Abstract

We demonstrate a passively Q-switched erbium doped fiber laser (EDFL) based on quantum dots (QD) CdSe as a saturable absorber (SA). The synthesized CdSe powder was embedded into a poly(methyl methacrylate) (PMMA) using emulsion polymerization process. The film is sandwiched between two fiber connector via an adapter to form a fiber-compatible SA device. By integrating the SA device into the EDFL ring cavity, the stable Q-switched operation is achieved at 1559.35 nm as the pump power is varied within 30–118 mW. The laser has a pump threshold of 20.4 mW. The pulse repetition rate shows an increasing trend from 33.2 to 68.45 kHz, whereas the pulse width exhibits a decreasing trend from 10.04 to 4.30 μs as the pump power is increased from 30 to 118 mW. The highest pulse energy of 11.83 nJ is obtained at a pump power of 118 mW. These results indicate that QD CdSe is a promising SA for Q-switching laser operation.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

Passively Q-switching fiber lasers have been widely researched in recent years due to their applications in many areas such as eye-safe LIDAR, medical surgery and environmental sensing (Delgado-Pinar et al. 2006; Zervas and Codemard 2014; Mears et al. 1986). Furthermore, there is no complex fiber pigtailed acoustic-optic or expensive and complex system are required in implementing all-fiber passively Q-switched fiber laser system. The Q-switching is realized by incorporating a saturable absorber (SA) device in a fiber laser cavity as a Q-switcher (Mb Hisyam et al. 2016). Previously, semiconductor saturable absorber mirrors (SESAMs) were widely used for the development of passively Q-switched fiber lasers (Wang et al. 2012; Petropoulos et al. 1999). However, due to its complicated fabrication, much simplified and cost-effective SAs with wideband tunability are needed, and thus the use of nanomaterial-based SAs has been explored and proposed. The recent discovery of graphene with its excellent optical properties (Bao et al. 2009; Novoselov et al. 2004) has immediately attracted interest to use it as SA which is easier to be fabricated, compact and effective in operation.

The success of graphene has encouraged the employment of other types of nanomaterials such as carbon nanotubes (Ahmed et al. 2015; Harun et al. 2012), topological insulators (TIs) (Yu et al. 2014; Chen et al. 2014) and transition metal dichalcogenides (TMDs) (Ismail et al. 2016a; Rusdi et al. 2016) as SAs. For instance, passively Q-switched fiber lasers have been demonstrated using molybdenum diselenide (MoSe2) (Ahmad et al. 2016a, b), and tungsten diselenide (WSe2) (Chen et al. 2016; Ahmad et al. 2016c) have been demonstrated. Other fascinating materials like black phosphorus (BP) have been effectively exhibited as SAs for Q-switching applications (Feng et al. 2016; Ahmad et al. 2016d; Ismail et al. 2016b; Rashid et al. 2016). Recently, quantum dots (QDs) semiconductor nanocrystals, another class of nanomaterial SA has also gained interest for many applications. QDs have unique optical and electronic properties such as broad excitation and narrow emission spectra, excellent photochemical stability, high photoluminescence (PL) quantum yields, and size-tunable emission profiles (Mahmoodi et al. 2016). In particular be that as it may, these qualities likewise make CdSe an exceedingly suitable ideal as a material for SA applications.

In this paper, a generation of Q-switching pulses is demonstrated in Erbium-doped fiber laser (EDFL) by using quantum dots (QD) CdSe film as a passive SA. The film is based on QD CdSe powder, which was embedded into a poly(methyl methacrylate) (PMMA) using emulsion polymerization process.

