Abstract

Large mode area (LMA) fibers are widely used in high power fiber lasers to solve the nonlinear problems. In this work, a novel structure of LMA fiber with heterogeneous helical claddings and an inner isolation ring (HHCR) designed for 2.0 μm is proposed, and coordinate transformation simulation technique is adopted to analyze the fiber mode transmission characteristics. Fiber parameters effects on mode transmission loss and bending characteristics are both analyzed in detail. For a straight fiber, the optimized fiber parameters are Λ = 22 ~ 23 mm, θ = 13° ~ 15°, R1 = 120 μm, R2 = 150 μm, n0 (n2) = 1.439 ~ 1.4392, n1 (n3) = 1.437 ~ 1.441, d = 2 ~ 4 μm, the single mode core diameter is 60 μm and the effective mode area is 2010 μm2. For a bent fiber, the optimized fiber parameters are Λ = 24 mm, θ = 9° ~ 10°, n0 (n2) = 1.439, n1 (n3) = 1.438, R1 = 120 μm, R2 = 150 μm, d = 2 ~ 5 μm, R = 0.4 ~ 0.5 m, the single mode core diameter is 64 μm and the effective mode area is 1950 μm2. Thus, the HHCR fiber can work efficiently for LMA and single mode operation. The isolation ring can effectively reduce the fundamental mode loss and improve the output spot quality. The fiber structure is all solid and the helix pitch is long, so it is relatively easy to fabricate and use. The proposed fiber will have good applications in high-power fiber lasers.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

High power fiber lasers are widely used in many fields such as national defense, medical treatment and manufacturing industry due to their many inherent merits (Limpert et al. 2002; Hideur et al. 2001). However, the increasing laser power demands larger mode area (LMA) of optical fiber to mitigate nonlinear effects (Jeong et al. 2004; Fini 2007; Song et al. 2008; Yang et al. 2012). Therefore, in recent years, various LMA optical fibers with special structure have been proposed. For example, Wang proposed a helical-core fiber (Wang et al. 2006), the core diameter is 30 μm, NA = 0.087, and the helix pitch is about 8.5 mm, which can support single mode operation. In 2014, Ma proposed a chirally coupled core (CCC) fiber with an octagonal central-core and 8 helical side cores (Ma et al. 2014), NA of the central-core is 0.068, and NA of side cores is 0.088. The helix pitch is 5.3 mm, the loss of LP01 mode is 0.2 dB/m near 1.0 μm, and they verified single-mode operation when fiber core exceeds 50 μm. The segmented cladding fiber (SCF) is another type of LMA fiber (Yang et al. 2022), which can support single mode operation when mode area is about 900 μm2. In Ref. (Zhou et al. 2015), a supermode calculation method for tapered multicore fiber is proposed, and which is designed to enlarge mode area. Photonic crystal fiber (PCF) is a typical large mode field fiber model (Coscelli et al. 2014), which mainly focus on lowering NA of the core to reduce the number of modes and to enlarge single mode area. The largest core size of flexible PCF LMA fibers is approximately 40 μm, while the core size of rod-type PCF is close to 100 μm and is mainly used in laboratory. Ref. (Yehouessi et al. 2016) reported a large mode area pixelated Bragg fiber in which some high refractive index rods were placed in cladding, the core diameter is 35 µm and the effective mode area is 510 µm2. Photonic bandgap fiber (PBGF) is another type of LMA PCF proposed by Chen et al. (Chen et al. 2023), the core diameter is 46 μm in the corner-to-corner direction, and the transmission spectrum is from 970 to 1180 nm. Malleville et al. recently proposed a new large-pitch fiber (LPF) (Malleville et al. 2021), the fiber geometry, relying on the modal sieve concept applied to an aperiodic cladding lattice, exacerbates the delocalization of higher-order modes (HOMs) out of the active core, the core diameter is higher than 70 µm. Gain-guided and index-antiguided (GG-IAG) fiber (Shen et al. 2017) has the largest single-mode core diameter (400 μm), but the loss is high and the laser efficiency is very low. Denisov et al. designed Leaky channel fiber (LCF) (Denisov et al. 2023), the core diameter is 22.5 μm, and when bending radius is 0.1 m, the fundamental mode (FM) loss is less than 0.1 dB/m in the spectral range from 0.9 µm to1.5 µm. Deepak Jain proposed multi trench fiber (MTF) in 2013(Jain et al. 2013), the fiber core can reach 100 μm, but the range of fiber parameters is relatively strict.

