Abstract

It is well known that surfactants play a vital role in aqueous-phase synthesis of gold nanoparticles (GNPs). However, to date, it remains challenging to fully elucidate the roles of surfactants, especially for the correlation between the molecular and aggregate structure of the employed surfactant and the structures of the resulting GNPs. In the study, the synthesis of GNPs in aqueous solution of a series of cationic gemini surfactants with different spacer length (12-s-12, s = 0, 2, 4, 6, 8, 10, and 12) has been investigated. A remarkable spacer length-dependent morphological evolution of nanorod→nanostar→nanoplate→spherical nanoparticle has been observed. The results show that the gemini surfactants can form the electrostatic complexes with AuI ions, and the complexes further self-assemble into the various aggregates of different sizes, which greatly alters the migration dynamics of AuI and eventually influences the growth kinetics of GNPs. The overall growth rate of the GNPs is determined by the combination of the monomer-AuI molecular weight, the size of aggregates, and the local concentration of AuI in the aggregates. Besides, the gemini surfactants with different spacer length could selectively anchor on various facets of GNPs, thus acting as the capping agents to direct the formation of the shaped GNPs. It is believed that the cationic gemini surfactants with different spacer length provide an excellent choice to control the growth kinetics and final morphology of GNPs, and this study provides new insights in surfactant-assisted synthesis of GNPs.

Graphical abstract

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

In the rapidly developing field of nanoscience, gold nanoparticles (GNPs) have continuously attracted considerable attention due to their intriguing size- and shape-dependent properties and a great promise for a wide spectrum of potential applications (Burda et al. 2005; Villa et al. 2015; Yang et al. 2015, 2016). During the past decades, the controlled synthesis of GNPs with tailored size and shape has been intensively studied and impressive progress has been achieved. To date, various synthetic methods such as seed-mediated synthesis, template synthesis, electrochemical synthesis, and interface synthesis are established to construct GNPs as diverse as spheres/polyhedral (Eguchi et al. 2012; Huang and Kim 2011; Ming et al. 2009), rods/wires (Gao et al. 2015; Lohse and Murphy 2013), belts (Zhao et al. 2008), plates (Chen et al. 2014; Millstone et al. 2009), dendrites (Lim and Xia 2011; Song et al. 2017), arrows (Wang et al. 2017a), helices (Wang et al. 2017b), and chiral particles (Lee et al. 2018). In these methods, surfactants are generally required to exert exquisite control over the thermodynamics and kinetics of nucleation and growth processes of GNPs (Bakshi 2016; Ortiz and Skrabalak 2014; Xiao and Qi 2011). In the early 2000s, a seminal work, i.e., surfactant-assisted seed-mediated synthesis of gold nanorods (GNRs), was developed by Murphy and El-Sayed group (Jana et al. 2001; Johnson et al. 2002; Nikoobakht and El-Sayed 2003), where cationic surfactant cetyltrimethyl ammonium bromide (CTAB) was identified as a crucial factor for the formation of GNRs. Since then, a great deal of effort has been devoted to illuminate the role of surfactant in the synthesis of GNPs through various ex-situ and in-situ techniques (Jackson et al. 2014; Li et al. 2016; Xu et al. 2017). Several hypotheses have been proposed, including but not limited to (i) the “templating mechanism”, where the GNP growth is spatially confined into nanoscaled domain of the surfactant aggregates such as micelle, vesicle, and lamellar structure, resulting in the crystal morphology similar to that of the aggregates (Gao et al. 2015; Wang et al. 2013b, c); (ii) the “crystal face-blocking mechanism”, known as shape-directing or capping agent, where the surfactant selectively anchors onto specific crystalline facets to alter the growth habit of nanocrystals, and thereby direct the shape of GNPs (Almora-Barrios et al. 2014; Xia et al. 2017; Xu et al. 2017; Zhang et al. 2016). However, it is still challenging to fully elucidate the roles of surfactants in the colloidal synthesis of GNPs.

