An efficient synthesis of 21-acetoxypregna-1,4,9(11),16-tetraene-3,20-dione, a key intermediate in the synthesis of highly active fluorinated corticosteroids from phytosterols, was developed. The method consisted of an original sequence of chemical and microbiological reactions and could be used to synthesize betamethasone, sinaflan, triamcinolone, and other fluorinated corticoids.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

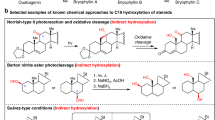

Syntheses of new steroidal compounds with high antiallergic and anti-inflammatory activity and simplification of preparation methods for known drugs of this class are critical problems and a promising direction in an area combining microbiological and chemical transformations of steroids. The goal of the present work was to develop an efficient synthetic method for dexamethasone from a phytosterol through the key intermediate 9α-hydroxyandrostenedione (9α-OH-AD, I), which was obtained by us earlier [1]. The path to preparing fluorinated steroid analogs from sterols was shortest and simplest if I was used because its 9α-OH group was easily dehydrated and allowed labor-intensive and uneconomical microbiological 11-hydroxylation to be avoided. Fluorinated corticosteroids were synthesized from I using a series of chemical and microbiological transformations that introduced the required modification into the steroid (Scheme 1).

Scheme. 1

According to the literature, the sequence of these processes could differ greatly. However, namely it and the selected methods for introducing the given functions determined the success of creating an economically efficient production technology. The reaction sequence was selected using methods for constructing pregnane and corticoid structures from androstenedione (AD) that were previously developed by us [2, 3]. The steroid functionalization sequence proposed by us included five steps, i.e., 1) dehydration of the 9α-OH to form a C9–C11 double bond; 2) construction of the pregnane side chain using the cyanohydrin version developed previously by us [2]; 3) addition of a dihydroxyacetone motif by sequential iodination and acetoxylation [3] to construct the corticosteroid structure; 4) introduction of the ring A C1–C2 double bond using an original culture of Pimelobacter simplex VKPM Ac-1632 [4]; and 5) introduction of the ring D 16,17-double bond via dehydration of the 17α-OH to produce the given tetraene structure.

Methods for dehydrating a 9α-OH group are rather widely described in the literature [5,6,7,8]. Mineral and organic acids and anhydrides and chlorides of mineral and organic acids are used as the dehydrating agents. The solvents are aromatic or chlorinated hydrocarbons, cyclic ethers, and organic bases. In several instances, the excess of water is removed to intensify the dehydration using azeotropic distillation with a Dean–Stark trap [9]. We used a variation of this method [5]. The reagents, reaction conditions, and a simple isolation method were carefully selected to achieve a stable high yield (>97% of theoretical) of 9(11)-dehydro derivative II and avoid formation of the undesired isomer androsta-4,8(9)-diene-3,17-dione, which was proven using PMR spectra. Possible undesired reactions involving tertiary C-9-OH could be avoided by performing the dehydration in the first synthetic step. The cyanohydrin method used to construct the pregnane chain was thoroughly elaborated by us for AD [2]. The method consisted essentially of the reaction of 17-ketosteroids with acetone cyanohydrin (ACCH) in the presence of a basic catalyst in lower aqueous alcohols at 35 – 38°C. Hydrocyanation of 17-ketosteroids did not occur stereoselectively and formed a mixture of epimeric 17β-cyano-and 17α-cyano derivatives despite the attractiveness of this method because the 17-ketone was selectively hydrocyanated [10]. However, the 17β-cyano-17α-OH isomer was needed for further chain growth.

