Abstract

The concepts of technology fusion describe the phenomenon of technology overlap. Despite its importance, the evolutionary trajectories of technology fusion are not explored well. The main contributions of this article have two aspects: One is the mathematical modeling of a two-dimensional technology fusion system with technical efficiency and convergence parameters that can determine the evolution trajectories of technology fusion; the other is to reveal the dynamics of the evolution process through robust analysis and improving the stability of technology fusion under external disturbances. A novel technology fusion analysis method is proposed for technology fusion by applying dynamic development scenarios of manufacturing technology and information technology to be robust under external disturbances. In this article, firstly, we introduce technical efficiency and convergence parameters to establish a two-dimensional technology fusion system. Secondly, according to the characteristics of different fusion stages, we select the order parameters at each stage and establish order parameters function to determine the evolution trajectories of technology fusion. Finally, the fixed-point theory and the bifurcation theory are used to analyze the robustness of each stage, and the robust theorem at different technology fusion stages is proposed. The research results show: (1) We find that the characteristics analysis of technology fusion can divide the technology fusion process into three different stages, and the main characteristics of each stage as the order parameter can better reveal the evolution trajectory of technology fusion. (2) We find that the dynamics of technology fusion are caused by competition between the driving force and the dissipating force in the process of technology fusion. (3) We find that the dynamics of the technology fusion process may cause technology fusion to fall into chaos. (4) We find that by reasonably changing the relationship between the driving force and the dissipating force, the technology fusion process can be kept stable.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

1 Introduction

Technology fusion addresses the phenomenon of technology overlap, and Curran [1] defines it as the blurring of boundaries between discontinuous areas of science, technology, market, or industry. Although scholars have widely recognized the phenomenon of technological fusion, they have not yet formed a unified understanding of its concept. Nygren [2] defined technology fusion as the horizontal fusion of different technologies. That is, based on the purpose of creating new functions or new products, technologies in different fields absorbed each other to expand their professional skills. Jeong [3] defined technology fusion as a technology replacement and believed that when innovative products (services) had similar properties but higher cost-effective properties than current products (services), they had stable interchangeability between them. Liuz [4] believed that in most cases, the innovations of technology substitution depended on technological breakthroughs in other industries and technological substitution would gradually cause industrial integration. Lei [5] defined technology fusion as technology complementarity and believed that a large platform or system formed by multiple technologies would achieve the goals of improving productivity, reducing user costs, and enriching product feature through technology complementarity. Xiao [6] described technology fusion as technology integration and believed that technology integration was the complementary cooperation phenomenon of multiple technologies included in the innovation of technology integration. In addition, technology convergence, fusion, merging, cross-fertilization, and hybridization are all terms used to address the phenomenon of technology overlap. At present, technological convergence and technological fusion are mainly used, and some works of the literature distinguish the differences between them. However, this paper believes that they are consistent, and the unified term is called “Technology fusion.” Technology fusion began to attract attention in the 1980s and even more in the 1990s when diffusion and overlaps among robotics, computing, and information and telecommunication technologies began to have a significant impact on the products and strategies of firms in several industries from information and communication technology (ICT) to consumer electronics, to mechatronics [7]. Since then, several fields have been characterized by fusion dynamics [8]. In recent years, with the rapid development of the new generation of information technology, such as IoT [9], cloud computing [10], and big data [11], there have been many noteworthy changes in recent innovation trends. The deep fusion of manufacturing technology and information technology has gradually become the main trend of technology fusion. For example, manufacturing grid (MGrid) [12], product-service systems (PSSs) [13], industrial PSSs(IPS2) [14, 15], cloud manufacturing (CMfg) [10], CPS (cyber-physical systems) [16], and CPPS (cyber-physical production systems) [17]. At present, China as a manufacturing country is in the dilemma of loss of cost advantage, weak international competitiveness, and low level of intelligence in the global value chain. Hence, China must constantly fuse manufacturing technology and information technology to improve the intelligence of manufacturing. However, through investigation, we found that in most areas of China, there are still serious problems in the development of manufacturing. The current problems in the manufacturing industry are mainly reflected in the low fusion degree of production technology and information technology, the low fusion degree of products and information technology, and the low fusion degree of information technology and company business. Therefore, if the Chinese manufacturing industry wants to break the existing status and realize the rapid development of the manufacturing industry, a proper understanding of the trajectories of technology fusion and the dynamics of the fusion process are critical in making policies, decisions, and plans in technology management [18]. More broadly, understanding technology fusion dynamics could be informative for the definition of science and technology policies, by enabling comparison among investments and other forms of support for interdisciplinary areas, with support for existing domains [19].

To explore the trajectories and dynamics process of technology fusion, qualitative analysis including theoretical analysis, case studies and quantitative analysis including taxonomies, and data analysis have been proposed. However, the prediction results of qualitative analysis lack rigorous scientific analysis and the uniform standards, quantitative analysis are faced with shortcomings such as difficulty in data collection and the interpretation of data results. In addition, they all lack a dynamic analysis of the evolution process of technological fusion. Hence, there is no systematic empirical evidence on the overall characteristics of technology fusion. Complex system theory can reveal the trajectories and dynamics of technology fusion through a nonlinear analysis of the technology fusion process. However, there are very little researches on complex system theory for technology fusion.

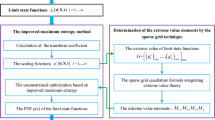

This article aims to fill this gap, and we propose data-driven modeling and nonlinear analysis methods. This method fully combines qualitative analysis and quantitative analysis and uses qualitative analysis to explain the results of quantitative analysis. Therefore, this method makes up for the shortcomings of difficult interpretation of quantitative analysis. In addition, the method can systematically describe the evolution trajectories of the fusion system and the dynamics of the evolution process. First, we introduce technical efficiency and convergence parameters to establish a two-dimensional staged model and then select the order parameters to establish the corresponding order parameter equation. The order parameter equation can determine the evolution direction of technology fusion at each stage. Second, we introduce robustness to describe the dynamics. By the fixed-point theory and the bifurcation theory, we can get the robustness of each stage. Through the above analysis, we can give systematic empirical evidence on the overall characteristics of technology convergence.

The article is organized as follows. Section 2 reviews the technology fusion literature. Section 3 analyzes the fusion of manufacturing technology and information technology. Section 4 analyzes the dynamic fusion mechanism of manufacturing technology and information technology. Section 5 analyzes the robustness of technology fusion. Section 6 provides case analysis. Section 7 discusses the advantages and disadvantages of this research. Section 8 concludes the article.

2 Research background

The related research methods of fusion trajectories and dynamics are mainly divided into two categories, one is qualitative analysis methods, and the other is quantitative analysis. Table 1 presents the classification of related research methods and their main advantages and disadvantages.

2.1 Qualitative analysis method of technology fusion

The qualitative analysis methods of technology fusion mainly include technology roadmap, Delphi method, and case study method. The technology roadmap can also use the Delphi method. (1) Technology roadmap [29] was first used in enterprise technology management. The application of technology roadmap in technology fusion research is mainly to predict the development trajectories of fusion technology through expert knowledge [30]. (2) Delphi method [31] is also known as an expert opinion method or expert letter inquiry survey method. The original purpose is to obtain the most reliable consensus opinion from a group of experts through a series of intensive questionnaire surveys and controllable feedback. The application of the Delphi method in technology fusion is mainly to obtain the consensus opinions of experts on the trajectories of technology fusion [33]. (3) Case analysis [32] refers to the method of analyzing a single object in combination with literature and obtaining general and universal laws of things. The application of case analysis in technology fusion is mainly to comprehensively analyze multiple factors of technology development and draw the dynamic development trajectories of technology fusion [34].

2.2 Quantitative analysis methods of technology fusion

The quantitative analysis methods of technology fusion mainly include statistical analysis, co-occurrence analysis, cluster analysis, citation analysis, input–output analysis, and big data analysis. (1) Statistical Analysis. Due to the complexity of technology fusion, Keungoui [35] proposed correlation analysis indicators. These indicators can be used for statistical analysis and presentation and can also be further enriched for correlation analysis from different perspectives. (2) Co-occurrence analysis. Fusion analysis shows that if a common content or form feature frequently appears in the same literature at the same time, it often indicates that the two features are closely related. In the research of technology fusion, scholars mainly conduct co-occurrence analysis from the perspectives of classification, patentees, and subject terms. Co-classification analysis has been widely used in technology fusion-related research [36]. (3) Cluster analysis mainly uses clustering technology to group data into different sub-categories according to technical fields. It is usually combined with co-occurrence analysis, citation analysis, and text mining analysis. The application of cluster analysis in technology fusion research is mainly to cluster co-occurrence matrix by subject or technology classification to discover the main fusion fields [37]. (4) Citation analysis refers to the analysis of the citation of the target patent and the citation of the target patent. Wei [38] used patent citation analysis to conduct empirical research on discoveries in the early stage of technology fusion to explore the direction of technology fusion. (5) Input–output analysis [39] is the principle and method of analyzing the quantitative dependence between input and output in a specific economic system. Input–output analysis can be used to discover the quantitative effects of different influencing factors in technology fusion research [40]. (6) Big data analysis is suitable for massive data analysis and can discover the key factors and fusion trends of technology fusion from the whole field data set [41]. Among them, affected by the difficulty of data set construction and analysis index data calculation, citation analysis and input–output analysis methods have poor applicability in large-scale data sets and are mainly suitable for a specific problem/field or smaller data sets.