Surfactants, as a typical kind of amphiphiles, can adsorb at liquid–solid interface and self-assemble into various aggregates in solution, which are considered to be endowed with multiple roles in regulating nanocrystal growth. In addition to the well-known roles of template and capping agents, both the monomers and aggregates of surfactants tend to form electrostatic complexes with gold ions (Bakshi 2016; Wang et al. 2013b, c), such as CTA-AuI micelles, which significantly influences the precipitation–dissolution equilibrium of Au precursor, the distribution of Au ions in aqueous solution, and the kinetics of Au ions diffusion. Besides, the viscosity of the reaction medium generally increases due to the presence of various surfactant aggregates, which lowers the mass transfer dynamics of the reductant and other reactants in growth medium, and eventually retards the growth kinetics of GNPs. For instance, Pérez-Juste et al. (2004) found that the binding of AuI ions to CTAB micelles extremely slowed down the collision frequency of AuI ions with the Au seeds, causing the crystal growth rate to be retarded by several orders of magnitude, thus playing a fundamental role in the formation of GNRs. Very recently, the kinetic role of surfactants was further confirmed by using an in-situ liquid-cell scanning transmission electron microscopy (STEM), where the growth rate of GNPs was notably reduced when CTAB was introduced, and the growth eventually followed a diffusion-limited mechanism with increasing the CTAB concentration (Canepa et al. 2018). Similarly, we have demonstrated that the growth rate of GNPs drastically decreased with increasing the concentration of a cationic gemini surfactant (hexamethylene-1,6-bis(dodecyl dimethylammonium bromide). Especially, at a higher surfactant concentration, large gemini surfactant-AuI vesicle was formed, and thus the growth rate of GNPs was extremely lowered, and even stagnated at the initial stage of the seeds (Wang et al. 2013a). Compared with micelles, the vesicles have a more significant influence on regulating the growth kinetics of GNPs. As well known, depending on their molecular structure, surfactants can self-assemble into various well-defined aggregates such as spherical micelle, rod-like micelle, worm-like micelle, vesicle, and lamellar structure. Due to the difference in the mass density and external shape, these aggregates can bring to different influences on the crystal growth. Accordingly, varying the molecular and the aggregates structure of used surfactants should provide a new mean to kinetic-controlled fabrication of GNPs. However, the systematic studies focusing on the kinetic roles originating from the diversity of molecular and aggregate structures of surfactants are now still scarce.

Herein, by using a library of cationic gemini surfactants with different spacer length, alkanediyl-α,ω-bis(dedecyl dimethylammonium bromide) (12-s-12, s = 0, 2, 4, 6, 8, 10, and 12, Table 1), we have investigated the effect of structural features and aggregate properties of the surfactants on seeded growth of GNPs. A series of novel GNPs such as rice-like nanorods, nanostars with unique morphology and “M”- or “Z”-type nanoplates have been obtained. The results show that the morphologies of gold products are determined by the spacer length and aggregate properties of the gemini surfactants. Besides, a dramatic difference of growth kinetics was observed in the growth solution in the presence of different gemini surfactants. The possible mechanism of the gemini surfactant-directed growth kinetics is proposed. This work indicates that the structural variations in monomer and aggregate of the used surfactants can greatly affect the rates of precursor reduction and direct the outcome, which may shed light on the surfactant-assisted synthesis of noble metal NPs.

Experimental

Chemicals

Chloroauric acid (HAuCl4·4H2O) was purchased from Shenyang Jinke Reagents Company. Silver nitrate (AgNO3), cetyltrimethylammonium bromide (CTAB), ascorbic acid (AA), and sodium borohydride (NaBH4) of analytical grade were obtained from Beijing Chemical Reagents Plant. Didodecyldimethyl ammonium bromide (DDAB) was purchased from TCI and used as received. For the purpose of uniformity in designation, we regard the DDAB as a kind of gemini surfactant and hereby named it as 12-0-12. Other gemini surfactants alkanediyl-α,ω-bis(dedecyl dimethylammonium bromide) (12-s-12, s = 2, 4, 6, 8, 10, and 12, s denotes the carbon atoms number of the spacer groups) were synthesized as reported in the literatures (Menger and Littau 1993; Zana et al. 1991) and were used after repeated recrystallization from ethanol. Ultrapure water (Milli-Q, 18.2 MΩ cm) was used to prepare all the solutions.

Synthesis and characterization of GNPs

Herein, GNPs were prepared according to the seed-mediated growth method. Briefly, the CTAB-capped gold seeds were made by quickly adding 600 μL of a freshly prepared, ice-cold NaBH4 solution (10 mM) into 9.4 mL of a mixed solution composed of HAuCl4 (0.25 mM) and CTAB (100 mM) under vigorous mixing. The solution color changed immediately from bright yellow to brown, indicating the formation of gold seeds. After 4~6 h aging, the gold seed solution was diluted five times for the next use. For the preparation of GNPs in the presence of 12-s-12 (s = 0, 2, 4, 6, 8, 10 and 12), the growth solution was prepared as follows: 600 μL of 12-s-12 solution (50 mM), 80 μL of HAuCl4 solution (20 mM), and 18 μL of AgNO3 solution (10 mM) were sequentially injected into 2.2 mL of H2O and mixed. After that, 96 μL of ascorbic acid solution (50 mM) was then added to it and mixed. Meanwhile, 96 μL of the diluted seed solution was added to the growth solution and mixed thoroughly. After the addition of the gold seed solution, the color of the reaction solution changed into blue within the time, suggesting the formation of larger GNPs. The growth temperature was kept at 30 °C for 14 h. The products were collected by centrifugation and washed several times with water and re-suspended in water for further characterizations.

The as-prepared GNPs were characterized by scanning electron microscopy (SEM, Hitachi S4800, 10 kV) and transmission electron microscopy (TEM, JEM-1011 or JEM-2100, 100 or 200 kV). SEM and TEM samples were prepared by placing one drop of the aqueous dispersion of gold product on a silicon wafer or a carbon-coated copper grid, allowing water to evaporate at ambient temperature. Besides, the growth procedure with some gemini surfactants was monitored by UV-vis spectroscopy (Shimadzu, UV-1601) using a 1 cm standard quartz cuvette.