As mentioned above, some fiber structure is complex or the parameter range is strict, they are difficult to prepare. Some fiber core diameters are not large enough or loss is high. They obtained some specific applications, especially in the fields of 1.0 μm band. Since the thulium doped fiber laser reached the kilowatt level in 2018 (Gaida et al. 2018), it has not achieved higher power, the main reason may be the severe quantum loss of thulium ions, which leads to severe thermal effects and prominent nonlinear effects. In order to increase the mode area of Tm3+-doped fiber lasers to overcome the adverse nonlinear effects. Recently, we proposed a novel type of heterogeneous helical cladding fiber (Shen et al. 2021a), the single mode core diameter is 60 μm, but there is no isolation ring between the core and the cladding, the loss and beam quality issues caused by boundary scattering (Because the cladding is composed of two materials spliced together) is serious (Shen et al. 2021b). In order to improve the performance of this new type of LAM fiber, now, an inner isolation ring is added between the heterogeneous helical cladding and the core in this paper, named as HHCR fiber, mode transmission performance of straight and bent fiber are both analyzed. Simulation results show that the fiber can be in an efficient single-mode working state when fiber core diameter is up to 60 μm. Isolation ring improves fiber core interface, which will furtherly ensure good beam quality based on single-mode operation. Simultaneously, the fiber structure is all-solid state that facilitates cutting, splicing, and other operations.

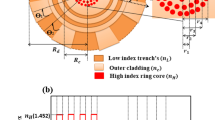

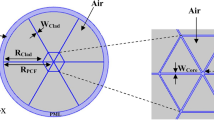

The HHCR fiber structure is showed in Fig. 1a is the cross section of the HHCR fiber, and (b) is the three-dimensional (3D) perspective graphics of the HHCR fiber. There is an added inner isolation ring between the core and the heterogeneous helical claddings, which will prevent the light in the core from leaking into the higher index cladding to improve the output spot quality. The radius and refractive index (RI) of the core are r and n0, respectively. The thickness and RI of the isolation ring is d and n1, respectively. The inner cladding consists of two different materials (RI of which are n2 and n3 respectively), and the radius is R1. The outermost layer is the outer cladding, and the corresponding radius and RI are R2 and n3.The helix pitch of the fiber is Λ. The center angle of the n2 cladding is θ. The relationship among n0, n1, n2 and n3 is n0 = n2 > n1 = n3, when light transmitted in the core, it will be coupled into n2 cladding, however, more HOMs power is coupled into n2 cladding, less FM mode power is coupled. Therefore, through parameter optimization design, HOMs can be filtered out while retaining FM for transmission in the fiber core.

2 Coordinate transformation technique

In order to simulate the mode transmission performance of the HHCR fiber, a coordinate transformation method was adopted (Wong et al. 2012; Nicolet et al. 2008), thus, we can use a 2D simulation model to simulate the 3D HHC fiber. Firstly, a helicoidal coordinate system (ξ1, ξ2, ξ3) can be deduced from the Cartesian coordinate system (x, y, z) in the following way (Nicolet et al. 2004):

β is the angular twist rate, β = 2π/Λ. β > 0 corresponds to a left-handed helical twist. Equation (1) describes a mapping between the helicoidal coordinate system and the Cartesian coordinate system. The relationship between them can be expressed by Jacobian matrix as:

Although the helicoidal coordinate system is not orthogonal, the Maxwell equations will still maintain the same form. What needs to be changed is to replace the original material permittivity ε and permeability µ with equivalent inhomogeneous anisotropic ones. The equivalent replacement formula is εh = εTh−1, µh = µTh−1(Napiorkowski and Urbanczyk 2014). T is the transformation matrix.

The inverse matrix is:

Thus, a helical fiber can be studied on the basis of a 2D simulation model. Compared with a 3D simulation model, this method retains the complete information of electromagnetic phenomena, reduces calculation time and computer resources.

3 Calculation theory of the HHCR fiber performance

Finite element modeling (FEM) is usually used to analyze the mode characteristics of optical fibers with complex structures (Napiorkowski and Urbanczyk 2014). Here, Comsol software is selected to simulate the HHCR fiber. Mode transmission loss, mode field area and bending characteristics are all analyzed based on the following theories (Saitoh and Koshiba 2003; Tsuchida et al. 2005).

