Abstract

This study presents the application of MAX phase material as a mode-locker in the thulium-holmium-doped fiber laser (THDFL) cavity in generating ultrashort pulses. MAX phase materials were rapidly developed for applications in the pulsed laser field due to their promising properties and characteristics, such as strong nonlinear absorption, high damage tolerance, and good thermal and electrical conductivities. Chromium Aluminum Carbide (Cr2AlC) MAX phase sample was explicitly introduced into the cavity by drop-casting the Cr2AlC onto the fabricated arc-shaped fiber. As a result, an ultrafast mode-locking laser system was achieved utilizing a Cr2AlC saturable absorber (SA) at a pump power of 115.8 mW, having a central wavelength of 1908.58 nm. The spectral bandwidth obtained was 3 nm, and a measured pulse repetition rate and pulse width of 12.14 MHz and 1.3 ps, respectively. The results indicate that Cr2AlC SA is a promising material to be used as a passive SA to initiate the mode-locking generation of fiber laser in the 1.9 μm band.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

1 Introduction

Optical fiber-based technology has drawn significant interest owing to its numerous advantages, namely, compactness, high beam quality, and alignment-free operation (Fermann and Hartl 2009), which enables them to be implemented in different applications such as optical sensing (Alias et al. 2022; Sa'ad et al. 2022; Lim et al. 2012) and fiber optic imaging (Hossain et al. 2012; Silva and Pang 2012). Other than these, optical fibers are also applied as optical sources, for instance, short-pulsed fiber lasers (Bao et al. 2009; Ismail et al. 2012; Ma et al. 2019) and multiwavelength fiber lasers (Ahmad et al. 2008; Harun et al. 2009; Wang et al. 2013). Specifically, ultrashort pulses have become an intense research topic among researchers due to their exceptional performance in communication, material processing, medicine, and others (Clowes 2008; Fermann and Hartl 2013; Liang et al. 2006). Rapid development has been done on optical-based devices covering S-, C-, and L-bands, and diverse schemes have been employed in generating ultrashort pulse lasers.

Mode-locking is a technique implemented to produce pulses of light of short durations with high repetition rates. A commonly used method is the passive mode-locking approach. In contrast with the active process, the passive means is realized by incorporating a saturable absorber (SA) to modulate the loss in the laser cavity. This approach offers the benefits of a low-cost technique, is simple to handle, and can generate stable pulses (Wang and Xu 2007). Different kinds of SA materials have been recognized for a wide range of optical materials, such as transition metal dichalcogenides (Chen et al. 2017; Liu et al. 2020; Mohanraj et al. 2016), black phosphorus (Luo et al. 2015; Sotor et al. 2015; Zhang et al. 2018), graphene (Fu et al. 2014; Ma et al. 2012; Sun et al. 2010), and topological insulators (Ahmad et al. 2022a, b; Zhao et al. 2012). Nonetheless, these SAs have their drawbacks, such as having low modulation depth and low damage threshold (Dong et al. 2012), narrow spectral bandwidth (Wang et al. 2015), low nonlinear absorption, and required complex fabrication process (Chen et al. 2015).

In recent years, an immense study has been done on a newly known MAX phase family, which has a unique combination of ceramic and metal-like properties. MAX phase exhibits the general formula "Mn+1AXn" where "M" is the transition material, "A" is the elemental group A, "X" corresponds to the C and/or N, and "n" takes the value of 1, 2, or 3, respectively. The fabrication of the MAX phase requires very minimal time and is cost-effective. This is because no strong etching solutions are needed for the etching process, therefore ensuring the simplicity of the approach. Over 60 MAX phases existed, and much more has yet to be discovered and studied. Chromium aluminum carbides (Cr2AlC) is one of the MAX phase materials with the main characteristic of filling the gap between ceramics and metals. This unique combination is the main reason for its special properties, including a fast recovery time, high damage tolerance, resistance to thermal shock, oxidation resistance, and lightweight resistance.