2 Preparation and characterization of CdSe-PMMA based SA

The synthesis of the QD CdSe presented in this paper is almost similar with the previous report by Hamizi and Johan (2010). The base elements of the synthesis were cadmium oxide (Cd) (99.99% purity), selenium metal (Se) (99.99% purity) and manganese acetate (Mn) (98% purity) as a precursor. In addition, paraffin oil and oleic acid were used as solvent and surfactant, respectively. First, the mixture of paraffin oil and oleic acid was prepared by the ratio of 5:3. Subsequently, this mixture was blended together with the CdO and Mn acetate in a three-neck flask under 160 °C temperature of Ar flow until it completely dissolved. In order to remove the remaining acetone, the Cd–Mn solution was distilled in vacuum. Concurrently, 0.16% of Se metal powder was dissolved in paraffin oil at heating temperature of 220 °C. Lastly, 5 ml of Cd–Mn solution was injected into the Se solution to enable the nucleation and gradual growth of QD CdSe. The final compound was then cleaned by five-time centrifugation process followed by methanol washing to remove the undesired element. The resulted compound was then dried in a vacuum oven to form high purity QD CdSe powder.

The CdSe powder was then characterized transmission electron microscopy (TEM), energy dispersive X-ray spectroscopy (EDS) and X-ray diffraction (XRD) to verify its nanoparticle size, composition, and crystal structure, respectively. The sample was prepared by placing a drop of a diluted methanol suspension of CdSe QD on the surface of a mesh copper film which then dried for several days. Figure 1a shows the TEM image, indicates that the average size of the QD CdSe particle is estimated at 10 nm diameter, in agreement with the standard QD size of 1–100 nm range. Figure 1b shows the EDS analysis, which confirms the existence of Se (0.32 wt%) and Cd (0.24 wt%) elements which is within the range of normal doping concentration. The C and O in the other two peaks correspond to impurities. Figure 1c depicts the typical XRD pattern of a CdSe QD which confirmed that all the reflections in the observed pattern indicate the characteristic peaks of the cubic crystal structure corresponding to (111), (220), (311) reflections (Mahmoodi et al. 2016). The results showing peaks around of 25.5°, 42° and 49.7° correspond to (111), (220) and (311) planes, respectively. The broad peak of the XRD confirmed that the CdSe QD is nano-sized.

In order for QD CdSe to become an SA device, it should be in the form of a film. Therefore, the QD CdSe that have been produced in the previous process was embedded into PMMA via emulsion polymerization process (DuChesne et al. 1999). PMMA acted as host material since it was well known of its high optical transparency and low photoluminescence background. First, 4 mg of QD CdSe powder was dissolved into 1 ml of PMMA liquid. Concurrently, 120 mg of hexadecyltrimethylammonium bromide (C16H33N(CH3)3Br) emulsifier was dissolved in 8 ml of distilled(DI) water followed by a heating process at 80 °C temperature. The solution was then stirred steadily while adding the QD CdSe-PMMA solution. The final solution was then cleaned by centrifugation process and drained with DI water. The near-solidified QD CdSe-PMMA was then quickly sandwiched between two flat glass plates, to form a film with the homogenous surface. Surface homogeneity is very important for SA since inhomogeneous surface will contribute to optical loss and pulse instability. The produced QD CdSe PMMA film is shown in Fig. 2a. The small portion of the film was attached on top of a standard fiber ferrule as shown in Fig. 2a to construct an all-fiber SA device (Sharma et al. 2009).

3 Experimental setup

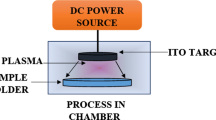

Schematic diagram of the proposed Q-switched fiber laser setup using CdSe PMMA film as SA is shown in Fig. 3. It employed a 2.4 m long Erbium-doped fiber (EDF) as the gain medium, which was pumped by 980 nm laser diode via a 980/1550 nm wavelength division multiplexer (WDM). An isolator was spliced after the gain medium to ensure unidirectional operation of the laser in the cavity. The CdSe PMMA SA device was inserted into the ring laser cavity to function as a Q-switcher. The SA device was realized by placing 1 mm × 1 mm QD CdSe film between two standard fiber ferrules end, adhered with index matching gel. The output of the laser was tapped out from the cavity via 10% port of the 10-dB optical coupler, which allows 90% of the photons to oscillate inside the cavity. The output spectrum wavelength was measured by an optical spectrum analyzer (OSA, Yokogawa AQ6370B) with resolution of 0.02 nm while the pulse characteristic was recorded using 500 MHz oscilloscope (OSC, GW Instek GDS-3352) and 7.8 GHz RF spectrum analyser (Anritsu MS2683A) coupled with a 1.2 GHz InGaAs photodetector (Thorlabs DET01CFC). The photodetector has a rise and fall time about less than 1 ns.