It can be seen from the above analysis that the current research on technology fusion has made great progress, but there are still shortcomings: (1) Lack of research on technology fusion from a systematic perspective. (2) Insufficient reflection on the dynamics of the trajectories of technology fusion. Therefore, only by adopting a system perspective can we more accurately and comprehensively understand and master the operating mechanism and dynamic characteristics of technology fusion. Evolutionary economics [42] took technology fusion as a link in a complex fusion process, and it emphasized the important role of competition, growth, resource constraints, and complex interdependencies in the fusion process. Therefore, based on the above evolutionary economic theory, Zhu [43], from the perspective of quality management, established a dynamic model to find out the internal evolution mechanism of technology fusion. Their research found the chaos effect in the process of technology fusion and then proposed a chaos control method to help enterprises continue to push technology fusion. Also, Zhu et al. [44] took technical efficiency as a measure of technology fusion to establish a technical efficiency evolution model and used convergence theory to discuss the evolution mode of technical efficiency in the three stages of technology fusion. The results showed that convergence intensity can effectively improve the performance of enterprises. But [43] did not conduct a phased study of technology fusion. Although [44] studied on technology fusion by different stages, the focus of the research was on technology convergence and there was no comprehensive research on technology fusion. Therefore, the research in this article can make up for these shortcomings.

The novel aspects of our research are as follows: (1) Using technical efficiency as an indicator to measure the different stages of technology fusion and convergence parameters as an indicator to measure the degree of technology integration and collaborative development, from a system modeling perspective, this paper constructs nonlinear dynamic models to quantitatively the process of technology fusion and reveals the complexity and dynamics of technology fusion, which overcomes the current research limitations represented by the qualitative analysis of the technology fusion. (2) To assess the robustness of the technology fusion, this paper uses the synergetic theory to extract the order parameters of the above nonlinear dynamic model and establishes the order parameter equation. And then this paper uses the fixed-point theorem and bifurcation theory to conduct a robust analysis of the order parameter equation and proposes the robust theorem of technology fusion at different stages. (3) From a robustness management perspective, this paper attempts to address the robustness of the technology fusion starting from the root causes, by selecting a reasonable investment to get a suitable technology development potential coefficient and determine favorable integration degree or collaborative development between manufacturing technology and information technology. The proposed method can reveal the trajectories and dynamics of technology fusion and offer a practical framework for managing the robustness of technology fusion, which facilitates the ex ante robustness-based design and the ex post robustness control of technology fusion.

3 Analysis of technology fusion between manufacturing technology and information technology

3.1 Interactive relationship between manufacturing technology and information technology

The two aspects of technology fusion in manufacturing enterprises are the integration of technologies and the dynamic collaborative development of technologies. In this paper, the technology fusion frame is mainly constructed by the development of different technologies and the integration and collaborative development of different technologies.

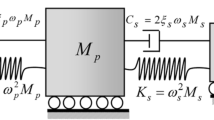

As shown in Fig. 1, on the one hand, the application of information technology promotes the enterprise’s manufacturing skills and management intelligence, help enterprises improve management efficiency, customer satisfaction, productivity and competitiveness and reduce operating cost, optimize production structure. On the other hand, in addition to the mutual promotion of internal manufacturing technology and information technology, the development and progress of internal technology are inevitably affected by the environmental. The introduction of external new technologies will inevitably drive internal technological progress. Under the circular effect of the internal and external technical environment, the manufacturing technology and information technology of the enterprise are continuously improved and updated.

Figure from Ref. [44]

Dynamic integration and collaborative development model.

It is worth noting that based on research needs, we abstract manufacturing technology and information technology for discussion. However, manufacturing technology and information technology are inseparable in practice. Many manufacturing technologies are integrated with information technology, but this is the root of fusion and the main reason we discuss technology fusion. That is to say, the manufacturing technology fused with information technology is still manufacturing technology, and the information technology of this paper includes information technology that has not been integrated with manufacturing technology, such as software technology and numerical control technology. Or information technology that can only exist independently, such as communication technology and information system, and their fusion with manufacturing technology mainly focuses on matching and cooperation.

Technology fusion stems from technological change and the emergence of new technologies [45]. Its main driving forces include rule breaking, product binding, and technology integration that integrates multiple products into systems. The role of rule breaking in promoting technology integration is reflected: Legal changes will lead to huge changes in market size and potential application of new technologies, which will disrupt existing rules. The results are mainly reflected in two aspects: First, R & D enterprises that have substitute technology in this industry and those enterprises in other industries that can directly apply technology to this industry join the competition and share market share. Second, lower customer switching costs and prolonged price wars destroy existing profit margins, thereby changing rules and disintegrating the internal structure of the industry. The role of product binding in promoting technology integration is reflected: The technical improvement of a product or platform will cause the enterprise to accelerate the improvement and innovation of complementary products to maintain its competitive advantage. The product binding strategy helps companies apply similar production processes to provide products and services to form economies of scale and cost-effectiveness, while increasing brand equity and differentiated competitive advantages. Also, the complexity of integrated systems has enabled companies to adopt technology diversification strategies to improve their technical experience and capabilities, so that integrated systems have an impact on the development of multiple industries from both the decentralized and integrated technologies.

3.2 The content and method of technology fusion between manufacturing technology and information technology

The manufacturing technology in this paper is a broad manufacturing technology, including the technology involved in the process from product production to sale. The information technology in this paper includes hardware technology, software technology, network technology, information security technology, information standardization technology, database technology, etc.

The fusion of manufacturing technology and information technology is the fusion of information technology with manufacturing technology, to achieve the global optimization of the entire manufacturing system, which not only exerts the overall benefits of manufacturing technology, but also reflects the huge advantages of information technology. The overall operation of a manufacturing enterprise includes four main functions: product design, product manufacturing, supply and marketing services, and decision management. These four functions provide a solid guarantee for the good operation of various tasks of the enterprise. Therefore, the fusion of manufacturing technology and information technology is mainly reflected in product design informatization, product manufacturing informatization, supply and marketing service informatization, enterprise management informatization, as shown in Fig. 2. In terms of product design, combining computer technology to improve the design accuracy and efficiency of products, to ensure the quality of products, and to lay a solid foundation for the smooth development of subsequent work, information technology in product design includes CAD, CAE, CAPP, CAM, PDM, DFX tools, and computer-aided innovative design (CAI), etc. In terms of product manufacturing, the fusion of information technology and manufacturing technology is reflected in digital equipment, including CNC machine tools, machining centers, etc. Currently, the fusion help enterprises improve the level of automation in the product manufacturing process, improve product manufacturing accuracy and efficiency, and ensure the smooth connection of the upper and lower processes. In terms of supply and marketing services, the fusion is reflected in the combination of information technology and modern management methods to improve the sales capacity and service quality. Currently, information technology includes CRM, SCM, EC, etc., which realizes the optimization of the entire operational process of the enterprises strategically and tactically. In enterprise decision management, fusion is reflected in the enterprise management platform. Through this platform, it helps enterprises to manage and regulate various activities in a unified manner, improve the processing quality of products in various tasks, and achieve overall efficient and coordinated operation. Currently, information technology includes the application of ERP methods in enterprise management. Through the feedback of logistics, information flow, and capital flow, it integrates the needs of customers with the internal production and operation activities of the enterprise and the resources of suppliers and is a brand-new management method that carries out business management completely according to user needs.

Figure from Ref. [45]

Fusion of manufacturing technology and information technology.

4 Analysis of the dynamic fusion mechanism of manufacturing and information technologies

4.1 Mathematical modeling

Basic assumptions and definitions of the model

Hypothesis 1

There is no significant change in the scale of production factors during the period of technological integration and collaborative development of enterprises.