Nevertheless, not all possible combinations are thermodynamically stable, Cr2AlC is one of the stable MAX phases in a wide range of temperatures which makes it useful for widespread industrial applications such as high train speed in China (Gonzalez-Julian 2020). Besides that, Cr2AlC has a low density which categorizes it as lightweight material to be compatible to replace with high damage tolerance ceramics with self-healing characteristics. In 2012, research was done on the optical conductivity, σ, of 20 different MAX phases, including Cr2AlC, at a wide frequency range. Cr2AlC is the series with M element in the fourth periodic table having the same shape as the axial and the planer curves and possessing the anisotropic optical conductivities of 1.32 (Lin et al. 2006; Mo et al. 2012). Furthermore, in a study by Najm et al. (2021), the soliton mode-locked laser based on the Cr2AlC MAX phase as SA has been successfully demonstrated in the 1.5 μm region.

In the previous studies by Ahmad et al. (2022a, b), a thulium-holmium-doped fiber (THDF) active fiber was used to generate a mode-locked pulse laser successfully. The first study reported the generation of mode-locked pulses using topological insulator (TI) antimony telluride (Sb2Te3). On the other hand, the tantalum aluminum carbide (Ta2AlC) MAX phase was implemented as the SA for the second study. It can be perceived that even using the same THDFL gain medium may result in different mode-locking characteristics due to the different properties possessed by each of the SA materials. Thus, it is interesting to investigate further the properties of different types of MAX phase materials that can withstand a high-humidity environment and a high-power operation. In this study, a MAX phase material, Cr2AlC, was proposed as a SA to generate a self-starting mode-locked thulium-holmium-doped fiber laser (THDFL). Foremost, arc-shaped single-mode fiber (SMF-28) was prepared by the wheel polishing method. Cr2AlC material was introduced by drop-casting the sample onto the fabricated arc-shaped fiber. The SA characteristics were studied, and mode-locked generation was attained at 1908.58 nm wavelength, 1.3 ps pulse width, and 12.14 MHz repetition rate. The spectral bandwidth achieved was about 3 nm with a threshold pump power of 115.8 mW. The experimental results prove the excellent characteristics and capability of the Cr2AlC MAX phase to generate stable mode-locked pulses. They could become a good candidate for generating ultrashort pulses for photonics applications.

2 Experimental method

2.1 Preparation of Cr2AlC MAX phase sample

To prepare the Cr2AlC MAX phase sample, 100 mg of Cr2AlC powder (Forsman Scientific (Beijing) Co. Ltd, China) was mixed with 10 mL of isopropyl alcohol (IPA) in a beaker. Then, the mixture was poured into a vial and underwent a sonication process in water for about 2 h to disperse the MAX phase powder-IPA mixture well and obtain a homogenous solution. Next, centrifugation was performed to separate the precipitate from the liquid suspension. Finally, the black supernatant decanted was kept and mixed with IPA to produce a diluted Cr2AlC solution and was used as the MAX phase sample in generating mode-locked pulses. The process of preparing the MAX phase material was illustrated in Fig. 1.

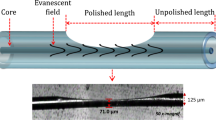

2.2 Cr2AlC/Arc-shaped fiber SA fabrication

The SA was prepared by first, fabricating the arc-shaped fiber. Then, the wheel polishing method was employed to polish one side of the single-mode fiber (SMF-28). Foremost, the polymer coatings of the middle part of the SMF-28 were stripped off in advance and placed on the polishing wheel by clamping both sides of the fiber with the clampers mounted on the polishing stage. The wheel was covered with sandpaper of 1000 grain size and was connected to a 5 V-DC motor. In order to monitor the fabrication process, a tunable laser source (TLS) of wavelength 1550 nm was connected to one end of the arc-shaped fiber and the other to the optical power meter (OPM). Optical power monitoring was done during the process until a loss of 3.0 dB was achieved. The experimental setup to fabricate the arc-shaped fiber is illustrated in Fig. 2a. The diameter of the fabricated fiber was also measured, having a diameter of 69 μm at the polished region. This process provides an interaction of the evanescent field and the external environment. The insertion loss of the bare arc-shaped fiber was also measured using a THDF laser at wavelength 1908.50 nm, giving a value of 5.31 dB without Cr2AlC. The high insertion loss obtained was primarily due to the high scattering losses from the arc-shaped polished area. This was done using sandpaper of grit P1000, which may not be fine enough. To reduce the scattering losses, the sandpaper needs to have a grit number higher than this value, which is not currently available in the laboratory. Another way to get around this to reduce the high scattering losses is to re-polish it again using a diamond paste film. It will further reduce surface roughness and scattering losses.

