Abstract

Platinum nanoparticles (Pt NPs) can be obtained successfully on glassy carbon (GC) substrates by spontaneous deposition taking place upon immersion of the GC electrode, at open circuit, in a 1 mM H2PtCl6 + 0.5 M H2SO4 solution. The metallic deposits were characterized by ex situ atomic force microscopy (AFM) and scanning electron microscopy/energy-dispersive X-ray spectroscopy (SEM-EDX) analysis. At long immersion times, AFM and SEM images show hemispherical Pt NPs of varying sizes (20–390 nm), and heights (50–185 nm), distributed mainly on the GC polishing lines. These deposits coexist with larger Pt clusters, including dendritic structures with sizes in the order of several micrometers, suggesting that both primary and secondary nucleation processes occur on the carbon surface. EDX spectrum confirmed that Pt indeed composes both types of deposits. Cyclic voltammetry was used to evaluate their catalytic activity, qualitatively, towards the hydrogen evolution reaction (HER). The voltammetric response of the GC electrode modified with Pt NPs generated at long immersion times evidenced a behavior similar to that of polycrystalline Pt electrodes, and an enhancement in the catalytic activity regarding HER.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Platinum nanoparticles (Pt NPs) dispersed onto carbon surfaces have been studied extensively to analyze their potential as catalyst materials, particularly for fuel cell applications (Singh et al. 2014; Ong et al. 2017; Samad et al. 2018). In the fabrication of this type of modified substrates, it is important to optimize the catalytic activity with the use of a lower metal load to reduce the production costs. To achieve this goal, it is necessary to control particle size, distribution, and dispersion due to the existing dependence between the catalytic activity and these parameters (Cherstiouk et al. 2003; Antolini 2016; Cao et al. 2016)

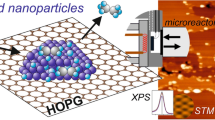

Efforts have been made to produce particular structures and shapes of Pt NPs on carbon substrates, employing different methods, among which electrodeposition and chemical reduction are the most commonly used (Rao and Trivedi 2005). On the other hand, it has been found that Pt nanoparticles could be formed spontaneously on highly ordered pyrolytic graphite (HOPG) surfaces (Zoval et al. 1998; Shen et al. 2001; Lu and Zangari 2006; Juarez et al. 2014). In this case, the complete mechanism of this phenomenon is not yet fully understood, since spontaneous metal deposition involves surface sensitive reactions. It has been proposed by Zoval et al. (1998) that the driving force of the spontaneous deposition process is the presence of oxidized functionalities such as aldehydes, ketones, and alcohols on the HOPG surface, and these functionalities work as reducing equivalents to Pt ions present in solution. The surface functional groups present at the carbon surfaces might also influence the dispersion, agglomeration, and surface diffusion of Pt nanoparticles (Rodríguez-Reinoso 1998). However, Juarez et al. (2014) have recently confirmed by a theoretical approach that, besides this hypothesis, there are another involved interactions which make this phenomenon more complicated to study thoroughly. These facts have served as a starting point to investigate the spontaneous deposition of Pt on glassy carbon (GC) substrate; this is a low-cost alternative, whose surface also contains carbon-oxygen functional groups similar to those of HOPG (Randin and Yeager 1975; Collier and Tougas 1987; Ray and McCreery 1999); the surface functional groups can undergo some phase transitions spontaneously, and therefore, the formation of metal nanoparticles could be expected at open circuit conditions.

We have reported previously, the spontaneous deposition of Pt nanoparticles on HOPG surfaces (Arroyo Gómez and García 2015), and demonstrated that, at long immersion times (2 h), large Pt clusters constituted mainly of different sized hemispherical particles were formed. In this case, the deposits covered almost entirely the electrode surface and exhibited sizes up to 250 nm and heights between 125 and 200 nm. Therefore, if this deposition process is also feasible on the GC surface, it could provide a useful method to obtain well-controlled amounts of Pt particles on GC varying the time of immersion for a given concentration of [PtCl6]2− ions in the solution, and could significantly simplify the preparation of new metal/GC catalyst materials.