Hypothesis 2

The convergence parameters of technology are directly proportional to the gap of technology efficiency between manufacturing technology and information technology.

Definition 1

The technology efficiency development potential coefficient refers to the maximum acceleration of the technology efficiency through investment means.

Definition 2

Technology integration refers to a method of creating new technologies with unified overall functions by reorganizing manufacturing technology and information technology according to certain technical principles or functions. It can often achieve the purpose of technical requirements that cannot be achieved by a single technology.

Definition 3

Technology collaborative development refers to manufacturing technology and information technology cooperating to complete a certain goal and achieve a win–win result of common development.

The purpose of technology integration is to create innovative technology to complete tasks that cannot be accomplished by a single technology. For manufacturing enterprises, a new technology is mature and brings technical efficiency to the enterprise only after the technologies are completely integrated. Otherwise, the incomplete integration of technology will cause a waste of two technical resources, not only will not improve the technical efficiency but will cause the technical efficiency to decline. Therefore, the technology will inhibit the improvement of technical efficiency in the stage of incomplete integration. The purpose of the collaborative development of technology is that the two technologies will cooperate with each other to complete the manufacturing task after complete integration and promote the development of the two technologies and the improvement of technical efficiency. Therefore, the collaborative development of technologies will promote the improvement of the efficiency of the two technologies. Also, enterprises will promote the development of technology efficiency through the introduction of new manufacturing technology and information technology. However, due to the limited resources of enterprises and the complexity of the manufacturing environment, therefore, manufacturing enterprises will be hindered in the process of technology fusion.

The details of the model are as follows:

-

1.

\( \alpha_{1} - \beta_{1} x(t) \) represents the growth rate of information technology efficiency. The parameter \( \alpha_{ 1} \) represents the maximum development potential coefficient of information technology efficiency, and it represents the maximum growth rate of information technology efficiency when the manufacturing enterprise independently develops information technology and the current production factor input structure remains unchanged.\( \beta_{1} x(t) \) represents the obstacles to the development of information technology efficiency at the current level of information technology.

-

2.

\( \gamma_{ 1} x(t)y(t) \) represents the impact of the collaborative development of technologies on the improvement of information technology efficiency. The parameter \( \gamma_{1} \) represents the convergence parameter of information technology to manufacturing technology and satisfies \( { - 1} \le \gamma_{1} \le 1 \). \( { - 1} \le \gamma_{1} \le 0 \) represents that information technology to manufacturing technology from complete nonintegration to complete integration. \( \gamma_{1} = - 1 \) represents complete nonintegration, and \( \gamma_{1} = 0 \) represents complete integration. \( 0 \le \gamma_{1} \le 1 \) represents that information technology to manufacturing technology from complete integration to fully collaborative development. \( \gamma_{1} = 1 \) represents fully collaborative development.

-

3.

\( \alpha_{2} - \beta_{2} x(t) \) represents the growth rate of manufacturing technology efficiency. The parameter \( \alpha_{ 2} \) represents the maximum development potential coefficient of manufacturing technology efficiency, and it represents the maximum growth rate of manufacturing technology efficiency when the manufacturing enterprise independently develops manufacturing technology and the current production factor input structure remains unchanged. \( \beta_{ 2} x(t) \) represents the obstacles to the development of manufacturing technology efficiency at the current level of manufacturing technology.

-

4.

\( \gamma_{ 2} x(t)y(t) \) represents the impact of the collaborative development of technologies on the improvement of manufacturing technology efficiency. The parameter \( \gamma_{ 2} \) represents the convergence parameter of manufacturing technology to information technology and satisfies \( { - 1} \le \gamma_{ 2} \le 1 \). \( { - 1} \le \gamma_{ 2} \le 0 \) represents that manufacturing technology to information technology from complete nonintegration to complete integration.\( \gamma_{ 2} = - 1 \) represents complete nonintegration, \( \gamma_{ 2} = 0 \) represents complete integration. \( 0 \le \gamma_{ 2} \le 1 \) represents that manufacturing technology to information technology from complete integration to complete collaborative development (Table 2). \( \gamma_{ 2} = 1 \) represents complete collaborative development.

Table 2 Notation and parameter values in the model

Therefore, based on the above analysis, we obtain the nonlinear dynamic model of the technology fusion system:

4.2 Model parameter calculation

Definition 1

Each technology input proportion of the enterprise will correspond to the maximum output. Production frontier [46] refers to the boundary surface formed by the maximum output set corresponding to the different technology inputs proportion of the enterprise

Definition 2

Technology efficiency [44] is defined as the ratio between the actual output of the decision-making unit and the maximum output under the same amount of input of production factors.

In this paper, we use technology efficiency as a scalar to measure the level of two technologies. To distinguish between manufacturing technology and information technology, we use \( x \) to define information technology efficiency, and \( y \) to represent manufacturing technology efficiency.

Definition 3

Information Technology Production Factor Set X = {Interface and communication technology, database technology, integrated framework technology, software technology, artificial intelligence technology, expert system, decision support system, data standard, sensor and control technology, neural network technology}. Manufacturing Technology Production Factor Set Y = {Production automation technology, process design technology, product inspection technology, machine tool and tool technology, single-machine processing unit and process control technology, engineering technicians and management personnel training and education in various advanced production technologies and programs}.

For a more intuitive discussion, we use one-dimensional output, which is only a reduction in dimension and does not affect the conclusion. We use \( E \) to represent the set of production factors, \( Q(E) \) to indicate the actual output corresponding to production factors \( E \), and \( Q^{*} (E) \) to indicate the output in production frontier corresponding to production factors \( E \). Therefore, the technology efficiency of the manufacturing enterprise is defined as \( \frac{Q}{{Q^{*} }} \) (Fig. 3).

Therefore information technology efficiency is defined \( x = \frac{{Q_{\text{information}} }}{{Q^{*}_{\text{information}} }} \) and satisfies \( x \le 1 \). Manufacturing technology efficiency is defined \( y = \frac{{Q_{\text{manufacturing}} }}{{Q^{*}_{\text{manufacturing}} }} \) and satisfies \( y \le 1 \).

Definition 4

Due to financial constraints and the complexity of the manufacturing environment, manufacturing enterprises’ technical efficiency development process usually encounters some obstacles. This paper uses the damping coefficients \( \beta_{ 1} ,\beta_{ 2} \) of technical efficiency to represent the obstacles during the development of technical efficiency.

At the same production level, if the production factor input ratio remains unchanged, the above calculation can be simplified to

Notation

For manufacturing enterprises, the damping coefficient is constant, which are affected by the complexity of the enterprise’s manufacturing environment, etc.

Definition 5

The convergence parameters \( \gamma_{ 1} ,\gamma_{ 2} \) represent the matching degree of one technology to another technology, which are used to measure the degree of technology integration and collaborative development.

The essence of convergence is the process of low performance moving closer to high performance and high-performance releasing energy to low performance. Manufacturing technology and information technology infiltrate each other in the process of technology fusion. The low technical efficiency moves closer to the high technical efficiency, and the high technical efficiency releases energy to the low technical efficiency. Therefore, we regard the technology fusion process as a convergence process. According to the element attributes of convergence, it can be divided into homogeneous convergence and heterogeneous convergence. The convergence of elements with the same attributes is homogenous convergence; otherwise, it is heterogeneous convergence. This paper takes manufacturing technology and information technology as two types of technical analysis. In view of the difference in the way of action of information technology and manufacturing technology, the convergence of information technology and manufacturing technology belongs to two-dimensional heterogeneous convergence. To put the two-dimensional heterogeneous convergence on the same scale and simplify the two-dimensional convergence problem to one-dimensional convergence, we define “integration” and “collaborative Development” to describe the convergence process, so that the discussion of heterogeneous convergence can be attributed to unified. To describe the degree of convergence, we define convergence parameters, as shown in Fig. 4.

