Abstract

The world energy crisis, as well as global warming, has intensified an urgent need for renewable energies. Solar radiation can be converted to electricity by solar cells readily; however, the high cost of photovoltaic systems has hindered its worldwide commercialization. Also, the solar cells cannot be integrated directly to skyscrapers. Therefore, luminescent solar concentrators have been developed. Here, we have proposed a novel and exciting structure for LSCs based on four different groups of QDs (generally superposition of QDs) with different sizes and materials to absorb photons from sunlight ranging from ultraviolet to near-infrared and then guide re-emitted photons to edge of LSC, which culminate in capturing photons by solar cells. We designed the QDs such that the absorption and emission spectra have minimum overlap leading to limited reabsorption losses. A Monte-Carlo ray-tracing simulation has been developed to model and evaluates the effectiveness of the proposed device. Then, we have optimized the QD’s concentration and LSC geometry to achieve maximum optical efficiency. For different quantum yields ranging from 0.4 to 1, we have obtained theoretically super high optical efficiency of 11–31%. The optimization results show a 67.8% enhancement in optical flux gain leading to 3.72-times more concentrated photon flux demonstrating our device’s commercialization potential. Besides, total absorbed photons, transparency, and ultimate fate of all photons were calculated. Finally, the proposed idea can be used to introduce a high-efficiency solar concentrator while extending the coverage of solar cells to make green energy.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

World temperature has reached 1.3 °C higher than the pre-industrial level, according to the European Center for Medium-Range Weather Forecast (ECMWF). The world community has agreed to limit global warming to below 2 °C, by signing the Paris Agreement. To reach this ambitious goal, the world requires a zero-greenhouse-gas-emitting power system; therefore, the transition to a fully-renewable-energy-based power system should be taken place as soon as possible (Pam et al. 2017; Statistics 2014). Photovoltaics is one of the most promising technologies directly converting solar energy to electricity (Panwar et al. 2011; Pearce 2002). However, the cost of solar panels should be reduced by the factor of 2–5 to make power from photovoltaics competitive with fossil fuels. The high price of crystalline silicon solar cells is chiefly due to silicon materials and its processing (Atwater and Polman 2010). Luminescent Solar Concentrator (LSC) can cut down the cost of generated solar power by decreasing the required amount of expensive solar panels (Rowan et al. 2008; van Sark et al. 2008). LSCs can be produced in different sizes, shapes, and colors, which make them a suitable option to be used as windows and building facades, turning them into power-generating objects. Accordingly, they can realize the concept of net-zero energy consumption buildings (Debije and Verbunt 2012; Reinders et al. 2016; Meinardi et al. 2017a; Wu et al. 2018; Bergren et al. 2018; Vasiliev et al. 2018). Unlike other solar concentrating systems, LSCs do not need any cooling system. Besides, they can concentrate both direct and diffuse light, indicating their independence of any tracking systems (Carrascosa et al. 1983; Khamooshi et al. 2014).

An LSC includes of thin flat plastic sheet doped with quantum dots (QDs) and edge-mounted solar cells. QDs absorb solar irradiance and then re-emit photons at a higher wavelength. These newly-generated photons are guided through edge-mounted solar cells because of total internal reflection, leading to electricity generation (Batchelder et al. 1979; Gallagher et al. 2007; Bomm et al. 2011). Different fluorophores have been exploited for LSC applications such as organic dyes (Bailey et al. 2007; Currie et al. 2008; Maggioni et al. 2013; Liu and Li 2015), lanthanide complex hybrids (Graffion et al. 2011; Nolasco et al. 2013), perovskites (Nikolaidou et al. 2016; Zhao et al. 2017), and QDs (Zhao et al. 2016; Shcherbatyuk et al. 2010; Reda 2008). Among these, QD LSCs have some significant advantages over others such as stability, tunable absorption and emission spectra, large absorption cross-section, ability to be solution-processed, and high quantum yield (QY) (Alivisatos 1996; Amdursky et al. 2009; Regulacio and Han 2010; Zhao et al. 2011; Amini et al. 2015a, b).

Monte-Carlo simulation is a form of a numerical method based on the generation of random numbers applicable to situations where no deterministic algorithm is available, or the problem variables have coupled degrees of freedom. This method has widespread applications in all aspects of science, including engineering, physics, mathematics, statistics, health, finance, and project management (Xinhua et al. 2012; Tezuka 1998; Domański et al. 2008; Bird 1980; Kwak and Ingall 2009; Collado et al. 2012). Monte-Carlo ray-tracing simulation is suitable to model LSCs application due to their probabilistic nature and various possible outcomes.

