Abstract

We investigated a three-channel reflective grating beam splitter with double-groove which eliminated ± 1st orders under TE and TM polarization. The grating has a polarization-dependent structure with different ridge thicknesses under TE and TM polarizations. Inhibitions of ± 1st orders are rarely reported from the previous work. The diffraction efficiency of the 0th order and ± 2nd orders for TE polarization orders can reach 32.7% and 33.3%, respectively. And the diffraction efficiency of 0th order and ± 2nd orders for TM polarization can reach 32.9% and 31.9%, respectively. It indicates that the uniformity of diffraction efficiency under the two polarizations also reaches more than 95%. The excellent bandwidth and tolerance make this grating suitable for a wide range of applications in the optical field. Compared conventional three-channel splitting, inhibitions of ± 1st orders are presented by double-groove microstructure.

Graphical Abstract

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

Modern electromagnetic investigation has gradually strict performance requirements for metamaterial devices (Sheta et al. 2022), whether it is civil or scientific research equipment, it needs to have high precision, high stability and other characteristics. Micro-nano gratings are very important optical devices (Wang et al. 2021, 2022a, b; Jia et al. 2022), which exhibit strong polarization correlation characteristics and abnormal transmission enhancement phenomena that are difficult to explain by classical diffraction theory at some specific wavelengths. This polarization characteristic and abnormal transmission enhancement effect have great potential in the field of optics. At present, micro-nano gratings have been widely used in the design of optical components, such as absorbers (Fu et al. 2022; Wu et al. 2020), polarization beam splitters (Fang and Wang 2021; Li et al. 2020), filters (Khonina et al. 2021) and circular polarizers, etc. It can realize polarization, transparency increase, beam splitting, high reflection, narrow band filtering and other functions.

Under micro-nano structures, the traditional scalar diffraction theory is no longer applicable, and vector diffraction theory is required for detailed analysis. In 1981, Moharam and Gaylord proposed rigorous coupled-wave analysis (RCWA) to analyze the diffraction behavior of planar gratings (Moharam and Gaylord 1981). With the development of modern optics, micro-nano gratings are now analyzed in addition to RCWA as well as modal method (Jin et al. 2021, 2022), finite difference time domain (FDTD) (Tsarev and Passaro 2020; Surawijaya et al. 2023) and finite element method (FEM) (Huang and Wang 2021).

Recently, the design of optical devices has developed rapidly, and many scholars have contributed to the design of micro-nano gratings. Among them, Gong et al. proposed a two-layer five-port diffraction grating by a polarization-independent design under normal incidence, which enables polarization-independent multiport outputs (Gong et al. 2020). Yin et al. designed a polarization-independent two-port beam splitter capable of 46% diffraction efficiency per port in the 800 nm band (Yin et al. 2020). Li et al. proposed a new type of high-uniformity nine-channel sandwiched fused silica diffraction grating (Li et al. 2022).

In this paper, a double-groove three-port reflective grating beam splitter is designed. The grating is a polarization-dependent grating, and the ridge thickness of the grating is different for TE and TM polarizations while other parameters remain the same. The grating has five diffraction orders, ensuring three effective output ports, 0th order and ± 2nd orders, by suppressing ± 1 orders. This article mainly uses the FEM to obtain the optimized parameters of the grating. The basic idea of the FEM is to discretize the continuous solution area of the research object into a set of finite and interconnected unit combinations in a certain way, and then analyze the units, and finally analyze them as a whole. FEM is a very effective numerical method that combines applied mathematics, modern mechanics and computer science and uses electronic computers to solve complex engineering structures. (Zaccaria et al. 2021; Iguchi et al. 2021). FEM is implemented through the multiphysics simulation. Under the condition of optimizing the grating parameters and incidence wavelength of 1550 nm at vertical incidence, the total diffraction efficiency of the 0th and ± 2nd orders under TE polarization can reach 99.3%, and the total diffraction efficiency of the 0th and ± 2nd orders under TM polarization can reach 96.7%. As a beam splitter, uniformity of more than 95% under TE and TM polarization is achieved.