In this paper, we believe that a technology with a short R & D cycle can quickly satisfy the needs of another technology. Therefore, a technology with a short R & D cycle has a stronger matching ability and the convergence parameter is larger. According to assumption 2, we can get

Therefore, the convergence parameters can be expressed as

where \( \Delta x(k) \) represents the changes of information technology efficiency \( x \) at time \( k \). \( d(x(k - 1)) \) represents the distance between information technology \( x \) and manufacturing technology \( y \) at time \( k - 1 \)(The distance function in this paper is the gap between the two technical outputs). \( \Delta y(k) \) represents the changes of manufacturing technology efficiency \( y \) at time \( k \). \( d(y(k - 1)) \) represents the distance between manufacturing technology \( y \) and information technology \( x \) at time \( k - 1 \). \( \gamma_{1}^{k} \) is the convergence parameter of information technology efficiency at time \( k \). \( \gamma_{2}^{k} \) is the convergence parameter of manufacturing technology efficiency at time \( k \). Obviously, \( \gamma_{i}^{k} (k = 1,2) \) are ratio of changes to distance. In practical problems, \( \gamma_{\text{i}}^{k} (i = 1,2) \) should be uncertain variables. For the convenience of calculation, we take the average of all moments on the same production frontier and treat them as constant:

Based on the above analysis, the convergence parameters are related to business investment in technology management, and the convergence parameters are constant if business investment for technology management is unchanged. Technology fusion is a gradual process of mutual penetration of manufacturing technology and information technology. According to technology integration and the collaborative development of technology, this paper specifies the convergence parameters \( - 1 \le \gamma_{1} ,\gamma_{2} \le 1 \). When \( - 1 \le \gamma_{1} ,\gamma_{2} \le 0 \), this stage is the technology integration stage. \( \gamma_{ 1} = - 1 \) represents that the integration of information technology and manufacturing technology is invalid, which is called complete nonintegration. \( \gamma_{ 1} = 0 \) represents that technology integration is effective at this time, called complete technical integration. Complete technical integration means that the interaction of information technology and manufacturing technology will neither promote the efficiency of information technology nor inhibit its development. \( 0< \gamma_{1} ,\gamma_{2} \le 1 \) represents technical collaborative development.\( \gamma_{ 1} = 1 \) represents the synchronization of information technology and manufacturing technology. Currently, information technology and manufacturing technology are completely collaborative. Similarly, the definition of the convergence parameter of manufacturing technology can be obtained. The relationship between \( \gamma_{ 1} \) and \( \gamma_{ 2} \) is shown in Fig. 4.

Definition 6

The technology efficiency development potential coefficients \( \alpha_{ 1} ,\alpha_{ 2} \) indicate that the maximum possible development acceleration before reaching the production frontier when the current technical level remains unchanged.

By definition, we can know that the technology efficiency development potential coefficients \( \alpha_{ 1} ,\alpha_{ 2} \) are related to the production frontier. When the production frontier does not change, the technology efficiency development potential coefficients will not change. Therefore, in the same production frontier, if the input ratio of production factors remains unchanged, the maximum output \( Q^{*} \) at different times remains unchanged, and the above calculation can be simplified as

In addition, to facilitate calculation, we just take the average value of the technology efficiency development potential coefficients on the same production frontier.

Due to the short development cycle of information technology, the development of information technology is always ahead of manufacturing technology. Furthermore, for manufacturing, the R & D and introduction of information technology are mainly to support the current manufacturing technology and improve the manufacturing informatization and automation of manufacturing enterprises. Therefore, the convergence rate of information technology to manufacturing technology is always faster than the convergence rate of manufacturing technology to information technology, so we can obtain \( \gamma_{ 1} > \gamma_{ 2} \).

4.3 Order parameter analysis of dynamic model of enterprise fusion

The enterprise technology fusion system is an open and complex system. To pursue efficiency and produce products that meet the needs of consumers, enterprises need to continuously invest resources to carry out technological fusion. Therefore, the investment of resources by enterprises forms the driving force for the development of technology fusion. However, the limited internal resources of the enterprise and the restrictions of the social environment will form the dissipating force to inhibit the development of enterprise technology fusion. The enterprise technology fusion system will go through various stages of the life cycle in the process of competition between the driving force and the dissipating force and may fall into chaos.

For manufacturing enterprises, the technology fusion generally consists of the following three stages. Stage I: Manufacturing technology efficiency is greater than information technology efficiency. Manufacturing enterprises can introduce new information technology through investment, which changes the production frontier of information technology, i.e., \( \alpha {}_{ 1} \) changed. When information technology efficiency satisfies \( |x - y_{10} | \le \delta \), it shows that the information technology of enterprises no longer lags behind the manufacturing technology. At this time, technology fusion can enter stage II. Stage II: Manufacturing technology efficiency and information technology efficiency satisfy \( |x - y| \le \delta \), manufacturing enterprises invest a lot of manpower, material and financial resources to improve the technology management level, so that the current technology management level can make full use of technology and improve the integration of technology or technology collaborative development. Furthermore, the fusion of information technology and manufacturing technology will be improved to greatly improve the technical efficiency of enterprises. At this time, information technology and manufacturing technology may appear in two situations: (1) When the information technology efficiency and the manufacturing technology efficiency satisfy \( x - y > \delta \), it means that the information technology in the enterprise has been ahead of the manufacturing technology. At this time, the technology fusion can enter stage III. Stage III: Information technology efficiency is higher than manufacturing technology efficiency, and the lagging development of manufacturing technology has become the bottleneck of technological fusion. Therefore, manufacturing enterprises will turn their attention to the introduction of new manufacturing technology to improve \( \alpha {}_{ 2} \). When information technology efficiency satisfies \( |y - x_{ 30} | < \delta \), it shows that the manufacturing technology of the enterprise no longer lags behind the information technology; at this time, technology fusion can enter stage II. (2) When information technology efficiency and manufacturing technology efficiency satisfy \( y - x > \delta \), it shows that the manufacturing technology of the enterprise has been ahead of the information technology, and technology fusion can enter stage I, where \( \delta \) represents the maximum technology efficiency error when manufacturing technology and information technology match.\( y_{10} \) represents the initial manufacturing technical efficiency of stage I. \( x_{30} \) represents the initial information technical efficiency of stage III.

Notation

In this paper, the fusion process is consisted of two parts: integration and collaboration development.

The dominant state variable is called the order parameter in the synergy theory [47]. Therefore, according to the above three stages, we give the order parameters and order parameter equations of the above three stages:

-

(1)

Stage I At this stage, the manufacturing technology level of enterprises is higher than that of information technology. Therefore, manufacturing enterprises will invest manpower, material, and financial resources to improve information technology, so that manufacturing technology and information technology will continue to match. Therefore, the investment and development of manufacturing technology at this stage is almost zero, and information technology has received a lot of investment and development. Therefore, information technology has become the decisive factor for the development of technology fusion, that is, the order parameter. According to the adiabatic elimination method, the change rate of manufacturing technology efficiency is 0:

$$ \begin{aligned} & \frac{{{\text{d}}x}}{{{\text{d}}t}} = \alpha_{1} x - \beta_{1} x^{2} + \gamma_{ 1} xy \\ & \frac{{{\text{d}}y}}{{{\text{d}}t}} = \alpha_{2} y - \beta_{2} y^{2} + \gamma_{ 2} xy = 0\\ \end{aligned} $$(2)

If current manufacturing technology efficiency \( y \ne 0 \), above Eq. (1) can be simplified to the following order parameter equation:

To reveal as much as possible the fusion law of manufacturing technology and information technology, Eq. (3) is discretized as:

In the development of information technology \( x(t + 1) = \left( {\alpha_{1} + \frac{{\gamma_{1} \alpha_{2} }}{{\beta_{2} }} + 1} \right)x(t) - \left( {\beta_{1} - \frac{{\gamma_{1} \gamma_{2} }}{{\beta_{2} }}} \right)x^{2} (t) \), \( \left( {\alpha_{1} + \frac{{\gamma_{1} \alpha_{2} }}{{\beta_{2} }} + 1} \right)x(t) \) represents the driving force, that is, a force that changes the efficiency of the original information technology, and \( \left( {\beta_{1} - \frac{{\gamma_{1} \gamma_{2} }}{{\beta_{2} }}} \right)x^{2} (t) \) means dissipating force. When the Information Technology Efficiency Development Potential Coefficient \( \alpha_{ 1} \) is small, the driving force is less than the dissipating force, and \( x(t) \) can only tend to a steady state. When \( \alpha_{ 1} \) gradually increases, the driving force changes from small to large, and a period-doubling bifurcation behavior will occur as shown in Fig. 5. When the driving force and the dissipating force are equal, chaos occurs. Therefore, enterprises will face two difficulties in the process of information technology fusion: (1) If an enterprise continues to improve information technology, due to the fierce competition between the driving force and the dissipative force, the development of enterprise information technology will begin to fluctuate until it falls into chaos. (2) However, if the enterprise does not improve information technology, that will make the product informatization low, leading to the entry of substitutes into the market and encroaching on the market share of the enterprise. At this time, the driving force is significantly less than the dissipating force; if the enterprise does not reform in time, the enterprise will eventually become bankrupt. Therefore, when an enterprise is improving information technology, managers must timely judge the relationship between the driving force and the dissipating force of the enterprise. Before the information technology development falls into chaos, the information technology development system should be forced to enter stage II.

