potential key parameters identified.

Materials and Methods

Materials

Paracetamol (PCM) was acquired from Fagron Services (Rotterdam, Netherlands) and sieved through a 1.0 mm sieve using a Turbosieve BTS 100 (L.B. Bohle, Ennigerloh, Germany). Microcrystalline cellulose (MCC, Vivapur® 101) was supplied by JRS Pharma (Rosenberg, Germany). In addition to neat paracetamol and MCC, binary powder blends with 20%, 40%, 60% and 80% drug load were produced by blending at 12 rpm for 15 min.

Methods

Roller Compaction

Roller compaction of paracetamol, MCC and the blends was performed with a Mini-Pactor® (Gerteis, Rapperswil-Jona, Switzerland) using knurled rolls with a diameter of 25 cm and width of 2.5 cm. Process parameters were set to a specific compaction force (SCF) of 3 kN/cm, gap width of 3 mm and roll speed of 1.5 rpm. The Mini-Pactor® was equipped with an oscillating star rotor and a 1.0 mm sieve for ribbon granulation.

Roller compaction of neat paracetamol as well as neat MCC was additionally performed with 9 kN/cm specific compaction force whereas the other process settings were kept the same with a gap width of 3 mm and roll speed of 1.5 rpm.

Particle Size Distribution

Particle size distribution (PSD) of powders and roller compacted material was assessed by dynamic image analysis using the X-Jet module of the CamSizer X2® (Retsch GmbH, Haan, Germany) with a dispersing air pressure of 25 kPa. Measurement was conducted in triplicate and samples were divided with the sample splitter RT 12.5 (Retsch GmbH, Haan, Germany) before measurement.

Density

The bulk (ρb) and tapped (ρt) densities were determined with a Granupack™ (GranuTools, Awans, France) by applying 500 taps and a tapping frequency of 1 Hz. The initial volume (V0) and volume after tapping (Vt) of a powder sample of known mass (m) were obtained in a steel cylinder. Bulk and tapped density were calculated as m/V0 and m/Vt, respectively. Powders and roller compacted materials were measured in triplicate.

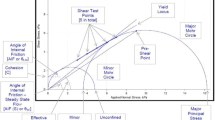

Effective Angle of Internal Friction and Flow Function Coefficient

The effective angle of internal friction (AIFe) and the flowability as the flow function coefficient (ffc) were determined by ring shear tester RST-XS (Dietmar Schulze Schüttgutmesstechnik, Wolfenbüttel, Germany) in triplicate. A normal preshear stress of 9000 Pa was applied and the samples were sheared at 1800, 4500 and 7200 Pa consolidation stress.

AIFe and ffc were evaluated according to Jenike [14] with the RSV 95 software (Dietmar Schulze Schüttgutmesstechnik, Wolfenbüttel, Germany) using straight line segments for regression.

Specific Surface Area & Surface Energy

Inverse gas chromatography was performed with the iGC-SEA (Surface Measurement Systems Ltd., Alperton, UK) to measure specific surface area (SSA) and surface energy (SE) of the powders and roller compacted materials. Data was analyzed with the SEA Analysis software (Surface Measurement Systems Ltd., Alperton, UK). A sample mass of approximately 500 mg was packed into silanized glass columns (3 mm inner diameter) and stoppered using silanized glass wool at both ends. Dead volume was determined by methane injections. Retention times of probe molecules and methane were determined using a flame ionization detector (FID). Samples were conditioned for 60 min at measurement settings of 30°C, 0% relative humidity and a 10 cm3/min nitrogen carrier gas flow.

SSA was calculated from the isotherm of physical adsorption of octane molecules onto the solid’s surface in the pressure range (p/p0) from 0.05 to 0.35 according to Brunauer–Emmett–Teller [15, 16].

Surface energy measurement was performed with the same sample columns, conditioning settings, temperature, relative humidity and nitrogen carrier gas flow as used for the SSA measurement.

According to Fowkes, the total SE (γt) can be divided into a dispersive and polar contribution [17]. The dispersive SE (γd) was determined with a series of alkanes, heptane, octane and nonane, according to the Dorris and Gray approach, where the contribution of a single methylene group (CH2) to the Gibbs free energy of adsorption (ΔG) is considered [18]. γd of a solid can therefore be calculated with the following equation.

with γCH2 as the surface energy of a methylene group, NA as the Avogadro constant, αCH2 as surface area of a methylene group, R as gas constant, T as the temperature and VN as the net retention volume of the alkanes with n + 1 and n carbon atoms.

