Abstract

Mining-induced groundwater inrush, a type of serious hazard for underground coal extraction, occurs in tunnel or coal face combined with a large volume of groundwater gushing. It has an impartible relationship with geological structures such as karst collapse pillar (KCP), which is widely distributed in North China. To analyze the effect of coal mining on groundwater inrush caused by seepage instability of the penetrated KCP (PKCP), stress and seepage coupling equations are used to model the seepage rule, and a numerical FLAC3D model is conducted to determine the shear stress, damage zone, pore pressure, seepage vectors and effect of damage zone on seepage field development. The results indicate that when PKCP and the surrounding rocks show dislocation, shear failure may occur, which leads to a shear sidewall channel for groundwater inrush. As mining advances, the damage zone in the PKCP and its crushed area develop gradually, and the simulated damage zone development was consistent with observed thicknesses of crushed rocks. Under the effect of the support pressure and unloading of the coal face, an obvious seepage concentrate channel with greater hydraulic head and seepage vectors will form within the edge of the PKCP; then, the shear sidewall channel will gradually move to the other side with the coal face near and away. When the damage zones are crushed through, the connected fractures will become a strong seepage channel in PKCP, named as pipe flow, which may cause groundwater inrush.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

Groundwater inrush in coal mines have resulted in millions of fatalities in many countries including the USA, Russia, Poland, Canada, Australia, Germany, Great Britain, India and especially China. During the past three decades, with the progress of high technology, the level of coal production and construction has been made a big improvement (Vutukuri and Singh 1995). For some developed countries, for example, the main method to control the accidental groundwater inrush in the USA is the application of the mine dewatering technology, and there was a handful accidental inundation (Singh 1986). However, in China, the groundwater inrush accidents still occur frequently and exceed 90 % of the accidental inundations due to water inflow from karst aquifers through coal seam floor (Li and Zhou 2006). Since 2000, the numbers of coal mine groundwater damage accidents have shown an upward trend. According to an incomplete statistics, from the year 2001 to 2005, there were 352 types of mine water damage accidents with 1733 deaths and missing.

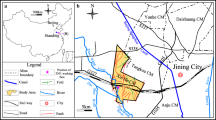

Effect of mining on groundwater inrush caused by seepage instability is mostly localized to the goaf, which is a cavity after underground coal extraction, above the mined area, plus a margin around the outside (Bai et al. 2013; Ma et al. 2016). Groundwater inrush depends on the coal geology (Zhang 2005; Li and Zhou 2006; Hu et al. 2014), coal type (Miao et al. 2011a), mining methods (Zhang and Peng 2005) and geological, physical and geomechanical rock behaviors (Miao et al. 2011b; Ma et al. 2013, 2014, 2015a, b; Rong and Bai 2014). It cannot be ignored that groundwater inrushes from aquifers underlying mining coal seams may also be induced by disclosing (exposed caused by mining) of karst collapse pillar (KCP), which is caused by the karst subsidence that occurs in carbonate rock distribution areas (Li and Zhou 2006; He et al. 2007). The existence of the geological phenomenon usually functions as a channel for groundwater inrush, thus posing a great threat to safe production in the mines (Bai et al. 2013; Ma et al. 2012; Ma and Bai 2015; Lu et al. 2015). KCPs are widespread in North China coalfields, in areas such as Shaanxi, Shanxi, Henan, Hebei, Shandong, Northern Jiangsu and Northern Anhui (He et al. 2009). Alterations in these regions have resulted in great damage to the coal seam panel and have drawn significant attention in the mining geology field (Troitzky 1993; He et al. 2009, 2010; Shi et al. 2014).

With the development of modern science theory and high technology, the range of KCP research extended rapidly to include the formation mechanisms (Qian 1988), morphological characteristics (Kang 1992; Shi et al. 1998) and spatial distribution of KCP (Yuan 1994). A number of theories were developed such as “gravity action formation theory” (Wang 1982), “gypseous salvation formation theory” (Qian 1988), “vacuum erosion formation theory” (Xu and Zhao 1988), “hydrothermal origin theory” (Chen 1993) and “cyclic expansion karst cave formation theory” (Shi et al. 1998). With the use of experimental and numerical methods, the emphasis of KCP research focused mainly on aspects such as the cause of formation, rule of development, groundwater inrush and structural characteristics of the pillar and sidewall rock body, e.g., pipe erosion and collapse of cohesion-less KCP (Tharp 1999), types of groundwater inrush channels (Zhang et al. 2000) and karst: maturity of the karst landforms, depth of the karst features, overburden thickness, lateral extent of the karst features, hydrogeology of the area, loading, etc. (Xeidakis et al. 2004; Yin and Zhang 2005; Wu et al. 2008a, b; He et al. 2010; Wu et al. 2011; Lokhande et al. 2013).