3.1 Mode transmission loss

Transmission loss is an important performance of an optical fiber. The loss coefficients of LP01, LP11 and LP21 modes are expressed as L01, L11 and L21 respectively. The calculation formula is as follows:

neff is the effective RI of modes, Im(neff) is the imaginary part of neff, and λ is the light wavelength.

3.2 Effective mode area

Effective mode area (Aeff) is an important parameter to measure the power density of optical fiber. Aeff can be expressed as:

E (x, y) is the transverse electric field component of the fundamental mode. It can be seen from Eq. (6) that the wider the transverse electric field distribution of the fiber section, the larger the effective mode area of the fiber.

3.3 Bending loss

The fiber bending loss can be calculated according to Eq. (7).

where, n is the initial RI of the optical fiber, n′ is the distribution of RI of a bending fiber, ρ is the photoelastic coefficient and the value is about 1.25 for silica fiber, R denotes bending radius, and x denotes the displacement from the center of the core in the curvature axis.

4 Numerical simulation results and discussions

The effects of the HHCR fiber parameters such as Λ, r, R1, R2, d, λ, n0, n1, n2, n3 and θ on the mode transmission characteristics are discussed next based on a Tm3+−doped fiber. The isolation ring and claddings can be made from pure silica glass and the RI of which is 1.438 at the wavelength of 2.0 μm. So we set n1 = n3 = 1.438.

4.1 Mode transmission loss

4.1.1 The effects of RI

RI has important influence on transmission loss coefficients. Figure 2a illustrates the variation of L01, L11and L21 with n0 (n2). L01, L11 and L21 all decrease with the increase of n0 (n2). When n0 (n2) = 1.439, d = 4 μm, L01 = 0.04 dB/m, L11 = 9.8 dB/m, L21 = 24.7 dB/m. When d = 2 μm, L01 = 0.05 dB/m, L11 = 12.4 dB/m, L21 = 37.9 dB/m. The thicker d, the smaller the loss, when d = 0, L01 = 0.24 dB/m, L11 = 18.65 dB/m, L21 = 27.86 dB/m, the loss of foundation mode (FM) is the largest. The simulation results show that the HHCR fiber can suppress high order modes (HOMs) efficiently. Figure 2b plots the variation of L01, L11 and L21 with n1 (n3). It can be seen from the figure that the change of n1 (n3) has little effect on the loss. Therefore, the RI of the related claddings has a wide selection range, and it is helpful for optical fiber fabrication.

4.1.2 The effects of r

The relationship between loss coefficient L, effective mode area Aeff and core radius r is showed in Fig. 3. With the increase of r, L01 is all lower than 0.1 dB/m when θ = 13° ~ 15°, L11 basically has a downward trend. When r = 30 μm, L01 = 0.05 dB/m, L11 = 12.6 dB/m, and the corresponding effective mode area reaches 2010 μm2. The mode discrimination has reached the international level (Jain and Sahu 2016). Simultaneously, when θ = 14° ~ 15°, r = 32 μm, L11 ≥ 3.97 dB/m, it also can suppress HOMs with a longer fiber.

4.1.3 The effects of λ

Figure 4 plots the variation of loss coefficients with wavelength λ. When λ changes from 1.98 μm to 2.02 μm, L01 is about 0.05 dB/m, which is very beneficial to laser amplification. L11 and L21 also keep higher than 10.0 dB/m. This means that the fiber can maintain SM operation at 2.0 μm.

4.1.4 The effects of Λ

The relationship between helix pitch Λ and loss coefficients is showed in Fig. 5. The transmission loss decreases with the increase of Λ. Meanwhile, the larger the thickness d, the lower the loss. When Λ is 22 mm ~ 23 mm and d = 2 μm-4 μm, L01 < 0.1 dB/m and L11 ≥ 6.3 dB/m. This means the fiber has a good mode discrimination and a wide adapted range for Λ and d to fabricate the fiber. When Λ is 21 mm, L01 > 0.2 dB/m, it is not beneficial to laser amplification, so it is not suitable for fiber lasers.