DLS

Dynamic light scattering (DLS) was employed to measure the size of the aggregates formed in mixed solutions of gemini surfactant, HAuCl4, and AA, and the characterizations were carried out with an LLS spectrometer (ALV/SP-125) with a multi-τ digital time correlator (ALV-5000). A solid–state He−Ne laser (output power of 22 mW at λ = 632.8 nm) was used as a light source, and the measurements were conducted at a scattering angle of 90°. The samples were injected into a 7 mL glass bottle through a 0.45 μm filter prior to measurements. The correlation function of scattering data was analyzed via the CONTIN method to obtain the distribution of diffusion coefficients (D) of the solutes, and then, the apparent equivalent hydrodynamic radius (Rh) was determined using the Stokes−Einstein equation Rh = kT/6πηD, where k is the Boltzmann constant, T is the absolute temperature, and η is the solvent viscosity. All the measurements were performed at 25.00 ± 0.05 °C.

Results and discussion

Seeded synthesis of GNPs with gemini surfactants

GNPs were synthesized using the well-developed seed-mediated growth method involving the preparation of gold seeds and subsequent crystal growth in a growth solution containing HAuCl4, AgNO3, ascorbic acid, and gemini surfactants. Figure 1a shows the chemical structures of the employed gemini surfactants, and Fig. 1b–h shows the TEM images of the GNPs synthesized in the presence of gemini surfactants with different spacer length. In the growth solution containing 12-0-12, short rice-like GNRs together with a small number of spherical GNPs were obtained (Fig. 1b). Interestingly, the products are nanostars when 12-2-12 was used (Fig. 1c). Figure 2a–c shows the low- and high-magnification SEM images of the obtained nanostars. Obviously, there are four nanotips in the horizontal direction and two protuberances in the vertical direction in each nanostar (another invisible protuberance is in the back of the nanostar). Figure 2d is the TEM image of a typical nanostar, which was further selected to carry out electron diffraction observation. The diffraction patterns present the characteristics of the [110] zone axis of fcc crystal (Fig. 2e), indicating it is a piece of nanocrystal sitting against a plane perpendicular to the [110] zone axis.

The nanostar shape remained in the products generated from the growth solution of 12-4-12, but the tips and edges of the nanostars are indistinct compared with those prepared in 12-2-12 solution (Fig. 1d). A dramatic morphological change occurred when the spacer length was elongated to s = 6, that is 12-6-12. As shown in Fig. 1e, two dimensional nanoplates in “M-type” and “Z-type” morphologies were generated, coexisting with a small amount of irregular nanoparticles. Figure 3a is a representative TEM image of an individual Z-type nanoplate. The ED pattern (inset of Fig. 3b) shows the formally forbidden (1/3){422} reflections, which can be indexed to the [͞111] zone axis of the fcc gold, indicating that the nanoplate adopts (111) facet as the top surface. The related HRTEM image (Fig. 3b) exhibits clear lattice fringes with a d spacing of 0.24 nm, which is ascribed to the 3 × {422} superlattice spacing of the fcc gold crystals, consistent with the SAED result. Especially at s = 8 (12-8-12), the two kinds of nanoplates with higher yield were formed (Fig. 1f). However, further increasing the spacer length to s = 10 (12–10–12) led to a sharp decrease of the nanoplate yield (Fig. 1g). At s = 12 (12–12–12), spherical nanoparticles with diameters less than 10 nm were obtained (Fig. 1h).

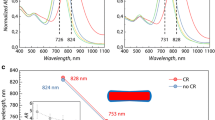

The optical properties of GNPs measured by UV-vis spectroscopy are depicted in Fig. 4. As expected, rice-like GNPs generated from 12-0-12 solution show two peaks at ~ 520 and ~ 700 nm, ascribing to the transverse and longitudinal plasmon bands of one-dimensional gold nanostructure. The star-shaped GNPs obtained from 12-2-12 and 12-4-12 solutions display a single peak at ~ 580 and ~ 550 nm, respectively. Interestingly, the spectra of the M-type and Z-type GNPs in 12-6-12 and 12-8-12 solutions are in the form of bimodal curves, which can be attributed to the anisotropic structure features of the GNPs. The spectrum of GNPs from 12-10-12 solution shows two peaks around at ~ 530 and ~ 640 nm because of the coexistence of the spherical and plate-like GNPs, in accordance with the TEM observation. As to the GNPs synthesized from 12-12-12 solution, a very weak peak around 519 nm can be seen, which is a character of the formation of spherical GNPs.