Of late, scholars conducted several theory and experimental studies on KCP and the related crushed rocks, e.g., based on seepage theory and groundwater dynamic theory of porous media, Yao et al. (2013) built a fluid–solid coupling model to analyze the groundwater inrush mechanisms of KCP. To investigate the mechanism of groundwater inrush from a coal seam floor, Bai et al. (2013) introduced variable mass dynamics and nonlinear dynamics and established a mechanical model–plug model to describe the behavior of water seepage flow in coal seam floor containing KCP. Mining would damage the KCP and its surrounding rocks, leading to the formation of a fracture zone. Ma et al. (2014) conducted an experimental investigation on permeability measurement of water flow in crushed rocks of KCP.

To investigate the effect of mining on shear sidewall groundwater inrush hazard caused by seepage instability of the penetrated karst collapse pillar (PKCP), we established stress and seepage coupling equations to model the mining-induced seepage rule, and FLAC3D numerical investigations were conducted to determine the shear stress, damage zone, pore groundwater pressure, seepage vectors and effect of damage zone on seepage field development of PKCP and the surrounding rocks.

2 Effect of mining on crushed zone development for PKCP

As shown in Fig. 1, Bai et al. (2013) described KCP shaped like a plug and is characterized by a geometric pattern of “thick at the bottom and thin at the top.” In the mining panel method, according to the position relationship between the KCP and coal face or roadway, when a coal face or roadway is penetrated by KCP, it is named as PKCP. As the mining advance, crushed zone tends to expand and the sidewall of PKCP, especially those near the goaf is easily damaged by the expansion, which may lead to a shear sidewall channel for groundwater inrush. It can be seen that the most dangerous place for groundwater inrush is the sidewall, and it is called the shear sidewall groundwater inrush mode. A shear sidewall stress and seepage coupling model and the related numerical model of the PKCP and the surrounding rocks will be established based on the mining panel method.

3 Shear sidewall stress and seepage coupling equations

In this article, the mass balance equations for surrounding rock matrix and fracture (crushed) rocks are same, but the constitutive relations for that are different. A basic assumption is that the crushed rocks can be treated as a quasicontinuum where volume-averaged quantities replace the local ones. Therefore, two balance equations for rocks and groundwater and a number of constitutive relations for the fully coupled equations (Zhu and Wei 2011) are described as follows.

3.1 Stress analysis based on damage evolution equation

Assume the initial crushed rock (PKCP) is elastic, using constitutive relationship defined by a generalized Hook’s law. A modified Navier’s equation, in terms of displacement under a combination of changes of applied stresses and pore groundwater pressures, can be expressed as:

where G is shear modulus, μ is the drained Poisson’s ratio, p is pore pressure, u i (i = x, y, z) is displacement, and F i is the component of the net body force in the i direction (i = x, y, z). The direction of applied stresses is negative for tension and that of pore pressures is negative for suction. The parameter α c (≤1) is Biot’s coefficient, which depends on the compressibility of the constituents and can be defined as

where \(K_{\text{rock}}\) is the effective bulk modulus of the surrounding rock, and \(K_{\text{kcp}}\) is the drained bulk modulus of the PKCP, which is described as

When the stress state satisfies the maximum tensile stress criterion or the Mohr–Coulomb criterion, the damage of PKCP in tension or shear is initiated, respectively (Zhu and Wei 2011), as expressed by:

where φ is internal frictional angle, f t and f c are uniaxial tensile and compressive strength, respectively, and F a and F b are two damage threshold functions, F a = 0, F b = 0 mean tension and shear damage of the porous rocks. Under any stress conditions, the tensile strain criterion is applied preferentially. Based on the results from Zhu and Wei (2011), the damage variable can be calculated as:

where D represents the damage variable, ɛ tm and ɛ cm are maximum tensile principal strain and maximum compressive principal strain when damage occurs, and n is a constitutive coefficient and it is 2.0. dF a > 0, dF b > 0 mean continuous loading after the two damage states, which will cause the increase in damage variable. dF a < 0, dF b < 0 mean unloading state, there is no new damage, the damage variable keep steady as last loading.