2 Double-groove grating splitter by inhibitions of ± 1st orders

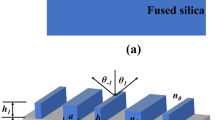

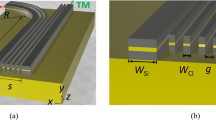

The 2D view of the grating we designed is shown in Fig. 1a and the 3D diagram is shown in Fig. 1b. As can be seen from the figure, \({h}_{1}\) represents the thickness of the grating ridge, d represents the grating period, \({h}_{m}\) represents the thickness of the reflective layer, and a and b represent the width of two different grating ridges, respectively. \({n}_{0}\), \({n}_{1}\) and \({n}_{2}\) represent the refractive index of the three materials, where \({n}_{0}\) represents the refractive index of air \({n}_{0}\)=1.00, \({n}_{1}\) represents the refractive index of the grating ridge and substrate, the refractive index is \({n}_{1}=1.44\) at 1550 nm, and \({n}_{2}\) represents the refractive index of the reflective layer Ag, \({n}_{2}= 0.14+11.37{\text{i}}\) at 1550 nm. Another important parameter in the grating is the duty cycle, unlike single-groove gratings, the duty cycle of a double-groove grating is defined as the ratio of the width of the grating ridge to half of the grating period (Gao and Wang 2020). Therefore, in this paper, the two duty cycles are defined as \({f}_{1}=2a/d\) and \({f}_{2}=2b/d\), respectively.

The grating parameters of this paper are calculated and optimized by FEM at wavelength of 1550 nm. Since the diffraction orders of the grating was determined to be 0th, ± 1st, and ± 2nd orders in the design, in order to reduce the amount of calculation, the influence of the grating period and the incident wavelength on the diffraction order of the grating is known from Xiong et al. (2022), and the formula is

where L is the maximum diffraction order of the grating and λ is incidence wavelength. The L of this paper is 2, so the range of the grating period d falls between 2 × wavelengths and 3 × wavelengths, i.e., 3100–4650 nm. The approximate range of the grating period d can be determined and FEM can be used to further optimize it, and finally the grating optimization parameters are obtained. Under TE polarization, the thickness of the grating ridge \({h}_{1}\) is 0.54 μm, the grating period d is 3938 nm, the duty cycle \({f}_{1}\) is 0.62, and the duty cycle \({f}_{2}\) is 0.48. Under TM polarization, \({h}_{1}\) is 1.03 μm, and the other of the grating parameters are the same as TE polarization. Since the reflection grating is designed, the thickness of the reflective layer has almost no effect on the diffraction efficiency, and the reflective layer parameter is designed to be 0.1 μm. More concise and clear grating parameters are detailed in Table 1.

After setting the grating parameters as FEM optimization parameters and the incident wavelength is 1550 nm, the diffraction efficiencies of 0th, ± 1st and ± 2nd orders under TE polarization are 32.7%, 0.1% and 33.3%, respectively. The diffraction efficiencies of 0th, ± 1st and ± 2nd orders under TM polarization are 32.9%, 1.3% and 31.9%, respectively. The total diffraction efficiencies of TE and TM polarization are 99.3% and 96.7%, respectively. Since the grating designed in this paper is a grating beam splitter that eliminates ± 1st order, the degree of suppression of ± 1st order and the uniformity of each diffraction order need to be considered. The degree of suppression of the ± 1st order can be seen intuitively, and the ± 1st order diffraction efficiency of both TE and TM polarization are very low. Then we define the uniformity formula as

where \({E}_{max}\) and \({E}_{min}\) in the formula represent the maximum and minimum value of 0th order and ± 2st orders under TE and TM polarization, respectively. \({E}_{avg}\) in the formula represents the average diffraction efficiency of the three ports (Lin and Wang 2021).