Growth rate of the GNPs with gemini surfactant

During the growth of GNPs, it was found that the reaction rate of GNPs in the growth solutions containing different gemini surfactants was largely influenced by their spacer length. Figure 5 is the optic photographs of the GNP solutions at different reaction time. The color of all the growth solutions immediately changed from dark yellow to colorless when the AA was added, indicative of the reduction of AuIII to AuI (Wang et al. 2013c). At the reaction time of 2 min, the color of growth solution containing 12-2-12 first altered from colorless to light blue, then gradually deepened into dark blue over time, and could not be distinguished after 15 min. The color of the growth solution containing 12-4-12 gradually changed to dark blue within 40 min, obviously slower than that of 12-2-12. The growth solutions with 12-6-12 and 12-8-12 became light blue in succession within 15 min and dark blue within 2 h. However, it is difficult to perceive obvious differences form their colors. To differentiate the growth rate of GNPs in 12-6-12 and 12-8-12, time-dependent UV-vis absorbance spectra were applied to monitor the reaction processes. The absorbance at 400 nm (A400 nm) was used as an indication of the amount of metallic Au presented in the sample (Angelomé et al. 2012). Figure 6 indicates the evolution of A400 nm as a function of time, and the results show that the growth rate of GNPs in 12-6-12 solutions is slightly faster than that in 12-8-12 ones. Besides, time-dependent UV-vis spectra were also used to trace the growth kinetics of GNPs in 12-2-12 and 12-6-12 solutions, and the results are in accordance with the optic results. For the growth solution with 12-10-12, its color turned into light pink within 1 h and gradually changed to purple at 2 h and dark purple at 14 h. Interestingly, the growth solutions containing 12-0-12 and 12-12-12 displayed no color change within 4 h but eventually turned into blue and light pink with 14 h, respectively. The growth dynamical characteristics of the GNPs in the solutions containing 12-0-12, 12-10-12, and 12-12-12 were easy to distinguish through their color changes, so that the time-dependent UV-vis spectrum tests were not carried out. The color change information clearly indicates that the spacer length of the gemini surfactants greatly influences the growth rate of GNPs. In brief, the growth rate of the GNPs monotonically decreases as the spacer length of the gemini surfactants is elongated from 2 to 12 methylene groups, while the growth rate in 12-0-12 solution is an exception and it is similar to that in 12-12-12.

Possible mechanism of the spacer length-directed morphological evolution

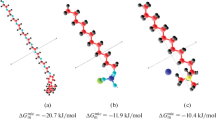

The formation of anisotropic fcc NPs is thermodynamically unfavorable that can be interpreted in terms of kinetic control (Lim and Xia 2011). In the seed-mediated synthesis of GNPs, seeds growing up to larger NPs is an autocatalytic reaction, whereby AuI ions discharge into Au0 through electron transfer at the surface of the electron-rich Au seeds (Pérez-Juste et al. 2004). Therefore, the collision frequency of AuI ions to Au seeds is a crucial factor to dictate the growth kinetics. In the growth media containing alkyl quaternary ammonium cationic surfactant, AuI ions tightly electrostatically bind with the quaternary ammonium cations of the surfactant to form surfactant-AuI complexes, and then the complexes spontaneously self-assemble into various aggregates (Wang et al. 2013a, c). Normally surfactant aggregates are in a dynamic equilibrium with monomers (Tucker et al. 2009). Besides, the formation and disassociation of surfactant-AuI complexes is also in equilibrium. Consequently, as illustrated in Fig. 7, AuI ions might be reduced to Au0 metal via three distinct routes: the free-hydrated AuI ions (route 1), the monomer gemini surfactant-AuI complexes (route 2), or the gemini surfactant aggregate-AuI complexes (route 3). Previous studies (Pérez-Juste et al. 2004; Wang et al. 2013c) found that AuI ions can form very stable complexes with quaternary ammonium surfactants, and the concentration of the free AuI ions in the growth medium is extremely low. Thereby, the growth kinetics of GNPs are determined by the frequency of collisions of the Au seeds with the AuI ions bound on the gemini surfactant monomers/aggregates, i.e., routes 2 and 3.