Polar SE (γab) can be divided into a Lewis acid part (γabs+) and Lewis base part (γabs−).

Therefore, γab is determined with a Lewis acidic probe (chloroform) and a Lewis base probe (ethyl acetate) based on the polarization approach described by Dong, Brendlé and Donnet [19] and the Della Volpe scale [20, 21]. γab+ and γab− is calculated from the polar Gibbs free energy ΔGab of the two probes with

ΔGab is obtained in this approach by plotting RTlnVN versus the molar deformation polarization of the probes PD,

where Mm, r and ρl represent the molar mass of the molecules, the refractive index of the probe and the density of the probe.

Due to the precise injection volume of the iGC-SEA system, a distribution of SE as a function of different surface coverages can be determined. Ten surface coverages ranging from 0.015 to 0.2 n/nm were analyzed. SE values at 0.06 n/nm surface coverage are displayed in Table I given that the trends with drug load and between the two manufacturing processes are equal for all analyzed surface coverages.

Measurements were performed with n = 1, the relative standard deviation of the SE measurement was shown to be below 4% [22].

Scanning Electron Microscopy

Scanning electron microscopy (SEM) using a LEO Gemini 1530 (Carl Zeiss AG, Oberkochen, Germany) was performed with an acceleration voltage of 5.0 kV and 50 × magnification to analyze surface morphology of the materials. Samples were sputtered with a 10 nm platin coating before measurement to improve electron conductivity.

Tablet Compression

Powders and roller compacted materials were compressed using a Styl’One Evolution compaction simulator (Medelpharm, Beynost, France) with round, flat faced punches with a diameter of 11.28 mm and a default compression profile without precompression at 20% compression speed. 25 tablets per powder blend or roller compacted materials were produced at each compression stress (50, 100, 150, 200, 300 and 400 MPa). A sample mass of 400 mg per tablet was weighed by Quantos dosing system QB1 (Mettler Toledo, Columbus OH, USA) with a deviation < 1%. Powders were filled into the die manually.

Tablet Characterization

Weight, thickness, diameter and breaking force of the tablets (n = 10) were determined using a MultiCheck VI (Erweka GmbH, Langen, Germany) with a constant tablet breaking speed of 2 mm/s.

For neat PCM, the tablet breaking force was below the limit of detection of the MultiCheck and tablet diameter and breaking force were determined via Texture Analyzer TA.XTplus (Winopal GmbH, Elze, Germany) with a tablet breaking speed of 2 mm/s (n = 10). The comparability of the determined values from MultiCheck and Texture Analyzer were evaluated in advance. Further information on the settings of the Texture Analyzer and comparability of the measurements by the two devices can be found in Supplementary Material A1 and A2.

Tablet Tensile Strength

Diametral tablet tensile strength (TTS) was calculated according to Fell and Newton [23]:

with F as the tablet breaking force, d as tablet diameter and t as tablet thickness.

Tablet Solid Fraction

Tablet solid fraction (SF) describes the non-porous part of the tablet and was calculated using the following equation with the tablet mass (m) and pycnometric density of the samples (ρp). Pycnometric density data is given in Supplementary Material A3.

Elastic Recovery

In-die compression analysis was performed using the applied compression forces and punch displacement data (n = 10). Elastic machine deformation was considered.

Total work of compaction (TWC) was defined as the integral of the force (F) over the distance (dD) covered between the compact height at start of the force application (D(0)) and at maximum force (D(Fmax)) according to Çelik and Marshall [24].

Elastic recovery work (ERW) was determined by the integral of the force (F) over the distance (D) covered between compact height at maximum force (D(Fmax)) and compact height reached at the end of the compression force (D(end)).