4.1.5 The effects of θ

The relationship between loss coefficients L01, L11, L21 and θ is showed in Fig. 6. When θ varies from 13° to 16°, L01, L11 and L21 all increase. When θ = 13° ~ 15°, L01 < 0.052 dB/m, L11 > 3.6 dB/m, L21 > 16.6 dB/m, the fiber can work as a LMA and SM fiber, especially, θ = 15° is an optimum parameter as a LMA and SM fiber. When θ = 16°, 0.1 dB/m < L01 < 0.2 dB/m, it is not the best choice for fiber lasers.

4.2 Bending characteristics

Considering the actual applications, it is necessary to study the bending characteristics of the HHCR fiber.

4.2.1 The effects of θ

In a bent optical fiber, a part of light cannot satisfy the condition of total internal reflection, so some light will escape from the fiber core, which will cause additional optical power loss. The effects of θ on bending loss are showed in Fig. 7. The loss can be effectively reduced by reducing θ value. When θ = 8°, L11 is too small to suppress HOMs, when θ = 11°, L01 = 0.33 dB/m, the loss of FM is high, and θ = 9° ~ 10° may be suitable for 0.4 m bending radius. In this case, Λ is 24 mm and is longer than that of the straight fiber discussed above.

4.2.2 The effects of r

Figure 8 depicts the bending loss changes with the fiber core radius r. When r ∈ (28, 32) μm, L01 < 0.18 dB/m, L11 > 7.29 dB/m, the fiber is suitable for single mode operation. The single mode core diameter is up to 64 μm. When the core radius increases, the outer diameter of the cladding does not change, resulting in a thinner cladding. However, when the fiber is bent, the radiation effect is enhanced, resulting in increased losses of FM.

4.2.3 Bending radius R

It can be seen from Fig. 9 that with the increase of bending radius R, the bending loss will decrease. The minimum bending radius R should be 0.4 m. When the bending radius R is 0.5 m, the bending loss of LP11 mode is 5.59 dB/m, if R increases furtherly, it may be difficult to filter out HOMs efficiently. Therefore, the suitable bending radius of the improved HHC fiber for single-mode operation is about 0.4 m ~ 0.5 m, and the corresponding mode field area range is 1938 μm2 ~ 1950 μm2.

4.2.4 The effects of Λ

Helix pitch Λ also influence the bending loss, as showed in Fig. 10, L01 decreases with the increase of Λ, when Λ = 24 mm and d = 4 μm, L01 = 0.12 dB/m and L11 = 8.5 dB/m, HOMs can be suppressed efficiently, So the optimum value of Λ is 24 mm, which is longer than that of the straight fiber.

4.2.5 The effects of λ

As shown in Fig. 11, with different bending radius R, L21, L11 and L01 all change slightly, this means that the mode discrimination is adapted to a wide wavelength range. When R = 0.4 m, λ = 2.0 μm, L01 = 0.14 dB/m, L11 = 9.98 dB/m, the HHCR fiber can efficiently suppress HOMs and keep single mode operation.

4.2.6 The effects of d

The isolation ring plays a key role in the HHCR fiber. As showed in Fig. 12, L01, L 11 and L 21 all decrease with the increase of d. Because a thicker ring will prevent the light in the core from radiating into the cladding. For θ = 10° and d ∈ (2, 5) μm, L01 changes from 0.14 dB/m to 0.11 dB/m, L11 changes from 9.4 dB/m to 7.5 dB/m. This shows there is a wide range of d can be used to fabricate the fiber.

