Abstract

An average laser power of 0.975 W is obtained from a small-bore copper vapor laser with an active volume of 0.377 cm3, i.e. a record specific average power of 2.6 W.cm− 3 is achieved for copper lasers of any type.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

Though the low-temperature variants of the copper vapor laser (CVL), such as copper bromide (CuBr) vapor laser (Sabotinov et al. 1975) and copper (Cu) HyBrID (Hydrogen Bromide In Discharge) laser (Livingstone et al. 1992), have three-time higher efficiency, incomparably less production and operation difficulties, significantly shorter warm-up time, they still can not reach the average output power of 550 W (Hackel and Warner 1993) achieved by single-tube CVL. The record-high average laser powers of 150 W and 201 W obtained through CuBr vapor laser (Kostadinov et al. 2023) and Cu HyBrID laser (Jones et al. 1994), respectively, are even lower than 250 W delivered via single power amplifier, which together with several other power amplifiers have produced an average output power higher than 10 kW (Hackel and Warner 1993). Moreover, CVLs possess higher laser pulse energy at the same average output power, due to the lower pulse repetition frequency (prf), higher peak pulsed power, shorter laser pulse duration, higher lasing stability, etc.

Exactly the opposite, when the average laser power extracted from unit volume, so called specific average output power, has been investigated, the CVL, CuBr vapor laser and Cu HyBrID laser with the same diameters of 4.5 mm, lengths of 30 cm and volumes of 4.77 cm3 of the active zones have generated average laser powers of 3.1 W (Vorob’ev et al. 1991), 6.7 W (Astadjov et al. 1994) and 9.5 W (Sabotinov et al. 1995), respectively. The authors have calculated that the corresponding specific average laser powers have been 1.3 W.cm− 3 for CVL with corrections made for copper pieces aperturing and window losses, 1.4 W.cm− 3 for CuBr vapor laser and 2 W.cm− 3 for Cu HyBrID laser. Further reduction in the active volume through reducing the active length to 7.5 cm and 2.54 cm (an inch) keeping the same active diameter of 4.5 mm (Sabotinov et al. 1995) has resulted in unsatisfactorily low average output powers of 1.67 W and several tens of mW, respectively. The specific average laser powers have been 1.4 W.cm− 3 and less than 0.1 W.cm− 3, respectively. Unfortunately, a decrease in the active zone diameter of the CuBr vapor laser and the Cu HyBrID laser below 4.5 mm will lead to growth of copper dendrites, which will partially obscure the laser beam. Fortunately, the CVLs suffer no such limitations. Furthermore, reduction in the active diameter keeping the active or cavity length high enough will result in a decrease in laser beam divergence down to the diffraction limit even with a flat-flat stable cavity. In our previous not yet published experiments a high-temperature CVL with a 4-mm bore and an active length of 30 cm, i.e. the active volume is 3.77 cm3, was studied. An average output power of 1.50 W was obtained, i.e. the specific average laser power was 0.4 W.cm− 3. In addition to the relatively low average output power, the diffraction-limited laser radiation was obtained only with a negative branch unstable cavity.

In this paper a high-temperature CVL with a 2-mm bore and an active length of 12 cm, which produces a maximum average output power of 0.975 W, is described, i.e. a record-high specific average laser power of 2.6 W.cm− 3 is achieved for lasers oscillating on the atomic copper self-terminating transitions of any type. Though laser pulse energy is relatively low in comparison with other lasers, such as CVL (Knowles and Brown 1995), CuBr vapor laser (Astadjov et al. 1994) and Cu HyBrID laser (Sabotinov et al. 1995), the specific laser pulse energy is from 4 to 6 times higher than the cited values. The laser tube is also investigated with a standard flat-flat stable resonator at three different cavity lengths. Experimentally determined laser beam divergence is near the diffraction-limited divergence of a Gaussian TEM00 beam.