With ERW to TWC the percentage ratio ER (%) was calculated as

Partial Least Square Regression

Partial least square regression (PLS) was applied for a multivariate analysis of the impact of characteristics of powders and roller compacted materials on the material’s tabletability. PLS was performed with the Unscambler X 10.5.1. software (Camo software inc., Magnolia, USA). The material properties from Table I were used as input parameters and TTS at 50, 100, 200, 300 and 400 MPa were used as response parameters for PLS. All input and result parameters were mean centered and unit variance scaled before partial least square regression. The powders and respective roller compacted materials of neat MCC, neat paracetamol and the binary blends with 20%, 40%, 60% and 80% drug load were included in the model. The NIPALS algorithm with a maximum of 100 iterations was applied. For internal validation of the created PLS model, a full cross validation was performed.

To compare the 3 kN/cm and 9 kN/cm roller compacted material, additional partial least square regression models with only neat MCC and PCM powder and 3 kN/cm roller compacted material as well as neat MCC and PCM powder and 9 kN/cm roller compacted material were created. Except for the use of TTS at only 100, 200 and 400 MPa as response parameter, the two models were generated in accordance with the description given above. The correlation loadings plots and weighted regression coefficients of these models can be found in the supplementary material B5-B8.

Results and Discussion

Material Characterization of Powders and Roller Compacted Materials

Particle size distribution, bulk and tapped density, ffc, the effective angle of internal friction, SSA and dispersive, polar and total surface energy of the powders and roller compacted materials with varying paracetamol content are displayed in Table I.

Roller compaction is a process often used for particle size enlargement. This could also be observed for neat MCC as roller compacted material displayed a much larger particle size than the powders. However, the difference in particle size between powder and roller compacted materials decreased with increasing drug load. In the materials with drug loads larger than 40% the powders even demonstrated larger particle size than the respective roller compacted material. An explanation was found in the well-known weak compaction properties of the thermodynamically stable and therefore commercially available polymorph I of paracetamol [25]. Roller compaction of neat paracetamol did not lead to the formation of stable granules, which is why rather the term roller compacted material than granules was used in this study. Due to its weak compaction properties, neat paracetamol was rather milled by the compaction process than granulated, which led to smaller particle size after roller compaction compared to the initial paracetamol powder. This was further supported by SEM imaging of the neat materials before and after roller compaction (Fig. 1), as much smaller particles and fractured areas were visible in paracetamol after roller compaction. Therefore, neat paracetamol represented a special case in the correlations of powder properties before and after roller compaction and mechanical characteristics.

The bulk and tapped density increased with drug load for powders as well as roller compacted materials. Roller compaction led to an increase in density for samples with drug load below 40% paracetamol but to a decrease in density for drug loads above 40% paracetamol compared to the powders. This was in alignment with the change in particle size distribution of the powders and respective roller compacted materials. In the blends with low paracetamol content, compacted granules were produced leading to higher densities than in the respective powders. Opposed to that, with increasing paracetamol drug load the amount of grinded and fractured particles after roller compaction increased, potentially leading to more interlocking of the particles during pouring or tapping and therefore to lower densities compared to the powders.

The SSA decreased with increasing drug load for powders as well as roller compacted materials as MCC demonstrated the highest SSA and neat paracetamol the lowest SSA. Comparing powders with respective roller compacted materials it was shown that, despite differences in particle size, the specific surface area of the materials was not strongly impacted by roller compaction except for paracetamol. With a roller compaction force of 3 kN/cm a relatively high porosity of the roller compacted particles could be expected for MCC and the blends with still intact structures of the primary particles in the roller compacted agglomerates and thus comparable SSA values for the material before and after roller compaction. This was also shown in previous studies [26]. As mentioned above, neat paracetamol represented a special case as the material was rather milled than granulated by the roller compaction process and therefore no porous granules were formed from primary particles. The resulting size reduction led therefore in this case to an increase in surface area compared to the neat paracetamol powder.

The polar, dispersive and total SE decreased with increasing drug load for the powders whereas in the roller compacted materials, the decrease with drug load is only minor for the polar and total SE, which could be explained as compensation by the increase in polar SE of neat PCM after roller compaction. As seen in the SSA, the biggest difference in SE between powder and roller compacted materials was seen in neat paracetamol, where the polar and consequently the total SE increased from powder to roller compacted material. This was likely a result of the fracturing of the paracetamol particles during roller compaction due to exposure of more polar high energy facets from paracetamol particle breakage at the weakest attachment energy plane. This would lead to more polar interaction consequently leading to higher polar surface energy [27, 28].