-

(2)

Stage II At this stage, the manufacturing technology level of the manufacturing enterprises is consistent with the information technology level. Therefore, manufacturing enterprises will invest to improve the technical integration and collaborative development of information technology and manufacturing technology. Therefore, manufacturing technology and information technology at this stage are decisive factors for the development of manufacturing enterprises, that is, order parameters. Therefore, according to Eq. (1), the fusion law of manufacturing technology and information technology can be expressed as:

$$ \begin{aligned} & x(t + 1) = (\alpha_{1} + 1)x(t) - \beta_{1} x^{2} (t) + \gamma_{ 1} x(t)y(t) \\ & y(t + 1) = (\alpha_{2} + 1)y(t) - \beta_{2} y^{2} (t) + \gamma_{ 2} x(t)y(t) \\ \end{aligned} $$(5)

Before the driving force and dissipating force of the information technology development are equal, the enterprise should change the resource investment strategy to make the information technology development enter a new stage II: the fusion development of manufacturing technology and information technology. At this stage, the investment strategy of the enterprise should increase the degree of fusion \( \gamma_{1} ,\gamma_{2} \) of the two technologies through resource investment, thereby increasing the driving force of the technology fusion system and enabling the continuous development of enterprise technology fusion. And before the driving force and the dissipating force are equal, the enterprise should enter a new phase of development.

-

(3)

Stage III With the continuous development of the industrial Internet of Things, industrial big data technology, etc., the information technology of manufacturing enterprises is gradually higher than that of manufacturing technology. Therefore, manufacturing enterprises will invest manpower, material resources, and financial resources to improve manufacturing technology. Therefore, the investment and development of information technology at this stage is almost zero and the manufacturing technology has received a lot of investment and development. Therefore, manufacturing technology has become a decisive factor for the development of technology fusion, that is, order parameters. According to the adiabatic elimination method, the change rate of information technology efficiency is 0:

$$ \begin{aligned} & \frac{{{\text{d}}x}}{{{\text{d}}t}} = \alpha_{1} x - \beta_{1} x^{2} + \gamma_{ 1} xy = 0\\ & \frac{{{\text{d}}y}}{{{\text{d}}t}} = \alpha_{2} y - \beta_{2} y^{2} + \gamma_{ 2} xy \\ \end{aligned} $$(6)

If current information technology efficiency \( x \ne 0 \), above Eq. (1) can be simplified to the following order parameter equation

To reveal as much as possible the fusion law of manufacturing technology and information technology, Eq. (7) is discretized as:

In the development of manufacturing technology \( y(t + 1) = \left( {\alpha_{2} + \frac{{\gamma_{2} \alpha_{1} }}{{\beta_{1} }} + 1} \right)y(t) - \left( {\beta_{2} - \frac{{\gamma_{1} \gamma_{2} }}{{\beta_{1} }}} \right)y^{2} (t) \), \( \left( {\alpha_{2} + \frac{{\gamma_{2} \alpha_{1} }}{{\beta_{1} }} + 1} \right)y(t) \) represents the driving force, that is, a force that changes the efficiency of the original manufacturing technology, and \( \left( {\beta_{2} - \frac{{\gamma_{1} \gamma_{2} }}{{\beta_{1} }}} \right)y^{2} (t) \) means dissipating force. When the Manufacturing Technology Efficiency Development Potential Coefficient \( \alpha_{ 2} \) is small, the driving force is less than the dissipating force, and \( y(t) \) can only tend to a steady state. When \( \alpha_{ 2} \) gradually increases, the driving force changes from small to large, and a period-doubling bifurcation behavior will occur as shown in Fig. 19. When the driving force and the dissipating force are equal, a situation in which the two forces compete with each other appears, that is, chaos occurs. Therefore, enterprises will face two difficulties in the process of manufacturing technology fusion: (1) If an enterprise continues to improve manufacturing technology, due to the fierce competition between the driving force and the dissipative force, the development of enterprise manufacturing technology will begin to fluctuate until it falls into chaos. (2) However, if the enterprise does not improve manufacturing technology, that will lead to low product productivity, high production cost, and low product quality, and will lead to the entry of substitutes into the market and encroaching on the market share of the enterprise. At this time, the driving force is significantly less than the dissipating force, and if the enterprise does not reform in time, the enterprise will eventually become bankrupt. Therefore, when an enterprise is improving manufacturing technology, managers must timely judge the relationship between the driving force and the dissipating force of the enterprise. Before the manufacturing technology development falls into chaos, the manufacturing technology should be forced to enter a new stage II.

5 Robustness analysis of dynamic model of enterprise technology fusion

Robustness originally means that the system can maintain its performance at a satisfactory level under the interference of internal and external environments. In recent years, the research on system robustness is mainly divided into the engineering field and the management field. The control system in the engineering field is a rigid system, which has strong anti-interference ability, and its sources of uncertainty have certain regularity and predictability [48,49,50,51]. However, the technology fusion system is a flexible system in the management field. Due to the influence of subjective and objective factors, its uncertainty is often random and difficult to predict. Therefore, the perspectives and methods of robustness research will also be different. Based on the above concept of robustness, this paper defines the robustness of the technology fusion system from two aspects: (1) stability of order parameters evolution trajectory of technology fusion system. It means that order parameters will temporarily deviate from a certain value when facing disturbance but will eventually return to this value automatically. (2) The final value of the evolution of the order parameter equation is not lower than the expected value of the manufacturing enterprises. According to the definition in this paper, we define the robustness of the technology fusion system into three categories: A robust state, if the values of the system order parameters are stable and higher than the expected value of enterprises. A weak robust state, if the values of the system order parameters are stable but not unique and all are higher than the expected value. A not robust state, if there is a value of the system order parameters that are unstable or lower than the expected value.

From the description in Sect. 3, the enterprise technology fusion system is a complex dynamic system with a dissipative structure. The enterprise needs to constantly change the technology development state to make the enterprise technology fusion cycle between different stages, to avoid the enterprise technology fusion from falling into chaos or stagnation. Therefore, the enterprise technology fusion system needs to enter the next state after the technology matures to avoid falling into chaos. In Sect. 4, through the definition of robustness, it can be known that by analyzing the robust evolution of technology fusion systems, it can help enterprises switch between different stages of technological fusion in time and avoid technological fusion from falling into chaos. Therefore, ensuring the robustness of the technology fusion system plays a vital role in the development of enterprise intelligence. It is also worth noting that the robust or weakly robust state of the technology fusion system is to ensure the stability of the technology fusion process at each stage from the early stage to the mature period, please refer to Fig. 26.

5.1 Robust analysis of stage I

Theorem 1

When a manufacturing enterprise is developing information technology, if the information technology efficiency development potential coefficient satisfies:

In addition, \( \beta_{1} > \frac{{\gamma_{1} \gamma_{2} }}{{\beta_{2} }} \) and \( \frac{{\alpha_{ 1} + \frac{{\gamma_{ 1} \alpha_{ 2} }}{{\beta_{ 2} }}}}{{\beta_{ 1} { - }\frac{{\gamma_{ 1} \gamma_{ 2} }}{{\beta_{ 2} }}}} \ge x^{ *} \). Then the technology fusion system of the enterprise is robust in the development stage of information technology, where \( x^{*} \) represents the enterprise expectation of information technology efficiency.

Proof

According to Eq. (4), let

We can obtain two fixed points of \( x_{t + 1} = f(x_{t} ) \):

According to the stability theorem, if \( x_{1} \) is stable, it must satisfy

If \( x_{ 2} \) is stable, it must satisfy

Therefore, according to the analysis, let \( \left\{ {\begin{array}{*{20}l} {\left| {\left. {f^{{\prime }} (x)} \right\|} \right._{{x_{1} }} \ge 1} \hfill \\ {\left| {\left. {f^{{\prime }} (x)} \right\|} \right._{{x_{2} }} < 1} \hfill \\ \end{array} } \right. \), we can obtain the stable condition of \( x_{ 2} \):

In other words, when \( - \frac{{\gamma_{1} \alpha_{2} }}{{\beta_{2} }} < \alpha_{1} < 2 - \frac{{\gamma_{1} \alpha_{2} }}{{\beta_{2} }} \), \( x_{1} \) is unstable and \( x_{2} \) stable. If \( x_{2} \ge x^{*} \), according to the definition of robustness in this paper, the technology fusion system is robustness when \( - \frac{{\gamma_{1} \alpha_{2} }}{{\beta_{2} }} < \alpha_{1} < 2 - \frac{{\gamma_{1} \alpha_{2} }}{{\beta_{2} }} \). Theorem 1 is verified.