In the present work, the surface modification of a GC electrode by spontaneously deposited Pt was investigated, taking into account the influence of the electrode surface conditions (surface morphology and surface roughness) on this phenomenon. This behavior was compared to that obtained using HOPG electrodes. The dependence of the open circuit potential (OCP) with immersion time was carried out to understand the deposition mechanism that takes place on the substrate surface. AFM and SEM-EDX techniques together with cyclic voltammetry were used to characterize the Pt deposits formed on GC. The catalytic effect for the hydrogen evolution reaction was analysed qualitatively by voltammetric measurements.

Experimental

The GC substrates (HTW, Germany) used as working electrodes, were rods (ϕ = 3 mm) sealed into a Teflon holder, with an exposure area of 0.0707 cm2. The electrode surface was mechanically polished to a mirror-like finish with an emery paper of progressively finer grain size, followed by 0.3 μm alumina paste and then, rinsed thoroughly with tri-distilled water.

The spontaneous formation of the Pt nanoparticles on GC was performed immersing the electrode in a 1 mM H2PtCl6 + 0.05 M H2SO4 solution, prepared with suprapure chemicals (E. Merck, Darmstadt) and tri-distilled water. All the experiments were carried out at a temperature of T = 298 K using a conventional three-electrode electrochemical cell. The counter electrode was a Pt sheet (1 cm2), and the reference electrode was a saturated calomel electrode, (SCE, EECS = 0.2415 V vs. SHE). All electrode potentials mentioned in this work, are referred to this electrode. The deposition took place at open circuit potential (OCP), and in order to evaluate the morphological changes of the Pt nanoparticles, different immersion times were used.

All the experiences were recorded using a computer-controlled EG&G Princeton Applied Research model 273A potentiostat-galvanostat. The characterization of Pt nanoparticles on GC was carried out by ex situ AFM, using a standard nanoscope III microscope (Digital Instruments, Santa Barbara, USA), operated in contact mode using a scanner of 15 μm and oxide-sharpened silicon nitride probes (Veeco Probes), and by SEM using a JEOL 35CF microscope integrated with an EDX DX-4 analyzer.

Results and discussion

Temporal OCP evolution

It has been well established that Pt is spontaneously deposited in HOPG substrates (Zoval et al. 1998; Shen et al. 2001; Lu and Zangari 2005; Juarez et al. 2014) but until now, this phenomenon hast not been reported to occur on GC surfaces. The oxidized functionalities at surface defects on HOPG electrodes are the driving force for the process (Zoval et al. 1998), the higher quantity of surface defects and the electrochemical performance of GC, compared to HOPG (Zittel and Miller 1965), are enough reasons to suspect that this phenomenon may also take place at the GC surface without any chemical or electrochemical pretreatment of the carbon electrode. To evaluate this hypothesis, open circuit potential (OCP) was measured for a GC electrode immersed in a 1 mM H2PtCl6 + 0.05 M H2SO4 solution.

It is well known that the spontaneous deposition of metals on certain materials is accompanied by changes in the surface potential of the substrate, which are related to the charge transfer due to the oxidation of the substrate and the reduction of the metal ion (Brankovic et al. 2001a, b). Figure 1 shows the typical OCP-time evolution after an immersion time of 2 h. In all experiences, the recorded OCP ranged between 520 and 550 mV. These values are slightly above to those reported for the PtCl62−/Pt and PtCl42−/Pt couples (Lu and Zangari 2005) (502 and 516 mV vs. ECS, respectively), indicating that Pt reduction could occur through these processes together with some influence of the anions present in solution. In our case, the difference of the potential values may be related to the presence of SO42− anions in the supporting electrolyte, which promote the reduction processes and increase the electrolyte conductivity (Lu and Zangari 2005). This difference could also be interpreted regarding the substrate activity, related to the amount of surface defects which contain functional groups that may be oxidized and provide the electrons necessary for the reduction of Pt from the plating solution. Anyway, the OCP data obtained in this work are similar to those reported for HOPG electrodes employing solutions with and without supporting electrolyte (Lu and Zangari 2006; Arroyo Gómez and García 2015; Quaino et al. 2005).