The ratio of epimers was determined quantitatively by thermodynamic factors, e.g., differences in stability and solubility, and depended significantly on the structure of the starting ketosteroid, solution pH, and solvent. However, sufficiently high yields and minimal amounts of impurities could be attained by using the AD hydrocyanation conditions developed previously by us [2] with slight adjustments of the temperature regime and amounts of reagents. As a rule, the corresponding cyanohydrins that were protected beforehand at the reactive Δ4-3-keto- and 17α-OH groups [2] were reacted with methyllithium [11,12,13,14] or a Grignard reagent [12, 15] for further transformation into 20-ketopregnanes. A Grignard reagent was chosen because it would be less problematical for industrial use than alkylation of the nitrile by methyllithium, which requires the use of low temperatures (–30°C). The tertiary OH was protected using trimethylsilyl or tetrahydropyranyl ethers or acetal protection with alkylvinyl ethers [10, 12, 14]. The Δ4-3-ketone could be protected by forming the enol ether, ketal, or enamine [12]. Ethyleneketal protection was chosen for the Δ4-3-ketone considering the ketalization method developed previously by us [2] that uses trialkylorthoformate for chemical binding of water. Our previous studies showed that exceedingly forcing conditions were required for Grignard alkylation of nitriles in derivatives with 3-OH and 17-OH groups [15, 16]. Therefore, an attempt was made to carry out the Grignard reaction without protecting the 17-position. Furthermore, this would also shorten the multi-step synthesis. The alkylation was developed by reacting a mixture of isomeric Δ4- and Δ5-ketals with MeMgCl in anhydrous toluene in a stream of inert gas at 0 – 5°C for 1.5 h followed by decomposition of the chloromagnesium complex by aqueous NH4Cl solution and acid hydrolysis of the 20-imino- and 3,3-ethyleneketal groups to form 3- and 20-carbonyls. Preparation of V featured a Grignard reaction in slightly polar toluene in the presence of a small amount of THF that was bound in the MeMgCl complex. The dihydroxyacetone chain was introduced using the literature method [3]. In this instance, the Δ9(11)-double bond did not affect the reaction despite the fact that the 9,11-double bond was a reactive functional group, i.e., an additional reaction center. The Δ1-double bond was introduced into ring A using the method developed previously by us [4]. The microbiological dehydration step used an original culture of P. simplex with high 1,2-steroid dehydrogenase activity. As a rule, the strain exhibited high activity without using a solubilizer. However, the 9(11)-double bond and 21-acetate in VI complicated significantly bioconversion of the substrate and caused a slow transformation rate and incomplete conversion. This problem was solved by performing the 1,2-dehydrogenation in the presence of methyl-β-cyclodex-trin (MCD) with a 7.5:1 mass ratio to substrate. This increased the degree of bioconversion to 90 – 94% after incubation for 8 ± 1 h. The tetraene structure of IX was constructed further by adding the 16,17-double bond to ring D, which was necessary to functionalize the 16- and 17-positions of corticosteroids, using acetylation of the 17α-OH of triene VII followed by cleavage by HOAc to form the resulting diacetate VIII. The sterically hindered OH was esterified in acetic anhydride in the presence of CaO under reflux as before [17]. The Δ4-3-ketone was not affected under these conditions. Efficient elimination of 17α-acetoxy groups in pregnane-type compounds by treatment with anhydrous KOAc in DMSO at 80 – 85°C under an inert gas [18] was applied to our derivative to produce target product IX in high yield and purity that enabled it to be used without further purification to synthesize highly active fluorinated corticosteroids.

Melting points were measured in capillaries on an OptiMelt MPA-100 apparatus (USA). Optical rotation [α]D was measured on an Atago AP-300 instrument (Russia) at 20 ± 0.5°C in CHCl3 (c 1%). IR spectra were taken on an M-80 Specord spectrometer.

PMR spectra were recorded on a Unity+400 spectrometer (Varian) at operating frequency 400 MHz.

Experimental Part

Androsta-4,9(11)-diene-3,17-dione (II). A solution of I (40 g) in anhydrous CH2Cl2 (300 mL) at –4°C was treated with a solution of ClSO3H (14 mL) in CH2Cl2 (60 mL), stirred at from –3 to 0°C for 1 h 40 min, and treated dropwise with H2O (500 mL) at <15°C. The organic layer was separated. The aqueous layer was extracted with CH2Cl2. The combined extracts were washed with H2O and saturated NaCl solution until the pH was 7.0. The CH2Cl2 was vacuum evaporated. The residue was treated with hexane (70 mL) and cooled at 6 ± 2°C for 2 h. The precipitate was filtered off, rinsed with hexane, and dried to afford II (36.12 g, 96.95% of theoretical) containing ~2% total steroidal impurities including 0.5% of the starting steroid (TLC). mp 198 – 202°C, [α]D + 217° (c 1.0, CHCl3). Lit. mp 194 – 201°C, [α]D + 221° (CHCl3) [5]. PMR spectrum, ppm; CDCl3): 0.87 (s, 3H, 18-CH3); 1.35 (s, 3H, 19-CH3); 5.75 (d, H on C-4); 5.55 (m, H on C-11).