The polished surface was then drop cast with 5.0 μL of the Cr2AlC sample and was left to dry for about 10 min, and the SA device was ready to be implemented to produce ultrafast mode-locked pulses. Figure 2b, the schematic diagram shows the arc-shaped SMF with MAX phase coating on the polished surface. It can be observed the presence of dark spots on the polished surface indicates the distributions of the Cr2AlC MAX phase material. The performance and repeatability of the SA will significantly depend on the material preparation and also the low loss of the arc-shaped fiber. High-quality material with no foreign impurities will be vital for the performance of the SA. On top of this, the arc-shaped fiber should have a lower insertion loss with a high-quality polished surface. This will improve the performance of the SA and its repeatability.

2.3 Material characterization

The structural analysis of the prepared MAX phase material was analyzed using a field emission scanning electron microscope (FESEM) Hitachi SU8220. Energy-dispersive X-ray (EDX) spectroscopy was done using an EDX unit attached to the FESEM, where the chemical characterization of Cr2AlC was analyzed and studied. The study on the surface topography and thickness of the MAX phase was also done using the Bruker Dektak XT step profiler. Next, the Renishaw In-Via microscope with an argon-ion laser at 514 nm wavelength was utilized to record the Raman spectra and to study the dangling bonds of the MAX phase sample.

A balance twin detector approach was used to measure the nonlinear optical properties of MAX phase Cr2AlC coated arc-shaped fiber SA. A commercial Toptica FemtoFerb femtosecond laser was utilized as the laser source having a 1950 nm central wavelength, repetition rate, and pulse duration of 29.76 MHz and 100 fs, respectively. The laser source was first connected to an attenuator and then to a 3 dB optical coupler. One part of the coupler was connected to the SA device and subsequently to the optical power meter, and the other was connected straight to the OPM as the SA reference. The proposed setup is schematically shown in Fig. 3. The output power was measured at different input intensities, and the experimental data gained was fitted using the relation given as follows:

where α(I), αs, αns, I, and Isat are the absorption coefficient, the saturable loss or modulation depth, non-saturable absorbance, input intensity and saturating intensity, respectively.

2.4 Experimental cavity setup

The experimental setup used in this study was shown in Fig. 4. A TH512 THDF active fiber supplied by CorActive was used as the gain medium. The THDF has a core diameter of 9 µm, a cut-off wavelength of 1700 nm, and an absorption coefficient of 18 dBm−1 at around 1560 nm. The remaining fiber, made of standard SMF-28 optical fiber, comes from the various optical components, having a core and cladding diameter of about 9 µm and 125 µm. The numerical aperture (NA) of the SMF-28 is 0.14, with an operating wavelength of 1260–1625 nm. Two laser diodes (LDs) (Princeton Lightwave Inc PSL) with a central operating wavelength of 1550 nm were used to pump the THDF active fiber. Each LD was spliced with a 1550 nm optical isolator to avoid any back-reflections and to protect the LDs. Then, each of the ISO ends was connected to a division multiplexer (WDM1,2) to guide the light to the THDF gain medium of 1.5 m length. Next, an optical isolator was connected to the WDM2 and connected to a 90:10 optical coupler. The 90% port of the coupler was connected to the SA device and then to the polarization controller, thus completing the optical cavity.

The total length of the THDF cavity was measured to be around 17.16 m, consisting of 1.5 m of thulium holmium gain medium and 15.66 m length of single-mode fiber. The group velocity dispersion (GVD) of THDF and SMF were computed as − 0.0572 ps2/m and − 0.0615 ps2/m, respectively. Referring to the equation, LTHDFGVDTHDF + LSMFGVDSMF, the net cavity fiber dispersion was calculated as − 1.049 ps2. With the computed net cavity dispersion obtained, the THDF laser will operate in the anomalous regime, also known as the soliton regime.