In principle, monomers or aggregates with a higher weight and a bigger size have a slower migration rate; the slow migration rate in turn results in a small collision frequency of AuI to seeds. Taking route 2 into account, the molecular weight of the gemini surfactant-AuI complexes increases with the elongation of the spacer length, thereby the migration rate of AuI ions and the resultant growth rate of the GNPs should be monotonically reduced in the order of 12-0-12 > 12-2-12 > 12-4-12 > 12-6-12 > 12-8-12 > 12-10–12 > 12-12-12. As far as route 3 is concerned, the migration of the AuI ions is controlled by the aggregate size. To stick out the aggregate effect, it is required to minimize the amount of the monomers in the growth solutions. Hence, the concentration of all the gemini surfactants in growth solutions was set to 10 mM, much higher than their critical aggregation concentrations (cac, Table 1), so the amount of monomers can be largely reduced. However, a higher concentration not only decreases the monomer content but also leads to a shape transition of the surfactant aggregates (Oda et al. 1999). Additionally, electrolytes such as HAuCl4 also influence the aggregate structures. Herein, after the addition of HAuCl4 and AA into the gemini surfactant solutions, the 12-0-12 mixtures displayed a distinct turbidity, indicating the formation of large aggregates; the 12-2-12 mixtures were clear and viscous solution possibly because of the generation of worm-like micelles, while other gemini surfactant solutions (s = 4, 6, 8, 10, and 12) still exhibited clear and inviscid features, suggesting the formation of small spherical or short rod-like micelles. The size distributions for all gemini surfactant aggregates from DLS measurements are shown in Fig. 8a, and the calculated values of hydrodynamic radius (Rh) are plotted in Fig. 8b. The results indicate that the aggregate size of different gemini surfactants follows the order of 12-0-12 > 12-2-12 > 12-12-12 > 12-10-12 > 12-8-12 > 12-4-12 > 12-6-12. Combining the information of turbidity, viscosity, and DLS data, it can be concluded that vesicles are formed in 12-0-12 solution, worm-like micelles are obtained in 12-2-12 solution and rod-like micelles with different aspect ratios are generated in the gemini surfactants with the spacer length s of 4, 6, 8, 10, and 12. Since the migration rate of aggregates is inversely proportional to their sizes, it is believed that the growth rate of GNPs should be in a reverse order, that is, 12-6-12 > 12-4-12 > 12-8-12 > 12-10-12 > 12-12-12 > 12-2-12 > 12-0-12.

In addition to the migration rate of AuI, the transport efficiency of AuI is also important for the kinetic control. We hypothesize that the AuI transport efficiency may be closely correlated with the local concentration of AuI ions on the different aggregates. Generally speaking, for surfactant aggregates, the larger aggregates have a more condensed molecular arrangement than that of smaller ones (Israelachvili et al. 1976; Mitchell and Ninham 1981). AuI ions bind onto the aggregates through the electrostatic attraction. Consequently, the local concentration of AuI in larger aggregates is higher than that in smaller ones. The higher local concentration of AuI will give rise to a higher reduction rate in the autocatalytic reaction, when only the AuI transport efficiency is considered.

Based on the abovementioned discussions, the diversity of the growth rate of GNPs in the presence of various gemini surfactants should be understood as follows. The overall growth rate of the GNPs is collectively determined by the migration dynamics of the monomer/aggregate-AuI complexes and the AuI transport efficiency. When the size of the gemini surfactant aggregates is large enough, the migration rate of the aggregate-AuI complexes dominates the final growth kinetics of the GNPs because of the sluggish migration rate of the large aggregates. In 12-0-12 solution, the largest aggregates, in the form of vesicles, were formed, then the migration of AuI ions from the vesicles to Au seeds greatly decelerated, and as a result, the rate growth of GNPs was the lowest. In the case of 12-12-12, the lowest migration rate of the monomer-AuI complex and the lower transport efficiency and local concentration of AuI jointly result in a tardy growth rate of GNPs, similar to the case in 12-0-12. On the contrary, the fastest growth rate can be realized by accumulating the accelerated factors. In 12-2-12 solution, the migration rate of monomer-AuI complex and the AuI transport efficiency are high enough so the related growth rate is the highest. In the solution containing 12-s-12 (s = 4, 6, 8, and 10), the growth rate of GNPs is also controlled by the migration rate and transport efficiency of AuI ions. To summarize, the growth rate of GNPs is determined by various factors, including migration rate and transport efficiency of AuI ions stemmed from the molecular and aggregate structures of surfactants. Low molecular weight, small aggregate size, together with high local concentration of AuI in the aggregate are in favor of a high growth rate.

As aforementioned, a distinct spacer length-dependent morphological evolution of nanorod→nanostar→nanoplate→nanoparticle is observed. According to the “facet-blocking” mechanism, final crystals are enclosed by the facets with the lowest growth rate because of the selective adsorption of capping agents (Xia et al. 2009). Obviously, the crystalline facets of the four kinds of NPs are different, indicating the adsorption selectivity of such gemini surfactants. Since the gemini surfactants have the same structure except the spacer length, the adsorption selectivity should be induced by the variation of the spacer length. The interaction between cationic surfactants and GNPs is mainly driven by the electrostatic attraction of positive charged head groups and the negative charged GNP surface. Furthermore, the elongation of spacer length lessens the charge density of the gemini surfactant monomer and aggregate, which may influence the adsorption selectivity of the gemini surfactants. It is known that the equilibrium separation between two quaternary ammonium cations is approximately equal to the length of six C-C bonds (Kern et al. 1994). That is to say, the head group of 12-6-12 is in the state of electrostatic equilibrium. We used the corresponding single chain surfactant counterpart dodecyltrimethylammonium bromide (DTAB) to replace 12-6-12, and the concentration of DTAB was set to twice or higher times of that of 12-6-12; however, only irregular polyhedral GNPs (Fig. 9) were obtained rather than the nanoplates formed in 12-6-12. The result clearly demonstrates that the hydrocarbon chain of the spacer group plays an important role in the adsorption process of gemini surfactant on the GNP surface. More importantly, this finding indicates that adsorption selectivity of gemini surfactants on GNPs can be controlled by modulating the spacer length.