The effective angle of internal friction (AIFe) is a measure for the internal friction in steady-state flow and is dependent among other things on friction and adhesive and cohesive forces between particles. Therefore, it can be an indicator for interparticle interactions [29]. AIFe decreased with increasing drug load for powders, which could also be seen in the roller compacted material but to a much lower extent. For neat MCC and the binary blends no difference in AIFe was seen between powder and respective roller compacted material and a similar trend for powder and respective roller compacted materials was also observed for the surface properties.

For neat paracetamol however, AIFe increased from powder to roller compacted material, which again was also seen for SSA and total SE. Consequently, the span in AIFe values as well as SSA and γt in the powders was larger than in the roller compacted materials. A larger SSA and higher SE due to milling of PCM during roller compaction likely increased the friction and adhesive-cohesive forces leading to higher AIFe in the roller compacted material compared to the PCM powder. Therefore, milling of PCM during roller compaction highlighted the relationship between cohesive-adhesive forces and surface properties such as SSA and SE.

The powders and roller compacted materials were easy flowing and neat paracetamol powder was even classified as free flowing. In the powders, ffc increased with drug load whereas the roller compacted materials demonstrated comparable flowability. Roller compaction did not improve flowability and even decreased flowability for samples with high paracetamol content. The smaller particle size and higher SSA of the grinded paracetamol after roller compaction leading to higher interparticle interactions would be an explanation for the worsened flowability after roller compaction, and in addition, also for the lower bulk and tapped density. However, one would have expected an improvement in the ffc of neat MCC and the low drug load blends due to the particle size enlargement after roller compaction. The comparable or reduced flowability of roller compacted MCC and low drug load blends compared to the powders therefore highlighted that flowability is not only dependent on particle size but must be impacted by multiple factors such as the particle shape and surface roughness. Consequently, roller compaction does not improve flowability due to particle size enlargement in all cases as multiple factors impact flow.

It is noteworthy that in most of the investigated material characteristics, trends observed with drug load evident in the powder transferred to the roller compacted materials as well such as in the bulk and tapped density, SSA, and AIFe and MCC properties often dominated the properties of the blends. Thus, although these findings are attributed to only one binary powder system and have to be validated by more API-excipient combinations, this systematic analysis of the PCM-MCC binary system already highlights the importance of initial material properties for formulation and the selection of excipients with beneficial attributes for the respective API. Comparing initial powders and roller compacted materials furthermore enables a systematic comparison of direct compression and roller compaction.

Manufacturability of Tablets

Mechanical Tablet Properties

Tablet tensile strength decreased with increasing drug load for powders and roller compacted materials (Fig. 2). Already small amounts of MCC strongly impacted the blend properties and improved tabletability of paracetamol-MCC blends as neat paracetamol did not generate tablets with a sufficient TTS of > 1 MPa for further processing [30], which highlights the importance of excipient characterization and the impact of excipients on the mechanical properties of a formulation. Comparing the mechanical tablet properties in the two processing routes direct compression and roller compaction, it became apparent that powders and respective roller compacted materials have comparable tabletability (TTS vs. compression pressure) for all drug loads and only a slight loss in tabletability was seen in Fig. 2. As a loss in tabletability due to roller compaction is strongly dependent on roller compaction force [31, 32], the comparable tablet properties of powder and respective roller compacted material can mainly be explained by the relatively low compaction force. The lower compaction force of 3 kN/cm was chosen as a compromise of representative process settings for the plastically deforming, strongly compressible MCC [33,34,35,36] and the prevention of amorphization of brittle, weakly compressible paracetamol at higher compaction pressures indicated by Jeon et al. and Tay et al. [6, 7] (Supplementary material A4). However, despite demonstrating comparable tabletability between powder and respective roller compacted material, there still was an effect of the roller compaction process detected for multiple material properties, as described in 3.1 and shown in Table I. Furthermore, neat PCM and MCC were additionally roller compacted at higher specific roller compaction forces of 9 kN/cm to validate that the conclusions of this study are as well applicable at higher roller compaction forces. The material characteristics and mechanical tablet properties of the 9 kN/cm roller compacted material are shown and discussed in detail in the supplementary material B1-B4.