3 Results and discussion

3.1 Characterization of Cr2AlC MAX phase

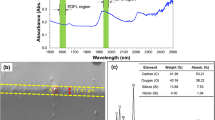

FESEM images of the Cr2AlC MAX phase were obtained from the FESEM analysis, as depicted in Fig. 5a. From the 10,000 × image magnification, the sample consists of flake-like morphology with irregular structure and few bound nano-laminated layers. The grain size was in the region of 0.5–5 μm. The constituent elements and the distribution of the Cr2AlC sample were studied using EDX analysis, and the results are presented in Fig. 5b and c. From Fig. 5b, the existence of strong signals of chromium (Cr), aluminum (Al), and carbon (C) elements have confirmed the formation of the Cr2AlC MAX Phase. From the elemental weight percentage analysis, the sample contains 12.27% weight of Cr, 3.37% weight of Al, and 6.49% weight of C functional group. The elemental mappings of Cr (red), Al (blue), and C (green) can be observed in Fig. 5c, which further indicates the uniformity of the distribution of the element in the Cr2AlC MAX Phase.

The Bruker Dektak XT step profiler features a trace analysis routine, and this equipment was used to investigate the topography of the prepared Cr2AlC MAX phase. The thickness of the layers was characterized, and the sample was first prepared by drop-casting the fabricated material onto a quartz slide. The sample was left to dry for a few hours before proceeding with the surface topography analysis. The average thickness of Cr2AlC was calculated from 5 sets of profilometry data, and the value obtained was about 0.11 µm. Based on the Raman spectrum plotted in Fig. 5d, three Raman characteristic peaks of the Cr2AlC MAX Phase can be seen, which are 153, 234, and 320 cm−1, respectively. These respective peaks can be assigned to the E2g, E1g, and A1g of Raman active modes (Spanier et al. 2005). It has also been investigated that all these Raman active modes arose due to the stretching and bending of Al–Cr–C covalent bond chains (Jingyang Wang et al. 2005). The nonlinear optical absorption of the as-prepared Cr2AlC/arc-shaped fiber was also studied, and the corresponding fitting curve was plotted in Fig. 5e. From the graph, the value of modulation depth, non-saturable loss, and saturation intensity of the device was determined to be 29.10%, 70.90%, and 0.34 MW/cm2, respectively.

3.2 THDFL with Cr2AlC SA

The cavity lasing was optimized beforehand to ensure the pulse lasing generated was not due to the nonlinearity in the cavity itself. Figure 6a shows the optical spectrum obtained by the THDF cavity in the absence of the SA device. Inserting the Cr2AlC/arc-shaped fiber-based SA produces a self-starting mode locking in the THDFL, as depicted in Fig. 6b, at a pump power of 115.8 mW with adjustment to the polarization controller (PC). It should be noted that the foremost reason for the shift in wavelength from 1955 to 1908 nm is due to the high insertion loss of the arc-shaped fiber and shifting of the oscillation towards the peak of the gain profile. Therefore, optimizing the insertion loss of the fabricated fiber allows the opportunity to choose the signal wavelength. Following the deposition of the Cr2AlC solution onto the prepared fiber, spectrum broadening can be observed, having 3 nm of full width at half maximum (FWHM), as shown in Fig. 6b. In addition, Kelly's spectral sidebands can be observed on the spectrum, suggesting the operation of the mode-locked fiber laser operating in the anomalous dispersion regime.

