Abstract

The process of formation and the characteristics of silver nanostructures created by pulsed laser annealing in the air are studied. Nanoparticles were obtained by way of irradiating thin silver films (62 and 175 nm) on the dielectric (glass) base with an excimer laser emission (λ = 193 nm). Created nanostructures were studied using the methods of scanning electron microscopy and optical spectrometry, the dependencies of the mean size of obtained nanoparticles and the position of their plasmonic resonance on the number of laser pulses (ranging from 270 to 30,000) were drawn out. Based on the shift of the plasmonic resonance, the use of given nanostructures as optical components with narrow-band extinction (for example, notch filter), the magnitude and center frequency of which can be specified in advance, is suggested.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

Unique electric, magnetic, optical and chemical qualities (Zhang et al. 2008; Zhao et al. 2006) of nanoparticles (or generally, nanoscale structures) are of interest both from the perspective of fundamental studies and technological implementation. Nanostructures are used in various fields of science and instrumentation: medicine (Dell’Aglio et al. 2015; Stuchinskaya et al. 2011; Urusov et al. 2015), spectroscopy (Atanasov et al. 2014) and many others.

Using nanoparticles (NPs) allows the control of both micro- and macroprocesses, including the processes of laser-matter interaction using localized surface plasmon resonance (LSPR) (Vollath 2008). The energy of LSPR is governed by the shape, size, and composition of NPs. Therefore, adjustment of precious metal NPs LSPR can be used to control the position of optical absorption maximum of the structures based on those NPs. Apart from that, the formation of monodisperse noble metal nanoparticles is of great interest for numerous applications, such as surface-enhanced Raman spectroscopy, catalysis or biosensing. However, the issue of determining a method of precious metals NPs synthesis, which would guarantee the abovementioned adjustments and allow the formation of monodisperse metal nanoparticles, remains open. A lot of NPs synthesis methods are known, which can be roughly divided into two principal groups: “non-laser-assisted” and laser-assisted. The first group includes such methods as thermal annealing (Araújo et al. 2016; Leonov et al. 2015; Tanyeli et al. 2013), including annealing on a pre-structured dielectric base (Le Bris et al. 2014), ion beam irradiation (Singh et al. 2012), nanosphere lithography (Chan et al. 2007) and others.

Recently laser-assisted methods of NPs formation attracted great attention due to provided chemical purity and the possibility of structure size control. The final size is determined not only by the properties of the environment but also by the properties of the radiation (wavelength, pulse duration, frequency, polarization), which can be manipulated via changing the parameters of the system. Among the laser-assisted methods, one can separate the methods based on ablation: in various mediums (liquid (Bae et al. 2002), gas (Boutinguiza et al. 2015) and others.); under exposure in both CW (Arakelyan et al. 2016), and pulsed regimes, including nanosecond (Mafune et al. 2000) and femtosecond (Murray and Shin 2008) pulse durations, as well as multibeam interaction (Phuoc et al. 2007). It is also important to say about NPs formation in the bulk of soda lime glass (Grabiec et al. 2012; Nacharov et al. 2008) and methods, which use thin metal films as targets and create nanostructures using laser-induced forward transfer (Murray and Shin 2008) or various self-organization effects of the films island structure (Hubenthal 2009; Qi et al. 2016; Vartanyan and Leonov 2016; Wenzel et al. 1999).

In this work, nanosecond pulsed laser dewetting of thin silver films is investigated to reveal the processes in the film during its exposure to series of laser pulses and the effect on its optical properties and to demonstrate an approach to obtain nanostructures with an adjustable size distribution.

