Approaches to certification of substances as reference standards (RSs) by the mass-balance method and the restrictions that must be considered when using this method are considered. Formulas for estimating the uncertainty of certified values are presented. Also, formulas missing from the literature are given to assess a) the uncertainty in the contents of organic impurities obtained by normalization of peak areas (heights) with correction factors and b) the uncertainty in the detection limits of the organic impurities. Recommendations for correct certification of reference standards by the mass-balance method are provided.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Certification of pharmaceutical reference standards (RSs) has been the focus of comparatively few publications. The most important recommendations for certification of RSs intended for drug substance and preparation quality control are given in the European pharmacopoeia [1] and the B. A. H. validation guideline [2]. Recommendations for certification of RSs are also given in the literature [3,4,5,6,7, 9,10,11,12] and in the USA pharmacopeia, where section <11> “USP Reference Standards” is included [8]. However, it considers only USP RSs. Recommendations for RS certification also appear in GOST national regulations, RMG, and ISO [13,14,15,16]. These regulations provide for a complex of special expensive interlaboratory investigations for RS certification. Such studies in pharmacopoeial analysis are difficult not only to finance but also to organize at a sufficient number of accredited laboratories. It is noteworthy that they contain requirements that are too strict for RS certification and, as a rule, excessive for RS certification in a pharmacy. Guideline R 50.2.058-2007 GSI [17] for estimating the uncertainties of certified RS compounds and materials can be viewed as a supplement to RMG 93-2009 GSI [15] because the estimation of uncertainties of certified RS compounds and materials is discussed in more detail in it.

Three methods are used most often for RS certification, i.e., 1) RS certification as secondary RSs using primary (usually pharmacopoeial) RSs; 2) RS certification by mass balance; and 3) RS certification by titration.

The mass-balance method is especially interesting because the European Pharmacopoeia considers it to be the main method for RS certification [1]. A series of studies in which the mass-balance method was used to certify drugs as RSs have now been published [18,19,20,21,22,23,24,25,26,27]. They and other publications [2, 9,10,11,12] present various formulas for calculating the content of main ingredient in the RS and for estimating the uncertainty of the RS certified value. This complicates the choice of required formulas and the estimate of the adequacy of the completed studies. Limitations that must be considered when using the mass-balance method to certify RSs are not discussed in any of the publications. These factors could lead to incomplete or even incorrect RS certification.

The goals of the present article were to examine the main approaches to RS certification by the mass-balance method and the required formulas, to identify the limitations when using the mass-balance method, and to give recommendations for increasing the reliability of the RS assigned values.

General information

The current classification of RSs that considers their specifics has been published [7]. The documentation required to certify drug substances as RSs was discussed in detail [1, 2, 7]. As a rule, a series of substance from batches with the lowest content of organic impurities that satisfies the specifications for all parameters is selected in practice to certify a substance as a RS. At least five samples are taken from the selected batch of substance and analyzed [28]. The content of main ingredient in the certified substance sample is calculated as required. The value calculated by mass balance and that obtained by a direct method (titration) are checked for equivalency. The sample is assigned the certified value and its uncertainty is calculated. It is noteworthy that the content of main ingredient in the RS is given without recalculating for dry substance, i.e., “as it is”, in contrast with substances. As a rule, drying (moisture removal) under defined conditions before use in analyses is provided for hygroscopic RSs. The certified value is assigned to the dry RS [1, 8].

1. Calculation of the RS certified value by the mass-balance method

The mass-balance method is based on the law of the conservation of mass and consists of the following. The contents of all impurities (organics, H2O, residual solvents, inorganic impurities) are substracted from 100% to give the certified value for the content of main ingredient in the RS (Patt). This produces the content of main ingredient “as it is”, i.e., as it is in percent:

where XRelSub is the content of organic impurities (as a rule, determined by chromatography using internal normalization of peak areas with correction factors); X W , water content (by Fisher); X R , content of residual organic solvents (by GC); and XInogSub, content of inorganic impurities. All X i are averages (%) of at least five samples of certified substance.

An alternate formula is used in the literature [2, and many others] to calculate the content of main ingredient by the mass-balance method:

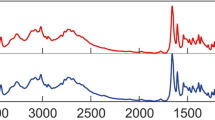

where Po is the average content of main ingredient in the certified substance determined by normalization of peak areas (heights) with correction factors. Sometimes, the chromatographic purity of peaks, i.e., normalization without correction factors, is used as Po. However, such an approach carries a high risk of incorrect RS certification. Therefore, additional methods such as differential scanning calorimetry (DSC) and NMR must be utilized. Then, the certified RS value is presented as the average content of main ingredient in the RS from chromatographic and other methods [24].