The elastic modulus of an element degrades monotonically as damage evolves based on the elastic damage theory, and the Young’s modulus of damaged rocks can be expressed as follows:

where E and E un are the Young’s modulus of the damaged and the undamaged rocks, respectively. In the current method, the element as well as its damage is assumed isotropic, so the D, E and E un are all scalar.

3.2 Seepage flow equation based on Darcy’s law

The constitutive relation for groundwater seepage flow can be expressed by Darcy’s law:

where ρ w is the water density, g is gravitational acceleration, z is the vertical coordinate, k is the intrinsic permeability in a general continuum, and μ w is the water viscosity. As shown in Fig. 2, during the water flow process, there should be an interface, i.e., seepage surface, between the saturated zone and dry zone. In other words, based on mass conservation law, the water surface between the saturated and non-saturated flow can be described as:

where h ws is the water surface between the saturated zone and dry zone, and m w is the mass density. Substituting Eq. (7) into the conservation equation of groundwater results as (Zhou et al. 1998; Sheng et al. 2008):

where ϕ is the porosity and β w denotes the bulk modulus of water.

3.3 Permeability evolution based on stress and seepage coupling equations

By concluding Sects. 3.1 and 3.2, Eqs. (1), (6) and (9) represent a set of fully coupled nonlinear equations governing the elastic damage process of saturated rocks. The equations account for coupled mechanical damage and groundwater flow of the constituents. Equation (1) implicits the effect of groundwater flow on the mechanical process; the porosity of rocks is closely dependent on the stress conditions, which is given as (Rutqvist and Tsang 2002):

where α ϕ is the stress sensitivity coefficient, which is equal to 5.0 × 10−8 (Pa) (Rutqvist and Tsang 2002), ϕ 0 is the porosity at zero stress, ϕ h is the residual porosity at high stress, and \(\bar{\sigma }_{\text{ef}}\) is the effective mean stress (with tension positive), which can be calculated as:

where α e is Biot’s effective stress coefficient as calculated in Eq. (2), and σ 1, σ 2 and σ 3 are first, second and third principal stresses, respectively. Besides, the permeability of rocks is correlated to the porosity according to the following exponential function:

where k 0 is the zero-stress permeability, and α k is 5.0, which is called damage-permeability effect coefficient to indicate the effect of damage on the permeability.

Furthermore, rock permeability during the deformation and failure process has been determined by laboratory experiments (Yao 2012), i.e., the last two different exponential functions can be used to express the rock permeability by deformation and damage in terms of volumetric strain, respectively, which is formulized as (Zhu and Wei 2011):

where ξ 1 and ξ 2 are two coefficients reflecting the permeability before and after peak value under compaction and damage, respectively.

4 Numerical modeling and simulation scheme

KCPs are crushed rocks in natural collapse strata and are characterized by the plug model. When the Ordovician limestone water can be connected to the lower coal seam by a PKCP, the seepage law for confined water shows a large difference between crushed rocks (PKCP) and complete rocks. Seepage in crushed rocks in a PKCP has a high probability to incur a groundwater inrush accident (Bai et al. 2013). Here, the deformation modulus and FLAC3D (Itasca Consulting Group Inc. 2009) were employed to simulate the mechanical state of a PKCP during coal seam mining panel.

The failure criterion chosen for the coal seam model is the strain-softening model based on the FLAC3D Mohr–Coulomb failure model, with non-associated shear and associated tension flow rules (Fama et al. 1995; Hoek 1990; Pietruszczak and Mro 1980; Singh et al. 2002). In this model, the cohesion and friction angle can be adjusted to soften the material after the onset of damage yielding by employing a user-defined piecewise linear function. In the standard Mohr–Coulomb model, these properties are constant.

FLAC3D stress and seepage coupling simulation needs to meet the following two conditions: The seepage media is equivalently uniform; seepage permeability k is constant. Then, it transforms the strain and stress into the seepage field change through the constitutive relations. According to the seepage theory, fractures within rock mass cannot be ignored. When the rock stress state changes, the permeability characteristics of these fractures will inevitably change, which cannot be achieved by the FLAC3D internal seepage model. Here, by writing FISH language, Eqs. (1), (8) and (11) were embedded into FLAC3D seepage model. Then, the seepage characteristics of PKCP under the influence of mining can be analyzed. The computing procedure is shown in Fig. 3.

There are several key points in Fig. 3:

-

1.

The “original rock balance” above refers to the balance state of original rock under no mining influence, including the balance of stress and seepage.

-

2.