Many shortcomings have hindered the commercialization of the LSCs, including the low overlap between absorption spectra of QDs and AM 1.5G (Erickson et al. 2014), inappropriate LSC size and scale (Coropceanu and Bawendi 2014), low quantum yield (QY) (Meinardi et al. 2015), and overlap between absorption and emission spectra (Zhao et al. 2017). AM 1.5G has a broad spectrum that cannot be fully absorbed by one type of QDs. A mismatch between QD’s absorption range and the solar spectrum is one of the most dominant loss mechanisms in LSC since the photons from the rest of the solar spectrum remain unabsorbed, and consequently, do not participate in output power efficiency. Also, most of the other works published earlier, do not have an authentic design process, and they have been chosen with the favor of the author rather than an optimization algorithm. In this paper, to address these problems, the superimposition idea (Goli Yousefabad et al. 2019; Amini et al. 2019; Dolatyari et al. 2019) has been used, and four different types of QDs have utilized to cover the solar spectrum from 300 to 1100 nm. Then, the LSC geometry has been optimized using the Monte-Carlo simulation. Also, we have calculated transparency and photon loss percentage that every event is responsible for.

2 LSC structure and possible phenomena

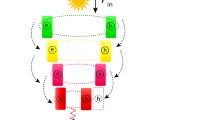

In the proposed structure, the LSC consists of the polymeric waveguide embedded with different types of QDs. The four faces (sidewalls) of it are covered by solar cells, and the light is irradiated on the front surface. The device is assumed to have a square front surface, and the size of it is denoted by x. Also, t shows the thickness of the LSC. Figure 1 exhibits a schematic of an LSC and all possible phenomena that can occur in an LSC. When a light beam is irradiated on the surface of the LSC, different phenomena take place. These events are described and explained in Fig. 1b. Generally, the QDs absorb incoming photons and re-emit other photons with a longer wavelength, which are detected by solar cells on the edge of LSC. Therefore, the received photons are converted to electrical energy by solar cells on edge. Thus, LSC plus sidewalls solar cells is a system to convert sunlight to green electrical power. The efficiency of this system is the main factor in evaluating its success and feasibility to use in practice. In this work, we introduce an exciting and novel method based on the superposition of colloidal QDs to enhance efficiency to at least 10% and even higher.

The proposed schematic structure, solar spectrum, the possible event that can occurre in an LSC. a Schematic structure of the QD-LSC. Different CdS/ZnS, CdSe/ZnS, GaAs/GaP, and InGaAs/AlAs QDs of various radii, absorbing different parts of depicted AM 1.5G spectrum embedded in PMMA material. Edge-mounted solar cells are demonstrated in gray. b Side view of the LSC and probable phenomena in it. All possible events in an LSC are illustrated: (1) Photons are reflected without even entering the LSC, (2) the entered photon are absorbed by the QD, then the QD emits the new photon, then the photon reach the solar cell after some total internal reflection, (3) the photons are absorbed by the QD, and then undergone non-radiative decay, (4) the photon pass through the LSC without being absorbed, (5) the initial photon are absorbed by a QD; then the QD emits a photon which is absorbed and lost by adjacent QDs, and (6) the initial photons are being absorbed by QD, then the newly-emitted photon escape from the escape cone

3 Monte-carlo ray tracing simulation

Monte Carlo ray tracing determines the ultimate fate of each photon according to physical phenomena such as absorption, reflection, transmission, and emission processes based on mathematical equations and empirical data, such as the Beer-Lambert law, Snell’s law, absorption spectrum, emission spectrum, quantum yield, and many other related factors and relations. A Monte Carlo simulation is developed to model and optimize the operation of LCS. The Monte-Carlo algorithm (Şahin et al. 2011; Rastkar Mirzaei et al. 2019; Slooff et al. 2008) used to model the proposed device is described as follows.

-

1

100,000 photons are initially assumed to participate in the simulation. The photons are distributed uniformly on the top surface of the LSC. The wavelength of each photon was sampled from the standard AM 1.5G solar spectrum. The sampling process begins with generating a probability density function (PDF) of the standard AM 1.5G solar spectrum. Then the PDF is converted to the cumulative distribution function (CDF), from which the wavelength of each photon is sampled using the inverse transform sampling method; this equals generating a random number between zero and one. Then, we find the corresponding wavelength. Figure 2 shows the PDF and CDF of CdS/ZnS (cyan), CdSe/ZnS (purple), GaAs/GaP (green), InGaAs/AlAs (Orange), and the solar spectrum, respectively. The PDF is directly generated from the AM 1.5G solar spectrum. The only difference is its normalization to the area of the curve.

$$PDF = \frac{{{\text{Distribution\;function}}}}{{{\text{Area\;of\;the\;Curve}}}}$$(1)We have defined the CDF as the area of the PDF curve until the ith term, to the whole area of the PDF. The equation Eq. 2 shows the relation used to calculate the CDF. We have used the trapezoidal method to calculate the area under the curve, where the \(\lambda_{j}\) is the jth term in the wavelength, and the k is the length of the wavelength vector.