2 Experimental details

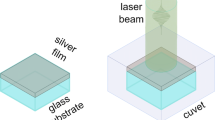

Silver thin films of different thicknesses (62 and 175 nm) were produced by magnetron sputtering in an argon atmosphere on a quartz substrate. The studied films were exposed to radiation of a pulsed ArF laser CL-7020 (Optosystems Ltd.) with its basic parameters: wavelength of 193 nm, duration of 17 ns, a maximum pulse energy of 200 mJ and a repetition rate of 20 Hz. The laser beam was focused by a plano-convex lens (fused silica, f = 50 mm) (Fig. 1) at normal incidence. The pulse energy was reduced before reaching the lens using an attenuator and monitored by Gentec Solo 2 laser power and energy meter connected with QE25 energy detector. All experiments were conducted in air at atmospheric pressure; an additional heating up to a temperature of 220 °C was implemented to avoid thermomechanical stresses during laser exposure. A number of laser pulses were in the range of 270–30,000 with a pulse energy of about 10–12 mJ. Based on the temperature estimations for the ‘film-substrate’ system (Metev and Veiko 2013) laser pulse energy was carefully adjusted to get a fluence, providing a heating up to film melting threshold. Non-irradiated silver films and the areas irradiated with a different number of laser pulses were studied using an MSFU-K microscope-spectrophotometer (LOMO) equipped with an R928 photomultiplier detector (Hamamatsu) to measure the extinction spectra. The film structure was analyzed with a MERLIN scanning electron microscope (Carl Zeiss).

3 Results and discussion

Our early studies of exposing the film to a single laser pulse of various energy resulted either in no change of a film surface or its damaging due to arising thermomechanical stresses. Therefore, all experiments presented here were conducted under exposure to a series of pulses with the use of a preheated sample.

Absorption of laser radiation by film lead to its heating with a consequent melting. The liquid layer of silver is in an unstable state (due to its small thickness) and tends to form an island structure because of the action of surface tension force (dewetting). With an increase in a number of laser pulses, the islands turn to structures (beads or spheroids) with dimensions of nanometer range, where LSPR can appear.

The abovementioned process was studied through the example of silver films with a thickness of 175 nm (Figs. 2, 3) and 62 nm (Figs. 4, 5) during its exposure to series of laser pulses. Resulted morphology was analyzed using scanning electron microscopy (SEM), and size distribution of obtained nanoparticles was calculated on the base of SEM images.

For 175 nm film, the island structure can be found after the action of 270 laser pulses (Fig. 2c), while nanoparticles start to appear after 1000 pulses. It can be proven both by a SEM image of the sample surface and the decrease of optical transmittance near 430 nm due to LSPR origin (Fig. 2c). With further increase in the number of laser pulses up to 30,000, nanoparticles appear in the entire area of exposure and their mean size decreases from 170 nm down to 10 nm (Fig. 3).

In the case of 62 nm film, it should be mentioned that due to lower film thickness it segregates into clusters even after a thermal action during preheating (Fig. 4a), although the clusters are relatively large with a broad size distribution. Increasing the number of incident pulses, one can find a decrease both in mean size and size distribution (Figs. 4, 5).

After the impact of 270 and 1000 pulses (Fig. 4b, c) the particles remained fairly large, with mean size >100 nm, but the dispersion decreased noticeably. Exposing the film to 3000, 10,000 and 30,000 pulses (Fig. 5) results in the nanoparticles formed on it having a mean size of <100 nm and an even more narrow size distribution.

The resulted structures exhibit two transmission valleys: a sharp one with minimum transmission near 430 nm and a broad one around 800 nm for all samples where nanoparticles are formed. This effect corresponds to a well-known phenomenon of light absorption and scattering by silver nanoparticles (Evanoff and Chumanov 2005).

The transmittance spectra of the films of various thickness were used to determine the dependencies of the plasmon resonance width, its spectral position, and the optical density in the resonance peak together with the mean size of nanoparticles on the number of laser pulses. The results are presented in Fig. 6.

For 62 nm film, the optical density in the plasmon resonance peak increases almost linearly with the number of laser pulses and a similar tendency can be found for 175 nm film. The wavelength corresponding to the plasmon resonance position increases with a transformation of a nanoparticle shape from a sphere to flattened spheroid (Wenzel et al. 1999), which indicates that smallest nanoparticles have a spherical shape.

The plasmon resonance FWHM almost linearly depends on the number of laser pulses, and it is inversely related to a mean size of nanoparticles. It should be mentioned that all of the abovementioned parameters are not the only function of nanoparticle size, but also strongly depend on the size distribution and the shape of nanoparticles.

The presented observations suggest that the decrease of the effective particles size should be related to evaporation-induced material loss. The final size distribution of silver nanoparticles corresponds to the balance between the size reduction of bigger particles due to evaporation and the merging of smaller particles through coalescence (Takami et al. 1999).