The corresponding pulse train of the generated mode-locked was illustrated in Fig. 6c. Based on the spectrum, the two successive mode-locked pulses were separated with a period of 82.3 ns. The round-trip time in the cavity corresponds to a repetition rate of 12.14 MHz, well matched to the cavity's total length of 17.16 m. From the RF spectrum plotted in Fig. 6e, the single-to-noise ratio (SNR) value at 300 Hz resolution bandwidth was measured at 64 dB, with a fundamental frequency of 12.14 MHz. Pulse duration was measured using an A.P.E Pulsecheck150 autocorrelator. The autocorrelation trace was depicted in Fig. 6d, with a pulse duration of 1.3 ps. With the obtained signal wavelength of 1908.58 nm wavelength and FWHM of 3 nm, the time-bandwidth product (TBP) for the passive mode-locked laser using hyperbolic-secant-squared (sech2) pulse profile as below,

where τ denotes the pulse width, and c represents the speed of light, whereas λ0 and ∆λ represent the center wavelength and the 3-dB bandwidth of the mode-locked optical spectrum, respectively. Hence, the TBP was calculated to be 0.321. However, a slight difference between the calculated and the theoretical limit of 0.315 may be due to the pulses being slightly chirped.

Figure 7 depicts the function of average output power versus different pump power values. The output power of the passive mode-locking THDFL was monitored using a Thorlabs S302C thermal-based power meter having initial lasing at a pump power of 70 mW. The appearance of mode-locked pulses started at 115.8 mW. The pulse energy was calculated to be 0.357 nJ, and the peak power of the mode-locked pulses was 277 W. Shorter pulses width would result in the higher peak power desired in mode-locking pulses. Based on the plotted graph, the slope efficiency obtained was about 3.1%. A relatively low-efficiency value was obtained, which may be due to the coated device's high insertion loss and the presence of foreign impurities in the material. On top of this, high non-saturable loss caused by the irregular surface roughness of the polished surface may also increase the non-saturable loss and eventually reduce the laser efficiency.

The stability measurement of the mode-locking operation was also tested by continuously observing the optical spectrum over 3 h. As a result, the long-term stability performance can be studied concerning the change in its central operation wavelength and the 3 dB bandwidth value. The results were shown in Fig. 8a and b. The first observation was marked at 0 min, and the subsequent optical spectra were taken in the time block of 15 min. Figure 8b shows no noticeable fluctuation in the central operating wavelength and FWHM values over this period. Therefore, it explains that the fabricated Cr2AlC-coated arc-shaped fiber SA exhibits long-term stability.

Table 1 compares the generated mode-locked pulses with different MAX phases used as the SA materials. Several studies have been done on implementing MAX phase materials as the SA at 1.5 μm region. In 2021, Najm et al. (2021) and Sun et al. (2021) conducted an experiment using Cr2AlC thin film and Ti2AlC thin film, respectively, to investigate the potential of MAX phase material in initiating the mode-locked pulsed laser. Another MAX phase material, V2AlC, was used by Lee et al. (2022) coated on the side-polished fiber to generate mode-locking at a 1.5 μm regime. It can be seen that the central wavelength (λc) obtained from the studies was around 1550 nm, and SNR value in the range between 50 and 70 dB. As for the pulse width (Δτ), Ti2AlC MAX phase SA produced the narrowest, value of 0.68 ps. The generation of mode-locked laser using MAX phase SA in a 2.0 μm region has also been studied. Ahmad et al. (2021) reported on the mode-locked laser generation using Ti2AlC coated on tapered fiber SA. The mode-locked laser operating at the central wavelength of 1933.82 nm with the SNR value of 70 dB was achieved. Although this work produced pulses nearer to the 2.0 μm wavelength region and have a higher SNR value than ours, the pulse width is broader. In the other work, Ahmad et al. (2022a, b) studied the mode-locked laser production by employing Ta2AlC MAX phase material coated on the arc-shaped fiber as the SA. The mode-locked operated at a central wavelength of about 1915 nm with pulse width and SNR value of 1.36 ps and 55.0 dB, respectively. Even though the Ta2AlC MAX phase-based SA could generate a mode-locked laser operating at a longer central wavelength than our work, it has a lower SNR value.