$$CDF_{i} = \frac{{\mathop \sum \nolimits_{j = 1}^{i} \frac{{\left( {PDF_{j + 1} + PDF_{j} } \right)\left( {\lambda_{j + 1} - \lambda_{j} } \right)}}{2}}}{{\mathop \sum \nolimits_{j = 1}^{k} \frac{{\left( {PDF_{j + 1} + PDF_{j} } \right)\left( {\lambda_{j + 1} - \lambda_{j} } \right)}}{2}}}$$(2)Fig. 2 PDF and CDF for AM1.5 solar spectrum and emission spectra of QDs with respect to the wavelength a PDF for AM1.5 solar spectrum (gray), CdS/ZnS (cyan) CdSe/ZnS (purple), GaAS/GaP (green), InGaAs/AlAs (Orange). b CDF for emission spectra of AM1.5 solar spectrum (gray), CdS/ZnS (cyan), CdSe/ZnS (purple), GaAS/GaP (green), and InGaAs/AlAs (Orange). (Color figure online)

-

2

The photons are assumed to hit the LSC with a normal angle. Some percent of photons, which are reflected from the top surface of the LSC, according to Snell’s law, should be removed from the rest of the LSC process.

$$R = \left( {\frac{n - 1}{n + 1}} \right)^{2}$$(3)where n is the refractive index of LSC waveguide, which is 1.5; therefore, about 4% of photons will be reflected from the top surface, which is regarded as reflection loss.

-

3

Then, we should calculate the distance in which QDs absorb the incoming photons. To do this, the Beer–Lambert law can be used that determines the probability of a photon being absorbed after moving along a distance, \(\Delta d\) (in cm),

$$P = 1 - 10^{ - A(\lambda )\Delta d}$$(4)Moreover,

$$\Delta d = - \frac{1}{A\left( \lambda \right)}\log P$$(5)A is the absorbance, which is measured from the absorption spectra of the QDs. In the simulation, absorption probability is generated by a random number. If the \(\Delta d\) is found to be larger than the LSC thickness (t), the photon will pass without absorption; otherwise, the photon is absorbed, and its position is stored.

-

4

In the next step, we should determine if the QD would emit the absorbed photon. It is done by the use of quantum yield (QY), which is defined by the ratio of a number of the photons emitted to the total number of photons absorbed. A random-generated number (β), between zero and one, is compared by quantum yield. If β is smaller than QY, the photon would be reemitted. The emission angle is randomly chosen (uniform distribution), and its wavelength is chosen from the CDF of the emission spectrum. The distance that photons cross after being reabsorbed is given by Eq. (6).

$$\Delta d = - \frac{1}{A(\lambda )}\log \beta$$(6) -

5

Then the photon’s new position after propagating \(\Delta d\) is stored. The photon should be checked if it is inside the LSC. If yes, then it must have probably been absorbed. If the answer is no, the photon must have an interaction with LSC surfaces.

-

6

The next objective is to figure out which surface it has interaction with. The photon will reach the solar cells if it hits the first four surfaces (surfaces with solar cells). If the photon hits the up or bottom surface of the LSC, two scenarios can be assumed: the photon escapes from the surface and is consequently lost. Second, the surface reflects the photon due to total internal reflection, and it is subsequently re-absorbed or reach the solar cells. This process is repeated for each of 100,000 photons. To assess LSC performance, we define some relations. We define optical efficiency as,

$$\eta_{opt} = \frac{\text{Collected\;photons}}{\text{incident\;photons}}$$(7)Until now, we have defined optical power efficiency. However, we need another parameter to evaluate the concentration of the LSC. Another parameter is geometric gain. The geometric gain is a measure of the maximum possible photon flux concentration of an LSC, with all its other factors as perfect.

$$G = \frac{{A_{LSC} }}{{A_{PV} }}$$(8)where \(A_{LSC}\) is the area of the upper face of the LSC, and the \(A_{PV}\) is the area of the faces (sidewalls) with attached solar cells. The product of geometric gain and optical efficiency defined as optical flux gain that is the most critical parameter for the LSC.

$$FG_{opt} = G\eta_{opt}$$(9)