17α-Hydroxy-17β-cyanoandrosta-4,9(11)-dien-3-one (III). A mixture of II (20 g), MeOH (60 mL), H2O (2.5 mL), and ACCH (18 mL) was stirred and treated with NaOH in MeOH (9 mL, 1 N, pH 8.5 – 9.0). The suspension was heated to 35 ± 2°C and stirred for 1.5 h until II dissolved completely. Crystallization began after 10 – 20 min. The mixture was treated slowly with H2O (12 mL), stirred for 3 h at the same temperature, and left at 18 – 20°C for 21 h. The suspension was stirred, treated slowly over 1 h with H2O (55 mL), stirred for another 2 h, cooled to 0 ± 2°C, and held for 2 h at this temperature. The resulting precipitate was filtered off and rinsed with cold MeOH–H2O (1:1) and H2O until neutral. The aqueous MeOH mother liquor together with the rinsings were left for 1 d at room temperature (18 – 20°C). The resulting precipitate was filtered off and rinsed with MeOH–H2O (1:1) and H2O. The combined crystalline precipitates were dried to afford the product (20.6 g, 94% of theoretical), mp 218 – 220°C, [α]D + 115°, + 120° (c 1.0, CHCl3). (Lit. mp 211 – 220°C, [α]D +118° (c 1.0, CHCl3) mp 218 – 220°C, [α]D + 115°, + 120° (c 1.0, CHCl3). (Lit. mp 211 – 220°C, [α]D +118° (c 1.0, CHCl3) [19]. The content of the 17β-OH-17α-cyano isomer impurity was <1%. C20H25NO2 MM 311.42. PMR spectrum (δ, ppm; CDCl3): 0.94 (s, 3H,18-CH3), 1.35 (s, 3H, 19-CH3), 3.35 (m), 5.75 (m, 1H, 4-H), 5.57 (m, 1H, 11-H).

17α-Hydroxy-17β-cyano-3,3-ethylenedioxyandrosta-5,9(11)-diene (IV). A mixture of (CH2OH)2 (12 mL, 13.38 g) and anhydrous TsOH (0.24 g) was stirred; treated with III (12 g), CH2Cl2 (120 mL, 159.12 g), and HC(OCH3)3 (6 mL, 5.88 g); and stirred for 2 h at 22 ± 2°C. CH2Cl2 was distilled at atmospheric pressure until the volume was halved. The mixture was cooled to 20 ± 2°C, stirred, treated with Et3N (0.3 mL), washed with H2O, and evaporated to dryness. The residue was treated with MeOH (12 mL) and triturated. The suspension was cooled to 0 ± 2°C and stored for 6 h. The precipitate was filtered off, rinsed with cold MeOH, and dried to afford IV (12.32 g, 90% of theoretical) that contained ~3% steroidal impurities including starting ketone III according to TLC. The compound could contain an impurity of the Δ5-isomer. The mixture of isomers was used without purification in the next step. mp 201 – 203°C, lit. mp 202 – 205°C [14]. C22H29NO3 MM 355.47. PMR spectrum, ppm; CDCl3): 0.91 (s, 3H, 18-CH3), 1.20 (s, 3H, 19-CH3), 3.95 (m, 4H, OCH2-OCH2); 5.40 (m, 1H, 6-CH); 5.54 (m, 1H, 11-CH).