The carrier of FLAC3D internal parameter assignment is a unit. The process of above-mentioned “Re-set k” is:

-

Determine coordinates of the unit.

-

Determine the unit memory address according to the coordinate.

-

Determined the unit IDs by memory address.

-

Assign the parameters to units by the recorded IDs.

-

The numerical model assumes a length of 300 m in the dip direction, a width of 200 m in the strike direction and a height of 140 m, as shown in Fig. 4. In this model, the confined aquifer is listed below, and the height of the key strata (hard rock) is 40 m above the confined aquifer. The upper aperture is 10 m, lower aperture is 20 m, and height is 90 m for the PKCP, which connects the lower coal seam and confined aquifer. The coal seam is penetrated by the PKCP.

To obtain the stress distribution in a panel, reasonable boundary conditions are established for the numerical model. The horizontal displacements of the four vertical planes of the model are restricted in the normal direction, and the vertical displacement at the base of the model is set to zero. At the top of the model, a vertical load (p = γH = 8 MPa) is applied to simulate the overburden weight. At the bottom of the model, water pore pressure in the confined aquifer is defined as 5 MPa. To simulate the roof falling during panel extraction, both the coal seam and immediate roof are extracted in the process of modeling. During the extraction, the goaf area is filled by a very soft elastic material to approximately simulate the support capability of the fallen rock from the roof. The Young’s modulus of this material is set at 190 MPa, and the Poisson’s ratio is 0.25 (Cheng et al. 2010; Jiang et al. 2012; Wang et al. 2013). The elastoplastic Mohr–Coulomb model with non-associated flow rules (Hoek 1990) is chosen as the failure criterion for the coal, roof and floor strata. The mechanical and seepage parameters applied in this simulation are given in Tables 1 and 2.

5 Modeling results

The numerical simulation begins with the mining 50 m from the PKCP, and the mechanical state was calculated at 20 m increments. Figure 5 shows the mining advanced 20, 40, 60, 80 and 100 m, with the distance of the coal face at 50 m, 30 m, 10 m before the center of the PKCP and −10, −30 m after the center of the PKCP, respectively. In this section, the vertical stress, damage zone, pore pressure, seepage vectors and effect of damage zone on seepage field development will be analyzed.

5.1 Shear sidewall failure evolution

5.1.1 Numerical simulation for shear stress and damage zone development

According to Eq. (4), Fig. 6 shows the shear stress evolution of the PKCP during coal panel extraction.

The shear stress distribution changes during coal panel extraction. In general, after the coal is extracted, the floor undergoes shear stress release and forms a relief area under the goaf, and the roof undergoes shear stress concentrates and forms a pressurized area above the goaf. Meanwhile, at the front of coal face, the floor undergoes shear stress concentrates and forms a pressurized area; furthermore, the roof undergoes shear stress release and forms a relief area. A shear zone is created at the back of the coal face, resulting in deformation of the floor.

The peak value of the shear stress increased with mining advance, in detail, before mining reaches the PKCP (mining advance less than 60 m); the position of the peak value of shear stress transfers to the front of the coal face, which increases the stress concentration and the stress diffusion range. Furthermore, when mining reaches the PKCP (mining advance greater than 80 m), the shear stress concentration not only transfers to the front of the coal face, but also to the intact strata above PKCP; this illustrates the shear failure evolution of crushed zones significantly depends on the mining activities, and the intact strata above PKCP can be easily destroyed by shear stress concentration. At this point, the shear stress behaviors should be observed carefully, to prevent the mining equipment damaged by the large shear stress.

Based on the computation results of Eqs. (4) and (5), Fig. 7 shows the mining-induced shear failure evolution of PKCP during coal panel extraction, in which Fig. 7a presents the shear stress distribution and Fig. 7b displays the damage zone distribution caused by shear stress concentrates.

As mining advances, the shear failure evolution of PKCP strongly depends on the mining activities, and the peak value of the shear stress of PKCP increases with mining advance. Specifically, when the coal face is far away before the PKCP (mining advance less than 40 m), the shear stress concentrates are distributed at the bottom of the PKCP, and concentrates area is small; therefore, the damage zone is distributed at the bottom of the PKCP, which means the effect of mining activities on the damage zone of the PKCP is not significant.

When mining advance reaches 60 m, the shear stress of the PKCP strongly depends on the panel extraction. The position of the peak value of the shear stress at middle left of the PKCP (about 15 m of floor) undergoes stress concentration (as blue color in Fig. 7a), as shown in Fig. 7b; the damage zone further development and the sidewall are easily destroyed; the damage zone is focused on the left wall (by the coal face side) and the corresponding crushed thickness of the PKCP reaches 28 m suddenly.