4 Results and discussion

To realize solar spectrum absorption coverage, core–shell QDs of CdS/ZnS, CdSe/ZnS, GaAs/GaP, and In0.8Ga0.2As/AlAs materials have been used. We have incorporated the FDTD method for solving the three-dimensional Schrödinger equation to design the absorption and emission spectra of various QD type. The resulting core radius and shell thickness were found to be 1.39 nm and 0.7 nm for CdS/ZnS to absorb blue color, 2.7 nm and 1.35 nm for CdSe/ZnS to absorb green part of the solar spectrum, 3.86 nm, and 1.93 nm for GaAs/GaP to absorb red section of AM 1.5G, and 5.14 nm and 2.85 nm for In0.8Ga0.2As/AlAs to absorb near-IR light. The absorption and emission spectra of QDs, as well as those for AM 1.5G solar spectrum, are exhibited in Fig. 3. As apparent from the figure, the absorption spectrum from different QDs has considerable overlap with the solar spectrum. Furthermore, the size of QDs is designed such that no overlap between the absorption spectrum of one QD type and the emission spectrum of the other type exists. The absorption and emission spectra for the same QDs have minimum overlap, resulting in low reabsorption loss. A stokes-shift of 440 meV, 357 meV, 170 meV, and 153 meV were obtained for CdS/ZnS, CdSe/ZnS, GaAs/GaP, and In0.8Ga0.2As/AlAs, respectively.

Solar spectrum, absorption and photoluminescence spectra of QDs with respect to the wavelength. The AM 1.5G solar spectrum, the absorbance (solid line), and the photoluminescence spectra (dashed line) for the CdS/ZnS (cyan), CdSe/ZnS (purple), GaAS/GaP (green), InGaAs/GaP (orange), and CdS/ZnS (cyan).The absorbance is depicted according to the left axis; the right axis is for the normalized photoluminescence. (Color figure online)

Monte-Carlo ray-tracing simulation requires four different input parameters, including absorption and emission spectra, quantum yield, and LSC waveguide dimensions. The quantum yield of considered QDs varies between zero and unity, depending on the synthesis method. We have assumed the QY to be 0.4, 0.6, and 1 for a thorough study. However, without losing generality, the quantum yield for the first two steps of optimization was assumed to be 0.4. We start with 12 × 12 × 0.3 cm3 LSC dimensions as an initial guess, corresponding to a geometric gain of 10.

To have high optical efficiency, the device needs to have considerable absorption. Thus, the absorbance of QDs should be optimized. Figure 4a shows optical efficiency concerning different absorbance values for three various LSC sizes. A steep increase in optical efficiency can be seen with increasing absorbance ending in a flat peak. After the absorbance of 8, the increase in optical efficiency is insignificant; therefore, we select this value for optimum absorbance. The corresponding QD concentrations for different absorbance values are given in Table 1. The effect of increasing LSC size can be seen in Fig. 4b, indicating that as we increase the LSC size, the LSC thickness also increases and brings an increase of LSC optical efficiency.

Optical efficiency, the percentage of absorbed photons, and optical flux gain with optimized absorbance of 8. a Optical efficiency with respect to the absorbance (QD concentration) for an LSC of 6 × 6×0.15 [cm] (cyan), 12 × 12 × 0.3 [cm] (red), and 24 × 24 × 0.6 [cm] (yellow) dimensions, b the percentage of absorbed photons versus geometric gain, c optical efficiency (cyan, left axis) and optical flux gain (red, right axis) with respect to different geometric gains to find the optimum geometric gain, d the percentage of absorbed photons for different LSC lateral sizes and the selected geometric gain (G = 12), e optical efficiency and f optical flux gain swept by LSC lateral size for quantum yields of 0.4 (cyan), 0.6 (red), and 1 (yellow). (Color figure online)

The next task is the determination of geometric gain (G), which plays a significant role in LSC’s overall performance as it defines the aspect ratio of the device. The ultimate goal of the designing of an LSC is lowering the cost of photovoltaic systems by cutting down the cost of generated solar power and decreasing the required amount of expensive solar cells. The objective can be achieved by higher geometric gains because the edge area on which solar cells are attached would be far smaller than the front surface of the LSC. However, the absorption of the photons and subsequently output power directly depend on LSC thickness. The relation between geometric gain and absorbed photons is presented in Fig. 4b. Hence, the tradeoff between energy flux gain and optical power efficiency is mandatory. Figure 4c represents flux gain energy and optical power efficiency against the geometric gain.

It is evident from Fig. 4c that the optical power efficiency decreases with increasing G, and accordingly, the energy flux gain increases with geometric gain. We have defined G the intersection of the two curves that determine optimum G number, which is roughly 12. In the last step of the geometric optimization of the LSC, we scale the device with selected geometric gain to find the optimum size of the LSC. The LSC size was 12 × 12 × 0.3 cm3, which is then changed to be 12 × 12 × 0.26 cm3 because of geometric gain of 12. Now, we scale the lateral size of the LSC with G = 12 from 6 to 60 cm to find the optimum LSC dimensions. Figure 4d represents the percentage of absorbed photons with increasing LSC lateral size (x). An increase in absorbed photons by enlargement of the LSC dimensions can be seen, which is due to the thicker waveguides. The slope of the curve is much higher in small lateral sizes than the larger ones. This phenomenon is because the enhancement in absorption cannot be done just by making thicker LSCs. The slope of absorption becomes lower as most of the photons which are in the absorption spectrum of QDs are absorbed already.