5 Conclusion

In this paper, we proposed a novel type of HHCR fiber, and mode transmission loss and bending characteristics are both analyzed based on the coordinate transformation technique and FEM. The effects of fiber parameters such as Λ, r, R1, R2, R, d, λ, n0, n1, n2, n3 and θ on the transmission loss of the HHCR fiber are analyzed in detail. For a straight fiber, the optimized parameters are Λ = 22 mm ~ 23 mm, θ = 13° ~ 15°, R1 = 120 μm, R2 = 150 μm, n0 (n2) = 1.439 ~ 1.4392, n1 (n3) = 1.437 ~ 1.441, d = 2 μm ~ 4 μm, λ = 1.98 μm ~ 2.02 μm, the single mode core diameter is 60 μm and the effective mode area is 2010 μm2. When the fiber core is heavily doped or used as the final amplification stage of a fiber amplifier, a shorter fiber is required sometimes, and the fiber can be used without bending. For a bent fiber, the optimized parameters are Λ = 24 mm, θ = 9° ~ 10°, n0 (n2) = 1.439, n1 (n3) = 1.438, R1 = 120 μm, R2 = 150 μm, d = 2 μm ~ 5 μm, R = 0.4 m ~ 0.5 m, λ = 1.96 μm ~ 2.04 μm, the single mode core diameter is up to 64 μm and the maximum effective mode area is 1950 μm2. For a traditional fiber, the single mode core diameter is only 28.5 μm according to the used refractive index (ncore = 1.439, ncladding = 1.438) calculated by V-parameter theory, the single mode core area of the HHCR fiber is about 5 times that of the traditional fiber. Thus, the laser power that can be withstood by the HHCR fiber is 5 times that of it, and the non-linear threshold will also be significantly improved. The core diameter of Tm-doped single mode fiber from Nufern Company is about 20 μm, and compared to it, the core area of the HHCR fiber is 10.24 times that of it. The simulation results illustrate the HHCR fiber can suppress HOMs and keep single mode operation efficiently, and the isolation ring can improve the beam quality. The HHCR fiber can be obtained by rotating the preform when it is drawing, the helix pitch is more than 20 mm and is longer than other helical fibers as mentioned above, so it is relatively easier to drawing. What′s more, the fiber adopts an all solid state structure, which is conducive to cutting and splicing, etc. This new type of fiber may have important applications in high power fiber lasers.

Data availability

Not applicable.

References

Chen, X., Huang, L.J., Yang, H., Xi, X.M., An, Y., Yan, Z.P., Chen, Y.S., Pan, Z.Y., Zhou, P.: Large-mode-area multi-resonant all-solid photonic bandgap fiber with low bending loss and robust single-mode operation. Opt. Laser Technol. 157, 108668 (1-9) (2023)

Coscelli, E., Molardi, C., Masruri, M., Cucinotta, A., Selleri, S.: Thermally resilient Tm-doped large mode area photonic crystal fiber with symmetry-free cladding. Opt. Express 22(8), 9707–9714 (2014)

Denisov, A., Dvoyrin, V., Kosolapov, A., Likhachev, M., Velmiskin, V., Zhuravlev, S., Semjonov, S.: All-glass single-mode leakage channel microstructured optical fibers with large mode area and low bending loss. Photonics 10(4), 465 (1-19) (2023)

Fini, J.M.: Design of large-mode-area amplifier fibers resistant to bend-induced distortion. J. Opt. Soc. Am. B 24(8), 1669–1676 (2007)

Gaida, C., Gebhardt, M., Heuermann, T., et al.: Ultrafast thulium fiber laser system emitting more than 1 kW of average power. Opt. Lett. 43(23), 5853–5856 (2018)

Hideur, A., Chartier, T., Özkul, C., et al.: All-fiber tunable ytterbium-doped double-clad fiber ring laser. Opt. Lett. 26(14), 1054–1056 (2001)

Jain, D., Sahu, J.K.: Large mode area single trench fiber for 2 μm operation. J. Lightwave Technol. 34(14), 3412–3417 (2016)

Jain, D., Baskiotis, C., Sahu, J.K.: Mode area scaling with multi-trench rod-type fibers. Opt. Express 21(2), 1448–1455 (2013)

Jeong, Y., Sahu, J.K., Payne, D.N., Nilsson, J.: Ytterbium-doped large-core fiber laser with 1.36 kW continuous-wave output power. Opt. Express 12(25), 6088–6092 (2004)

Limpert, J., Schreiber, T., Clausnitzer, T., et al.: High-power femtosecond Yb-doped fiber amplifier. Opt. Express 10(14), 628–638 (2002)

Ma, X.Q., Zhu, C., Hu, I.N., Kaplan, A., Galvanauskas, A.: Single-mode chirally-coupled-core fibers with larger than 50µm diameter cores. Opt. Express 22(8), 9206–9219 (2014)

Malleville, M.A., Leconte, B., Dauliat, R., Jamier, R., Schwuchow, A., Wondraczek, K., Roy, P.: Pre-compensation of thermally induced refractive index changes in a depressed core fully aperiodic large-pitch fiber for high average power operation. Opt. Lett. 46(12), 2956–2959 (2021)