When mining advance is greater than 80 m (the coal face passed the PKCP as 10 m), the position of the peak value of the shear stress at middle right of the PKCP (about 10 m of floor) undergoes stress concentration, but a wide relief area appeared inside the PKCP, resulting in a large decline in shear stress, which lead to an expansion of the damage zone. The upper and lower damage zones connect. The crushed thickness for the PKCP reaches 32 m; this will create a shear sidewall channel for groundwater inrush.

After that, when mining advance reaches 100 m, the shear stress within the PKCP located in the unloading area of the coal face reduced, the position of the peak value of the shear stress at the top and bottom of the PKCP, and the peak value for mining advances 100 m, it decreased a half of the amount than that for 80 m, which prove the mining activity can create a shear stress relief area for PKCP.

5.1.2 An in situ test for crushed thickness

When a PKCP exists in the floor strata, the effective distance between aquifer and coal seam is reduced greatly, and this makes it easier for groundwater to intrude into the mining working area. In mining practice, in situ rock failures measurement principle (Yin et al. 2015) were usually used to reproduce mining-induced water inrush for PKCP. The in situ crushed thicknesses of coal face 5310 at Chengzhuang Coal Mine, Shanxi Province, China, which contains PKCP in floor strata, were tested according to this principle. In the water injection rock failures measurement principle, average flow rate means the crushed condition of the designed borehole, and a higher flow rate means more serious damage to the borehole.

As shown in Fig. 8, as coal seam mining advances, three testing depths, i.e., 26, 28, 30, 32 and 34 m, were assigned in the coal pillar between coal haulage and materials haulage roadway. The in situ testing results (see Fig. 9) indicate that when coal face is 30 m from the PKCP, the crushed thickness is less than 26 m; however, when coal face is less than 20 m from the PKCP, the crushed thickness of the PKCP suddenly reaches 26–30 m. When the coal face passed PKCP as 5 m approximately, the flow rate meets maximum, which means the crushed thickness reaches maximum during the test process; meanwhile, the flow rate was kept at 0 m3/h for the testing thickness of 34 m, so the maximum crushed thickness during the test process locates 30–34 m. The water flow rate decreases until coal face passed PKCP as 20 m, and after that, the water flow rate keeps steady. In addition, the maximum flow rate is 0.38 m3/h and the steady rate is 0.11 m3/h for the testing thickness of 32 m during the test process, and the rock failure for crushed thickness of 32 m can be regarded as imperceptibility; therefore, the maximum crushed thickness is 32 m approximately. The in situ testing results were consistent with the numerical results; this shows the correction of numerical prediction.

5.2 Pore groundwater pressure

Figure 10 shows the pore groundwater pressure during mining panel extraction. Figure 11 shows the pore groundwater pressure in different positions of PKCP.

PKCP is constituted with crushed rocks in the floor strata, which is the main upward seepage channel for water from confined aquifer, but because of the water-resisting property of PKCP, the water pressure will be consumed along with upward PKCP.

When coal face reaches the edge of PKCP, the hydraulic head difference on both sides of PKCP is big, and the hydraulic head near coal face is higher, which indicates a large activation degree of the left side of PKCP, which will create a channel for groundwater inrush, and after that, the hydraulic head difference on both sides of PKCP decreases.

Figure 11 shows the pore pressure distribution of the center of PKCP for the distance from PKCP to aquifer.

In general, from Fig. 11a, it can be drawn that as mining advances, the pore water pressure of the center of PKCP decreases with the increase in distance from PKCP to aquifer, and this is main because of the water-resisting property of PKCP.

As mining advances, the pore water pressure distribution of the center of PKCP for different position is slightly different. In more detail:

-

as shown in Fig. 11b, the pore pressure of distance 10–16 m for mining advance of 60, 80 and 100 m from PKCP to aquifer shows bigger than that for mining advance of 20 and 40 m;

-

as shown in Fig. 11c, the pore pressure of distance 22–40 m from PKCP to aquifer increased when mining advance from 20 m changed to 40 m, and from 40 m changed to 60 m;

-

as shown in Fig. 11d, when the distance from PKCP to aquifer increases from 42 m, the pore pressure for mining advance of 40 m is bigger than that for mining advance of 60, 80 and 100 m; this is main because of the effect of mining connection, which causes the pore pressure relieving; however, at the top of PKCP (the distance from PKCP to aquifer as 54–60 m), the pore pressure for mining advance of 80 and 100 m shows bigger than that for other mining advances, which indicate the PKCP has already created a channel for groundwater inrush.