The optical efficiency of the device and optical flux gain for three different QYs are depicted in Fig. 4e, f, respectively. For small lateral sizes, we observe a low optical efficiency and optical flux gain, which is attributed to low absorption because of thinner devices. The optical efficiency and flux gain increase with device size enlargement. This increase is due to higher absorption and optimal devise size. With the continuation of device size enlargement, the optical efficiency and optical flux gain begin to saturate, owing to absorption saturation. For the device of 60 × 60 × 1.25 cm3 dimensions, extraordinary optical efficiencies of 11.8, 13.8, and 31% have been achieved, respectively. Comparing to other studies that have efficiencies up to 7.1% (Meinardi et al. 2015), our results (even with low QY of 0.4) show a significant improvement in LSC design, which can further make scale up production of LSC achievable. The ultimate goal of an LSC is to lower the cost of the photovoltaic system by concentrating photons. An LSC is cost-effective only if its optical flux gain is above 100; i.e. when the equivalent photon flux reaches the solar cells with the solar cell directly placed toward the sun. For a device with 60 × 60 × 1.25 cm3 dimensions, we have optical flux gain of 141.6, 213.6, and 372, respectively. Thus, even with QY as low as 0.4, our device can be commercialized. The results of the geometric optimization stage for three different quantum yields are summarized in Table 2.

Our proposed structure has demonstrated outstanding optical efficiencies. Higher optical efficiencies imply high photon absorption, resulting in lower transparency. Figure 5a illustrates sampled photons from AM 1.5G, and the photons passing through the LSC without absorption (transparency), as well as the photons reaching the output. We have defined transparency as can be seen in Eq. 10. The percentage of reflected photons are subtracted from the percentage of passed photons without being absorbed

Transparency of LSC with the size of 60 × 60 × 1.25 cm3 and QY of unity at different wavelegths with various concentrations. a Sampled photons from AM 1.5G (gray), photons passing through the LSC (transparency, red), and the photons reaching the output (solar cells, cyan, according to the wavelength of photons), and b transparency of LSCs with only CdS (cyan), CdSe (purple), GaAs/GaP (green), and InGaAs/AlAs (orange) for different QD concentrations ranging from 105 to 1017 (cm−3). (Color figure online)

We have low transparency when incident photons with a wavelength in the range of the QDs absorption; however, the transparency at other wavelengths is maximum. We can see the Stokes-shifted photons in the output, depicted in blue. The number of these photons depends on that of the absorbed ones; e.g., CdSe/ZnS QDs contribute to output more than CdS/ZnS because there are more photons in the absorption range of CdSe/ZnS than that of CdS/ZnS. Figure 5b shows the total transparency of a single-QD-type structure according to the concentration of the QDs ranging from 105 to 1017. As it is apparent, the transparency decreases with increasing concentration, and for concentrations below 1010, the transparency for single-QD-type LSC consisting of CdS/ZnS is the most transparent case because of insufficient available photons in its absorbing range as well as low absorption cross-section of each CdS QD; furthermore, the GaAs is the least transparent one for its high absorption cross-section. As the concentration increases dramatically, after the concentration of 1011, transparency of the LSCs with CdS/ZnS and CdSe/ZnS significantly decreases, especially for CdSe/ZnS, since there are more photons to be absorbed in its absorption range. However, for GaAs and InGaAs/InAs, we can see a saturation after 1011 concentration, because all available photons have been absorbed. The transparency of superimposed-type, as well as single-QD-type LSC with optimized concentrations and waveguide dimensions, have been summarized in Table 3. The superimposed structure consists of all four kinds of QDs with the corresponding mentioned concentration in Table 3.

At the last attempt to analyze our proposed structure, we have scrutinized the fate of every photon contributing to the simulation. According to Monte-Carlo simulation, 53.7% of photons passing through LSC without absorption. Additionally, 4% of photons are reflected from the top surface without entering the device due to the refractive index difference between air and the LSC waveguide. Finally, 42.3% of the photons are absorbed by the QDs, having the possibility to reach the edge of the device. However, not all of the absorbed photons find a way to the exit aperture. For quantum yield 0.4, 0.6, and 1 the percentage of 60, 42.3, and 0 of these photons are lost due to non-unity quantum yield. Moreover, 10.1, 15.6, and 28.3% of the absorbed photons are lost from escape cone, and 27.9, 42.1, and 71.7% of the absorbed photons reach the edge of the LSC, respectively. Finally, it should be better to compare solar concentrators reported before with the results of this work (Cao et al. 2013, 2017; Huang et al. 2016; Luo et al. 2017; Meinardi et al. 2015, 2017b; Niu et al. 2016; Qu et al. 2015; Sk et al. 2014; Zhao et al. 2016, 2017; Zhou et al. 2016a, b). A Table 4 is given below to summarize the highly efficient LSCs made with different QDs. The difference between optical efficiency our work and others are obvious even in low quantum yield, and this is because of the superimposition of different quantum dots. Also, we did a geometric optimization to make most of the power while keeping high efficiency.

