Abstract

Application of nanotechnology in drilling fluids for the oil and gas industry has been a focus of several recent studies. A process for the in situ synthesis of nanoparticles (NPs) into drilling fluids has been developed previously in our group and showed that calcium-based NPs (CNPs) and iron-based NPs (INPs), respectively, with concentrations of 0.5–2.0 wt% can dramatically improve filtration properties of commercial drilling fluids in a laboratory environment. In this work, a modified process for the emulsion-based synthesis of NPs on a 20 m3 volume and its subsequent full-scale field testing are presented. Comparison between NP carrier fluids prepared under controlled environment in the laboratory and those prepared on a large scale in a mixing facility revealed very little variation in the main characteristics of the drilling fluid; including the size of the solid constituents. Transmission electron microscopy photographs suggest an average CNP particle size in the carrier fluid of 51 ± 11 nm. Results from the full-scale field test showed that total mud losses while drilling with CNP-based invert emulsion were on average 27 % lower than in the case of conventional fluids. This loss prevention falls within the range observed in the laboratory.

Graphical Abstract

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Loss of drilling fluids is one of the leading causes of non-productive time and drilling problems. An estimate two decades ago showed that cost associated with fluid loss exceeds $1B annually (Liu and Civan 1994). Invasion of drilling fluid filtrate and suspended solids into a near-wellbore region during drilling operations leads to formation damage and can cause wellbore instability, severe permeability impairment, and a substantial decline in production (Shahri and Zabihi 2012; Jiao and Sharma 1996). In addition, invasion of wellbore fluids often masks the data acquired by most logging tools and has a detrimental impact on formation evaluation (El-Wazeer et al. 1999).

These issues are partially circumvented using lost circulation materials (LCMs), which plug formation pores or fracture throats, form a filter cake, and reduce filtrate flux into formation. Bridging occurs when the size of particles is approximately 1/3 that of a pore opening, and there exists an optimum LCM size range that makes them effective at sealing a respective size of a pore or fracture (Zakaria et al. 2012). Commonly used LCM are granular or fibrous solids ranging anywhere between several µm to several mm in size, which limits their performance in sub-micron pores, such as in the case of tight formations or induced fractures (Nelson 2009). Once a pore opening is bridged and cake is formed, flow of mud filtrate into the formation is described by the radial form of Darcy’s law, and depends on internal properties of the cake, such as porosity and permeability, composition, particle distribution, thickness, compressibility, resistance to erosion under dynamic conditions, and surface forces between particles (Jiao and Sharma 1994). As a result, a thin, quick-forming, filter cake with low permeability can reduce mud losses, prevent fracture formation or propagation by creating a seal between the formation and the hydrostatic pressure in the wellbore, reduce the possibility of differential sticking and can be easily removed by acid wash or hole cleaning.

Recently, several studies have shown that drilling muds that combine conventional LCM with particles in the nanometer domain can dramatically reduce fluid loss and form a thinner filter cake, compared to drilling fluids containing LCM alone (Amanullah and Al-Tahini 2009; Amanullah et al. 2011; Contreras et al. 2014a; Zakaria et al. 2012; Nwaoji et al. 2013; Hoelscher et al. 2013; Li et al. 2013). Due to their small size and high surface area, finely dispersed nanoparticles (NPs) are able to form tighter packing structures and effectively fill the gaps between the micron-sized particles that would otherwise permit fluid flow. Subsequently, this leads to lower permeability and reduced filtrate flux. This process is illustrated in Fig. 1. Furthermore, NPs and their agglomerates can also serve as bridging agents in the case of micro- or nanopores, as was demonstrated in experiments on shales (Sensoy et al. 2009; Contreras et al. 2014b).

In line with these observations, previous experiments on invert emulsion drilling fluids conducted in our lab have shown that in situ prepared NPs are effective at reducing filtrate volume in low pressure, low temperature as well as high pressure, high temperature (HPHT) fluid loss tests (Zakaria et al. 2012). Generally, standard fluid loss tests do not necessarily correspond to the actual mud losses experienced while drilling (Santos et al. 1999). The main goals of the current work were to scale-up the in situ NP preparation method developed earlier in our laboratory to an industry-scale process, and carryout full-scale field testing using NP-based drilling fluid. Six full-scale field tests were conducted in order to provide reliable observations on the performance of NPs under real-life conditions. Depending on the total depth (TD) and diameter of a borehole, volume of mud in a given well can exceed 200 m3. Even at a low concentration of 0.5 wt%, more than a metric ton of NPs would have to be produced onsite. Since better control of mixing was deemed necessary, field testing employed a ‘carrier’ approach, whereby a custom invert emulsion of 20 m3 volume containing 5 wt% in situ calcium-based NPs (CNPs) was first prepared in a specialized mixing facility, then delivered to a rig site where it was diluted to the target concentration.