Therefore, at the present stage, we propose that the distinct spacer length-dependent morphological evolution of GNPs can be interpreted by two main factors: (1) the growth rate of GNPs is greatly influenced by the used gemini surfactants through changing the migration rate and transport efficiency of AuI ions by different monomer-AuI and aggregate-AuI complexes; and (2) the gemini surfactants with different spacer length could selectively anchor on various facets of GNPs, thus acting as capping agents to direct the formation of GNPs.

Conclusions

In summary, the study investigates the seeded growth of GNPs in the presence of a series of gemini surfactants with different spacer length. The GNPs undergo a remarkable evolution of nanorod→nanostar→nanoplate→spherical nanoparticle with the elongation of the spacer length of the gemini surfactants in growth solutions. The kinetic role of gemini surfactants is proposed to interpret such spacer length-dependent morphological evolution of GNPs. On one hand, the gemini surfactants form electrostatic complexes with AuI ions and the complexes further self-assemble into various aggregates in different size, which in turn greatly influences the growth kinetics by changing the mobility of AuI. The overall growth rate is determined by the combination of the monomer-AuI molecular weight, the size of aggregates, and the local concentration of AuI in the aggregates. On the other hand, due to the variation of spacer length, gemini surfactants display the diversity of their capping behaviors on the growing GNPs. This work indicates that the structural features and aggregation types of surfactants can greatly affect the construction of GNPs, which may shed light on the surfactant-assisted synthesis of noble metal NPs.

References

Almora-Barrios N, Novell-Leruth G, Whiting P, Liz-Marzán LM, López N (2014) Theoretical description of the role of halides, silver, and surfactants on the structure of gold nanorods. Nano Lett 14:871–875. https://doi.org/10.1021/nl404661u

Angelomé PC, Heidari Mezerji H, Goris B, Pastoriza-Santos I, Pérez-Juste J, Bals S, Liz-Marzán LM (2012) Seedless synthesis of single crystalline Au nanoparticles with unusual shapes and tunable LSPR in the near-IR. Chem Mater 24:1393–1399. https://doi.org/10.1021/cm3004479

Atkin R, Craig VSJ, Wanless EJ, Biggs S (2003) Adsorption of 12-s-12 gemini surfactants at the silica−aqueous solution interface. J Phys Chem B 107:2978–2985. https://doi.org/10.1021/jp026626o

Bakshi MS (2016) How surfactants control crystal growth of nanomaterials. Cryst Growth Des 16:1104–1133. https://doi.org/10.1021/acs.cgd.5b01465

Burda C, Chen X, Narayanan R, El-Sayed MA (2005) Chemistry and properties of nanocrystals of different shapes. Chem Rev 105:1025–1102. https://doi.org/10.1021/cr030063a

Canepa SA, Sneed BT, Sun H, Unocic RR, Mølhave K (2018) Influence of cetyltrimethylammonium bromide on gold nanocrystal formation studied by in situ liquid cell scanning transmission tlectron microscopy. J Phys Chem C 122:2350–2357. https://doi.org/10.1021/acs.jpcc.7b06383

Chen L, Ji F, Xu Y, He L, Mi Y, Bao F, Sun B, Zhang X, Zhang Q (2014) High-yield seedless synthesis of triangular gold nanoplates through oxidative etching. Nano Lett 14:7201–7206. https://doi.org/10.1021/nl504126u

Danino D, Talmon Y, Zana R (1995) Alkanediyl-.alpha.,.omega.-bis(dimethylalkylammonium bromide) surfactants (dimeric surfactants). 5. aggregation and microstructure in aqueous solutions. Langmuir 11:1448–1456. https://doi.org/10.1021/la00005a008

Eguchi M, Mitsui D, Wu H-L, Sato R, Teranishi T (2012) Simple reductant concentration-dependent shape control of polyhedral gold nanoparticles and their plasmonic properties. Langmuir 28:9021–9026. https://doi.org/10.1021/la3002114

Fontana A, De Maria P, Siani G, Robinson BH (2003) Kinetics of breakdown of vesicles from didodecyldimethylammonium bromide induced by single chain surfactants and by osmotic stress in aqueous solution. Colloid Surf B 32:365–374. https://doi.org/10.1016/j.colsurfb.2003.08.003

Gao X, Lu F, Dong B, Liu Y, Gao Y, Zheng L (2015) Facile synthesis of gold and gold-based alloy nanowire networks using wormlike micelles as soft templates. Chem Comm 51:843–846. https://doi.org/10.1039/C4CC08549C

Huang Y, Kim D-H (2011) Synthesis and self-assembly of highly monodispersed quasispherical gold nanoparticles. Langmuir 27:13861–13867. https://doi.org/10.1021/la203143k