Since pulsed laser annealing was carried out in the air, the formation of oxide on the surface of particles is possible. The oxidation of small metal particles red-shifts the LSPR position (Brandt et al. 1997), but there is opposite situation for 62 nm film and unclear trend for 175 nm. Therefore, it can be assumed that in the first case oxide formation is negligible, while for thicker film oxidation may occur and contribute to the final structure. Moreover, recently it was reported (Vartanyan and Leonov 2016), that for 10 ns single pulse exposure of silver island film on a dielectric substrate, there was almost no difference in extinction spectra for exposure in a vacuum and air at atmospheric pressure. From here one can say that for a small number of laser pulses oxidation does not play a significant part.

4 Summary

In conclusion, silver nanoparticle arrays are obtained using a self-organization approach based on dewetting of a silver layer onto a silica substrate under the exposure of UV laser pulses with nanosecond duration. This process allows for the fabrication of large area systems via a simple and potentially cost effective processes. The array organization is demonstrated by SEM images analysis, showing a change in nanoparticle mean size and size distribution with a different number of laser pulses. Optical properties of these structures are investigated experimentally, and LSPR features are studied and associated with an alteration of dimensions. This approach represents the first step to the fabrication of plasmonic substrates with optical manipulation capability.

References

Arakelyan, S.M., Veiko, V.P., Kutrovskaya, S.V., Kucherik, A.O., Osipov, A.V., Vartanyan, T.A., Itina, T.E.: Reliable and well-controlled synthesis of noble metal nanoparticles by continuous wave laser ablation in different liquids for deposition of thin films with variable optical properties. J. Nanoparticle Res. 18, 155 (2016)

Araújo, A., Mendes, M.J., Mateus, T., Vicente, A., Nunes, D., Calmeiro, T., Fortunato, E., Águas, H., Martins, R.: Influence of the substrate on the morphology of self-assembled silver nanoparticles by rapid thermal annealing. J. Phys. Chem. C. 120(32), 18235–18242 (2016)

Atanasov, P.A., Nedyalkov, N.N., Dikovska, A.O., Nikov, R., Amoruso, S., Wang, X., Bruzzese, R., Hirano, K., Shimizu, H., Terakawa, M., Obara, M.: Noble metallic nanostructures: preparation, properties, applications. J. Phys. Conf. Ser. 514, 12024 (2014)

Bae, C.H., Nam, S.H., Park, S.M.: Formation of silver nanoparticles by laser ablation of a silver target in NaCl solution. Appl. Surf. Sci. 197–198, 628–634 (2002)

Boutinguiza, M., Comesaña, R., Lusquiños, F., Riveiro, A., Del Val, J., Pou, J.: Production of silver nanoparticles by laser ablation in open air. Appl. Surf. Sci. 336, 108–111 (2015)

Brandt, T., Hoheisel, W., Iline, A., Stietz, F., Träger, F.: Influence of molecular adsorbate layers on the optical spectra of small metal particles. Appl. Phys. B. 65, 793–798 (1997)

Chan, G.H., Zhao, J., Hicks, E.M., Schatz, G.C., Van Duyne, R.P.: Plasmonic properties of copper nanoparticles fabricated by nanosphere lithography. Nano Lett. 7, 1947–1952 (2007)

Dell’Aglio, M., Mangini, V., Valenza, G., De Pascale, O., De Stradis, A., Natile, G., Arnesano, F., De Giacomo, A.: Silver and gold nanoparticles produced by pulsed laser ablation in liquid to investigate their interaction with Ubiquitin. Appl. Surf. Sci. 374, 297–304 (2015)

Evanoff, D.D., Chumanov, G.: Synthesis and optical properties of silver nanoparticles and arrays. ChemPhysChem 6, 1221–1231 (2005)

Grabiec, M., Wolak, A., Véron, O., Blondeau, J.-P., Pellerin, N., Allix, M., Pellerin, S., Dzierżkega, K.: Laser-driven precipitation and modification of silver nanoparticles in soda lime glass matrix monitored by on-line extinction measurements. Plasmonics 7, 279–286 (2012)

Hubenthal, F.: Nanoparticles and their tailoring with laser light. Eur. J. Phys. 30, S49–S61 (2009)

Le Bris, A., Maloum, F., Teisseire, J., Sorin, F.: Self-organized ordered silver nanoparticle arrays obtained by solid state dewetting. Appl. Phys. Lett. 105, 203102 (2014)

Leonov, N.B., Gladskikh, I.A., Polishchuk, V.A., Vartanyan, T.A.: Evolution of the optical properties and morphology of thin metal films during growth and annealing. Opt. Spectrosc. 119, 450–455 (2015)