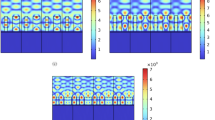

The uniformity of TE and TM polarization diffraction efficiency are calculated to be 98.2% and 96.9%, respectively. More intuitive diffraction efficiency data are shown in Table 2. Figure 2a shows the normalized electric field distribution diagram under TE polarization, and Fig. 2b shows the normalized electric field distribution diagram under TM polarization, it can be seen that the energy is distributed periodically, and most of the energy is radiated from the top of the grating ridge. We further compared the performance of other grating beam splitters with this paper in the same wavelength band. Table 3 shows the results of the references compared to the results of this paper (Zhou et al. 2022a; Shu et al. 2016). Based on eliminating ± 1st orders, three-branch can be exhibited by the double-groove microstructure.

3 Discussion and analysis

In the actual manufacturing process of the grating, errors will inevitably occur, which will cause the various parameters of the grating to change and affect the diffraction efficiency (Zheng et al. 2020; Zhou et al. 2022). In addition to the tolerances of manufacture, the nature of the incident wave also affects the diffraction efficiency. Next, we analyze the influence of grating ridge thickness, grating period, duty cycle of the two grating ridges, the wavelength of the incident wave and the angle of incidence on the diffraction efficiency. We define that when changing parameters, the total diffraction efficiency of the grating is greater than 90% and the diffraction efficiency of 0th order and ± 2nd orders are greater than 30% as the superior parameters. Double-groove grating has better suppression of ± 1 orders than conventional grating beam splitters. In the following parametric analysis, the diffraction efficiency of the ± 1 orders is suppressed to less than 5%.

3.1 Effect of grating tolerances on diffraction efficiency

Figures 3 and 4 shows the effect of the change in grating ridge thickness \({h}_{1}\) on the diffraction efficiency and uniformity, respectively. Figure 3a is the diffraction efficiency under TE polarization, and Fig. 3b is the diffraction efficiency under TM. It can be seen from the figure that under TE polarization, the diffraction efficiency is qualified when the grating ridge thickness is between 0.5 and 0.6 μm. Under TM polarization, the diffraction efficiency is eligible when the grating ridge thickness is between 0.8 and 1.3 μm. It can be seen that there is a great tolerance for the grating thickness \({h}_{1}\), where the tolerance can reach 0.5 μm under TM polarization.

The grating designed in this paper has two grating ridges with different duty cycles, and the influence of the common change of duty cycles \({f}_{1}\) and \({f}_{2}\) on the diffraction efficiency needs to be considered. Figure 5a–c show the diffraction efficiency distribution as \({f}_{1}\) and \({f}_{2}\) change under TE polarization, as shown in Fig. 5d–f show the diffraction efficiency distribution under TM polarization. The contour plot can more intuitively see the effect of the change of two parameters on the third parameter. Figures 6 and 7 shows the effect of the change in grating ridge thickness \(d\) on the diffraction efficiency and uniformity, respectively. The parameter variation range is 3838–4038 nm. Within the test range, the grating period d meets the requirements. From the above several grating parameters analysis, the tolerances of the grating are excellent.

3.2 The effect of the properties of the incident wave on the diffraction efficiency

The bandwidth of the grating is also an important indicator to evaluate a grating, which determines the wavelength range in which the grating can operate. Figure 8a shows the effect of incident wave wavelength on diffraction efficiency under TE polarization, the test range is 1500–1600 nm, and the diffraction efficiency meets the requirements when the incident wave wavelength falls between 1525 and 1555 nm. Under TM polarization, the grating exhibits excellent bandwidth. Figure 8b shows the effect of incident wave wavelength on diffraction efficiency under TM polarization, and the test range is the same as TE, it can be seen that the diffraction efficiency in the test meets the conditions. The bandwidth of this grating performs well under TM polarization.