Israelachvili JN, Mitchell DJ, Ninham BW (1976) Theory of self-assembly of hydrocarbon amphiphiles into micelles and bilayers. J Chem Soc Faraday Trans II 72:1525–1568. https://doi.org/10.1039/F29767201525

Jackson SR, McBride JR, Rosenthal SJ, Wright DW (2014) Where’s the silver? Imaging trace silver coverage on the surface of gold nanorods. J Am Chem Soc 136:5261–5263. https://doi.org/10.1021/ja501676y

Jana NR, Gearheart L, Murphy CJ (2001) Seed-mediated growth approach for shape-controlled synthesis of spheroidal and rod-like gold nanoparticles using a surfactant template. Adv Mater 13:1389–1393. https://doi.org/10.1002/1521-4095(200109)13:18<1389::AID-ADMA1389>3.0.CO;2-F

Johnson CJ, Dujardin E, Davis SA, Murphy CJ, Mann S (2002) Growth and form of gold nanorods prepared by seed-mediated, surfactant-directed synthesis. J Mater Chem 12:1765–1770. https://doi.org/10.1039/B200953F

Kern F, Lequeux F, Zana R, Candau SJ (1994) Dynamic properties of salt-free viscoelastic micellar solutions. Langmuir 10:1714–1723. https://doi.org/10.1021/la00018a018

Lee H-E, Ahn H-Y, Mun J, Lee YY, Kim M, Cho NH, Chang K, Kim WS, Rho J, Nam KT (2018) Amino-acid- and peptide-directed synthesis of chiral plasmonic gold nanoparticles. Nature 556:360–365. https://doi.org/10.1038/s41586-018-0034-1

Li F, Luan Y, Liu X, Xu G, Li X, Li X, Wang J (2011) Investigation on the aggregation behaviors of DDAB/NaDEHP catanionic vesicles in the absence and presence of a negatively charged polyelectrolyte. Phys Chem Chem Phys 13:5897–5905. https://doi.org/10.1039/C0CP01365J

Li T, Senesi AJ, Lee B (2016) Small angle x-ray scattering for nanoparticle research. Chem Rev 116:11128–11180. https://doi.org/10.1021/acs.chemrev.5b00690

Lim B, Xia Y (2011) Metal nanocrystals with highly branched morphologies. Angew Chem Int Ed 50:76–85. https://doi.org/10.1002/anie.201002024

Lohse SE, Murphy CJ (2013) The quest for shape control: a history of gold nanorod synthesis. Chem Mater 25:1250–1261. https://doi.org/10.1021/cm303708p

Menger FM, Littau CA (1993) Gemini surfactants: a new class of self-assembling molecules. J Am Chem Soc 115:10083–10090. https://doi.org/10.1021/ja00075a025

Millstone JE, Hurst SJ, Métraux GS, Cutler JI, Mirkin CA (2009) Colloidal gold and silver triangular nanoprisms. Small 5:646–664. https://doi.org/10.1002/smll.200801480

Ming T, Feng W, Tang Q, Wang F, Sun L, Wang J, Yan C (2009) Growth of tetrahexahedral gold nanocrystals with high-index facets. J Am Chem Soc 131:16350–16351. https://doi.org/10.1021/ja907549n

Mitchell DJ, Ninham BW (1981) Micelles, vesicles and microemulsions. J Chem Soc Faraday Trans II 77:601–629. https://doi.org/10.1039/F29817700601

Nikoobakht B, El-Sayed MA (2003) Preparation and growth mechanism of gold nanorods (NRs) using seed-mediated growth method. Chem Mater 15:1957–1962. https://doi.org/10.1021/cm020732l

Oda R, Huc I, Homo J-C, Heinrich B, Schmutz M, Candau S (1999) Elongated aggregates formed by cationic gemini surfactants. Langmuir 15:2384–2390. https://doi.org/10.1021/la9814889

Ortiz N, Skrabalak SE (2014) On the dual roles of ligands in the synthesis of colloidal metal nanostructures. Langmuir 30:6649–6659. https://doi.org/10.1021/la404539p

Pérez-Juste J, Liz-Marzán LM, Carnie S, Chan DYC, Mulvaney P (2004) Electric-field-directed growth of gold nanorods in aqueous surfactant solutions. Adv Funct Mater 14:571–579. https://doi.org/10.1002/adfm.200305068

Song J, Yang X, Yang Z, Lin L, Liu Y, Zhou Z, Shen Z, Yu G, Dai Y, Jacobson O, Munasinghe J, Yung B, Teng GJ, Chen X (2017) Rational design of branched nanoporous gold nanoshells with enhanced physico-optical properties for optical imaging and cancer therapy. ACS Nano 11:6102–6113. https://doi.org/10.1021/acsnano.7b02048

Tucker I, Penfold J, Thomas RK, Grillo I (2009) Monomer−aggregate exchange rates in dialkyl chain cationic−nonionic surfactant mixtures. Langmuir 25:2661–2666. https://doi.org/10.1021/la803329a