5 Conclusion

In summary, an LSC containing CdS/ZnS, CdSe/ZnS, GaAs/GaP, and In0.8Ga0.2As/AlAs QDs was designed such that the QDs cover the solar spectrum from 300 nm to 1100 nm. The proper radius of core/shell QDs was obtained by solving the Schrodinger equation with the FDTD method to make reabsorption loss as low as possible. A Monte-Carlo ray-tracing method was developed to model the LSC device. We have also considered three different quantum yields to study their effect on optical efficiency. Then LSC geometry was optimized to be of 60 × 60 × 1.25 (cm3) dimensions (which was initially 12 × 12 × 0.3 (cm3)). We have achieved 37.8% and 65.3% enhancement in optical efficiency and optical flux gain by geometric optimization for a device with a unity quantum yield. The optical efficiency of 11.8, 13.8, and 31% have been gained for 0.4, 0.6, and unity quantum yields, respectively. We have found that the broadening in the absorption range to cover the entire solar spectrum has increased optical efficiency astonishingly. Also, losses from each possible event were calculated in detail.

References

Alivisatos, A.P.: Semiconductor clusters, nanocrystals, and quantum dots. Science (80-) 271, 933–937 (1996)

Amdursky, N., Molotskii, M., Gazit, E., Rosenman, G.: Self-assembled bioinspired quantum dots: optical properties. Appl. Phys. Lett. 94, 41–44 (2009)

Amini, P., et al.: High-performance solution processed inorganic quantum-dot LEDS. IEEE Trans. Nanotechnol. 14, 911–917 (2015a)

Amini, P., Dolatyari, M., Rostami, G., Rostami, A.: High throughput quantum dot based LEDs. Energy Effic. Improv. Smart Grid Components. Rijeka InTech, pp. 293–324 (2015b)

Amini, P., Matloub, S., Rostami, A.: Multi-wavelength solution-processed quantum dot laser. Opt. Commun. (2019). https://doi.org/10.1016/j.optcom.2019.124629

Atwater, H.A., Polman, A.: Plasmonics for improved photovoltaic devices. Nat. Mater. 9, 205–213 (2010)

Bailey, S.T., et al.: Optimized excitation energy transfer in a three-dye luminescent solar concentrator. Sol. Energy Mater. Sol. Cells 91, 67–75 (2007)

Batchelder, J.S., Zewai, A.H., Cole, T.: Luminescent solar concentrators 1: theory of operation and techniques for performance evaluation. Appl. Opt. 18, 3090–4110 (1979)

Bergren, M.R., et al.: High-performance CuInS2 quantum dot laminated glass luminescent solar concentrators for windows. ACS Energy Lett. (2018). https://doi.org/10.1021/acsenergylett.7b01346

Bird, G.A.: Monte-Carlo simulation in an engineering context. Rarefied gas Dyn. Int. Symp., pp. 239–255 (1980)

Bomm, J., et al.: Fabrication and full characterization of state-of-the-art quantum dot luminescent solar concentrators. Sol. Energy Mater. Sol. Cells 95, 2087–2094 (2011)

Cao, L., Meziani, M.J., Sahu, S., Sun, Y.-P.: Photoluminescence properties of graphene versus other carbon nanomaterials. Acc. Chem. Res. 46, 171–180 (2013). https://doi.org/10.1021/ar300128j

Carrascosa, M., Unamuno, S., Agullo-Lopez, F.: Monte Carlo simulation of the performance of PMMA luminescent solar collectors. Appl. Opt. 22, 3236–3241 (1983)

Collado, J., et al.: Application of Monte Carlo simulation in industrial microbiological exposure assessment. Appl. Monte Carlo Method Sci. Eng. (2012). https://doi.org/10.5772/15283

Coropceanu, I., Bawendi, M.G.: Core/shell quantum dot-based luminescent solar concentrators with reduced reabsorption and enhanced efficiency. Nano Lett. 14, 4097–4101 (2014)

Currie, M.J., Mapel, J.K., Heidel, T.D., Goffri, S., Baldo, M.A.: High-efficiency organic solar concentrators for photovoltaics (80-). Science 321, 226–228 (2008)

Debije, M.G., Verbunt, P.P.C.: Thirty years of luminescent solar concentrator research: solar energy for the built environment. Adv. Energy Mater. 2, 12–35 (2012)