4 Result and discussion

Continuous wave operation was begun at a pump power of 23 mW, and stable Q-switched pulses were achieved when the pump power was increased to 30 mW. Figure 4a shows the output spectrum of the self-started Q-switched EDFL at the threshold pump power of 30 mW. It centered at 1559.35 nm with a 3-dB bandwidth of 0.38 nm. The spectral broadening is observed due to the self-phase modulation (SPM) effect in the laser cavity (Tai et al. 2003). Figure 4b–d illustrate the typical oscilloscope traces of the Q-switched pulse trains at pump powers of 30 mW, 56 mW and 118 mW, respectively. Unlike the fixed repetition rate of a mode-locked fiber laser (Rusdi et al. 2016) the pulse repetition rate in our laser increased with the pump power. This is a typical feature of passive Q-switching operation (Ismail et al. 2016a). To verify that the passive Q-switching was attributed to the CdSe PMMA film, the SA device was replaced with a common clean ferrule connector. In this case, no Q-switched pulses were observed on the oscilloscope even when the pump power was adjusted over a wide range. This finding confirmed that the CdSe SA was responsible for the passively Q-switched operation of the EDFL.

Figure 5a shows the pulse repetition rate and pulse width of the Q-switched fiber laser as functions of the incident pump power. By increasing the pump power from 30 to 118 mW, the pulse repetition rate increases from 33.2 to 68.45 kHz while the pulse duration responds inversely to the pumping rate, decreasing from 10.04 to 4.30 μs. This result confirms that passive Q-switching operation was successfully achieved. Above pump power of 118 mW, the Q-switched pulses became unstable or even disappeared as typically observed in certain passively Q-switched fiber lasers (Petropoulos et al. 1999). Subsequently, when the pump power was adjusted back to a level below 118 mW, the stable Q-switched pulse train appeared again. Hence, unstable Q-switched operation at high pump power may be attributed to over-saturation of the CdSe SA rather than to thermal damage (Hamizi and Johan 2010). On the other hand, the pulse width could be further reduced by shortening the laser cavity lifetime or improving the modulation depth of the CdSe PMMA based SA. The mode-locking operation can be generated if the cavity has a balanced nonlinearity and dispersion effects. Moreover, minimizing an intra-cavity loss may contribute also to the development of strong mode-locked pulses.

The measured average output power and the calculated corresponding single-pulse energy are shown in Fig. 5b. The average output power almost linearly increases with the input pump power up to a maximum of 0.81 mW at a pump power of 118 mW. The corresponding efficiency, as given by the slope, is 0.67%. Such low efficiency combined with the long-term stability verifies the advantageous optical and mechanical properties of the CdSe PMMA based SA. Figure 5b also shows that the measured pulse energy, which initially increases linearly, tends to become saturated after a pump power of 118 mW. The maximum pulse energy of 11.83 nJ is much higher than those of Q-switched fiber lasers using black phosphorus (Ahmad et al. 2016d; Ismail et al. 2016b) and titanium dioxide (TiO2) (Ahmad et al. 2016e) as passive Q-switching devices. Further improvement could be achieved by optimizing the fabrication parameters of the CdSe-PMMA based SA.

Figure 6 shows the corresponding radio-frequency (RF) profile, with 0.2 kHz resolution bandwidth taken at a repetition rate of 68.45 kHz. It has a signal-to-noise ratio (SNR) of 37 dB. The generated Q-switching pulses are stable and uniform during the several-hour operation, which confirms that CdSe-SA has good SA property and robust for practical applications.

5 Conclusion

We experimentally showed a passively Q-switched EDFL operating at 1559.35 nm by utilizing a CdSe-PMMA based SA. To the best of our knowledge, this is the first study in which a CdSe-PMMA based SA has been used as the SA in a Q-switched EDFL cavity. The CdSe SA was fabricated via emulsion polymerization process. The Q-switching operation was successfully achieved from 33.2 to 68.45 kHz and pulse width from 10.04 to 4.30 µs with maximum calculated pulse energy of 11.83 nJ. All of the results confirmed that the CdSe-PMMA has good optical property that makes it favorable for SA applications in cost-effective Q-switched EDF lasers.