Theorem 2

When a manufacturing enterprise is developing information technology, if the convergence parameter of manufacturing technology satisfies \( \gamma_{ 2} > - \frac{{\alpha_{2} \beta_{1} }}{{\alpha_{1} }} \), when information technology convergence parameter satisfies \( \gamma_{1} < \frac{{\beta_{1} \beta_{2} }}{{\gamma_{2} }} \), by increasing the initial degree of information technology integration or collaborative development, the enterprise can effectively improve information technology efficiency in the development of information technology and reduce the investment cost of the enterprise.

Proof

: In the development stage of information technology, enterprises can effectively change the production frontier of information technology by introducing new information technology. The changes in production frontiers lead to changes in information technology efficiency development potential coefficient \( \alpha_{ 1} \). According to Theorem 1, when the information technology efficiency development potential coefficient satisfies \( - \frac{{\gamma_{1} \alpha_{2} }}{{\beta_{2} }} < \alpha_{1} < 2 - \frac{{\gamma_{1} \alpha_{2} }}{{\beta_{2} }} \), the technology fusion system is in a robust state, and the information technology efficiency is stable at \( x = \frac{{\alpha_{ 1} + \frac{{\gamma_{ 1} \alpha_{ 2} }}{{\beta_{ 2} }}}}{{\beta_{ 1} { - }\frac{{\gamma_{ 1} \gamma_{ 2} }}{{\beta_{ 2} }}}} \). Now, when \( \gamma_{2} > 0 \) and \( \gamma_{1} < \frac{{\beta_{1} \beta_{2} }}{{\gamma_{2} }} \), if \( \gamma_{ 1} \) becomes bigger, \( \alpha_{ 1} + \frac{{\gamma_{ 1} \alpha_{ 2} }}{{\beta_{ 2} }} \) will become bigger and \( \beta_{ 1} { - }\frac{{\gamma_{ 1} \gamma_{ 2} }}{{\beta_{ 2} }} \) will become smaller; thus, \( x = \frac{{\alpha_{ 1} + \frac{{\gamma_{ 1} \alpha_{ 2} }}{{\beta_{ 2} }}}}{{\beta_{ 1} { - }\frac{{\gamma_{ 1} \gamma_{ 2} }}{{\beta_{ 2} }}}} \) will become bigger. When \( \gamma_{2} < 0 \) and \( \gamma_{1} > \frac{{\beta_{1} \beta_{2} }}{{\gamma_{2} }} \), we derive \( x = \frac{{\alpha_{ 1} + \frac{{\gamma_{ 1} \alpha_{ 2} }}{{\beta_{ 2} }}}}{{\beta_{ 1} { - }\frac{{\gamma_{ 1} \gamma_{ 2} }}{{\beta_{ 2} }}}} \) about \( \gamma_{ 1} \) and obtain \( \frac{dx}{{d\gamma_{1} }} = \frac{{\alpha_{2} \beta_{1} - \alpha_{1} |\gamma_{2} |}}{{\beta_{2} \left( {\beta_{ 1} + \frac{{\gamma_{ 1} |\gamma_{ 2} |}}{{\beta_{ 2} }}} \right)^{2} }} \). Through the derivative function we can know that when \( \gamma_{ 2} > - \frac{{\alpha_{2} \beta_{1} }}{{\alpha_{1} }} \), \( \frac{dx}{{d\gamma_{1} }} \ge 0 \). That means that when \( \gamma_{ 1} \) becomes bigger, \( x = \frac{{\alpha_{ 1} + \frac{{\gamma_{ 1} \alpha_{ 2} }}{{\beta_{ 2} }}}}{{\beta_{ 1} { - }\frac{{\gamma_{ 1} \gamma_{ 2} }}{{\beta_{ 2} }}}} \) will become bigger. In summary, when \( \gamma_{ 2} > - \frac{{\alpha_{2} \beta_{1} }}{{\alpha_{1} }} \), if \( \gamma_{ 1} \) becomes bigger, \( x = \frac{{\alpha_{ 1} + \frac{{\gamma_{ 1} \alpha_{ 2} }}{{\beta_{ 2} }}}}{{\beta_{ 1} { - }\frac{{\gamma_{ 1} \gamma_{ 2} }}{{\beta_{ 2} }}}} \) will become bigger. In addition, because \( \gamma_{ 1} \) becomes bigger, \( 2 - \frac{{\gamma_{1} \alpha_{2} }}{{\beta_{2} }} \) will decrease. Therefore, the change of the production frontier of the enterprise will be reduced compared with the original, and the investment of the enterprise will be reduced, which verifies Theorem 2.

Through the investment of information technology, enterprises change the production frontier of information technology; therefore, information technology development efficiency potential coefficient \( a_{1} \) also changes. Stable promotion of technology fusion is very important for manufacturing enterprises, so enterprises should make information technology efficiency development potential coefficient \( a_{1} \) change within a robust range \( \left( { - \frac{{\gamma_{1} \alpha_{2} }}{{\beta_{2} }},2 - \frac{{\gamma_{1} \alpha_{2} }}{{\beta_{2} }}} \right) \). However, when \( y_{10} - \frac{2}{{\beta_{1} - \frac{{\gamma_{1} \gamma_{2} }}{{\beta_{2} }}}} > \delta \), it means that if the information technology efficiency development potential coefficient \( a_{1} \) of an enterprise changes in a robust interval, the technology fusion cannot enter stage II. Therefore, enterprises need to jump out of the current robust range of information technology efficiency development potential coefficient. Currently, \( x_{2} \) is no longer stable. When the value of \( \alpha_{ 1} \) deviates slightly from \( 2 - \frac{{\gamma_{1} \alpha_{2} }}{{\beta_{2} }} \), \( \{ x_{t} \} \) no longer converges to \( x_{2} \), and two subsequences \( x_{1}^{*} ,x_{2}^{*} \) will appear and satisfy \( x_{2t} \to x_{1}^{*} ,x_{2t + 1} \to x_{2}^{*} (t \to \infty ) \). That is, small changes of \( \alpha_{1} \) will lead to the development of information technology efficiency into two different development paths. Currently, the robustness of the evolution path of the technology fusion system in the development stage of information technology decreases. And as \( \alpha_{ 1} \) continues to change, there may be 4 times period bifurcation. At this time, if \( \alpha_{ 1} \) change a little at the 4 times period bifurcation point that will make the development of information technology efficiency appear 4 development paths, which makes the information technology efficiency robust lower than 2 times period. So with the increase of \( \alpha_{ 1} \), the period-doubling bifurcation will affect the robustness of the technology fusion system. Therefore, in the development of information technology, it is very important for the robust operation of manufacturing enterprises to master the period-doubling bifurcation point of the evolution of information technology efficiency. The following gives the algorithm for finding the period-doubling bifurcation point and the robust theorem of period-doubling evolution.

Theorem 3

In the development stage of information technology, if the values \( x_{1}^{*} ,x_{2}^{*} , \cdots x_{{ 2^{i} }}^{*} \) are stable fixed points of information technology efficiency within \( 2^{i} \) times period and satisfy \( x_{i}^{*} \ge x^{*} (i = 1,2, \cdots 2^{i} ) \), then the technology fusion system is weak robustness when \( b_{i - 1} \le \alpha_{1} \le b_{i} \), where \( b_{i - 1} \) is \( 2^{i} \) times period bifurcation point, \( b_{i} \) is \( 2^{i} \) times period bifurcation point.

Theorem 4

In the development stage of information technology, assuming the values \( x_{1}^{*} ,x_{2}^{*} , \cdots x_{{ 2^{i} }}^{*} \) are stable fixed points of information technology efficiency within \( 2^{i} \) times period, if there is \( x_{i}^{*} \in \{ x_{1}^{*} ,x_{2}^{*} , \cdots x_{{ 2^{i} }}^{*} \} \) and satisfies \( x_{i}^{*} < x^{ *} (i \in \{ 1,2, \cdots 2^{i} \} ) \), then the technology fusion system is not robust when \( b_{i - 1} \le \alpha_{1} \le b_{i} \). According to self-similarity, if \( \alpha_{1} > b_{i} \), technology fusion is nonrobust.

The following gives an algorithm for solving the period-doubling bifurcation point and judging the period-doubling evolution of information technology efficiency according to Theorems 3 and 4.

5.2 Robust analysis of stage II

In Phase II, not considering the development of information technology and manufacturing technology, we mainly discuss how enterprises can increase the integration and the collaborative development of manufacturing technology and information technology through investment in technology management.