A comparable tablet porosity for powders and their respective roller compacted materials was shown by their compactability plots (Supplementary material A5). It was shown that SF slightly increased with increasing drug load with the exception of neat PCM in both processes. The ER (%) at one lower (100 MPa), one medium (200 MPa) and one higher (400 MPa) compression pressure is exemplarily displayed in Fig. 3 as the same trends were observed for all compression pressures except for 400 MPa. With increasing drug load, ER% increased with drug load in both processes as neat MCC has the lowest and neat PCM the highest ER% values. High ER% is often associated with tablet defects which again illustrated the weak compaction properties of paracetamol and the improvement of its mechanical tablet properties by already small amounts of excipient. In contrast to neat paracetamol, neat MCC and the blends did not demonstrate differences in powder and respective roller compacted material in the ER (%), again supporting the similar mechanical behavior of the materials in direct compression and roller compaction despite differences in PSD and density. Neat PCM had the highest ER% in powders and roller compacted materials highlighting its strong elastic deformation. PCM powder demonstrated slightly higher ER (%) than the roller compacted material at 400 MPa compression pressures. In contrast to MCC, paracetamol mechanical properties were not sufficient to form stable granules in roller compaction, nevertheless similar trends before and after roller compaction became apparent for the two materials. For both, paracetamol and MCC, tableting properties were similar before and after roller compaction whereas in the material characterization, differences before and after roller compaction were visible for paracetamol and MCC.

Multivariate Data Analysis

A multivariate analysis of the material properties and tabletability of the PCM-MCC powders and roller compacted materials was performed to identify material properties impacting the tabletability and to reveal underlying correlations. Partial least square regression is a commonly used multivariate analysis method to reduce dimensionality and determine correlations between input (material characteristics) and response (tabletability) parameters. In a correlation loadings plot, input parameters that are closely located to the responses are positively correlated to them and input parameters that are located on the opposite direction are negatively correlated to the responses. Figure 4 shows the correlation loadings plot of factor 1 and 2, which together explained 93% of the variance in the tablet tensile strength data of the PCM-MCC powders and roller compacted materials. A strong negative correlation of the bulk and tapped density with the tablet tensile strengths at different compression pressures is displayed in Fig. 4 as well as a positive correlation of the tablet tensile strengths with SSA, the effective angle of internal friction and also the surface energy, especially the dispersive surface energy. Thus, the multivariate PLS regression indicates SSA, AIFe, γd as well as bulk and tapped density as potential key parameters for tabletability of PCM, MCC and their blends, which is as well shown by the weighted regression coefficients of the PLS regression model in Fig. 5. In addition, the flow properties and particle size did not show a correlation to TTS in the PLS regression.

Process Routes

A positive correlation of SSA as well as AIFe was shown in the PLS model. Powder and respective roller compacted material had similar AIFe and SSA values except for neat PCM, which indicated comparable interparticle forces and bonding area during tablet compression between powders and roller compacted materials, leading to similar mechanical tablet properties such as the tablet tensile strength. This was also supported by the SSA-TTS plots (Fig. 6) illustrating a similar strong correlation between specific surface area and tablet tensile strength in direct compression and roller compaction. Linear regression for SSA and TTS exemplary at 100 and 400 MPa displayed R2 values of 0.91 and 0.95 and residual sum of squares (RSS) of 1.73 and 3.93 for the powders. R2 values of 0.87 and 0.93 and RSS of 2.06 and 6.10 were calculated for the roller compacted materials. Although neat PCM demonstrated an increase in SSA after roller compaction due to the above described grinding, no improvement in tabletability is seen for the roller compacted PCM as SSA was still low with 0.19 m2/g.