References

Ahmad, H., Suthaskumar, M., Tiu, Z., Zarei, A., Harun, S.: Q-switched erbium-doped fiber laser using MoSe2 as saturable absorber. Opt. Laser Technol. 79, 20–23 (2016a)

Ahmad, H., Rashid, F., Azzuhri, S., Salim, M., Shaharuddin, R., Ismail, M., Razak, M.: The generation of passive dual wavelengths Q-switched YDFL by MoSe2 film. Laser Phys. Lett. 13, 115102 (2016b)

Ahmad, H., Ruslan, N., Ismail, M., Reduan, S., Lee, C., Sathiyan, S., Sivabalan, S., Harun, S.: Passively Q-switched erbium-doped fiber laser at C-band region based on WS2 saturable absorber. Appl. Opt. 55, 1001–1005 (2016c)

Ahmad, H., Salim, M., Thambiratnam, K., Norizan, S., Harun, S.: A black phosphorus-based tunable Q-switched ytterbium fiber laser. Laser Phys. Lett. 13, 095103 (2016d)

Ahmad, H., Reduan, S., Ali, Z.A., Ismail, M., Ruslan, N., Lee, C., Puteh, R., Harun, S.: C-band Q-switched fiber laser using titanium dioxide (TiO2) as saturable absorber. IEEE Photonics J. 8, 1–7 (2016e)

Ahmed, M., Ali, N., Salleh, Z., Rahman, A., Harun, S., Manaf, M., Arof, H.: Q-switched erbium doped fiber laser based on single and multiple walled carbon nanotubes embedded in polyethylene oxide film as saturable absorber. Opt. Laser Technol. 65, 25–28 (2015)

Bao, Q., Zhang, H., Wang, Y., Ni, Z., Yan, Y., Shen, Z.X., Loh, K.P., Tang, D.Y.: Atomic-layer graphene as a saturable absorber for ultrafast pulsed lasers. Adv. Funct. Mater. 19, 3077–3083 (2009)

Chen, Y., Zhao, C., Chen, S., Du, J., Tang, P., Jiang, G., Zhang, H., Wen, S., Tang, D.: Large energy, wavelength widely tunable, topological insulator Q-switched erbium-doped fiber laser. IEEE J. Sel. Top. Quantum Electron. 20, 315–322 (2014)

Chen, B., Zhang, X., Guo, C., Wu, K., Chen, J., Wang, J.: Tungsten diselenide Q-switched erbium-doped fiber laser. Opt. Eng. 55, 081306–081306 (2016)

Delgado-Pinar, M., Zalvidea, D., Diez, A., Pérez-Millán, P., Andres, M.: Q-switching of an all-fiber laser by acousto-optic modulation of a fiber Bragg grating. Opt. Express 14, 1106–1112 (2006)

DuChesne, A., Bojkova, A., Rottstegge, J., Glasser, G., Neher, D., Krieger, S.: Film formation of heterogeneous latex systems—a comparative study by mechanical testing, electron microscopy, interferometry and solid state NMR. Phys. Chem. Chem. Phys. 1, 3871–3878 (1999)

Feng, T., Mao, D., Cui, X., Li, M., Song, K., Jiang, B., Lu, H., Quan, W.: A filmy black-phosphorus polyimide saturable absorber for Q-switched operation in an erbium-doped fiber laser. Materials 9, 917 (2016)

Hamizi, N.A., Johan, M.R.: Synthesis and size dependent optical studies in CdSe quantum dots via inverse micelle technique. Mater. Chem. Phys. 124, 395–398 (2010)

Harun, S., Ismail, M., Ahmad, F., Ismail, M., Nor, R., Zulkepely, N., Ahmad, H.: A Q-switched erbium-doped fiber laser with a carbon nanotube based saturable absorber. Chin. Phys. Lett. 29, 114202 (2012)