Napiorkowski, M., Urbanczyk, W.: Rigorous simulations of a helical core fiber by the use of transformation optics formalism. Opt. Express 22(19), 23108–23120 (2014)

Nicolet, A., Zolla, F., Guenneau, S.: Modelling of twisted optical waveguides with edge elements. Eur. Phys. J. -Appl. Phys. 28(2), 153–157 (2004)

Nicolet, A., Zolla, F., Ould Agha Y., Guenneau, S.: “Geometrical transformations and equivalent materials in computational electromagnetism,” COMPEL—The international journal for computation and mathematics in electrical and electronic engineering 27(4): 806–819 (2008).

Saitoh, K., Koshiba, M.: Leakage loss and group velocity dispersion in air-core photonic bandgap fibers. Opt. Express 11(23), 3100–3109 (2003)

Shen, X., Zhang, L.L., Ding, J.Y., Wei, W.: Design, fabrication, and optical gain performance of the gain-guided and index-antiguided Nd3+-doped phosphate glass fiber. J. Opt. Soc. Am. B 34(5), 998–1003 (2017)

Shen, X., Yang, Z.J., Xi, X.M., Zhang, Z.X., Wei, W.: Numerical investigation for the mode transmission characteristics of a large mode area optical fiber with heterogeneous helical claddings designed for 2.0 µm. Opt. Lett. 46(17), 4342–4345 (2021)

Shen, X., Yang, Z.J., Chen, S., Yang, G.L., Zhang, L.L., Wei, W.: Fabrication and Performance of a Heterogeneous-Helical-Cladding Fiber. IEEE Photonics J. 13(4), 7100603 (1-3) (2021)

Song, Y.J., Hu, M.L., Liu, Q.W., Li, J.Y., Chen, W., Chai, L., Wang, Q.Y.: A mode-locked Yb3+-doped double-clad large-mode-area fiber laser. Acta. Phys. Sin. 57(8), 5045–5048 (2008)

Tsuchida, Y., Saitoh, K., Koshiba, M.: Design and characterization of single-mode holey fibers with low bending losses. Opt. Express 13(12), 4770–4779 (2005)

Wang, P., Cooper, L.J., Sahu, J.K., Clarkson, W.A.: Efficient single-mode operation of a cladding pumped ytterbium-doped helical-core fiber laser. Opt. Lett. 31(2), 226–228 (2006)

Wong, G.K.L., Kang, M.S., Lee, H.W., Biancalana, F., Conti, C., Weiss, T., Russell, P.S.: Excitation of orbital angular momentum resonances in helically twisted photonic crystal fiber. Science 337(6093), 446–449 (2012)

Yang, H.R., Li, X.Y., Hong, W., Hao, J.H.: Equilateral pentagon polarization maintaining photonic crystal fibre with low nonlinearity. Chin. Phys. B 21(2), 024211 (1-5) (2012)

Yang, S., Zhang, W.T., She, Y.L., Du, H., Tu, S.: A large mode area parabolic-profile core fiber with modified segmented in cladding. Photonics 9(10), 783 (1-12) (2022)

Yehouessi, J.P., Vanvincq, O., Cassez, A., Douay, M., Quiquempois, Y., Bouwmans, G., Bigot, L.: Extreme large mode area in single-mode pixelated Bragg fiber. Opt. Express 24(5), 4761–4770 (2016)

Zhou, X., Chen, Z., Zhou, H., Hou, J.: Theoretical investigation of core mode cut-off condition for tapered multicore fiber. Photon. Res. 3(5), 224–228 (2015)

Funding

Project is supported by the National Natural Science Foundation of China (grants 62075099), State Key Laboratory of Luminescent Materials and Devices, South China University of Technology, Guangzhou 510640, China (2023-skllmd-16).

Author information

Authors and Affiliations

Contributions

The authors completed the research and writing of this paper together. All authors reviewed the manuscript.

Corresponding author

Ethics declarations

Confict of interest

The authors declare that they have no competing interests.

Ethical approval

Not applicable.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Shen, X., Zhou, J. & Li, Y. Mode transmission performance study of a novel heterogeneous helical cladding fiber with an isolation ring. Opt Quant Electron 56, 1197 (2024). https://doi.org/10.1007/s11082-024-06869-8

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s11082-024-06869-8