2 Experimental setup

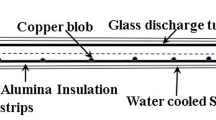

The construction of the new laser tube is schematically depicted in Fig. 1. The active zone is confined by six Al2O3 ceramic inserts, which have inside and outside diameters of 2 mm and 6 mm, respectively, and are coaxially mounted in a BeO ceramic tube with an inside diameter of 6 mm and a length of 14 cm. The two end inserts are 1.5 cm long, while the other inserts are 2 cm in length. The Cu pieces, which are not larger than 2 mm, are placed between the Al2O3 ceramic inserts. Hence the length of the active zone is 12 cm, i.e. the active volume is 0.377 cm3. Compact thermal ZrO2 powder insulation of the discharge zone is applied between the BeO ceramic insert and the basic tube made of fused quartz. Cylindrical copper electrode is used as the grounded electrode, while the high-voltage electrode is made of porous copper. The laser cavity consists of a flat high-reflectivity mirror for 510.6 nm and 578.2 nm, respectively, and a plane-parallel BK7 glass plate having one-side anti-reflection coating as an output coupler.

The investigated laser tube is excited via an electrical excitation scheme with peaking capacitor, so called capacitor charge transfer circuit. The average output power is measured through a calorimetric power–energy meter Scientech Inc. Vector S310 with a sensitivity range from 200 nm to 10 μm.

3 Results and discussion

Preliminary study on the laser tube showed that the average electrical power must be limited to no more than 1 kW, since the Al2O3 ceramic inserts were completely melted and the laser volume were fully apertured.

The average output power as a function of the average electrical power is shown in Fig. 2 with all the relevant input parameters listed on the graph. Specific average laser power is presented as a second vertical axis for convenience. A monotonic growth of the laser power with the increase in the input power is observed.

The dependence of the average laser power on the neon (Ne) buffer-gas pressure is presented in Fig. 3 as well as all the relevant input conditions. Specific average output power is presented as a second vertical axis for convenience. A monotonic growth of the laser power with the decrease in the Ne buffer-gas pressure is observed, as it has been reported for the CVL (Vorob’ev et al. 1991).

The obtained results given in bold are compared in Table 1 with the record-high results achieved so far with CVLs (Vorob’ev et al. 1991; Knowles and Brown 1995), CuBr vapor laser (Astadjov et al. 1994) and Cu HyBrID laser (Sabotinov et al. 1995).

Although the main goal is to achieve higher specific average laser power, which is undeniable accomplished, the specific laser pulse energy is 3.7-time higher than the highest value achieved so far (Sabotinov et al. 1995).

The divergence of each pass (or double-pass) of the CVL radiation for any stable optical resonator is inversely proportional to the length (or the doubled length) of the optical cavity (Salimbeni 1996). A CVL (Brown and Coutts 1996) with an active volume of 4.8 cm3 (5.5-mm bore and an active length of 20 cm) has produced as much power with diffraction-limited beam quality with a plane-plane resonator as when it has been configured with an unstable cavity. This result and the extremely low inside diameter of our laser tube inspires the investigation of the laser beam divergence with a plane-plane resonator. Laser beam divergence is experimentally determined through beam diameter measurement at different distances, namely 10 m, 25 m and 50 m, for three different cavity lengths, namely 40 cm, 100 cm and 180 cm. Average output power is also measured for each cavity length. The obtained results are summarized in Table 2. The lowest beam divergence is achieved for the resonator length of 180 cm and it is compared in Table 3 with the calculated divergences of a Gaussian TEM00 beam and a diffraction-limited flat-top beam.

Studying transverse beam distribution, a diffraction ring patterns are observed for each mirror separation. The minimums grow deeper with the increase in the cavity length and are zeros, as it is seen in Fig. 4, for the cavity length of 180 cm. Moreover, at the cavity length of 180 cm the same pattern is observed for single- and double-pass laser radiation, i.e. without output coupler. The alignment of the output coupler only increases the laser power. Such pattern has been also reported for a CVL with a beam propagation factor M2 of 1.3 (Withfold et al. 2004).

4 Conclusions

The small-bore copper vapor laser with an active volume of 0.377 cm3 delivers an average laser power of 0.975 W, i.e. a record specific average power of 2.6 W.cm− 3 is obtained for copper lasers of any type. Though the increase in comparison with the highest value of 2.0 W.cm− 3 achieved so far is 30%, the obtained specific laser pulse energy of 123 µJ.cm− 3 is 3.7-fold higher than the highest value achieved to date. Experimentally determined laser beam divergence for flat-flat stable cavity is near the diffraction-limited divergence of a Gaussian TEM00 beam and lower than the diffraction-limited divergence of a flat-top beam.