Theorem 5

In the stage of technology integration and collaborative development, if information technology convergence parameter \( \gamma_{ 1} \) and manufacturing technology convergence parameters \( \gamma_{ 2} \) satisfy

Also

Then the technology fusion system is robust in the stage of technology integration and collaborative development, where \( y^{*} \) represents the enterprise expectation value of manufacturing technology efficiency.

Proof

We calculate the fixed point of Eq. (5):

and obtain 4 fixed points

All other fixed points have a variable with zero technical efficiency except for \( X_{4} \). Therefore, only \( X_{4} \) can satisfy the needs of enterprises in this stage of technology integration and collaborative development. So, we only discuss the stability of \( X_{4} \). Firstly, we construct the Jacobian matrix of \( X_{4} (\frac{{\alpha_{1} \beta_{2} + \alpha_{2} \gamma_{1} }}{{\beta_{1} \beta_{2} - \gamma_{1} \gamma_{2} }},\frac{{\alpha_{2} \beta_{1} + \alpha_{1} \gamma_{2} }}{{\beta_{1} \beta_{2} - \gamma_{1} \gamma_{2} }}) \):

and obtain the characteristic equation of the above matrix

By solving Eq. (9), two eigenvalues are obtained:

Now we let

we can obtain six situations:

-

Situation 1: If \( {\rm I} = 0,\varPi > 0 \), \( X_{4} \) is unstable.

-

Situation 2: If \( {\rm I} = 0,\varPi < 0 \), \( X_{4} \) is unstable.

-

Situation 3: If \( {\rm I} > 0,\varPi > 0 \), \( X_{4} \) is unstable.

-

Situation 4: If \( {\rm I} > 0,\varPi < 0 \), \( X_{4} \) is stable.

-

Situation 5: If \( {\rm I} < 0,\varPi > 0 \), \( X_{4} \) is unstable.

-

Situation 6: If \( {\rm I} < 0,\varPi < 0 \), \( X_{4} \) is unstable.

Through the above analysis, in the case of \( X_{4} > 0 \), only Situation 4 satisfies the requirements of robustness, and the theorem is verified.

Theorem 6

Enterprises in the stage of technology integration and collaborative development, when manufacturing technology convergence parameter \( \gamma_{ 2} < 0 \), if \( \alpha_{2} \beta_{1} + \alpha_{1} \gamma_{2} < 0 \), increasing the gap \( \Delta \) between the information technology convergence parameter and manufacturing technology convergence parameter will inhibit the improvement of the technology efficiency. However if \( \alpha_{2} \beta_{1} + \alpha_{1} \gamma_{2} \ge 0 \), increasing the gap \( \Delta \) will promote the improvement of information technology efficiency. When manufacturing technology convergence parameter \( \gamma_{ 2} \ge 0 \), increasing the gap \( \Delta \) will promote the improvement of technology efficiency.

Proof

Enterprises invest in technology management to improve the integration and collaborative development of manufacturing technology and information technology; as a result, the information technology convergence parameter \( \gamma_{ 1} \) and manufacturing technology convergence parameter \( \gamma_{ 2} \) will be changed. According to Theorem 5, when the information technology convergence parameter and manufacturing technology convergence parameter satisfy

technology fusion system is in a robust state in the stage of technology integration and collaborative development and the technology efficiency is stable at

Because information technology develops faster than manufacturing technology, the information technology convergence parameter \( \gamma_{ 1} \) is larger than the manufacturing technology convergence parameter \( \gamma_{ 2} \), and the gap between \( \gamma_{ 1} \) and \( \gamma_{ 2} \) is generally constant \( (\gamma_{ 1} - \gamma_{2} = \Delta ) \). Therefore, the stable value of technical efficiency can be expressed:

Now, if \( \gamma_{ 2} < 0 \), \( \beta_{1} \beta_{2} - \Delta \gamma_{2} { - }\gamma_{ 2}^{ 2} \) will become bigger by increasing the gap \( \Delta \), hence \( y = \frac{{\alpha_{2} \beta_{1} + \alpha_{1} \gamma_{2} }}{{\beta_{1} \beta_{2} - \Delta \gamma_{2} { - }\gamma_{ 2}^{ 2} }} \) will decrease. In addition, we take derivation for \( x = \frac{{\alpha_{1} \beta_{2} + \alpha_{2} (\Delta + \gamma_{2} )}}{{\beta_{1} \beta_{2} - \Delta \gamma_{2} - \gamma_{2}^{2} }} \) about \( \Delta \), and we can obtain \( \frac{{{\text{d}}x}}{{{\text{d}}\Delta }} = \frac{{\beta_{2} (\alpha_{2} \beta_{1} + \alpha_{1} \gamma_{2} )}}{{(\beta_{1} \beta_{2} - \Delta \gamma_{2} - \gamma_{2}^{2} )^{2} }} \). When \( \alpha_{2} \beta_{1} + \alpha_{1} \gamma_{2} < 0 \), \( \frac{{{\text{d}}x}}{{{\text{d}}\Delta }} < 0 \). So we increase \( \Delta \), \( x = \frac{{\alpha_{1} \beta_{2} + \alpha_{2} (\Delta + \gamma_{2} )}}{{\beta_{1} \beta_{2} - \Delta \gamma_{2} - \gamma_{2}^{2} }} \) will decrease. When \( \alpha_{2} \beta_{1} + \alpha_{1} \gamma_{2} \ge 0 \), \( \frac{{{\text{d}}x}}{{{\text{d}}\Delta }} \ge 0 \). So we increase \( \Delta \), \( x = \frac{{\alpha_{1} \beta_{2} + \alpha_{2} (\Delta + \gamma_{2} )}}{{\beta_{1} \beta_{2} - \Delta \gamma_{2} - \gamma_{2}^{2} }} \) will increase.

If \( \gamma_{ 2} \ge 0 \), increasing gap \( \Delta \),\( \alpha_{1} \beta_{2} + \alpha_{2} (\Delta + \gamma_{2} ) \) will become bigger and \( \beta_{1} \beta_{2} - \Delta \gamma_{2} - \gamma_{2}^{2} \) will become smaller, so \( x = \frac{{\alpha_{1} \beta_{2} + \alpha_{2} (\Delta + \gamma_{2} )}}{{\beta_{1} \beta_{2} - \Delta \gamma_{2} - \gamma_{2}^{2} }} \) will become bigger. Similarly \( y = \frac{{\alpha_{2} \beta_{1} + \alpha_{1} \gamma_{2} }}{{\beta_{1} \beta_{2} - \Delta \gamma_{2} { - }\gamma_{ 2}^{ 2} }} \) will become bigger. In summary, the theorem is verified.

In stage II, manufacturing enterprises mainly invest in technology management. By introducing technical management personnel and organizing employees to learn and train, the utilization rate of manufacturing technology and information technology in manufacturing enterprises is improved and technology integration and collaborative development are continuously improved. When the technology efficiency satisfies \( |x - y| > \delta \), technology fusion will enter stage I or stage III. If \( x - y > \delta \), technology fusion will enter stage III, otherwise stage I.

5.3 Robust analysis of stage III

Theorem 7

When an enterprise is developing manufacturing technology, if the manufacturing technology efficiency development potential coefficient satisfies:\( - \frac{{\gamma_{2} \alpha_{1} }}{{\beta_{1} }} < \alpha_{2} < 2 - \frac{{\gamma_{2} \alpha_{1} }}{{\beta_{1} }} \), and \( \beta_{ 2} > \frac{{\gamma_{1} \gamma_{2} }}{{\beta_{1} }} \), \( \frac{{\alpha_{2} + \frac{{\gamma_{2} \alpha_{1} }}{{\beta_{1} }}}}{{\left( {\beta_{2} - \frac{{\gamma_{1} \gamma_{2} }}{{\beta_{1} }}} \right)}} \ge y^{*} \), then the technology fusion system is robust in the development stage of manufacturing technology.