4 Conclusion

The Cr2AlC MAX phase successfully produced mode-locked pulses operating in the 1.9 µm wavelength region. The MAX phase/arc-shaped SMF-based SA was successfully prepared via a simple polishing and dropped casting technique. Passively mode-locked pulses were produced after the implementation of the prepared Cr2AlC SA device into the THDF laser setup having 1908.58 nm wavelength and pulse duration of 1.3 ps with a 12.14 MHz repetition rate. The lower laser efficiency is primarily due to the low coupling ratio of the 10:90 coupler used to extract the output power. The other factor would be the scattering loss of the arc-shaped fiber, which can be improved by using sandpaper with a finer grit or polished using a diamond paste film. The mode-locked laser stability was also tested, and it was proven that the SA device possesses long-term stability characteristics with no apparent fluctuation in the center wavelength and FWHM values observed. The SNR value obtained of 64 dB further proved the stability of the Cr2AlC MAX phase material.

Availability of data and materials

Data will be made available on request.

References

Ahmad, H., Thambiratnam, K., Sulaiman, A.H., Tamchek, N., Harun, S.W.: SOA-based quad-wavelength ring laser. Laser Phys. Lett. 5(10), 726–729 (2008)

Ahmad, H., Kahar, N.A., Ramli, R., Yusoff, N., Reduan, S.A., Ismail, M.F., Yasin, M.: The performance of Ti2C MXene and Ti2AlC MAX phase as saturable absorbers for passively mode-locked fiber laser. Opt. Fiber Technol. 67, 102683 (2021)

Ahmad, H., Sadafi, N., Yusoff, N., Samion, M.Z., Ismail, M.F., Chong, W.Y.: Arc-shaped fiber coated with Ta2AlC MAX phase as mode-locker for pulse laser generation in thulium/holmium doped fiber laser. Optik 252, 168508 (2022a)

Ahmad, H., Makhfuz, M.J.M., Yusoff, N., Reduan, S.A.: Thulium holmium-doped fiber laser mode-locked using Sb2Te3 saturable absorber coated arc-shaped fiber. Infrared Phys. Technol. 125, 104228 (2022b)

Alias, M.A., Ahmad, H., Samion, M.Z., Sa’ad, M.S., Sing, L.K., Grattan, K.T.V., Rahman, B.M.A., Brambilla, G., Zaini, M.K., Bayang, L., Ismail, M.F.: Highly sensitive temperature-independent fbg-based sensor embedded in thermoplastic polyurethane using 3D printing technology for the measurements of torsion. Sens. Actuator A Phys. 346, 113889 (2022)

Bao, Q., Zhang, H., Wang, Y., Ni, Z., Yan, Y., Shen, Z.X., Loh, K.P., Tang, D.Y.: Atomic-layer graphene as a saturable absorber for ultrafast pulsed lasers. Adv. Funct. Mater. 19(19), 3077–3083 (2009). https://doi.org/10.1002/adfm.200901007

Chen, Y., Jiang, G., Chen, S., Guo, Z., Yu, X., Zhao, C., Zhang, H., Bao, Q., Wen, S., Tang, D., Fan, D.: Mechanically exfoliated black phosphorus as a new saturable absorber for both q-switching and mode-locking laser operation. Opt. Express. 23(10), 12823–12833 (2015)

Chen, H., Yin, J., Yang, J., Zhang, X., Liu, M., Jiang, Z., Wang, J., Sun, Z., Guo, T., Liu, W., Yan, P.: Transition-metal dichalcogenides heterostructure saturable absorbers for ultrafast photonics. Opt. Lett. 42(21), 4279–4282 (2017)

Clowes, J.: Next generation light sources for biomedical applications. Opt. Photonik 3(1), 36–38 (2008)

Dong, Z., Li, H., Xia, H., Liu, Y., Wang, Z., Chen, Y.: Passively Q-switched erbium-doped fiber laser using a graphene saturable absorber. In: Asia Communications and Photonics Conference and Exhibition (2012)

Fermann, M.E., Hartl, I.: Ultrafast fiber laser technology. IEEE J. Sel. Top. Quantum Electron. 15(1), 191–206 (2009)

Fermann, M.E., Hartl, I.: Ultrafast fibre lasers. Nat. Photonics 7(11), 868–874 (2013)