Data availability

No datasets were generated or analysed during the current study.

References

Astadjov, D.N., Dimitrov, K.D., Little, C.E., Sabotinov, N.V., Vuchkov, N.K.: A CuBr vapor laser with 1.4 W/cm3 average output power. IEE J. Quantum Electron. 30(6), 1358–1360 (1994)

Brown, D.J.W., Coutts, D.W.: Beam quality issues in copper vapour lasers. In: Little, C.E., Sabotinov, N.V. (eds.) Pulsed Metal Vapor Lasers, pp. 241–254. Kluwer Academic, Dordrecht (1996)

Hackel, R.P., Warner, B.E.: Copper-pumped dye laser system at Lawrence Livermore National Laboratory. In: Proceedings of SPIE 1859, 120–129 (1993)

Jones, D.R., Maitland, A., Little, C.E.: A high-efficiency 200 W Average Power Copper HyBrID laser. IEEE J. Quantum Electron. 30(10), 2385–2390 (1994)

Knowles, D.S., Brown, D.J.W.: Compact 24-kHz copper-laser-pumped Ti:Sapphire laser. Opt. Lett. 20(6), 569–571 (1995)

Kostadinov, I.K., Temelkov, K.A., Astadjov, D.N., Slaveeva, S.I., Yankov, G.P.: High-power copper bromide vapor laser. Opt. Quant. Electron. 55, Art1291 (2023)

Livingstone, E.S., Jones, D.R., Maitland, A., Little, C.E.: Characteristics of a copper bromide with flowing Ne-HBr buffer gas. Opt. Quant. Electron. 24, 73–82 (1992)

Sabotinov, N.V., Telbizov, P.K., Kalchev, S.D.: Bulgarian Patent no 28674 (1975)

Sabotinov, N.V., Akerboom, F., Jones, D.R., Maitland, A., Little, C.E.: A copper HyBrID laser with 2 W/cm3 specific average output power. IEE J. Quantum Electron. 31(4), 747–753 (1995)

Salimbeni, R.: Beam quality issues in CVL applications. In: Little, C.E., Sabotinov, N.V. (eds.) Pulsed Metal Vapor Lasers, pp. 229–240. Kluwer Academic, Dordrecht (1996)

Vorob’ev, V.B., Kalinin, S.V., Klimovskii, I.I., Kostadinov, I., Krestov, V.A., Kubasov, V.N., Marazov, O.: Copper vapor laser with an average specific output power exceeding 1 W/cm3. Sov. J. Quantum Electron. 21, 1067–1068 (1991)

Withfold, M.J., Brown, D.J.W., Mildren, R.P., Carman, R.J., Marshal, G.D., Paper, J.A.: Advances in copper laser technology: Kinetic enhancement. Prog. Quantum Electron. 28, 165–196 (2004)

Acknowledgements

This work was supported by the Project KP-06-H37/2 “Basic research and development of high-beam-quality high-power laser system oscillating in visible spectral range” of Bulgarian National Science Fund.

Author information

Authors and Affiliations

Contributions

I. K. designed and developed the laser tube, conducted the experiment and constructively reviewed the first draft of the manuscript.K. T. participated and assisted in the experiment, drew some of the figures, found the relevant references and wrote the manuscript.S. S. processed the data and drew some of the figures.G. Y. is the coordinator of the Project KP-06-H37/2 “Basic research and development of high-beam-quality high-power laser system oscillating in visible spectral range” of Bulgarian National Science Fund.All authors approved the scientific content of the manuscript prior to submission.

Corresponding author

Ethics declarations

Conflict of interest

The authors have no conflicts of interest to declare that are relevant to the content of this article. The authors also state that the results, which are presented in this paper, are new and original and do not exists in publicly archived datasets.

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Kostadinov, I.K., Temelkov, K.A., Slaveeva, S.I. et al. A copper vapor laser with 2.6 W/cm3 specific average output power. Opt Quant Electron 56, 1234 (2024). https://doi.org/10.1007/s11082-024-07201-0

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s11082-024-07201-0