In practice, all terms in Eqs. (1) and (2) do not have to be considered to certify RSs in most instances. The content of inorganic impurities XInogSub can most often be ignored [2]. Furthermore, the content of organic solvents and/or H2O can also be disregarded from a practical viewpoint if they contribute less than 0.05 or 0.1% to the total. Correspondingly, the contributions of such terms to the uncertainty of the certified value can be neglected. This contracts considerably the volume of work and financial expense of RS certification.

Equation (1) should theoretically give the most accurate PAtt value for identical impurity contents. However, the calculations showed that the difference in the results obtained using Eqs. (1) and (2) was insignificant and less than 0.1% if the content of organic impurities XRelSub ≤ 1.0% and the total contents of H2O (including water of crystallization) and residual organic solvents X W + X R ≤ 10.0% or XRelSub ≤ 2% and X W + X R ≤ 5%, i.e., this difference can in most instances be neglected. The exceptions are substances such as crystal hydrates and solvates and hygroscopic substances. If Eq. (2) is used to certify them as RSs, then the content of main ingredient should be calculated first using Eqs. (1) and (2) and the difference between results should be confirmed to be <0.1%. Otherwise, use of Eq. (2) is not recommended.

The mass-balance method with a strict theoretical basis has an important advantage over other methods for certifying RSs. The content of main ingredient in a RS, PAtt, a priori can never exceed 100% for certification of substances by the mass-balance method. Therefore, the unpleasant situations that are sometimes encountered with other methods for certifying RSs, when it turns out that PAtt if formally greater than 100% although this is physically impossible, cannot occur. In such instances, either the RS is formally assigned PAtt = 100.0%, which justifiably raises doubt in the users of the RS if the RS specification indicates total impurities # 0.06% (i.e., P % 99.94%, which is <100.0% by round-off rules), or additional analyses are performed. However, this increases significantly the costs for RS certification.

An important limitation of the mass-balance method, in addition to the aforementioned advantage, is the need to invoke correction factors to determine the impurity contents by chromatographic methods. Strictly speaking, the mass-balance method requires consideration of correction factors of all impurities to determine the total organic impurities XRelSub. Obviously, this requirement cannot be fulfilled in the overwhelming majority of instances. Therefore, the risk of obtaining an incorrect value for the content of main ingredient in a certified substance always exists because correction factors of some impurities are not considered. The following procedure can be used to minimize the aforementioned risk and also to limit additional research to a reasonable amount.

First, determine correction factors not for all impurities but only those that a) are heightened-risk impurities that practically do not absorb or have absorption comparable with that of the main ingredient at the working wavelength. This indicates that the correction factor differs greatly from 1 (these impurities can be determined using a diode-array detector at the impurity spectral peak maximum) and b) should be identified according to the ICH [29] (these are identified impurities of content >0.1% for a daily drug dose >2 g or >0.05% for a daily drug dose >2 g). Normalization without correction factors is adequate for assigning impurities as identified.

Second, evaluate the equivalency of analytical results for the contents of main ingredient in the certified substance that were obtained by mass balance and direct methods (as a rule, titration), gradually adjusting the correction factors to reach equivalency, i.e., an iterative approach. The proposed iterative approach consists of the following. Determine the impurity content XRelSub with the same correction factors (if they exist) given in this procedure using the same impurity determination method that was used for quality control of the certified substance. Then, calculate PAtt using the mass-balance method. Check the equivalency of the PAtt value and the main ingredient content in the certified substance as determined by a direct method PDir. The recommended direct method for obtaining the PDir value is to subtract the total organic impurities from the direct determination of the main ingredient content. A formula for titration methods that corresponds to this recommendation has been published ([2], p. 156). If PAtt and PDir are equivalent, then the RS is assigned the certified PAtt value. If it is found that PAtt and PDir are inequivalent, then proceed as follows. Determine sequentially first the correction factors for the heightened-risk impurities and then for impurities with the greatest percent contents (from normalization results without correction factors) and consider them in the calculation of XRelSub. Increase gradually the number of impurities for which the correction factors are considered until equivalent results are obtained for the impurity contents by the mass-balance method PAtt and the direct method PDir. A RS is assigned the certified PAtt value only after PAtt and PDir become equivalent. Let us emphasize that the aforementioned procedure can be used once and then the mass-balance method (with the necessary correction factors) to certify a RS without determining PDir.