Fu, B., Hua, Y., Xiao, X., Zhu, H., Sun, Z., Yang, C.: Broadband graphene saturable absorber for pulsed fiber lasers at 1, 1.5, and 2 μm. IEEE J. Sel. Top. Quantum Electron. 20(5), 411–415 (2014)

Gonzalez-Julian, J.: Processing of MAX phases: from synthesis to applications. J. Am. Ceram. Soc. 104(2), 659–690 (2020)

Harun, S.W., Shahi, S., Ahmad, H.: Compact brillouin-erbium fiber laser. Appl. Opt. 34(1), 46–48 (2009)

Hossain, M.M.M., Lu, G., Yan, Y.: Optical fiber imaging based tomographic reconstruction of burner flames. IEEE Trans. Instrum. Meas. 61(5), 1417–1425 (2012)

Ismail, M.A., Ismail, M.A., Harun, S.W., Zulkepely, N.R., Nor, R.M., Ahmad, F., Ahmad, H.: Nanosecond soliton pulse generation by mode-locked erbium-doped fiber laser using single-walled carbon-nanotube-based saturable absorber. Appl. Opt. 51(36), 8621–8624 (2012)

Lee, J., Kwon, S.Y., Lee, J.H.: Harmonically mode-locked Er-doped fiber laser at 1.3 GHz using a V2AlC MAX phase nanoparticle-based saturable absorber. Opt. Laser Technol. 145, 107525 (2022)

Liang, C., Lee, K.F., Levin, T., Chen, J., Kumar, P.: Ultra stable all-fiber telecom-band entangled photon-pair source for turnkey quantum communication applications. Opt. Express. 14(15), 6936–6941 (2006)

Lim, K.S., Aryanfar, I., Chong, W.Y., Cheong, Y.K., Harun, S.W., Ahmad, H.: Integrated microfibre device for refractive index and temperature sensing. Sensors 12(9), 11782–11789 (2012)

Lin, Z., Zhuo, M., Zhou, Y., Li, M., Wang, J.: Atomic scale characterization of layered ternary Cr2AlC. Ceram. J. Appl. Phys. 99(7), 076109 (2006)

Liu, X., Gao, Q., Zheng, Y., Mao, D., Zhao, J.: Recent progress of pulsed fiber lasers based on transition-metal dichalcogenides and black phosphorus saturable absorbers. Nanophotonics 9(8), 2215–2231 (2020)

Luo, Z.C., Liu, M., Guo, Z.N., Jiang, X.F., Luo, A.P., Zhao, C.J., Yu, X.F., Xu, W.C., Zhang, H.: Microfiber-based few-layer black phosphorus saturable absorber for ultra-fast fiber laser. Opt. Express. 23(15), 20030–20039 (2015)

Ma, J., Xie, G.Q., Lv, P., Gao, W.L., Yuan, P., Qian, L.J., Yu, H.H., Zhang, H.J., Wang, J.Y., Tang, D.Y.: Graphene mode-locked femtosecond laser at 2 μm wavelength. Opt. Lett. 37(11), 2085–2087 (2012)

Ma, C., Wang, C., Gao, B., Adams, J., Wu, G., Zhang, H.: Recent progress in ultrafast lasers based on 2D materials as a saturable absorber. Appl. Phys. Rev. 6(4), 041304 (2019)

Mo, Y., Rulis, P., Ching, W.Y.: Electronic structure and optical conductivities of 20 max-phase compounds. Phys. Rev. B 86(16), 165122 (2012)

Mohanraj, J., Velmurugan, V., Sivabalan, S.: Transition metal dichalcogenides based saturable absorbers for pulsed laser technology. Opt. Mater. 60, 601–617 (2016)

Najm, M.M., Al-Hiti, A.S., Nizamani, B., Zhang, P., Arof, H., Rosol, A.H., Yasin, M., Harun, S.W.: Ultrafast laser soliton mode-locked at 1.5 μm region based on Cr2AlC MAX phase as a saturable absorber. Opt. Eng. 60(6), 66116 (2021)