Finally, the influence of incidence angle on the diffraction efficiency is considered. Figure 9a, b represent the relationship between angle of incidence and diffraction efficiency under TE and TM polarization, respectively. Under TE polarization, when the angle of incidence is in the range of −0.08 to 0.05 rad, i.e., the degree is −4.6 −2.9°, the diffraction efficiency meets the requirements. Under TM polarization, when the angle of incidence is in the range of −0.02 to 0.1 rad, i.e., the degree is −1.2 −5.7°, the diffraction efficiency meets the requirements.

4 Conclusion

In this paper, a reflective grating beam splitter with double-groove and three port outputs is designed. We use the FEM to optimize the grating parameters. When the grating parameters are set to the optimal parameters, the diffraction efficiencies of 0th and ± 2nd orders under TE polarization are 32.7% and 33.3%, respectively, and the diffraction efficiency of 0th and ± 2nd stages under TM polarization are 32.9% and 31.9%, respectively. The effects of grating parameter and incident wave properties on diffraction efficiency were analyzed. And the tolerance and bandwidth of this grating behaves well. The stability of this grating makes its application scenarios more extensive.

References

Fang, J., Wang, B.: T-type high-efficiency transmission grating for 7-channel beam separation. Optik 231, 166391 (2021)

Fu, C., Wang, B., Zhu, X., Xiong, Z., Huang, Y.: Narrowband absorbers based on multi-ridge gratings. Optik 257, 168839 (2022)

Gao, C., Wang, B.: Double-groove reflection grating for three-channel beam separation at infrared wavelength. Laser Phys. 30(7), 076201 (2020)

Gong, B., Wen, H., Li, H.: Polarization-independent two-layer grating with five-port splitting output under normal incidence. IEEE Photonics J. 12(2), 6500208 (2020)

Huang, Z., Wang, B.: Polarization-insensitive high-efficiency two-dimensional metal-dielectric grating by nanodisks arrays. Phys. Scr. 96(12), 125518 (2021)

Iguchi, A., Morimoto, K., Tsuji, Y.: Bidirectional beam propagation method based on axi-symmetric full-vectorial finite element method. IEEE Photonics Technol. Lett. 33(14), 707–710 (2021)

Jia, T., Ren, Y., Wang, X., Qi, Y., Wen, X.: Theoretical study of 2D sub-wavelength structure fabrication via surface plasmon excitation utilizing the enhanced Kretschmann structure combined with sample rotation. Opt. Quantum Electron. 54(4), 208 (2022)

Jin, G., Liu, W., Ye, Z., Jia, W., Xie, Y., Zhou, C.: High efficiency polarization-independent slanted grating for RGB bands. IEEE Photonics J. 13(4), 5100108 (2021)

Jin, G., Jia, W., Bayanheshig, Xie, Y., Zhou, C.: High-efficiency broadband polarization-independent reflective grating with double-layer dielectric rectangle groove in Littrow mounting. Appl. Sci.-Basel 12(17), 8612 (2022)

Khonina, S.N., Kazanskiy, N.L., Butt, M.A.: Spectral characteristics of broad band-rejection filter based on Bragg grating, one-dimensional photonic crystal, and subwavelength grating waveguide. Phys. Scr. 96(5), 055505 (2021)

Li, G., Duan, X., Huang, Y., Liu, K., Ren, X.: Flat transmitted serrated-phase high-contrast-index subwavelength grating beam splitter. Chin. Opt. Lett. 18(11), 110504 (2020)

Li, H., Huang, T., Lu, L., Hu, Z., Yu, B.: High-efficiency nine-port beam splitting output enabled by a dielectric lamellar sandwiched fused-silica grating. Opt. Laser Technol. 145, 107465 (2022)

Lin, Z., Wang, B.: Polarization-selective splitter with double structure periodic ridges. Opt. Eng. 60(4), 045108–045108 (2021)

Moharam, M.G., Gaylord, T.K.: Rigorous coupled-wave analysis of planar-grating diffraction. JOSA 71(7), 811–818 (1981)