Two methods can be used to assess the equivalency of the main-ingredient contents obtained by the mass-balance method PAtt and a direct method, as a rule, titration, PTitr. The first is the well-known method for comparing two variances using the Fisher F-criterion and the Student t-criterion [28, p. 121] or the single-factor ANOVA method that is easily performed in Excel [30]. These methods should be given preference because they are based in theory. However, these methods can sometimes give negative results for an unfavorable ratio of random and systematic errors. Therefore, a more complicated alternate approach [9, 11] can be used if the difference of PAtt and PDir is practically insignificant, e.g., <0.32B [see Eq. (3)]. It consists of the following. Confirm that results for the main-ingredient contents found by mass balance and titration are consistent when assigning a certified value PAtt by the mass-balance method. For this, calculate from the experimental titration results the uncertainty of the certified value UAtt. Calculate the average result \( {\overline{X}}_{\mathrm{Titr}} \) and the uncertainty of the main-ingredient content UTitr. Then, check that the following relationships are fulfilled for the obtained results:

where max∆As is the maximum allowed uncertainty of the quantitative determination; B = 100 – B H %, BH is the upper limit of the normalized content of main ingredient in the certified substance (%). Fulfillment of Eqs. (3) and (4) is in fact a simplified requirement for the equivalency of PAtt and PTitr. Nevertheless, it is adequate for RS certification by the mass-balance method and can be used in practice.

2. Use of NMR and DSC methods, alternate approaches to RS certification by the mass-balance method

NMR [18, 22, 27] or DSC [19, 21, 23, 25] have been used to determine the contents of main ingredient and impurities (XRelSub) in certified substances. DSC is used as a direct method to determine XRelSub; NMR, as an indirect one. The content of main ingredient calculated from NMR data is subtracted from 100%. Then, PAtt is calculated by a mass-balance method. NMR and DSC are used comparatively rarely to certify RSs. This is not surprising because NMR and DSC have limitations for determining impurities that are as serious as those of chromatography. This neutralizes their advantages over chromatographic methods. The limitation of NMR for determining impurity contents is the need to identify and use in calculations only isolated resonances of the main ingredient and the impurity molecules. This is a complicated problem due to the risk of an incorrect determination of XRelSub if the structures of any impurities are unknown. For DSC, impurities can be determined correctly only if the certified substance has a rather high content of main ingredient (as a rule, >99.0 mol%) and does not contain solid solutions of impurities [31, 32]. Therefore, the analytical result from DSC is usually monitored using chromatography to estimate the impurity content and the average of these methods is used.

3. Potential and limitation of using mass loss on drying instead of the sum of X W and X ResSol

Mass loss with drying (X D ) instead of the sum of the water content by Fisher (X W ) and residual organic solvents (XResSol) is allowed to be used in Eqs. (1) and (2) for the mass-balance method in the European pharmacopoeia and other guidelines. However, thermogravimetric analysis showed that certain substances can contain strongly held capillary-bound water [31] that cannot be removed by heating, including under conditions regulated in pharmacopoeias for the parameter “Mass loss on drying”. The content of such water can be comparable with that of the organic impurities in the substance. Therefore, the validity of replacing the sum of X W and X R by X D must be evaluated when certifying RSs intended to determine the content of the main ingredient in substances. Such an evaluation can be made once during method development for RS certification. The statistical method comparing two means, i.e., the Fisher F-criterion and the Student t-criterion [28, p. 121], and the single-factor ANOVA method [30] can be used for this. Also, the insignificance of the difference between the mass losses on drying and the sum of the water and residual organic solvent contents (in %) can be evaluated according to the condition:

where max∆As is the maximum allowed uncertainty of the quantitative determination according to Eq. (3).

4. Calculation of the uncertainty of the certified RS value

The uncertainty of the certified RS value is now usually calculated as the expanded uncertainty [15,16,17, 33,34,35,36,37,38] based on the uncertainty principle. The introduction and use of the uncertainty instead of the error is related to the attempt to convert from practically undefined quantities such as the error and true value [39] and to the identification and consideration of the error sources.