Surface analysis

Different amounts of Pt were found to deposit spontaneously on GC surfaces, after varying the immersion time, ti, in the chloroplatinic acid solution, and characterized by ex situ AFM and SEM-EDX analysis. Initially, the topography of the Pt-free substrate shows a rough surface with typical lines originated by the polishing treatment (mean roughness Ra < 2 nm). After a relatively short immersion time (ti = 200 s), a small amount of metal deposits with a mean particle size of 32 nm, was observed on the substrate (Fig. 2a), indicating that the driving force for metal adsorption is not enough to produce considerable nucleation of Pt clusters. However, with increasing the immersion time to ti = 7200 s (2 h), highly covered regions of Pt crystals were evidenced (Fig. 2b).

Figure 2b, c shows a representative AFM image of the Pt-decorated GC electrode and the corresponding size distribution, respectively. Indeed, the hemispherical Pt nanoparticles are distributed over the surface, mainly on the polishing lines of the substrate; with sizes ranged between 20 and 390 nm. Despite the wide range of diameters observed, the predominant Pt particle size was below 150 nm (Fig. 2c). Unlike the HOPG where the active sites are preferably distributed at the step edges of the surface, the Pt clusters are located randomly on the substrate. Size diversity of metal deposits is consistent with a progressive nucleation and growth mechanism. This growth and the coalescence of Pt crystals is promoted by the presence of the supporting electrolyte, which allows the nanoparticles to reach a critical size and then move on the substrate surface to grow in a hemispherical shape (Lee et al. 1998). A cross-sectional analysis of the marked lines in the AFM image was carried out, indicating a maximum particle height of 0.185 μm (Fig. 2d).

Analysis of the AFM images from different regions of the samples also shows aggregates of interconnected particles (Fig. 3a). These are similar to Pt deposits observed by Zoval et al. (1998) as diffuse rings on the HOPG electrode after 1 min immersion in a chloroplatinic solution using 0.1 M HCl as supporting electrolyte, and those generated via sol-gel impregnating a silica surface (Mizukami et al. 1994). The higher surface non-uniformity lead to the aggregation of the Pt, generating large dendritic structures (Fig. 3), and this formation could be assumed as a secondary nucleation process on the surface of previously deposited Pt (Sherstyuk et al. 2000). A Pt dendrite consists of a central stem with wide side branches decorated by some small nanoparticles; the branch length can reach a width of 11.4 μm and a length higher than 12 μm (Fig. 3b). This characteristic morphology of Pt crystals could be explained by the anisotropic surface diffusion of the adsorbed Pt atoms, and the relatively long deposition time used. The three-dimensional growth morphology from hemispherical nanoparticles to form larger structures depends on coalescence and mobility of Pt on the surface, as it was pointed out before.

SEM images also corroborate the formation of large dendritic deposits surrounded by smaller ones (Fig. 4a). It could be suggested that the particles, which exist near the dendritic structures would be predominantly incorporated in their branches, thus leading to a denuded zone for small clusters. Higher magnification of this region (Fig. 4b) reveals that, around the large dendrites, the islands with smaller size exhibit also a dendritic shape, whereas the most remote crystallites, even smaller, evidence a more compact structure. In this case, the dendritic structure could be associated with the generation of Cl− anions as a result of the formation of metallic Pt. These anions could be adsorbed on Pt crystals, blocking active sites for subsequent Pt reduction, and could influence the morphology of the deposits (Lee et al. 1998). The EDX spectrum (Fig. 4c) confirmed that Pt indeed composes both compact nanoparticles as well as dendritic structures, also showing the presence of the C and O signals corresponding to the substrate and superficial oxides, respectively.

Anyway, taking into account the observed microstructure of Pt deposits, it could be assumed that both primary and secondary nucleation processes occur on the carbon surface, i.e., growth of isolated nuclei forming islands, which come into contact and coalesce, and those that grow beyond a certain size due to anion adsorption causing a secondary nucleation of Pt crystals. A formation mechanism can be proposed considering primary and secondary nucleation on the GC surface, as shown in the schematic illustration of Fig. 5.

On the contrary, Pt nucleates on the HOPG substrate forming irregular agglomerates on step edges, which transforms, at the same immersion time (2 h) used in this work, to large clusters, mainly constituted by hemispherical particles of different sizes (Arroyo Gómez and García 2015). Therefore, the influence of the substrate structure on the nucleation behavior of the spontaneously deposited Pt crystals can be clearly evidenced.