17α-Hydroxypregna-4,9(11)-diene-3,20-dione (V). A solution of MeMgCl (22.45%) in THF (44 mL) under a stream of dry Ar was stirred. THF (20 mL) was distilled off at atmospheric pressure, during which the temperature of the reaction mixture rose from 70 to 112°C. The resulting suspension was cooled to 70 ± 5°C and treated with anhydrous toluene (200 mL). Solvents were distilled at atmospheric pressure until the vapor temperature reached 110°C. The suspension was stirred, cooled to –5 ± 2°C, and treated with a suspension of IV (10 g) in anhydrous toluene (40 mL) over 5 – 10 min. The temperature rose to 0 ± 5°C, at which the reaction mixture was stirred for 1.5 h, treated with NH4Cl (5.0 g) solution in H2O (40 mL) (temperature rose from 0 to 45 – 50°C) and dropwise with conc. HCl (8 mL) until weakly acidic with pH = 6.5, and heated to 85 ± 2°C for 15 – 20 min until the precipitate dissolved completely. The organic layer was separated and evaporated in vacuo to dryness. The residue was treated with MeOH (100 mL), refluxed, treated with conc. HCl (1 mL), stirred under reflux for 10 – 12 min, cooled to 20°C, and treated with NaOAc (2.5 g) in H2O (20 mL). The MeOH was evaporated in vacuo. The mixture was cooled, stirred, and treated with H2O (100 mL) from a dropping funnel over 15 – 20 min. The suspension was stirred for 30 min at 20°C. The precipitate was filtered off, rinsed with H2O, and dried to afford a crystalline precipitate (8.54 g) containing 82 – 84% 17α-hydroxypregna-4,9(11)-diene-3,17-dione (V); ~3% 17β-hydroxy-17α- methylandrosta-4,9(11)-dien-3-one; and 2 – 3% unidentified impurities (TLC and PMR). The yield of crude V was 92.4% of theoretical calculated from IV. Recrystallization from MeOH (90 mL) with activated carbon (0.8 g) gave a white crystalline precipitate (7.85 g, 85% of theoretical) with 3% steroidal impurities (TLC). mp 207 – 211°C. Lit. mp 206 – 211°C [20]. PMR spectrum, ppm; CDCl3): 0.68 (s, 3H, 18-CH3); 1.33 (s, 3H, 19-CH3); 2.27 (s, 3H, 21-CH3); 2.78 (s, OH); 5.53 (m, 1H, 11-CH); 5.73 (d, 1H, 4-CH).

21-Acetoxy-17α-hydroxypregna-4,9(11)-diene-3,20-dione (VI).

Iodination. A solution of V (10.0 g) in CH2Cl2 (80 mL) and MeOH (30 mL) at 20°C was treated in portions with CaO (7.62 g) in H2O (0.5 mL) and I2 (10.0 g) and CaCl2 (2.4 g) in MeOH (60 mL). The temperature rose to 28°C. The suspension was stirred for 1 h with natural cooling, treated with H2O (100 mL), and left for 10 min. The precipitate was filtered off and rinsed with CH2Cl2–MeOH (4:1) and CH2Cl2. The aqueous layer was separated and extracted with CH2Cl2. The combined extracts were evaporated in vacuo to dryness. The residue was triturated with MeOH, filtered off, and dried to afford 17α-hydroxy-21-iodopregna-4,9(11)-diene-3,20-dione (Va) as a yellow solid in quantitative yield. The product was used without further purification for acetoxylation.

Acetoxylation. A solution of Va in Me2CO (140 mL) was treated with anhydrous KOAc (13.8 g), stirred, refluxed for 3 h under an inert gas, cooled to room temperature, poured with stirring into H2O (1.4 L), and stirred for 30 min. The crystals were filtered off, rinsed with H2O, and dried at 50 – 55°C to afford cream-tinted 21-acetoxy-17α-hydroxypregna-4,9(11)-diene-3,20-dione (VI, 10.82 g, 92% of theoretical), mp 207 – 209°C, lit. mp 230 – 232°C [22]. 2.5% Total steroidal impurities (TLC). PMR spectrum, ppm; CDCl3): 0.64 (s, 3H, 18-CH3); 1.32 (s, 3H, 19-CH3); 2.16 (s, 3H, 21-OC(O)CH3); 2.18 (s, 3H, 17-OC(O)CH3); 4.63 (d, 1H, 21-CH); 4.83 (d, 1H, 21-CH); 5.53 (m, 1H, 11-CH); 5.73 (s, 1H, 4-CH).