Labels and sometimes certificates for RSs often show the certified value of the main-ingredient content PAtt, the uncertainty u after a comma and not a ± sign, and the coverage coefficient (see below) after a comma. Commas are used to indicate that PAtt cannot exceed 100%. It is noteworthy that the uncertainty for RSs may not be indicated on labels and certificates according to the literature [1, point 4.2.4]. An important acceptance criterion for PAtt is also given in this point, “If the calculated uncertainty is less than a previously established value that is considered insignificant with respect to the acceptance criterion for quantitative determination, then the PAtt value is accepted.”

A generalized formula for calculating the expanded uncertainty UAtt of the certified RS value obtained by the mass-balance method can be written [3, 15, 17, 24, 25, 38, 40,41,42,43]:

where k is the coverage coefficient; U(Hom) and U(Stab), standard uncertainties obtained by estimating the homogeneity of the main-ingredient content in the certified substance samples and by estimating its stability; U(XAtt), the combined uncertainty of the main-ingredient uncertainty in the certified substance expressed as the quadratic root of the sum of the squares of standard uncertainties of the terms in Eq. (1) and the uncertainty associated with the impurity limit of detection U(LOD) [24]:

The recommended coverage coefficient k = 2 [33, section 2.3.3] is usually used in Eq. (6) without considering if k = 2 is justified or not. This can give an incorrect estimate of the expanded uncertainty both for RS certification and for evaluation of any analytical results. For example, coverage coefficient k can be much greater if less than six samples are analyzed. In such instances, refinement of the coverage coefficient is recommended. This can be done according to the literature as follows [15, 17].

The number of effective degrees of freedom νeff is calculated beforehand using the special Welch—Satterthwaite equation [15, 17, 44]:

where UAtt is the expanded uncertainty of the certified value calculated using Eq. (6); in the denominator, U(XAtt) is the combined uncertainty of the main-ingredient content in the certified substance, Eq. (7); U(Hom) and U(Stab), standard uncertainties in the estimate of the homogeneity, Eqs. (25) and (26), and in the estimate of the stability, Eq. (28); ν, the number of degrees of freedom: ν(XAtt), in the determination of the main-ingredient content, νHom and νStab, in the estimate of the distribution homogeneity (content) of main ingredient in vials and the stability of the certified substance, respectively. The well-known table of the dependence of the Student criterion on the number of degrees of freedom is used to determine coverage coefficient k after calculating νeff. The two-sided Student criterion for ν = νeff is found for a given confidence probability P (usually 95%). An example of a coverage coefficient that exceeded significantly 2 can be cited in a publication [44] in which five samples were titrated, νeff = 6 was calculated, and the coverage coefficient for six degrees of freedom, 2.45, was determined from a table of the Student criterion. It is noteworthy that the number of degrees of freedom would be ν = n – 1 = 4 for the usual statistical processing of the experimental titration data for five samples (n = 5).

It should be emphasized that the estimate of the expanded uncertainty of the certified RS value is simpler if the RS is certified using Eq. (2) rather than Eq. (1) because a more complicated calculation of the contribution of correction factors is required if Eq. (1) is used. Examples of calculating the expanded uncertainty of the certified RS value were published [18,19,20,21,22,23,24,25, 34, 38].

4.1. Estimate of U Att for determination of the main-ingredient in a RS using Eq. ( 1 ). In this instance, the estimate of the combined uncertainty of the content of organic impurities U(XRelSub) causes the greatest difficulty. Let us introduce the formulas required to estimate UAtt according to Eqs. (6) and (7).

4. 1. 1. Calculation of the combined uncertainty U(X RelSub ) of the organic impurity content X RelSub

The formula for determining the content of organic impurities by the peak-area normalization method with correction factors can be written in simplified form:

where S0 is the peak area of the main (drug) ingredient; f i and S i , correction factor and impurity peak area of impurity i.

Then, the combined uncertainty U(XRelSub) of the XOrgImp value can be calculated from Eq. (9) using the following formulas:

where U is the standard uncertainty of the parameter shown in parentheses; SD Si and SD So , standard deviations of peak areas of impurity i and main ingredient that were obtained during the determination of the content of organic impurities in the certified substance; SD S fi , standard deviation of peak areas S fi of impurity i obtained during determination of correction factor f i . These standard deviations are calculated from the formula:

where SD n is the standard deviation calculated from the analytical results for n samples; n j and SD j , number of parallel determinations for analyzing the j-th sample and standard deviation of the analytical results for the j-th sample; ν, number of degrees of freedom.