Sheta, E.M., Choudhury, P.K., Ibrahim, A.-B.M.A.: Tri-controllable polarization insensitive graphene-InSb pixelated metamaterial for thermal sensing. Optik 260, 169057 (2022)

Shu, W., Wang, B., Li, H., Lei, L., Chen, L., Zhou, J.: Encapsulated grating for three-port beam splitter in reflection. Mod. Phys. Lett. B 30(06), 1650070 (2016)

Surawijaya, A., Chandra, Z., Sulthoni, M.A., Idris, I., Adiono, T.: Modeling and simulation of Si grating photodetector fabricated using MACE method for NIR spectrum. Electronics 12(3), 663 (2023)

Tsarev, A., Passaro, V.M.N.: Numerical simulation of optical sensing by the far field pattern radiated by periodic grating strips over silica buffer on the silicon wire waveguide. Sensors 20(18), 5306 (2020)

Wang, Y., Wang, D., Zhang, X., Huang, T., Zhao, X., Zeng, S.: Design of sub wavelength-grating-coupled Fano resonance sensor in mid-infrared. Plasmonics 16(2), 463–469 (2021)

Wang, M., Li, P., Li, S., Xu, Y., Yao, C.: Hundred-watt level average power CPA system with all-fiberized laser amplifiers based on CFBG stretcher and CVBG compressor. Optik 53, 168597 (2022a)

Wang, C., Wang, D., Xu, Y., Leng, Y.: Full-aperture chirped-pulse grating compression with a non-uniform beam. Opt. Commun. 507, 127613 (2022b)

Wu, P., Wang, Y., Yi, Z., Huang, Z., Xu, Z., Jiang, P.: A near-infrared multi-band perfect absorber based on 1D gold grating Fabry-Perot structure. IEEE Access 8, 72742–72748 (2020)

Xiong, Z., Wang, B., Zhou, J.: Triple-layer array splitter for zeroth-order suppressing under normal incidence. Optik 267, 169743 (2022)

Yin, Z., Lu, Y., Yu, J., Zhou, C.: A broadband polarization-independent two-port beam splitter under normal incidence based on encapsulated metal-dielectric reflective grating. Chin. Opt. Lett. 18(7), 070501 (2020)

Zaccaria, C., Mancinelli, M., Pavesi, L.: A fem enhanced transfer matrix method for optical grating design. J. Lightwave Technol. 39(11), 3521–3530 (2021)

Zheng, Y., Kai, X., Gao, P., Duan, J.: Fabrication tolerance analysis of grating couplers between optical fibers and silicon waveguide. Optik 201, 163490 (2020)

Zhou, Y., Li, X., Wang, B., Li, L.: Application of dual-structure grating for equal three-channel splitting in reflection. Optik 259, 169014 (2022a)

Zhou, J., Dong, S., Wei, Z., Zhang, J., Deng, X., Wang, Z., Cheng, X.: Two-dimensional guided-mode resonance gratings with an etch-stop layer and high tolerance to fabrication errors. Opt. Express 30(14), 25907–25917 (2022b)

Funding

This work is supported by the Key Laboratory of Biomedical Imaging Science and System, Chinese Academy of Sciences.

Author information

Authors and Affiliations

Contributions

XW: Data curation, Validation, Investigation, Writing—original draft. BW: Conceptualization, Methodology, Supervision, Project administration, Writing- review & editing. JH: Formal analysis.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Ethical approval

Not applicable.

Consent to participate

Not applicable.

Consent for publication

Not applicable.

Data availability

The datasets analyzed during the current study are available in the present article.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Wang, X., Wang, B. & Huang, J. Eliminating ± 1st orders by double-groove microstructure for three-branch electromagnetic wave splitting. Opt Quant Electron 56, 523 (2024). https://doi.org/10.1007/s11082-023-06120-w

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s11082-023-06120-w