The PLS model illustrated a positive correlation for the surface energy, especially the dispersive surface energy, and tablet tensile strength, which can be explained by the direct relation of the surface energy to the work of cohesion and adhesion. The dispersive surface energy had a strong correlation in the PLS model to TTS as similar dispersive surface energy was shown for powder and respective roller compacted material comparable to what was seen in TTS for powder and respective roller compacted material. However, the polar and consequently the total SE of neat PCM increased after roller compaction, whereas for neat MCC and 20% PCM the total SE decreased slightly after roller compaction leading to only minor differences in polar and total SE values between neat PCM and neat MCC after roller compaction. Thus, the correlation of surface energy and TTS, which was shown in the PLS, was as well detectable in the bivariate evaluation (Fig. 7) for the powders but was not as explicitly shown for the roller compacted materials in Fig. 7. Therefore, the PLS model revealed a correlation of surface energy and TTS that would not be as explicitly apparent in the bivariate data evaluation which highlights that multivariate analysis could be a valuable extension to bivariate data analysis. Further, the additional PLS models of neat PCM and MCC powder and 3 kN/cm SCF as well as neat PCM and MCC powder and 9 kN/cm SCF (Supplementary material B5-B8) displayed the same correlations and important material characteristics for tabletability in supplementary material B5-B8, supporting that the identified potential key parameters for tabletability of PCM and MCC in this study are valid for direct compression as well as roller compaction.

In addition, the opposing trends in particle size for powder and respective roller compacted material did not transfer into the tablet properties,

Drug Load

The SSA, AIFe and dispersive SE of the powders and roller compacted materials displayed a decreasing trend with increasing drug load as seen in the mechanical tablet properties. This supports the hypothesis that lower adhesive and cohesive forces result in lower tabletability as visualized in the PLS correlation loadings plot (Fig. 4) and Fig. 6. A negative correlation between TTS and density descriptors was revealed in the PLS regression. In bulk and tapped density, an opposing trend to the mechanical tablet properties was demonstrated as with increasing drug load the powder and roller compacted material densities decreased. A negative correlation for bulk density and TTS could be the result of possibly less interparticle interactions due to a decreased degree of deformation during compression at higher bulk density due to less porosity in the powder bed [37, 38]. This is in alignment with the indicated decreasing interparticle interaction due to decreasing SSA, AIFe and decreasing dispersive SE with increasing drug load.

The particle size distribution did not demonstrate a correlation to the mechanical tablet properties as PSD increased with drug load in the powders and decreased with drug load in the roller compacted material yet the same trends in processability were seen with drug load for both process routes, demonstrating that although particle size impacted powder properties such as flowability of the roller compacted material, mechanical tableting properties in this case are predominated by other properties than the PSD, which are rather inherent material properties than bulk properties.

The effects of initial material properties on mechanical tablet properties are complex and codependent and the combination of bivariate analysis as well as a multivariate data analysis approach allowed for a deeper understanding of potential critical properties and exposure of underlying correlations between initial material properties and tabletability.

The results obtained in this study are valid for the PCM-MCC system solely and further materials with a broad variety of properties as well as more combinations of APIs and excipients would need to be analyzed to expand the conclusions from this study and to gain more general validity. However, it is a very important foundation to initially understand effects on mechanical tablet properties in binary systems to then be able to systematically examine which can be generalized and transferred to more complex formulations.

Conclusion

To elucidate the impact of powder properties on the mechanical tablet properties, paracetamol, MCC and binary blends thereof were systematically analyzed and compared in two processing routes, direct compression as well as roller compaction (3 kN/cm and 9 kN/cm SCF). Density descriptors, surface properties such as surface area and surface energy and other indicators of interparticle interaction such as the effective angle of internal friction were identified in bivariate as well as multivariate data analysis as potential key parameters for the tabletability of MCC and paracetamol in direct compression as well as roller compaction. It became evident, that individual material properties alone are not sufficient to describe the complete processability of a powder and that a more holistic approach such as multivariate data analysis is beneficial to reveal underlying correlations and to better understand the multicollinearities of material properties impacting tabletability. More materials need to be analyzed in subsequent experiments to provide general validity to the results obtained in this study.

Data Availability

All data supporting the findings of this study are available within the paper and its Supplementary Material A and B.

References

Leane M, Pitt K, Reynolds G, Anwar J, Charlton S, Crean A, et al. A proposal for a drug product Manufacturing Classification System (MCS) for oral solid dosage forms. Pharm Dev Technol. 2015;20:12–21.

Barjat H, Checkley S, Chitu T, Dawson N, Farshchi A, Ferreira A, et al. Demonstration of the Feasibility of Predicting the Flow of Pharmaceutically Relevant Powders from Particle and Bulk Physical Properties. J Pharm Innov. 2021;16:181–96.

Wilms A, Kleinebudde P. Towards better understanding of the influence of process parameters in roll compaction / dry granulation on throughput, ribbon microhardness and granule failure load. Int J Pharm X. 2020;2(November):100059. https://doi.org/10.1016/j.ijpx.2020.100059.