Dolatyari, M., Jafari, A., Rostami, A., Klein, A.: Transparent display using a quasi-array of Si-SiO2 core-shell nanoparticles. Sc. Rep. 9, 1–12 (2019). https://doi.org/10.1038/s41598-019-38771-9

Domański, G., et al.: The use of the Monte Carlo method to determine optical parameters of tissue. Polish J. Med. Phys. Eng. 13, 23–32 (2008)

Erickson, C.S., et al.: Zero-reabsorption doped-nanocrystal luminescent solar concentrators. ACS Nano 8, 3461–3467 (2014)

Gallagher, S.J., Norton, B., Eames, P.C.: Quantum dot solar concentrators: electrical conversion efficiencies and comparative concentrating factors of fabricated devices. Sol. Energy 81, 813–821 (2007)

Gao, T., Wang, X., Yang, L.-Y., He, H., Ba, X.-X., Zhao, J., Jiang, F.-L., Liu, Y.: Red, yellow, and blue luminescence by graphene quantum dots: syntheses, mechanism, and cellular imaging. ACS Appl. Mater. Interfaces. 9, 24846–24856 (2017)

Goli Yousefabad, H., Matloub, S., Rostami, A.: Ultra-broadband optical gain engineering in solution-processed QD-SOA based on superimposed quantum structure. Sci. Rep. 10, 1–10 (2019)

Graffion, J., et al.: Modulating the photoluminescence of bridged silsesquioxanes incorporating Eu3+ -complexed n, n′-diureido-2, 2′-bipyridine isomers: application for luminescent solar concentrators. Chem. Mater. 23, 4773–4782 (2011)

Huang, P., Shi, J., Zhang, M., Jiang, X., Zhong, H., Ding, Y., Cao, X., Wu, M., Lu, J.: Anomalous light emission and wide photoluminescence spectra in graphene quantum dot: quantum confinement from edge microstructure. J Phys Chem Lett 7, 2888–2892 (2016)

Khamooshi, M., et al.: A review of solar photovoltaic concentrators. Int. J. Photoenergy 2014, 1625–1636 (2014)

Kwak, Y., Ingall, L.: Exploring monte carlo simulation applications for project management. IEEE Eng. Manag. Rev. 37, 83–83 (2009)

Liu, C., Li, B.: Multiple dyes containing luminescent solar concentrators with enhanced absorption and efficiency. J. Opt. 17, 25901 (2015)

Luo, Y., Xu, Y., Li, M., Sun, L., Hu, G., Tang, T., Wen, J., Li, X.: Tuning the photoluminescence of graphene quantum dots by fluorination. J Nanomater (2017). https://doi.org/10.1155/2017/9682846

Maggioni, G., Campagnaro, A., Carturan, S., Quaranta, A.: Dye-doped parylene-based thin film materials: application to luminescent solar concentrators. Sol. Energy Mater. Sol. Cells 108, 27–37 (2013)

Meinardi, F., et al.: Highly efficient large-area colorless luminescent solar concentrators using heavy-metal-free colloidal quantum dots. Nat. Nanotechnol. 10, 878–885 (2015)

Meinardi, F., Bruni, F., Brovelli, S.: Luminescent solar concentrators for building-integrated photovoltaics. Nat. Rev. Mater. 2, 17072 (2017a)

Meinardi, F., Ehrenberg, S., Dhamo, L., Carulli, F., Mauri, M., Bruni, F., Simonutti, R., Kortshagen, U., Brovelli, S.: Highly efficient luminescent solar concentrators based on earth-abundant indirect-bandgap silicon quantum dots. Nat. Photonics 11, 2017 (2017b)

Nikolaidou, K., et al.: Hybrid perovskite thin films as highly efficient luminescent solar concentrators. Adv. Opt. Mater. 4, 2126–2132 (2016)

Niu, X., Li, Y., Shu, H., Wang, J.: Revealing the underlying absorption and emission mechanism of nitrogen-doped graphene quantum dots. Nanoscale 8, 19376–19382 (2016). https://doi.org/10.1039/c6nr06447g

Nolasco, M.M., et al.: Engineering highly efficient Eu(iii)-based tri-ureasil hybrids toward luminescent solar concentrators. J. Mater. Chem. A 1, 7339–7350 (2013)

Pam, M. et al.: Global energy system based on 100% renewable energy—power sector. Energy watch group, LUT University (2017)

Panwar, N.L., Kaushik, S.C., Kothari, S.: Role of renewable energy sources in environmental protection: a review. Renew. Sustain. Energy Rev. 15, 1513–1524 (2011)

Pearce, J.M.: Photovoltaics—a path to sustainable futures. Futures 34, 663–674 (2002)