Due to the production of the channel for groundwater inrush at the top of PKCP, it can be seen that when the mining advance is less than 40 m (distance between coal face and PKCP is less than 10 m), once the failure zones below the floor connect with the fractures around the PKCP, groundwater inrush accidents may occur.

5.3 Groundwater seepage vectors

Seepage vectors reflect the seepage velocity and fracture connectivity in rock mass. Figure 12 shows the seepage vectors changing as mining advances.

The seepage vector in PKCP is always higher than the surrounding rocks, which shows PKCP is a good channel for seepage-induced groundwater conducting.

A seepage vector direction is always pointing to the position that has the greatest impacts on the PKCP, such as the seepage vector concentration in Fig. 12c, d. Subsequently, the concentrated vectors change to be a seepage concentrate channel, and the channel position changes with the coal face advancing, vectors redistribute, and one side of vectors gradually reduce while the other side is gradually concentrated, shown in Fig. 12e. These are similar to the changing law of pore water pressure.

As shown in Fig. 12c, d, when the distance from coal face to PKCP is 10 m, the crushed zone for left side of KCP development, seepage vector increased, and when the distance from coal face to PKCP is −10 m, pore pressure and seepage vector step increased, the maximum seepage vectors increased to 3.164 × 105 m/day, and sidewall groundwater inrush happens easily.

The maximum seepage vectors decrease as mining advances from 20 m to 40 m and increases rapidly as mining advances from 40 to 80 m, because PKCP is successively impacted by support pressure and unloading of the coal face. Therefore, the stress field changes constantly, which causes new fractures to appear with the natural fractures closing and then expanding inside the PKCP.

5.4 Effect of damage zone on seepage field development

Connection through the damage zone is one of the important reasons that cause the development of the seepage field. As Fig. 13 shows, seepage vectors sharply increase caused by the damage zone connecting in the edge of PKCP. This causes the maximum seepage vectors change from 1.519 to 3.164 × 105 m/day, which changes nearly 2.803 × 105 times. Then, seepage in the edge of the PKCP will become the “pipe flow,” when the coal face passed PKCP as 10 m; the upper and lower damage zones connect. The crushed thickness for the PKCP reaches 32 m; this creates a channel for groundwater inrush, which caused groundwater inrush hazard.

6 Conclusions

In order to analyze the effect of coal seam mining on groundwater inrush hazard caused by seepage instability of the PKCP, stress and seepage coupling equations were used to model the seepage rule, and FLAC3D numerical investigations were conducted to determine the vertical stress, damage zone, pore groundwater pressure, seepage vectors and effect of damage zone on seepage field development of a PKCP and the surrounding rocks. The results indicate that PKCP formed by the overburden cave collapse is shaped like a plug. The insides are irregular structures and are mostly formed by crushed rocks. When the PKCP and the surrounding rocks show dislocation, shear failure may occur, which will lead to a shear sidewall channel for groundwater inrush. As mining advances, the damage zone in the PKCP develops gradually, the comparison between in situ testing crushed thickness results, and numerical damage zone development shows the correction of numerical simulation. Under the effect of the support pressure and unloading of the coal face, an obvious seepage concentrate channel with greater hydraulic head and seepage vectors will form within the edge of the PKCP. Then, the shear sidewall channel will gradually move to the other side with the coal face near and away. When the damage zones are crushed through, the connected fractures will become a strong seepage channel in PKCP, named as pipe flow, which is a great threat to the occurrence of groundwater inrush.

References

Bai HB, Ma D, Chen ZQ (2013) Mechanical behavior of groundwater seepage in karst collapse pillars. Eng Geol 164:101–106

Chen SP (1993) Formation of karst collapse pillar in Fengfeng area in Hebei. Carsologica Sin 12(3):233–244

Cheng YM, Wang JA, Xie GX, Wei WB (2010) Three-dimensional analysis of coal barrier pillars in tailgate area adjacent to the fully mechanized top caving mining face. Int J Rock Mech Min Sci 47:1372–1383

Fama MED, Trueman R, Craig MS (1995) Two- and three dimensional elasto-plastic analysis for coal pillar design and its application to high wall mining. Int J Rock Mech Min Sci 32:215–225

He KQ, Guo D, Du W, Wang R (2007) The effects of karst collapse on the environments in North China. Environ Geol 52(3):449–455