Mafune, F., Kohno, J., Takeda, Y., Kondow, T., Sawabe, H.: Formation and size control of sliver nanoparticles by laser ablation in aqueous solution. J. Phys. Chem. B. 104, 9111–9117 (2000)

Metev, S.M., Veiko, V.P.: Laser-Assisted Microtechnology. Springer, New York (2013)

Murray, P.T., Shin, E.: Formation of silver nanoparticles by through thin film ablation. Mater. Lett. 62, 4336–4338 (2008)

Nacharov, A.P., Nikonorov, N.V., Sidorov, A.I., Tsekhomskii, V.A.: Influence of ultraviolet irradiation and heat treatment on the morphology of silver nanoparticles in photothermorefractive glasses. Glas. Phys. Chem. 34, 693–699 (2008)

Phuoc, T.X., Soong, Y., Chyu, M.K.: Synthesis of Ag-deionized water nanofluids using multi-beam laser ablation in liquids. Opt. Lasers Eng. 45, 1099–1106 (2007)

Qi, D., Paeng, D., Yeo, J., Kim, E., Wang, L., Chen, S., Grigoropoulos, C.P.: Time-resolved analysis of thickness-dependent dewetting and ablation of silver films upon nanosecond laser irradiation. Appl. Phys. Lett. 108, 211602 (2016)

Singh, U.B., Agarwal, D.C., Khan, S.A., Mohapatra, S., Tripathi, A., Avasthi, D.K.: A study on the formation of Ag nanoparticles on the surface and catcher by ion beam irradiation of Ag thin films. J. Phys. D. Appl. Phys. 45, 445304 (2012)

Stuchinskaya, T., Moreno, M., Cook, M.J., Edwards, D.R., Russell, D.A.: Targeted photodynamic therapy of breast cancer cells using antibody-phthalocyanine-gold nanoparticle conjugates. Photochem. Photobiol. Sci. 10, 822–831 (2011)

Takami, A., Kurita, H., Koda, S.: Laser-induced size reduction of noble metal particles. J. Phys. Chem. B. 103, 1226–1232 (1999)

Tanyeli, I., Nasser, H., Es, F., Bek, A., Turan, R.: Effect of surface type on structural and optical properties of Ag nanoparticles formed by dewetting. Opt. Exp. 21, A798–A807 (2013)

Urusov, A.E., Petrakova, A.V., Kuzmin, P.G., Zherdev, A.V., Sveshnikov, P.G., Shafeev, G.A., Dzantiev, B.B.: Application of gold nanoparticles produced by laser ablation for immunochromatographic assay labeling. Anal. Biochem. 491, 65–71 (2015)

Vartanyan, T.A., Leonov, N.B.: Changes in morphology and optical properties of silver island films on transparent dielectric substrates under exposure to laser radiation. Opt. Spectrosc. 120, 628–632 (2016)

Vollath, D.: Nanomaterials: An Introduction to Synthesis, Properties and Applications. Wiley-VCH, Weinheim (2008)

Wenzel, T., Bosbach, J., Goldmann, A., Stietz, F., Träger, F.: Shaping nanoparticles and their optical spectra with photons. Appl. Phys. B. 69, 513–517 (1999)

Zhang, A., Zhang, J., Fang, Y.: Photoluminescence from colloidal silver nanoparticles. J. Lumin. 128, 1635–1640 (2008)

Zhao, Y., Jiang, Y., Fang, Y.: Spectroscopy property of Ag nanoparticles. Spectrochim. Acta A Mol. Biomol. Spectrosc. 65, 1003–1006 (2006)

Acknowledgements

The authors are grateful to S.I. Kudryashov for providing the samples. This work was partially supported by the Government of the Russian Federation (Grant No. 074-U01) for ITMO University.

Author information

Authors and Affiliations

Corresponding author

Additional information

This article is part of the Topical Collection on Fundamentals of Laser Assisted Micro- and Nanotechnologies.

Guest edited by Eugene Avrutin, Vadim Veiko, Tigran Vartanyan and Andrey Belikov.

Rights and permissions

About this article

Cite this article

Ageev, E.I., Aminov, I.R., Baranov, M.A. et al. Evolution of thin silver films under exposure to laser pulses in the air. Opt Quant Electron 49, 56 (2017). https://doi.org/10.1007/s11082-016-0874-6

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s11082-016-0874-6