4. 1. 2. Calculation of combined uncertainty U(X ResSol ) of residual organic solvent content X ResSol

The content of the i-th solvent (X i , ppm) in the substance is usually calculated using a formula of the type:

where S i is the solvent peak area on the chromatogram of the test solution; S0i, solvent peak area on the chromatogram of a standard solution; a0i, RS weight of solvent i (mg); a i , weight of substance (mg) for determining solvent i; D0i, dilution during preparation of solvent i standard solution; and D i , dilution during preparation of the test solution.

The factor P/100, which was intended to consider the content of main ingredient in the solvent RS, was omitted from Eq. (16) because it had practically no effect on the uncertainty of X i .

Equation (17) was used in correspondence with Eq. (16) to calculate the combined uncertainty of the content of residual organic solvents U(X R ) [24]:

where U(S i ), U(S0i), U(a i ), and U(a0i) are standard deviations of the parameters given in parentheses; U(D i ) and U(D0i), quadratic roots of the sum of squares of the standard uncertainties of the volumetric flasks, pipettes, and cylinders used to prepare the test and standard solutions, respectively.

4. 1. 3. Calculation of the combined uncertainty U(X W ) of the water content X W

The water content in the certified substance is determined by Fisher titration. Two versions are used, i.e., coulometric or potentiometric (volumetric). Simple formulas for determining water are usually sufficient to calculate the uncertainty in the water content in the certified substance [47].

Coulometric method

The formula for the calculation is:

where X W is the water content determined by coulometric titration (%); m W , amount of water determined in the sample (mg); mblank, amount of water determined in a titration blank (mg); and msample, mass of substance sample (mg).

The combined uncertainty of the determined water content in the certified substance by the coulometric method U(X W ) is [24]:

where U values in the square root are standard uncertainties (deviations) of the parameters shown in parentheses.

Potentiometric (volumetric) method

The formula for the calculation is:

where X W is the water content determined by a potentiometric (volumetric) method (%); F, Fisher reagent titer (mg/mL); Vsample, volume of Fisher reagent consumed in titrating the substance sample (mL); Vblank, volume of Fisher reagent consumed in titrating the blank (mL); and msample, mass of substance sample (mg).

The combined uncertainty of the determined water content in the certified substance by the potentiometric (volumetric) method U(X W ) is:

where U values in the square root are standard uncertainties (deviations) of the parameters shown in parentheses.

4. 1. 4. Calculation of combined uncertainty of inorganic impurity (ash) content U(X InorSub )

The formula for the calculation is:

where XInorSub is the content of inorganic impurities in the certified substance (%), msample, mass of substance sample for ash determination (mg); and mash, mass of ash (mg).

The combined uncertainty of the determined content of inorganic impurities (ash) in the certified substance is:

where U values in the square root are standard uncertainties (deviations) of the parameters shown in parentheses.

4. 1. 5. Calculation of uncertainty associated with the limit of detection of organic impurities U(LOD)

The uncertainty associated with the limit of detection of the impurities U(LOD) must also be considered when evaluating the uncertainty of the determined organic impurities U(XRelSub) by chromatographic methods [24]. The uncertainty comes in two types, i.e., A and B. Type A uncertainty is evaluated using statistical methods. It is always expressed in standard deviations as a standard, combined, or expanded uncertainty. Type B uncertainty is evaluated by non-statistical methods and is based on certain assumptions about the dependence of the distribution function of the measured quantity [33]. Justified formulas for calculating U(LOD) have not been published. Nevertheless, the U(LOD) value should logically be expressed using standard deviations of peak areas at the LOD level of the main ingredient according to the generally accepted approach for evaluating the uncertainty [15, 17].

For this, a solution of the main (drug) ingredient with a concentration corresponding to the LOD should be prepared. This solution is chromatographed the same number of times as the test solution is chromatographed to determine the impurities during RS certification. The uncertainty of the LOD of the organic impurities is calculated using the formula:

where SDLOD is the standard deviation of the main-ingredient peak area in chromatograms of the solution with the LOD concentration; STestSol, average peak area of the main ingredient on chromatograms of the test solution for determining organic impurities or better, the average main-ingredient peak area in chromatograms of the reference solution multiplied by the concentration ratio of the test and reference solutions; f i , correction factor for identified impurity i; 1, correction factor for the main ingredient; and 100, factor for calculating in percent. The first term in parentheses in the square root of Eq. (24) is the relative standard uncertainty of the content of any unidentified impurity; the second term in parentheses, relative standard uncertainty of the content of identified impurity i.