He KQ, Yu GM, Lu YR (2009) Palaeo-karst collapse pillars in northern China and their damage to the geological environments. Environ Geol 58(5):1029–1040

He KQ, Zhang SQ, Wang F (2010) The karst collapses induced by environmental changes of the groundwater and their distribution rules in China. Environ Earth Sci 10:1075–1084

Hoek E (1990) Estimating Mohr–Coulomb friction and cohesion values from the Hoek–Brown failure criterion. Int J Rock Mech Min Sci 27:227–229

Hu XY, Wang LG, Lu YL, Yu M (2014) Analysis of insidious fault activation and water inrush from the mining floor. Int J Min Sci Technol 24(4):477–483

Itasca Consulting Group Inc. (2009) FLAC3D (Fast Lagrangian Analysis of Continua in 3 Dimensions), version 4.0. Minneapolis

Jiang YD, Wang HW, Xue S, Zhao YX, Zhu J, Pang XF (2012) Assessment and mitigation of coal bump risk during extraction of an island longwall panel. Int J Coal Geol 95(1):20–33

Kang Y (1992) A discussion of karst collapse formulation patterns. Hydrogeol Eng Geol 19(4):32–33 (in Chinese and abstract in English)

Li GY, Zhou WF (2006) Impact of karst water on coal mining in North China. Environ Geol 49:449–457

Lokhande RD, Murthy VMSR, Singh KB (2013) Pot-hole subsidence in underground coal mining: some Indian experiences. Geotech Geol Eng 31(2):793–799

Lu HF, Yao DX, Shen D, Cao JY (2015) Fracture mechanics solution of confined water progressive intrusion height of mining fracture floor. Int J Min Sci Technol 25(1):99–106

Ma D, Bai HB (2015) Groundwater inflow prediction model of karst collapse pillar: a case study for mining-induced groundwater inrush risk. Nat Hazards 76(2):1319–1334

Ma D, Mao XB, Li C, Du F (2012) Boundary integral computation of elastic water resisting key strata under the condition of discontinuous load. CMES 83(6):561–574

Ma D, Miao XX, Chen ZQ, Mao XB (2013) Experimental investigation of seepage properties of fractured rocks under different confining pressures. Rock Mech Rock Eng 46:1135–1144

Ma D, Miao XX, Jiang GH, Bai HB, Chen ZQ (2014) An experimental investigation of permeability measurement of water flow in crushed rocks. Transp Porous Media 105:571–595

Ma D, Bai HB, Chen ZQ, Pu H (2015a) Effect of particle mixture on seepage properties of crushed mudstones. Transp Porous Media 108(2):257–277

Ma D, Miao XX, Chen ZQ, Mao XB (2015b) Erratum to: Experimental investigation of seepage properties of fractured rocks under different confining pressures. Rock Mech Rock Eng 48:2183

Ma D, Bai HB, Miao XX, Pu H, Jiang BY, Chen ZQ (2016) Compaction and seepage properties of crushed limestone particle mixture: an experimental investigation for Ordovician karst collapse pillar groundwater inrush. Environ Earth Sci 75:11

Miao XX, Cui XM, Wang JA, Xu JL (2011a) The height of fractured water-conducting zone in undermined rock strata. Eng Geol 120:32–39

Miao XX, Li SC, Chen ZQ, Liu WQ (2011b) Experimental study of seepage properties of broken sandstone under different porosities. Transp Porous Media 86:805–814

Pietruszczak S, Mro Z (1980) Numerical analysis of elastic-plastic compression of pillars accounting for material hardening and softening. Int J Rock Mech Min Sci 17:199–207

Qian XP (1988) The formation of gypsum karst collapse pillars and hydrogeologic implications. Carsologica Sin 7(4):344–346 (in Chinese and abstract in English)

Rong HR, Bai HB (2014) Pore structure characteristics of the relative water-resisting layer on the top of the Ordovician in Longgu coal mine. Int J Min Sci Technol 24(5):657–661

Rutqvist J, Tsang CF (2002) A study of caprock hydromechanical changes associated with CO2-injection into a brine formation. Environ Geol 42:296–305

Sheng JC, Liu J, Zhu WC, Elsworth D, Liu JX (2008) Stress analysis of a borehole in saturated rocks under in situ mechanical, hydrological and thermal interactions. Energy Sour A Recovery Util Environ Eff 30(2):157–169

Shi J, Lian D, Yang S (1998) A discussion of karst collapse. Geol Min Res North China Mag 13(3):264–266 (in Chinese and abstract in English)