21-Diacetoxy-17α-hydroxypregna-1,4,9(11)-triene-3,20-dione (VII). Microbiological dehydrogenation of VI (15.0 g) was performed in the presence of methyl-β-cyclodextrin (MCD) with a 7.5:1 mass ratio to substrate under nonsterile conditions in phosphate buffer at pH 7.6. The overall volume of the mixture was 3 L. The transformation was performed at 28 ± 1°C, pO2 80 – 95%, and stirring rate 400 – 600 rpm. Samples (0.001 L) were taken every 2 h to monitor the accumulation of 21-acetoxy-17α-hydroxypregna-1,4,9(11)-triene-3,20-dione using TLC and HPLC. The substrate was quantitatively converted to the acetylated 1(2)-dehydro analog after 8 h. When the dehydrogenation was finished, the culture liquid (3.0 L) was transferred to an extractor and extracted with EtOAc (6.0 L) with stirring for 15 min. The aqueous phase was separated and extracted again with EtOAc (5 L) under the same conditions. The combined extracts (11 L) were evaporated in a rotary evaporator at 55 ± 5°C and residual pressure 35 ± 5 kPa until crystallization started. The precipitate was treated with EtOAc (0.1 L). The solution was worked up with activated carbon (2 g). The lightened steroid solution was evaporated to dryness in a rotary evaporator. The resulting residue was treated with hexane–Et2O (20 mL, 3:1) and stored in a refrigerator for 5 h. The resulting precipitate was filtered off, rinsed with cold hexane–Et2O (3:1), and dried to constant mass to afford VII (12.6 g, 84.5% of theoretical), mp 217 – 220°C. λmax 239 nm, ε = 14800. 2% Total impurities (TLC). M+384. PMR spectrum, ppm; CDCl3): 0.65 (s, 3H, 18-CH3); 1.38 (s, 3H, 19-CH3); 2.15(s, 3H, 21-OC(O)CH3); 4.81 (d, 1H, 21-CH); 5.03(d, 1H, 21-CH); 5.55 (d, 1H, 11-CH); 6.05 (t, 1H, 4-CH); 6.26 (dd, 1H, 2-CH); 7.17 (d, 1H, 1-CH).

17α,21-Diacetoxypregna-1,4,9(11)-triene-3,20-dione (VIII). A mixture of VII (10.0 g), acetic anhydride (150 mL), and CaO (5.0 g) was stirred and refluxed for 8 h. The reaction mixture was cooled to 20°C, poured with stirring into aqueous NH4OH solution (5%, 1000 mL) at <10°C, and stirred for 1 h. The precipitate was filtered off, rinsed with H2O until neutral, and dried to afford VIII (10.7 g, 96.5% of theoretical). Total steroidal impurities were 2%; mp 206 – 210°C. The product was used without further purification in the next step. Crystallization from Me2CO–hexane (1:1) gave a sample with mp 221 – 222°C, lit. mp 222 – 223°C [21]. MM 426.51. C25H30O6. PMR spectrum, ppm; CDCl3): 0.72 (s, 3H, 18-CH3); 1.38 (s, 3H, 19-CH3); 2.04 (s, 3H, 21-OC(O)CH3); 2.88 (s, 3H, 17-OC(O)CH3); 5.53 (m, 1H, 11-CH); 6.01 (d, 1H, 4-CH); 6.2 (d, 1H, 2-H); 7.1 (m,1H, 1-H).

21-Acetoxypregna-1,4,9(11),16-tetraene-3,20-dione (IX). A solution of VIII (10.0 g) in DMSO (100 mL) under an inert gas was stirred, treated quickly with anhydrous KOAc (5.0 g), heated to 80 – 85°C, stirred at this temperature for 2 h, cooled to 20 ± 2°C, poured with stirring into H2O (1000 mL) cooled to 0 ± 2°C, and stirred at this temperature for 1 h. The resulting precipitate was filtered off, rinsed with H2O, and dried to afford crude IX (8.46 g, 99.5% of theoretical) as a beige powder containing according to PMR data up to 5% steroidal impurities including 3% VIII and 2% unidentified impurities. The solution of crude product (8.46 g) in toluene (125 mL) was filtered through a layer of silica gel (26 g) (layer height was approximately equal to the diameter). The steroid was eluted by toluene (200 mL). Vacuum evaporation of the toluene afforded IX (7.73 g, 90% of theoretical) as an almost white crystalline solid containing up to 2% VIII. mp 171 – 172°C, lit. mp 172 – 174°C [22]. PMR spectrum, ppm; CDCl3): 0.91 (s, 3H, 18-CH3); 1.42 (s, 3H, 19-CH3); 2.17 (s, 3H, 21-OC(O)CH3); 2.17(s, 3H, 21-OCOCH3); 4.89 d and 5.03 d, H2, C-21); 5.55 (m, 1H, 11-CH); 6.06 (t, J = 1.8 Hz, 1H, 4-CH); 6.28 (dd, 1H, 2-CH); 6.76 (m, 1H, 16-CH); 7.21 (d, 1H, 1-CH).