Razavi SM, Scicolone J, Snee RD, Kumar A, Bertels J, Cappuyns P, et al. Prediction of tablet weight variability in continuous manufacturing. Int J Pharm. 2020;575:118727. https://doi.org/10.1016/j.ijpharm.2019.118727.

Van Snick B, Holman J, Vanhoorne V, Kumar A, De Beer T, Remon JP, et al. Development of a continuous direct compression platform for low-dose drug products. Int J Pharm. 2017;529(1–2):329–46. https://doi.org/10.1016/j.ijpharm.2017.07.003.

Jeon I, Betz G. Roll compaction as a dry granulation method for paracetamol. J Drug Deliv Sci Technol. 2011;21(3):257–62. https://doi.org/10.1016/S1773-2247(11)50035-8.

Tay JYS, Han QE, Liew CV, Sia Heng PW. Investigation on the effect of roller compaction on paracetamol. Pharm Dev Technol. 2020;25(1):100–6. https://doi.org/10.1080/10837450.2019.1676783.

Paul S, Sun CC. Gaining insight into tablet capping tendency from compaction simulation. Int J Pharm. 2017;524(1–2):111–20. https://doi.org/10.1016/j.ijpharm.2017.03.073.

Mangal S, Meiser F, Tan G, Gengenbach T, DA Morton V, Larson I. Applying surface energy derived cohesive – adhesive balance model in predicting the mixing, flow and compaction behaviour of interactive mixtures. Eur J Pharm Biopharm. 2016;104:110–6. https://doi.org/10.1016/j.ejpb.2016.04.021.

Wünsch I, Finke JH, John E, Juhnke M, Kwade A. Influence of the drug deformation behaviour on the predictability of compressibility and compactibility of binary mixtures. Int J Pharm. 2022;122117. https://doi.org/10.1016/j.ijpharm.2022.122117.

Sun CC. Decoding powder tabletability: Roles of particle adhesion and plasticity. J Adhes Sci Technol. 2011;25(4–5):483–99.

Fichtner F, Mahlin D, Welch K, Gaisford S, Alderborn G. Effect of Surface Energy on Powder Compactibility. Pharm Res. 2008;25(12):2750–9.

El Gindy NA, Samaha MW. Tensile strength of some pharmaceutical compacts and their relation to surface free energy. Int J Pharm. 1983;3:35–46.

Jenike AW. Storage and flow of solids. Bull No123 Utah Eng Exp Stn. 1964;53(26):1–198.

Brunauer S, Emmett PH, Teller E. Adsorption of Gases in Multimolecular Layers. J Am Chem Soc. 1938;60(2):309–19.

Thielmann F, Burnett DJ, Heng JYY. Determination of the Surface Energy Distributions of Different Processed Lactose Determination of the Surface Energy Distributions. Drug Dev Ind Pharm. 2007;33(11):1240–53. https://doi.org/10.1080/03639040701378035.

Fowkes FM. Attractive Forces at Interfaces. Ind Eng Chem. 1964;56(12):40–52.

Dorris GM, Gray DG. Adsorption of n-alkanes at zero surface coverage on cellulose paper and wood fibers. J Colloid Interface Sci. 1980;77(2):353–62.

Dong S, Brendlé M, Donnet JB. Study of solid surface polarity by inverse gas chromatography at infinite dilution. Chromatographia. 1989;28(9–10):469–72.

Della Volpe C, Siboni S. Some reflections on acid-base solid surface free energy theories. J Colloid Interface Sci. 1997;195(1):121–36.

Della Volpe C, Siboni S. Acid – base surface free energies of solids and the definition of scales in the Good – van Oss – Chaudhury theory. J Adhes Sci Technol. 2000;14(2):235–72.

Reutenauer S. Reproducibility of the dispersive component of surface energy measured by inverse gas chromatography - part I. Surface Measurement Systems Ltd., technical note 801; 2002.

Fell JT, Newton JM. Determination of Tablet Strength by the Diametral-Compression Test. J Pharm Sci. 1970;59(5):688–91. https://doi.org/10.1002/jps.2600590523.