Ismail, E., Kadir, A., Latiff, A., Ahmad, H., Harun, S.: Q-switched erbium-doped fiber laser operating at 1502 nm with molybdenum disulfide saturable absorber. J. Nonlinear Opt. Phys. Mater. 25, 1650025 (2016a)

Ismail, E., Kadir, N., Latiff, A., Ahmad, H., Harun, S.: Black phosphorus crystal as a saturable absorber for both a Q-switched and mode-locked erbium-doped fiber laser. RSC Adv. 6, 72692–72697 (2016b)

Mahmoodi, N.M., Oveisi, M., Arabi, A.M., Karimi, B.: Cadmium selenide quantum dots: synthesis, characterization, and dye removal ability with UV irradiation. Desalin. Water Treat. 57, 16552–16558 (2016)

Mb Hisyam, M., Rusdi, M.M.F., Latiff, A.A.A., Harun, S., Harun, S.: PMMA-doped CdSe quantum dots as saturable absorber in a Q-switched all-fiber laser. Chin. Opt. Lett. 14, 081404–081408 (2016)

Mears, R., Reekie, L., Poole, S., Payne, D.: Low-threshold tunable CW and Q-switched fibre laser operating at 1.55 μm. Electron. Lett. 3, 159–160 (1986)

Novoselov, K.S., Geim, A.K., Morozov, S.V., Jiang, D., Zhang, Y., Dubonos, S.V., Grigorieva, I.V., Firsov, A.A.: Electric field effect in atomically thin carbon films. Science 306, 666–669 (2004)

Petropoulos, P., Offerhaus, H., Richardson, D., Dhanjal, S., Zheludev, N.: Passive Q-switching of fiber lasers using a broadband liquefying gallium mirror. Appl. Phys. Lett. 74, 3619–3621 (1999)

Rashid, F., Azzuhri, S.R., Salim, M., Shaharuddin, R., Ismail, M., Ismail, M., Razak, M., Ahmad, H.: Using a black phosphorus saturable absorber to generate dual wavelengths in a Q-switched ytterbium-doped fiber laser. Laser Phys. Lett. 13, 085102 (2016)

Rusdi, M., Latiff, A., Hanafi, E., Mahyuddin, M., Shamsudin, H., Dimyati, K., Harun, S.: Molybdenum disulphide tape saturable absorber for mode-locked double-clad ytterbium-doped all-fiber laser generation. Chin. Phys. Lett. 33, 114201 (2016)

Sharma, A., Sharma, S.K., Sharma, M., Pandey, R., Reddy, D.: Structural and optical investigation of semiconductor CdSe/CdS core–shell quantum dot thin films. Spectrochim. Acta Part A Mol. Biomol. Spectrosc. 72, 285–290 (2009)

Tai, C.-Y., Wilkinson, J. S., Perney, N., Netti, M. C., Baumberg, J. J.: Self-phase modulation induced spectral broadening of ultrashort laser pulses in tantalum pentoxide (Ta) rib waveguide, In: CLEO/Pacific Rim Taipei, p. 2652 (2003)

Wang, H.-Y., Xu, W.-C., Luo, A.-P., Dong, J.-L., Cao, W.-J., Wang, L.-Y.: Controllable dissipative soliton and Q-switched pulse emission in a normal dispersion fiber laser using SESAM and cavity loss tuning mechanism. Opt. Commun. 285, 1905–1907 (2012)

Yu, Z., Song, Y., Tian, J., Dou, Z., Guoyu, H., Li, K., Li, H., Zhang, X.: High-repetition-rate Q-switched fiber laser with high quality topological insulator Bi2Se3 film. Opt. Express 22, 11508–11515 (2014)

Zervas, M.N., Codemard, C.A.: High power fiber lasers: a review. IEEE J. Sel. Top. Quantum Electron. 20, 219–241 (2014)

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Ismail, E.I., Kadir, N.A.A., Latiff, A.A. et al. Passively Q-switched erbium-doped fiber laser using quantum dots CdSe embedded in polymer film as saturable absorber. Opt Quant Electron 51, 182 (2019). https://doi.org/10.1007/s11082-019-1897-6

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s11082-019-1897-6