Shi LQ, Qiu M, Wei WX, Xu DJ, Han J (2014) Water inrush evaluation of coal seam floor by integrating the water inrush coefficient and the information of water abundance. Int J Min Sci Technol 24(5):677–681

Singh RN (1986) Mine inundations. Int J Mine Water 5(2):1–28

Singh R, Sheorey PR, Singh DP (2002) Stability of the parting between coal pillar workings in level contiguous seams. Int J Rock Mech Min Sci 39(1):9–39

Tharp TM (1999) Mechanics of upward propagation of cover-collapse sinkholes. Eng Geol 52(1):23–33

Troitzky GM (1993) Sinkhole danger-engineering problem of covered karst, applied karst geology. Balkema, Rotterdam, pp 231–232

Vutukuri VS, Singh RN (1995) Mine inundation-case histories. Mine Water Environ 14:107–130

Wang R (1982) Cause of formation of karst collapse pillar in northern China. Hydrogeol Eng Geol 9(1):37–41

Wang HW, Jiang YD, Zhao YX, Zhu J, Liu S (2013) Numerical investigation of the dynamic mechanical state of a coal pillar during longwall mining panel extraction. Rock Mech Rock Eng 46(5):1211–1221

Wu Q, Xu H, Pang W (2008a) Advances and challenges of GIS and DBMS applications in karst. Environ Geol 54(5):937–943

Wu Q, Xu H, Pang W (2008b) GIS and ANN coupling model: an innovative approach to evaluate vulnerability of karst water inrush in coalmines of north China. Environ Geol 54:937–943

Wu Q, Xing LT, Ye CH, Liu YZ (2011) The influences of coal mining on the large karst springs in North China. Environ Earth Sci 64:1513–1523

Xeidakis GS, Torok A, Skias S, Kleb B (2004) Engineering geological problems associated with karst terrains: their investigation, monitoring, and mitigation and design of engineering structures on karst terrains. Bull Geol Soc Greece 36:1932–1941

Xu WG, Zhao GR (1988) Vacuum erosion caused karst collapse. Hydrogeol Eng Geol 16(1):2190–2194 (in Chinese)

Yao BH (2012) Research on variable mass fluid–solid coupling dynamic theory of crushed rock mass and application. China University of Mining and Technology, Xuzhou (in Chinese and abstract in English)

Yao BH, Wei JP, Wang DK, Ma D, Chen ZQ (2013) Numerical study of seepage property of karst collapse columns under particle migration. CMES 91(2):81–100

Yin SX, Zhang JC (2005) Impacts of karst paleo-sinkholes on mining and environment in northern China. Environ Geol 48:1077–1083

Yin SX, Zhang JC, Liu DM (2015) A study of mine water inrushes by measurements of in situ stress and rock failures. Nat Hazards 79(3):1961–1979

Yuan D (1994) Karstology of China. Geological Publishing House, Beijing (in Chinese)

Zhang JC (2005) Investigations of water inrushes from aquifers under coal seams. Int J Rock Mech Min Sci 42:350–360

Zhang JC, Peng SP (2005) Water inrush and environmental impact of shallow seam mining. Environ Geol 48:1068–1076

Zhang Y, Qu Y, Liu G, Lu P (2000) Some problems of karstic collapse pillars in North-China-type coalfields. J Eng Geol 1:35–39 (in Chinese and abstract in English)

Zhou Y, Rajapakse R, Graham J (1998) A coupled thermoporoelastic model with thermo-osmosis and thermal-filtration. Int J Solids Struct 35(34–35):4659–4683

Zhu WC, Wei CH (2011) Numerical simulation on mining-induced water inrushes related to geologic structures using a damage-based hydromechanical model. Environ Earth Sci 62:43–54

Acknowledgments

This work was supported by the Fundamental Research Funds for the Central Universities (2015XKZD06), the Innovative Research Group of the National Natural Science Foundation of China (51421003) and the National Natural Science Foundation of China (51574228 and 51504243). The authors would like to thank two anonymous referees for their careful reading of this article and valuable suggestions.

Author information

Authors and Affiliations

Corresponding authors

Rights and permissions

About this article

Cite this article

Ma, D., Miao, X., Bai, H. et al. Effect of mining on shear sidewall groundwater inrush hazard caused by seepage instability of the penetrated karst collapse pillar. Nat Hazards 82, 73–93 (2016). https://doi.org/10.1007/s11069-016-2180-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11069-016-2180-9