Sa’ad, M.S., Ismail, M.F., Zaini, M.K., Grattan, K.T., Rahman, B.M., Brambilla, G., Sing, L.K., Ahmad, H.: Temperature-independent vibration sensor based on fabry–perot interferometer using a fiber bragg grating approach. Opt. Eng. 61(03), 037101 (2022)

Silva, I., Pang, G.: Characteristics of radiation induced light in optical fibres for portal imaging application. Radiat. Phys. Chem. 81(6), 599–608 (2012)

Sotor, J., Sobon, G., Macherzynski, W., Paletko, P., Abramski, K.M.: Black phosphorus saturable absorber for ultrashort pulse generation. Appl. Phys. Lett. 107(5), 51108 (2015)

Spanier, J.E., Gupta, S., Amer, M., Barsoum, M.W.: Vibrational behavior of the Mn+1AXn phases from first-order raman scattering (M = Ti, V, Cr, A = Si, X = C, N). Phys. Rev. B Condens. Matter. 71(1), 2–5 (2005)

Sun, Z., Hasan, T., Torrisi, F., Popa, D., Privitera, G., Wang, F., Bonaccorso, F., Basko, D.M., Ferrari, A.C.: Graphene mode-locked ultrafast laser. ACS Nano 4(2), 803–810 (2010)

Sun, G., Feng, M., Zhang, K., Wang, T., Li, Y., Han, D., Song, F.: Q-switched and mode-locked Er-doped fiber laser based on MAX phase Ti2AlC saturable absorber. Results Phys. 26, 104451 (2021)

Wang, Y., Xu, C.-Q.: Actively Q-switched fiber lasers: switching dynamics and nonlinear processes. Prog. Quantum Electron. 31(3–5), 131–216 (2007)

Wang, J., Zhou, Y., Lin, Z., Meng, F., Li, F.: Raman active phonon modes and heat capacities of Ti2AlC and Cr2AlC ceramics: first-principles and experimental investigations. Appl. Phys. Lett. 101902, 8–11 (2005)

Wang, P., Weng, D., Li, K., Liu, Y., Yu, X., Zhou, X.: Multi-wavelength erbium-doped fiber laser based on four-wave-mixing effect in single mode fiber and high nonlinear fiber. Opt. Express 21, 324–326 (2013)

Wang, J., Cai, Z., Xu, P., Du, G., Wang, F., Ruan, S., Sun, Z., Hasan, T.: Pulse dynamics in carbon nanotube mode-locked fiber lasers near zero cavity dispersion. Opt. Express. 23(8), 9947–9958 (2015)

Zhang, M., Wu, Q., Zhang, F., Chen, L., Jin, X., Hu, Y., Zheng, Z., Zhang, H.: 2D black phosphorus saturable absorbers for ultrafast photonics. Adv. Opt. Mater. 7(1), 1800224 (2018)

Zhao, C., Zhang, H., Qi, X., Chen, Y., Wang, Z., Wen, S., Tang, D.: Ultra-short pulse generation by a topological insulator based saturable absorber. Appl. Phys. Lett. 101(21), 211106 (2012)

Funding

We would like to thank the Ministry of Higher Education, Malaysia under their contribution through the HiCoE Phase II (PRC-2014) and the Universiti Malaya for their funding through Grants RU005-2021 and RK021-2019.

Author information

Authors and Affiliations

Contributions

HA: Conceptualization, Supervision, Writing—Reviewing and Editing. MJMM: Formal analysis, Visualization, Writing—Original draft. NY: Resources, Writing—Original draft. NS: Investigation, Analysis. MZS: Methodology, Investigation. MY: Visualization, Writing—Reviewing.

Corresponding authors

Ethics declarations

Competing interest

The authors declare no conflicts of interest that are relevant to the content of this article.

Ethical approval

Not applicable.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Ahmad, H., Makhfuz, M.J.M., Yusoff, N. et al. Mode-locked operation in thulium-holmium doped fiber laser based on Cr2AlC MAX phase SA coated arc-shaped fiber. Opt Quant Electron 55, 228 (2023). https://doi.org/10.1007/s11082-022-04499-6

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s11082-022-04499-6