Note. A formally simpler formula for the calculation was proposed [48] as U(LOD) = LOD/Cdet, where LOD is the solution concentration corresponding to the impurity limit of detection and Cdet, test solution concentration for determining impurities. However, this formula was presented without justification. Furthermore, it is not applicable to impurities for which correction factors must be considered.

4. 1. 6. Evaluation of standard uncertainty of the homogeneity of main-ingredient content U(Hom) in vials with RS samples

The single-factor ANOVA method is used for reliable calculation of U(Hom) [30, 37, 41]. Vials with weighed samples of certified substance (number of vials = p) can be viewed as groups. The calculation of U(Hom) starts with a determination of the standard deviation of the main-ingredient content, i.e., intergroup MSamong and intragroup MSwithin with j analyses (samples) for each vial {e.g., Table 4 in previous work [15] listed Dispersion analysis; an MS column; and lines among groups (MSamong) and within groups (MSwithin)}. Then, the standard uncertainty of the homogeneity of the main ingredient is calculated using the formula [24, 25]:

If U(Hom) is greater than \( \sqrt{MS_{\mathrm{within}}} \), then the evaluation of U(Hom) is finished. Otherwise, U(Hom) is calculated using the formula [24]:

where νmsw is the number of degrees of freedom for calculating \( \sqrt{MS_{\mathrm{within}}} \), equal to p(j – 1). For example, p = 15 and j = 3 in the previous work [24]. The RS is weighed (50 mg) into vials, 15 of which are chosen at random. Three samples from each vial are analyzed. The content of main ingredient in each of the samples is determined (%) by a direct method (titration).

4. 1. 7. Evaluation of standard uncertainty of the stability U(Stab) of the certified RS

The stability of samples of the certified batch of substance is investigated during long-term storage according to the ICH [49]. As a minimum, samples are analyzed at five points because at least five data points are needed for reliable evaluation of the linear regression coefficient of the function [28, p. 190]. For example, these points were 0, 1, 2, 4, 6, and 12 months of natural storage in the previous works [24, 25].

The linear regression of the main-ingredient content X (%) in the certified substance is calculated as a function of its storage time t:

The standard deviation of the regression line slope SD b is determined. Then, the uncertainty of the stability U(Stab) is calculated using the formula [15, 24, 25]:

4. 2. Evaluation of U Att , uncertainty of main-ingredient content in RS during RS certification by the mass-balance method according to Eq. ( 2 )

A different formula for evaluating the expanded uncertainty is used if Eq. (2) is used to certify the RS by the mass-balance method. The uncertainty of P0, U(P1), is calculated instead of U(XRelSub) [24]. All other required formulas were discussed above.

5. Evaluation of the uncertainty of the main-ingredient content in the RS U(X Att ) from results of interlaboratory studies

An approach to evaluating the uncertainty of interlaboratory analytical results using the expanded uncertainty was presented before [43]. An example for interlaboratory analyses of a phenoxymethylpenicillin sample (the contents of main ingredient, water, and impurities were determined in nine laboratories) was given. It is important that this approach was theoretically justified and could be used to certify RS using interlaboratory studies.

6. Choice of Student criterion, one-sided or two-sided (P = 95%), for evaluating the uncertainty of the certified RS value

The one-sided Student criterion at the 95% confidence probability (P = 95%) is recommended in Ukraine for evaluating uncertainties of analytical results including those for RS certification [11, p. 1066]. Agreement with the European Pharmacopoeia was claimed [1]. However, the agreement was not direct but only indirect and formal. Aformula for calculating the maximum allowed relative standard deviation RSDmax as a function of the number of injections is given in the European Pharmacopoeia, Section 2.2.46, for determining the main-ingredient content in substances (Assay). The two-sided Student criterion with P = 90%, which is numerically equal to the one-sided criterion with P = 95%, is used in it [1].

Moreover, a table for two-sided and not one-sided Student criteria {[15], p. 24, formula (9.3); p. 27, table B2} with the same confidence probability (95%) is used in RMG 93-2009 GSI “Determination of metrological characteristics of standard samples” for determining the coverage coefficient in the formula for the expanded uncertainty of certified RS values. In our opinion, this is more logical because the possibility that the desired value can be not only less than but also greater than the one-sided experimental value is taken into account. Use of the two-sided Student criterion leads to greater uncertainty for the same confidence probabilities P and number of degrees of freedom ν because it is always greater than the one-sided criterion. As a result, the condition of Eq. (3) can be fulfilled for the one-sided Student criterion and not for the two-sided one but not the reverse. Therefore, the two-sided Student criterion is preferred for certifying RSs.