Villa A, Dimitratos N, Chan-Thaw CE, Hammond C, Prati L, Hutchings GJ (2015) Glycerol oxidation using gold-containing catalysts. Acc Chem Res 48:1403–1412. https://doi.org/10.1021/ar500426g

Wang W, Han Y, Gao M, Wang Y (2013a) Facile synthesis of two-dimensional highly branched gold nanostructures in aqueous solutions of cationic gemini surfactant. CrystEngComm 15:2648–2656. https://doi.org/10.1039/C3CE26527G

Wang W, Han Y, Gao M, Wang Y (2013b) Template synthesis of braided gold nanowires with gemini surfactant–HAuCl4 aggregates. J Nanopart Res 15:1380. https://doi.org/10.1007/s11051-012-1380-9

Wang W, Han Y, Tian M, Fan Y, Tang Y, Gao M, Wang Y (2013c) Cationic gemini surfactant-assisted synthesis of hollow Au nanostructures by stepwise reductions. ACS Appl Mater Interfaces 5:5709–5716. https://doi.org/10.1021/am4011226

Wang Q, Wang Z, Li Z, Xiao J, Shan H, Fang Z, Qi L (2017a) Controlled growth and shape-directed self-assembly of gold nanoarrows. Sci Adv 3:e1701183. https://doi.org/10.1126/sciadv.1701183

Wang Y, He J, Mu X, Wang D, Zhang B, Shen Y, Lin M, Kübel C, Huang Y, Chen H (2017b) Solution growth of ultralong gold nanohelices. ACS Nano 11:5538–5546. https://doi.org/10.1021/acsnano.7b00710

Xia Y, Xiong Y, Lim B, Skrabalak SE (2009) Shape-controlled synthesis of metal nanocrystals: simple chemistry meets complex physics? Angew Chem In Ed 48:60–103. https://doi.org/10.1002/anie.200802248

Xia Y, Gilroy KD, Peng H-C, Xia X (2017) Seed-mediated growth of colloidal metal nanocrystals. Angew Chem In Ed 56:60–95. https://doi.org/10.1002/anie.201604731

Xiao J, Qi L (2011) Surfactant-assisted, shape-controlled synthesis of gold nanocrystals. Nanoscale 3:1383–1396. https://doi.org/10.1039/C0NR00814A

Xu Y, Chen L, Ye X, Wang X, Yu J, Zhao Y, Cao M, Xia Z, Sun B, Zhang Q (2017) Cooperative interactions among CTA+, Br− and Ag+ during seeded growth of gold nanorods. Nano Res 10:2146–2155. https://doi.org/10.1007/s12274-016-1404-3

Yang X, Yang M, Pang B, Vara M, Xia Y (2015) Gold nanomaterials at work in biomedicine. Chem Rev 115:10410–10488. https://doi.org/10.1021/acs.chemrev.5b00193

Yang P, Zheng J, Xu Y, Zhang Q, Jiang L (2016) Colloidal synthesis and applications of plasmonic metal nanoparticles. Adv Mater 28:10508–10517. https://doi.org/10.1002/adma.201601739

Zana R (1996) Gemini (dimeric) surfactants. Curr Opin Colloid Interface Sci 1:566–571. https://doi.org/10.1016/S1359-0294(96)80093-8

Zana R, Talmon Y (1993) Dependence of aggregate morphology on structure of dimeric surfactants. Nature 362:228–230. https://doi.org/10.1038/362228a0

Zana R, Benrraou M, Rueff R (1991) Alkanediyl-.alpha.,.omega.-bis(dimethylalkylammonium bromide) surfactants. 1. effect of the spacer chain length on the critical micelle concentration and micelle ionization degree. Langmuir 7:1072–1075. https://doi.org/10.1021/la00054a008

Zhang Q, Jing H, Li GG, Lin Y, Blom DA, Wang H (2016) Intertwining roles of silver ions, surfactants, and reducing agents in gold nanorod overgrowth: pathway switch between silver underpotential deposition and gold–silver codeposition. Chem Mater 28:2728–2741. https://doi.org/10.1021/acs.chemmater.6b00389

Zhao N, Wei Y, Sun N, Chen Q, Bai J, Zhou L, Qin Y, Li M, Qi L (2008) Controlled synthesis of gold nanobelts and nanocombs in aqueous mixed surfactant solutions. Langmuir 24:991–998. https://doi.org/10.1021/la702848x

Funding

This work was financially supported by the National Natural Science Foundation of China (21633002), the Chongqing Science and Technology Commission (cstc2017shmsA30018), and the Foundation of Chongqing University of Arts and Sciences (P2017CH11, 2017RCH02).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no competing interests.

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Wang, W., Han, Y., Zhu, J. et al. Seeded growth of gold nanoparticles in aqueous solution of cationic gemini surfactants with different spacer length: influences of molecular and aggregate structures. J Nanopart Res 21, 24 (2019). https://doi.org/10.1007/s11051-019-4465-x

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s11051-019-4465-x