Electrochemical characterization

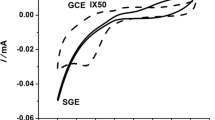

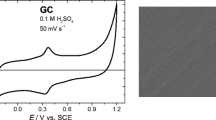

The characterization of the Pt NPs modified GC substrate was carried out in a 0.5 M H2SO4 solution. After an immersion time of 2 h, the cyclic voltammogram of the Pt-modified electrode showed similar features to those of polycrystalline platinum, as presented in Fig. 6a. The differences between the two voltammograms could be associated with a low surface area related with large sized Pt particles observed by AFM and SEM (Mukerjee 1990). Nevertheless, the Pt-modified electrode showed the main voltammetric features, i.e., the reduction of Pt oxide during the cathodic sweep, which is observed at E ~ 500 mV, followed by the hydrogen adsorption at E < 0 mV. In the anodic direction, the corresponding desorption of the adsorbed hydrogen and the Pt oxide formation processes are shown. The voltammetric response is similar to that reported for Pt-modified HOPG electrodes (Zoval et al. 1998; Lu and Zangari 2006; Fortuin et al. 2018).

The catalytic activity of the Pt-modified surfaces was evaluated qualitatively by cyclic voltammetry. Figure 6b shows the voltammetric results for the GC electrode modified with Pt deposits, using different immersion times. The current observed in the hydrogen evolution region is increased with immersion time, and the onset potential (Eonset) value for the HER becomes 400–420 mV more positive than that of the unmodified GC substrate. This behavior can be attributed to an increase in the Pt load at higher deposition times, leading to an enhanced catalytic activity. Table 1 summarizes the values of the HER onset potential and the maximum cathodic current obtained in the potential region considered, for Pt nanoparticles deposited at different immersion times on GC surfaces. It is indicated that the Pt nanoparticles generated with an immersion time of 7200 s, exhibit the most positive onset potential value which may favor the proton reduction kinetics, with a maximum cathodic current (Imax) of 5.32 mA. These results suggest that the GC substrate modified with spontaneously deposited Pt NPs could be a promising electrocatalyst material for the HER. Further work is in progress to evaluate the kinetic parameters through Tafel plots to study the mechanism of HER.

Conclusions

It was demonstrated that platinum nanoparticles were formed on GC substrates by a spontaneous deposition process. The OCP vs. immersion time profiles revealed potential values higher than those of the PtCl62−/Pt and PtCl42−/Pt couples, suggesting that some of these processes could take place and be influenced by the presence of SO42− anions.

Pt deposits with different shapes and sizes were generated spontaneously on GC surfaces at long immersion times, i.e., hemispherical nanoparticles with a broad size distribution, and large dendritic structures observed on different regions of the substrate, the latter being regarded as a secondary nucleation process. The voltammetric data of the GC electrode modified with Pt NPs generated at an immersion time of 2 h, evidenced a behavior similar to that of polycrystalline Pt electrodes. The voltammetric response regarding HER showed an enhancement in the catalytic activity with the deposition time, showing a pronounced effect for Pt NPs formed on GC electrodes after an immersion time of 2 h.

References

Antolini E (2016) Structural parameters of supported fuel cell catalysts: the effect of particle size, inter-particle distance and metal loading on catalytic activity and fuel cell performance. App Catal B 181:298–313

Arroyo Gómez JJ, García SG (2015) Spontaneous deposition of Pt-nanoparticles on HOPG surfaces. Surf Interface Anal 47:1127–1131

Brankovic SR, McBreen J, Adžic RR (2001a) Spontaneous deposition of Pd on the Ru (0001) surface. J Electroanal Chem 503:99–104

Brankovic SR, McBreen J, Adžic RR (2001b) Spontaneous deposition of Pd on a Ru (0001) surface. Surf Sci Lett 479:L363–L368

Cao S, Tao F, Tang Y, Li Y, Yu J (2016) Size- and shape-dependent catalytic performances of oxidation and reduction reactions on nanocatalysts. Chem Soc Rev 45:4747–4765

Cherstiouk OV, Simonov PA, Savinova ER (2003) Model approach to evaluate particle size effects in electrocatalysis: preparation and properties of Pt nanoparticles supported on GC and HOPG. Electrochim Acta 48:3851–3860

Collier WG, Tougas TP (1987) Determination of surface hydroxyl groups on glassy carbon with X-ray photoelectron spectroscopy preceded by chemical derivatization. Anal Chem 59:396–399