The materials and recommendations discussed above will undoubtedly be useful to all scientists that use RSs to develop and control the quality of drugs and substances because the mass-balance method is modern and very accurate for certifying substances as RSs. These are primarily scientists at research laboratories and analytical-control laboratories, including quality-control laboratories.

References

European Pharmacopoeia, EP 8.5, Part 5.12 (2015).

Validation of analytical procedures, Establishment (handling and characterization) of reference standards in the testing of medical products, B. A. H., Bonn (2009), pp. 149 – 154; Validation of analytical procedures for drug manufacturers, Typical handbook for drug manufacturers [in Russian], V. V. Beregovykh (ed.), Littera, Moscow (2008), pp. 97 – 106.

T. P. J. Linsinger, J. Pauwels, A. M. H. van der Veen Heinz Schimmel, and A. Lamberty, Accredit. Qual. Assur., 6, 20 – 25 (2001); http://citeseerx.ist.psu.edu/viewdoc/download?doi=10.1.1.198.3356&rep=rep1&type=pdf

EEE / RM/ 062rev3, The Selection and Use of Reference Materials, Eurochem Guide (2002); https://www.eurachem.org/images/stories/Guides/pdf/EEE-RM-062rev3.pdf

EA-4 / 14INF:2003, The Selection and Use of Reference Materials, Rev. 16, European Accreditation (2015).

W. Hauck, Pharm. Res., 29, 922 – 931 (2012).

V. A. Merkulov, E. I. Sakanyan, V. I. Klimov, et al., Khim.-farm. Zh., 49(11), 54 – 56 (2015); Pharm. Chem. J., 49(11), 776 – 778 (2015).

United States Pharmacopeia, USP38 – NF33 (2015).

D. A. Leont’ev, Farmakom, No. 1/2, 44 – 51 (2006).

D. A. Leont’ev, Farmakom, No. 1/2, 25 – 32 (2012).

D. A. Leont’ev, Pharmaceutical Reference Standards, in: Analytical Chemistry in the Design, Standardization, and Quality Control of Drugs [in Russian], V. P. Georgievskii (ed.), NTMT, Vol. 3, Kharkov (2011), pp. 1064 – 1117.

D. A. Leont’ev, A. I. Grizodub, M. G. Levin, and T. N. Dotsenko, Farmakom, No. 3, 1 – 13 (2002).

GOST R 8.694-2010 (guideline ISO 35:2006), Reference standards of materials (substances). General statistical principles for determining metrological characteristics [in Russian], Gosstandart of Russia, Moscow (2010).

RMG 55-2003 GSI, Evaluation of metrological characteristics of reference standards [in Russian], Statinform, Moscow (2003).

RMG 93-2009 GSI, Evaluation of metrological characteristics of reference standards [in Russian], Statinform, Moscow (2011).

ISO Guide 34, Standard Application Document for Reference Material Producers, (2009).

R. 50.2.058-2007 GSI, Evaluation of uncertainties of certified values of reference standards [in Russian], Standartinform, Moscow (2008).

S.-Y. Liu and C.-Q. Hu, Anal. Chim. Acta, 602(1), 114 – 121 (2007).

Ki Ma, H. Wang, M. Zhao, and J. Xing, Anal. Chim. Acta, 650(2), 227 – 233 (2009).

R. Nogueira, E. C. P. do Rego, M. V. B. Sousa, et al., Braz. J. Pharm. Sci., 47(2), 339 – 350 (2011).

R. Nogueria, W. F. C. Rocha, T. E. Silva, et al., J. Braz. Chem. Soc., 23(3), 435 – 444 (2012); http://www.scielo.br/scielo.php?script=sci_arttext&pid=S0103-50532012000300009.

R. Nogueira, B. Garrido, R. Borges, et al., Eur. J. Pharm. Sci., 48(33), 502 – 513 (2013).

S.-H. Kim, J. Lee, S. Ahn, et al., Bull. Korean Chem. Soc., 34(2), 532 – 538 (2013).

N. Gong, B. Zhang, F. Hua, et al., Steroids, 92, 25 – 31 (2014); http://ncps.imm.ac.cn/upload/files/20153/000904_12_%E9%BE%9A%E5%AE%81%E6%B3%A2.pdf.