Proof

According to Eq. (8), let \( y_{t + 1} = \left( {\alpha_{2} + \frac{{\gamma_{2} \alpha_{1} }}{{\beta_{1} }} + 1} \right)y_{t} + \left( {\frac{{\gamma_{1} \gamma_{2} }}{{\beta_{1} }} - \beta_{2} } \right)y_{t}^{2} \), we can obtain two fixed points of \( y_{t + 1} = f(y_{t} ) \):

According to the stability theorem, if \( y_{1} \) is stable, it must satisfy

If \( y_{ 2} \) is stable, it must satisfy

Therefore, according to the analysis, let \( \left\{ {\begin{array}{*{20}c} {\left| {\left. {f^{\prime } (y)} \right\|} \right._{y1} \ge 1} \\ {\left| {\left. {f^{\prime } (y)} \right\|} \right._{{y_{2} }} < 1} \\ \end{array} } \right. \), we can obtain stable condition of \( y_{ 2} \):

In other words, when \( - \frac{{\gamma_{2} \alpha_{1} }}{{\beta_{1} }} < \alpha_{2} < 2 - \frac{{\gamma_{2} \alpha_{1} }}{{\beta_{1} }} \) and \( \beta_{ 2} > \frac{{\gamma_{1} \gamma_{2} }}{{\beta_{1} }} \),\( y_{1} \) is unstable and \( y_{2} \) stable. If \( y_{2} \ge y^{*} \), according to the definition of robustness in this paper, the technology fusion system is robustness when \( - \frac{{\gamma_{2} \alpha_{1} }}{{\beta_{1} }} < \alpha_{2} < 2 - \frac{{\gamma_{2} \alpha_{1} }}{{\beta_{1} }} \) and \( \beta_{ 2} > \frac{{\gamma_{1} \gamma_{2} }}{{\beta_{1} }} \).

Theorem 8

When an enterprise is developing manufacturing technology, if the manufacturing technology convergence parameter satisfies \( \gamma_{ 2} < \frac{{\beta_{1} \beta_{2} }}{{\gamma_{ 1} }} \), by increasing the initial degree of manufacturing technology integration and collaborative development, the enterprise can effectively improve manufacturing technology efficiency in the development of manufacturing technology and can reduce the investment cost of enterprises.

Proof

: In the development stage of manufacturing technology, enterprises can effectively change the production frontier of manufacturing technology. As a result, the changes of production frontiers lead to changes of the manufacturing technology efficiency development potential coefficient \( \alpha_{ 2} \). According to Theorem 7, when the manufacturing technology efficiency development potential coefficient satisfies \( - \frac{{\gamma_{ 2} \alpha_{ 1} }}{{\beta_{ 1} }} < \alpha_{ 2} < 2 - \frac{{\gamma_{ 2} \alpha_{ 1} }}{{\beta_{ 1} }} \), the technology fusion system is in a robust state and the manufacturing technology efficiency is stable at \( y = \frac{{\alpha_{ 2} + \frac{{\gamma_{ 2} \alpha_{ 1} }}{{\beta_{ 1} }}}}{{\beta_{ 2} { - }\frac{{\gamma_{ 1} \gamma_{ 2} }}{{\beta_{ 1} }}}} \). By stage II, we obtain \( \gamma_{ 1} > 0 \). So \( \gamma_{ 2} < \frac{{\beta_{1} \beta_{2} }}{{\gamma_{ 1} }} \), if \( \gamma_{ 2} \) becomes bigger, \( \alpha_{ 2} + \frac{{\gamma_{ 2} \alpha_{ 1} }}{{\beta_{ 1} }} \) will become bigger and \( \beta_{ 2} { - }\frac{{\gamma_{ 1} \gamma_{ 2} }}{{\beta_{ 1} }} \) will become smaller, thus \( y = \frac{{\alpha_{ 2} + \frac{{\gamma_{ 2} \alpha_{ 1} }}{{\beta_{ 1} }}}}{{\beta_{ 2} { - }\frac{{\gamma_{ 1} \gamma_{ 2} }}{{\beta_{ 1} }}}} \) will become bigger. In addition, because \( \gamma_{ 2} \) becomes bigger,\( 2 - \frac{{\gamma_{ 2} \alpha_{ 1} }}{{\beta_{ 1} }} \) will decrease. Therefore, the change of the production frontier of the enterprise will be reduced compared with the original, that is, the investment of the enterprise will be reduced. Theorem 8 is verified.

Through the investment of manufacturing technology, enterprises change the production frontier of manufacturing technology. As a result, the manufacturing technology development efficiency potential coefficient \( a_{ 2} \) also changes. Stable promotion of technology fusion is very important for manufacturing enterprises, so enterprises should make manufacturing technology efficiency development potential coefficient change within a robust range \( ( - \frac{{\gamma_{2} \alpha_{1} }}{{\beta_{1} }},2 - \frac{{\gamma_{2} \alpha_{1} }}{{\beta_{1} }}) \). However, when \( x_{30} - \frac{2}{{\beta_{ 2} - \frac{{\gamma_{1} \gamma_{2} }}{{\beta_{ 1} }}}} > \delta \), it means that if the manufacturing technology efficiency development potential coefficient \( a_{ 2} \) changes in a robust interval, the technology fusion cannot enter stage II. Therefore, enterprises need to jump out of the current robust range of manufacturing technology efficiency development potential coefficient. At this time, when \( \alpha_{2} \ge 2 - \frac{{\gamma_{2} \alpha_{1} }}{{\beta_{1} }} \), \( y_{2} \) is no longer stable. When the value of \( \alpha_{ 2} \) deviates slightly from \( 2 - \frac{{\gamma_{2} \alpha_{1} }}{{\beta_{1} }} \), \( \{ y_{t} \} \) no longer converges to \( y_{2} \), and two subsequences \( y_{1}^{*} ,y_{2}^{*} \) will appear and satisfy \( y_{2t} \to y_{1}^{*} ,y_{2t + 1} \to y_{2}^{*} (t \to \infty ) \). That is, small changes of \( \alpha_{ 2} \) will lead to the development of manufacturing technology efficiency into two different development paths. Currently, the robustness of the technology fusion system in the development stage of manufacturing technology decreases. And as \( \alpha_{ 2} \) continues to change, there may be a 4 times period bifurcation. In other words, if \( \alpha_{ 2} \) changes a little at the 4 times period bifurcation point that will make the development of manufacturing technology efficiency appear 4 development paths, which makes the manufacturing technology efficiency robust be lower than 2 times period. So with the increasing of \( \alpha_{ 2} \), the period-doubling bifurcation will affect the robustness of the technology fusion system in the manufacturing technology development stage. Therefore, in the development of manufacturing technology, it is very important for the robust operation of manufacturing enterprises to master the period-doubling bifurcation point of the evolution of manufacturing technology efficiency. The following gives the algorithm for finding the period-doubling bifurcation points and the robust theorem of period-doubling evolution.

Theorem 9

In the development stage of manufacturing technology, if the values \( y_{1}^{*} ,y_{2}^{*} , \ldots y_{{2^{i} }}^{*} \) are stable fixed points of manufacturing technology efficiency within \( 2^{i} \) times period and satisfy \( y_{i}^{*} \ge y^{*} \,(i = 1,2, \ldots 2^{i} ) \), then the technology fusion system is weak robustness when \( c_{i - 1} \le \alpha_{ 2} \le c_{i} \), where \( c_{i - 1} \) is \( 2^{i} \) times period bifurcation point; \( c_{i} \) is \( 2^{i} \) times period bifurcation point.

Theorem 10

In the development stage of manufacturing technology, assuming the values \( y_{1}^{*} ,y_{2}^{*} , \ldots y_{{ 2^{i} }}^{*} \) are stable fixed points of manufacturing technology efficiency within \( 2^{i} \) times period, if there is \( y_{i}^{*} \in \{ y_{1}^{*} ,y_{2}^{*} , \ldots y_{{ 2^{i} }}^{*} \} \) and satisfies \( y_{i}^{*} < y^{*} (i \in \{ 1,2, \ldots 2^{i} \} ) \), then the technology fusion system is not robust when \( c_{i - 1} \le \alpha_{2} \le c_{i} \). According to self-similarity, if \( \alpha_{2} > c_{i} \), technology fusion is also not robust.

The following gives an algorithm for solving the period-doubling bifurcation point and judging the period-doubling evolution of manufacturing technology efficiency according to Theorems 9 and 10.

6 Case study

As mentioned above, the technology fusion of manufacturing enterprises follows three stages. Stage I is that manufacturing technology is ahead of information technology. Enterprises are committed to the development of information technology. Stage II is that manufacturing technology and information technology are at a flat state. Enterprises invest in technology management to improve technology integration and collaborative development. In stage III, manufacturing technology lags information technology and enterprises are committed to the development of manufacturing technology. Since then, the three phases have cycled with each other.

This paper selects a small- and medium-sized tool manufacturing company “Yonggu Group” located in Wenzhou, China, for case analysis. During the 7 years from 2013 to 2020, due to financial constraints, the enterprise did not carry out technology introduction but based on the enterprise’s existing information technology and manufacturing technology, through technology integration and collaborative development to continuously promote technology fusion. Since there is no introduction of new technology, the enterprise’s information technology efficiency development potential coefficient and manufacturing technology development potential coefficient have not changed. Its development potential coefficient and damping coefficient are