Fortuin AC, Jackson C, Carlechi E, Doyle BP, Shnier A, Kriek RJ, Ray SC, Billing DG, Wamwangi D, Scherer GG, Levecque PBJ (2018) Towards practical applications of EQCN experiments to study Pt anchor sites on carbon surfaces. Electrocatalysis 9:271–278

Juarez MF, Fuentes S, Soldano GJ, Avalle, Santos E (2014) Spontaneous formation of metallic nanostructures on highly oriented pyrolytic graphite (HOPG): an ab initio and experimental study. Faraday Discuss 172:327–347

Lee I, Chan KY, Phillips DL (1998) Growth of electrodeposited platinum nanocrystals studied by atomic force microscopy. Appl Surf Sci 136:321–330

Lu G, Zangari G (2005) Electrodeposition of platinum on highly oriented pyrolytic graphite. Part I: electrochemical characterization. J Phys Chem B 109:7998–8007

Lu G, Zangari G (2006) Electrodeposition of platinum nanoparticles on highly oriented pyrolitic graphite: part II: morphological characterization by atomic force microscopy. Electrochim Acta 51:2531–2538

Mizukami F, Taniguchi F, Kiyozumi Y, Kobayashi A, Izutsu H, Maeda K (1994) The formation of rings of platinum dots and the control of the size of platinum particles on silica surfaces using organic—inorganic composites. Adv Mater 6:856–858

Mukerjee SJ (1990) Particle size and structural effects in platinum electrocatalysis. J Appl Electrochem 20:537–548

Ong BC, Kamarudin SK, Basri S (2017) Direct liquid fuel cells: a review. Int J Hydrog Energy 42:10142–10157

Quaino PM, Gennero de Chialvo MR, Vela ME, Salvarezza RC (2005) Self-assembly of platinum nanowires on HOPG. J Argent Chem Soc 93:215–224

Randin JP, Yeager E (1975) Differential capacitance study on the edge orientation of pyrolytic graphite and glassy carbon electrodes. J Electroanal Chem Interfacial Electrochem 58:313–322

Rao CRK, Trivedi DC (2005) Chemical and electrochemical depositions of platinum group metals and their applications. Coordin Chem Rev 249:613–631

Ray KG, McCreery RL (1999) Characterization of the surface carbonyl and hydroxyl coverage on glassy carbon electrodes using Raman spectroscopy. J Electroanal Chem 469:150–158

Rodríguez-Reinoso F (1998) The role of carbon materials in heterogeneous catalysis. Carbon 36:159–175

Samad S, Loh KS, Wong WY, Lee TK, Sunarso J, Chong ST, Daud WRW (2018) Carbon and non-carbon support materials for platinum-based catalysts in fuel cells. Int J Hydrog Energy 43:7823–7854

Shen P, Chi N, Chan KY, Phillips DL (2001) Platinum nanoparticles spontaneously formed on HOPG. Appl Surf Sci 172:159–166

Sherstyuk OV, Pron’kin SN, Chuvilin AL, Salanov AN, Savinova ER, Tsirlina GA, Petrii OA (2000) Platinum electrodeposits on glassy carbon: the formation mechanism, morphology, and adsorption properties. Russ J Electrochem 36:741–751

Singh RN, Awasthi R, Sharma CS (2014) Review: an overview of recent development of platinum-based cathode materials for direct methanol fuel cells. Int J Electrochem Sci 9:5607–5639

Zittel HE, Miller FJ (1965) A glassy-carbon electrode for voltammetry. Anal Chem 37:200–203

Zoval JV, Lee J, Gorer S, Penner RM (1998) Electrochemical preparation of platinum nanocrystallites with size selectivity on basal plane oriented graphite surfaces. J Phys Chem B 102:1166–1175

Acknowledgments

The authors wish to thank the Universidad Nacional del Sur (Argentina) and CONICET-PIP No. 0853 for the financial support of this work. J.J. Arroyo-Gómez acknowledges a fellowship granted by CONICET.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Rights and permissions

About this article

Cite this article

Arroyo-Gómez, J.J., García, S.G. Platinum nanoparticles spontaneously formed on glassy carbon substrates. J Nanopart Res 20, 320 (2018). https://doi.org/10.1007/s11051-018-4427-8

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s11051-018-4427-8