Celik M, Marshall K. Use of a compaction simulator system in tabletting research. Drug Dev Ind Pharm. 1989;15(5):759–800. Available from: https://www.academia.edu/41300485. Accessed 29 Oct 2021.

Joiris E, Di Martino P, Berneron C, Guyot-Hermann A-M, Guyot J-C. Compression Behavior of Orthorombic Paracetamol. Pharm Res. 1998;15(7):1122–30.

Herting MG, Kleinebudde P. Studies on the reduction of tensile strength of tablets after roll compaction / dry granulation. Eur J Pharm Sci. 2008;70:372–9.

Sunkersett MR, Grimsey IM, Doughty SW, Osborn JC, York P, Rowe RC. The changes in surface energetics with relative humidity of carbamazepine and paracetamol as measured by inverse gas chromatography. Eur J Pharm Sci. 2001;13:219–25.

Prasad KVR, Sheen DB, Sherwood JN. Fracture property studies of paracetamol single crystals using microindentation techniques. Pharm Res. 2001;18(6):867–72.

Mullarney MP, Hancock BC. Improving the Prediction of Exceptionally Poor Tableting Performance : An Investigation into Hiestand ’ s ‘“ Special Case”.’ J Pharm Sci. 2004;93(8):2017–21.

Pitt KG, Heasley MG. Determination of the tensile strength of elongated tablets. Powder Technol. 2013;238:169–75. https://doi.org/10.1016/j.powtec.2011.12.060.

Sun CC, Kleinebudde P. Mini review: Mechanisms to the loss of tabletability by dry granulation. Eur J Pharm Biopharm. 2016;106:9–14. https://doi.org/10.1016/j.ejpb.2016.04.003.

Skelbæk-Pedersen AL, Vilhelmsen TK, Rantanen J, Kleinebudde P. The relevance of granule fragmentation on reduced tabletability of granules from ductile or brittle materials produced by roll compaction/dry granulation. Int J Pharm. 2020;2021(592):120035. https://doi.org/10.1016/j.ijpharm.2020.120035.

Keizer HL, Kleinebudde P. Elastic recovery in roll compaction simulation. Int J Pharm. 2020;573:118810. https://doi.org/10.1016/j.ijpharm.2019.118810.

Nesarikar VV, Patel C, Early W, Vatsaraj N, Sprockel O, Jerzweski R. Roller compaction process development and scale up using Johanson model calibrated with instrumented roll data. Int J Pharm. 2012;436(1–2):486–507. https://doi.org/10.1016/j.ijpharm.2012.06.027.

Herting MG, Kleinebudde P. Roll compaction / dry granulation : Effect of raw material particle size on granule and tablet properties. Int J Pharm. 2007;338:110–8.

Csordas K, Wiedey R, Kleinebudde P. Impact of roll compaction design, process parameters, and material deformation behaviour on ribbon relative density. Drug Dev Ind Pharm. 2018;44(8):1295–306. https://doi.org/10.1080/03639045.2018.1446444.

Johansson B, Alderborn G. The effect of shape and porosity on the compression behaviour and tablet forming ability of granular materials formed from microcrystalline cellulose. Eur J Pharm Biopharm. 2001;52:347–57.

Nordström J, Alderborn G. Degree of compression as a potential process control tool of tablet tensile strength. Pharm Dev Technol. 2011;16(6):599–608.

Acknowledgements

The authors gratefully acknowledge Axel Becker and Anke Marx for providing analytical support in conducting the inverse gas chromatography measurements and the scientific discussion.

Funding

No funding was received for conducting this study.

Author information

Authors and Affiliations

Contributions

Lena Mareczek: Conceptualization, Investigation, Formal analysis, Writing – original draft. Carolin Riehl: Conceptualization, Supervision, Writing – review & editing. Meike Harms: Software, Writing – review & editing. Stephan Reichl: Conceptualization, Supervision, Writing – review & editing.

Corresponding author

Ethics declarations

Conflict of Interest

The authors have no financial or proprietary interests in any material discussed in this article.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Mareczek, L., Riehl, C., Harms, M. et al. Elucidating the Impact of Material Properties on Tablet Manufacturability for Binary Paracetamol Blends. Pharm Res 41, 185–197 (2024). https://doi.org/10.1007/s11095-023-03626-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11095-023-03626-6