G. Ni, W. Xi, Z. Bi, et al., J. Pharm. Biomed. Anal., 89, 106 – 110 (2014).

F. Su, X. Dai, and H. Li, Pharm. Anal. Acta., 6, No. 7, 1 – 5 (2015).

J. M. Rodrigues, E. C. P. Rego, E. F. Guimaraes, et al., J. Braz. Chem. Soc., 26(5) (2015).

K. Doerffel, Statistics in Analytical Chemistry, VCH, Weinheim, FRG (1987), 192 pp.

International Conference on Harmonization (ICH), Tripartite Guideline. ICH Q3A(R2), Impurities in New Drug Substances, Geneva (2006).

N. A. Epshtein, Razrab. Regist. Lek. Sredstv, No. 1, 106 – 117 (2016).

W. W. Wendlandt, Chemical Analysis: A Series of Monographs on Analytical Chemistry and its Applications, Vol. 19: Thermal Methods of Analysis, 2nd ed., Wiley Interscience, New York (1974) [Russian translation, V. A. Stepanov and V. A. Bershtein (eds.), Mir, Moscow (1978)].

A. P. Arzamastsev and P. L. Senov, Drug reference standards [in Russian], Meditsina, Moscow (1978), pp. 56 – 69.

EURACHEM / CITAC Guide CG 4, Quantifying Uncertainty in Analytical Measurement, 3rd Ed., EURACHEM / CITAC Guide (2012).

C. Quan, H. Yao, and C. Hou, Agric. Sci., 4(9B), 89 – 96 (2013).

C. Burgess, Pharm. Technol., 37(9), 62 (2013); http://www.pharmtech.com/basics-measurement-uncertainty-pharma-analysis? pageID=3.

K. Gates, N. Chang, I. Dilek, et al., J. Anal. Toxicol., 33, 532 – 539 (2009).

A. M. H. van der Veen and J. Pauwels, Accredit. Qual. Assur., 5, 464 – 469 (2000).

R. Nogueira, E. C. P. do Rego, M. Vinicius, et al., Braz. J. Pharm. Sci., 47(2), 339 – 350 (2011).

R. L. Kadis, Zavod. Lab., 74, 61 – 67 (2008).

A. M. H. van der Veen, T. Linsinger, and J. Pauwels, Accredit. Qual. Assur., 6, 26 – 30 (2001).

A. M. H. van der Veen, T. P. J. Linsinger, A. Lamberty, and J. Pauwels, Accredit. Qual. Assur., 5, 257 – 263 (2000).

A. M. H. van der Veen, T. P. J. Linsinger, H. Schimmel, et al., Accredit. Qual. Assur., 6, 290 – 294 (2001).

P. Dehouck, Y. Vander Heyden, J. Smeyers-Verbeke, et al., Anal. Chim. Acta, 481, 261 – 272 (2003).

R. H. Obenauf and N. Kocherlakota, SPEX CertiPrep, The Application Notebook (2005), pp. 26 – 28.

S. R. Davies, M. Alamgir, B. K. H. Chan, et al., Anal. Bioanal. Chem., 407, 7983 – 7993 (2015).

Calculation of Measurement Uncertainty. An Example for Titration, Mettler-Toledo AG (2014); http://us.mt.com/dam/LabDiv/lps/uncertainty/white_paper_measurement_of_uncertainty_in_titration.pdf.

S. Inagaki, T. Asakai, M. Numata, et al., Anal. Methods, 6, 2785 – 2790 (2014); http://pubs.rsc.org/en/content/getauthorversionpdf/C3AY42314J.

P. Konieczka and J. Namiesnik., J. Chromatogr. A, 1217, 882 – 891 (2010).

International Conference on Harmonization (ICH) Harmonised Tripartite Guideline, ICH Q1A(R2), Stability Testing of New Drug Substances and Products, Geneva (2003).

Author information

Authors and Affiliations

Additional information

Translated from Khimiko-Farmatsevticheskii Zhurnal, Vol. 51, No. 10, pp. 48 – 57, October, 2017.

Rights and permissions

About this article

Cite this article

Epshtein, N.A. Certification of Reference Standards in Pharmacy: Mass Balance Method. Pharm Chem J 51, 928–937 (2018). https://doi.org/10.1007/s11094-018-1718-4

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11094-018-1718-4