Qu, D., Zheng, M., Li, J., Xie, Z., Sun, Z.: Tailoring color emissions from N-doped graphene quantum dots for bioimaging applications. Light Sci. Appl. 4, e364–e365 (2015). https://doi.org/10.1038/lsa.2015.137

Rastkar Mirzaei, M., Rostami, A., Matloub, S., Mirtaghiogli, H.: Design and optimization of graphene quantum dot-based luminescent solar concentrator using Monte-Carlo Simulation. In: International Conference on Data Science, Machine Learning and Statistics (2019)

Reda, S.M.: Synthesis and optical properties of CdS quantum dots embedded in silica matrix thin films and their applications as luminescent solar concentrators. Acta Mater. 56, 259–264 (2008)

Regulacio, M.D., Han, M.Y.: Composition-tunable alloyed semiconductor nanocrystals. Acc. Chem. Res. 43, 621–630 (2010)

Reinders, A.H.M.E. et al.: Leaf roof—designing luminescent solar concentrating PV roof tiles. In: Conference record of the IEEE photovoltaic specialists conference 2016-Nov, pp. 3447–3451 (2016)

Rowan, B.C., Wilson, L.R., Richards, B.S.: Advanced material concepts for luminescent solar concentrators. IEEE J. Sel. Top. Quantum Electron. 14, 1312–1322 (2008)

Şahin, D., Ilan, B., Kelley, D.F.: Monte-Carlo simulations of light propagation in luminescent solar concentrators based on semiconductor nanoparticles. J. Appl. Phys. 110, 033108 (2011)

Shcherbatyuk, G.V., Inman, R.H., Wang, C., Winston, R., Ghosh, S.: Viability of using near infrared PbS quantum dots as active materials in luminescent solar concentrators. Appl. Phys. Lett. 96, 2008–2011 (2010)

Sk, M.A., Ananthanarayanan, A., Huang, L., Lim, K.H., Chen, P.: Revealing the tunable photoluminescence properties of graphene quantum dots. J. Mater. Chem. C 2, 6954–6960 (2014). https://doi.org/10.1039/c4tc01191k

Slooff, L.H., et al.: A luminescent solar concentrator with 7.1% power conversion efficiency. Phys. Status Solidi Rapid Res. Lett. 2, 257–259 (2008)

Statistics, I.E.A.: Key World Energy Statistics. International Energy Agency, Paris (2014)

Tezuka, S.: Financial applications of Monte Carlo and quasi-Monte Carlo methods. In: Hellekalek, P., Larcher, G. (eds.) Random and quasi-random point sets, pp. 303–332. Institut für Mathematik Universität Salzburg Salzburg Austria, Springer, New York (1998)

van Sark, W.G.J.H.M., et al.: Luminescent solar concentrators—a review of recent results. Opt. Express 16, 21773–21792 (2008)

Vasiliev, M., Alameh, K., et al.: Applied sciences spectrally-selective energy-harvesting solar windows for public infrastructure applications. Appl. Sci. 8, 1–15 (2018)

Wu, K., Li, H., Klimov, V.I.: Tandem luminescent solar concentrators based on engineered quantum dots. Nat. Photonics 1, 105–110 (2018)

Xinhua, L., Yongzhi, L., Hao, L.: Theory and application of monte carlo method the basic principle and characteristics of monte carlo method the steps of Monte Carlo method. Adv. Intell. Soft Comput. 2, 841–848 (2012)

Zhao, H., Chaker, M., Wu, N., Ma, D.: Towards controlled synthesis and better understanding of highly luminescent PbS/CdS core/shell quantum dots. J. Mater. Chem. 21, 8898–8904 (2011)

Zhao, H., et al.: Absorption Enhancement in “Giant” core/alloyed-shell quantum dots for luminescent solar concentrator. Small (2016). https://doi.org/10.1002/smll.201600945

Zhao, H., Zhou, Y., Benetti, D., Ma, D., Rosei, F.: Perovskite quantum dots integrated in large-area luminescent solar concentrators. Nano Energy 37, 214–223 (2017)

Zhou, S., Xu, H., Gan, W., Yuan, Q.: Graphene quantum dots: recent progress in preparation and fluorescence sensing applications. RSC Adv. 6, 110755–110788 (2016a)

Zhou, Y., Benetti, D., Fan, Z., Zhao, H., Ma, D., Govorov, A.O., Vomiero, A., Rosei, F.: Near-infrared, highly efficient luminescent solar concentrators. Adv. Energy Mater. 6, 1501913 (2016b). https://doi.org/10.1002/aenm.201501913

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Mirzaei, M.R., Rostami, A., Matloub, S. et al. Ultra-high-efficiency luminescent solar concentrator using superimposed colloidal quantum dots. Opt Quant Electron 52, 327 (2020). https://doi.org/10.1007/s11082-020-02442-1

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s11082-020-02442-1