The developed method was practically attractive and promising because the proposed original reaction sequence could be used to synthesize betamethasone, triamcinolone, and other medically useful fluorinated corticoids because of the ability to functionalize the obtained intermediate 1,4,9(11),16(17)-tetraene at those steroid positions (6, 9, 16, and side-chain C17) that are responsible for the anti-inflammatory, antiallergic, antishock, and other unique types of biological activity typical of corticosteroids.

References

N. E. Voishvillo, N. V. Rodina, et al., RU Pat. 2,351,645, Apr. 10, 2009; Byull. Izobret., No. 10 (2009).

V. A. Andryushina, T. S. Savinova, et al., RU Pat. 2,156,255, Sept. 20, 2000; Byull. Izobret., No. 26 (2000).

V. A. Andryushina, T. S. Savinova, et al., RU Pat. 2,156,256, Sept. 20, 2000; Byull. Izobret., No. 26 (2000).

V. A. Andryushina, N. E. Voishvillo, et al., RU Pat. 2,215,038, Oct. 27, 2003; Byull. Izobret., No. 30 (2003).

J. M. Beaton, J. E. Huber, et al., US Pat. 4,127,596, Nov. 28, 1978.

S. Solyom, K. Szilagyi, and L. Toldy, J. Prakt. Chem., 330(2), 309 – 312 (1988).

J. N. M. Batist and A. F. Marx, EP0253415, Mar. 14, 1990.

J. N. M. Batist, et al., EP0294911, Oct. 14, 1992.

A. V. Kazantsev, T. S. Savinova, et al., RU Pat. 2,532,902, Nov. 20, 2014; Byull. Izobret., No. 32 (2014).

W. Nagata and M. Yoshioka, Org. React., 25, 255 (1977).

J. N. M. Batist, A. F. Marx, et al., EP0263569, Dec. 9, 1992; Chem. Abstr., 109, 129460v (1988).

M. N. Ryakhovskaya and G. S. Grinenko, Khim.-farm. Zh., 26(9 – 10), 97 – 106 (1992).

M. I. Ryakhovskaya, E. V. Popova, E. M. Dolginova, and G. S. Grinenko, Khim.-farm. Zh., 21(4), 478 – 481 (1987); Pharm. Chem. J., 21(4), 297 – 300 (1987).

J. Nitta, S. Fujimori, and T. Haruyama, Bull. Chem. Soc. Jpn., 58(3), 978 – 980 (1985).

E. V. Popova, V. A. Andryushina, and G. S. Grinenko, Khim. Prir. Soedin., 3, 324 – 327 (1984).

G. S. Grinenko, V. A. Andryushina, and E. V. Popova, in: Abstracts of Papers from the Vth Conference of Chemistry and Biotechnology of Natural Products, Vol. 3, Bulgaria (1989), pp. 197 – 208.

JP Pat. 53009755, 1978.

N. N. Gireva, L. F. Mikhaleva, L. G. Gatsenko, and L. V. Steshina, SU Pat. 819,119; Byull. Izobret., No. 13 (1981).

V. H. VanRheenen, US Pat. 4,500,461, Feb. 19, 1985.

K. P. Shephard and V. H. VanRheenen, US Pat. 4,041,055, Aug. 9, 1977.

J. Fried, K. Florey, E. F. Sabo, et al., J. Am. Chem. Soc., 77, 4181 (1955).

H. Mendelson, L. L. Smith, and V. E. Origoni, US Pat. 2,864,834, Dec. 16, 1958.

Acknowledgments

The work was financially supported by RAS Presidium Program Development of New Biotechnology Methods for Preparing Highly Active Fluorinated Corticosteroids with Anti-inflammatory and Antiallergic Activity Using a Combined Scheme from Phytosterols through 9α-Hydroxy-AD Using Biotransformation of Newly Designed Immobilized Biocatalysts (Project No. 1201371077).

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated from Khimiko-Farmatsevticheskii Zhurnal, Vol. 52, No. 9, pp. 27 – 31, September, 2018.

Rights and permissions

About this article

Cite this article

Andryushina, V.A., Stytsenko, T.S., Karpova, N.V. et al. Efficient Synthesis of 21-Acetoxypregna-1,4,9(11),16-Tetraene-3,20-Dione, a Key Intermediate in the Synthesis of Highly Active Fluorinated Corticosteroids from 9α-Hydroxyandrostenedione. Pharm Chem J 52, 776–780 (2018). https://doi.org/10.1007/s11094-018-1898-y

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11094-018-1898-y