Materials and methods

Large-scale carrier emulsion synthesis

Without delving into proprietary details, industry-scale synthesis of NP-based carrier emulsion followed a bench-scale process developed in our laboratory (Husein et al. 2012). The CNPs were produced via a water–oil (W/O) microemulsion approach, which served as a mechanism to achieve size control and particle stabilization during chemical co-precipitation of aqueous precursors (Husein and Nassar 2007a, b, 2008). The CNPs were selected for the field implementation due to their good performance in laboratory fluid loss experiments, known compatibility with invert emulsion drilling fluids, low toxicity and inexpensive and widely available precursors. In order to minimize the impact of the carrier emulsion on the basic properties of the drilling fluid, the final formulation was based on an 83/17 ratio of O/W, similar to that used in the drilling operation, and only contained typical oilfield chemicals and additives. The industry-scale process was implemented in a drilling fluids mixing facility equipped with a 150 hp centrifugal pump and high-pressure shear jets.

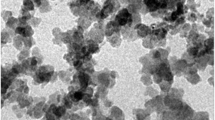

Particle size analysis

Particle size of CNP produced via carrier approach was measured using transmission electron microscopy (TEM; Hitachi H7650), operating at 100 kV accelerating voltage. An aliquot of the carrier emulsion was taken prior to addition of organophilic clays and diluted in absolute ethanol. Following centrifugation at 4000 rpm for 10 min, washing with ethanol was repeated four more times to ensure removal of residual oil and emulsifiers. Subsequently, centrifuged solids were washed with deionized water five times to remove excess lime until pH value reached 7. Finally, white powder was dispersed in ethanol and one drop was added onto carbon-coated copper TEM grid for analysis.

Particle size distribution in the as-prepared laboratory and the field-based carrier emulsions was measured using a Malvern Zetasizer Nano ZS operating at 633 nm wavelength and 25 °C (Malvern Instruments Ltd., UK). Samples were first diluted in tetrahydrofuran (Sigma Aldrich, USA) to achieve a concentration of ~100 ppm and then sonicated for 10 min prior to taking the measurement. Four duplicates and two different concentrations per sample were measured and reported as the average. Refractive index and absorbance were tuned to match the material of interest. Distribution and cumulants fit were monitored to ensure that the data met quality criteria and that the background signal of other components in the sample be minimized.

Drilling fluids testing

In order to determine the performance of the carrier emulsion approach for NP preparation and addition relative to our previous techniques (Husein et al. 2012), six different virgin and recycled commercial invert emulsion drilling fluids were tested in the laboratory. All drilling fluid testing was carried out using industry-standard equipment and following the American Petroleum Institute (API) procedures (API 2014). Drilling fluid samples were sheared at 7500 rpm for 30 min using a Hamilton Beach HMD-200 mixer equipped with a sine-wave spindle prior to measurements. Table 1 lists the properties of the fluids involved.

Mud weight (MW) was measured at standard temperature and pressure using a FANN model 140 mud balance (part number 206768, FANN, USA). Three measurements were collected per sample following high-shear mixing. Prior to taking a reading, mud cup was tapped with a metal cap to release gas bubbles. Electrical stability (ES) of the invert emulsion drilling fluids was measured with an OFITE ES tester (model #131-50, OFI, USA). After 30 min of high-shear mixing, a sample of the drilling fluid was transferred into a FANN heating cup (part number 101558383, FANN, USA) set at 50 °C. Temperature was allowed to equilibrate over a 10-min period, after which a sample was rapidly stirred for 2–3 s using a probe, and the reading was taken. Rheology of the drilling fluid samples was evaluated at 50 °C using a FANN model 35 viscometer (FANN, USA). Sample was placed in a heating cup stirred at 600 rpm for 10 min. Dial readings were taken at 600, 300, 200, 100, 6, and 3 rpm. Finally, gel strength was measured at 10 s and 10 min. Dial readings at 600 and 300 were used to calculate the yield point and the plastic viscosity per the following equations:

where μ p is plastic viscosity (cP), τ y is yield point (lb/100 ft2), θ 300 and θ 600 are dial readings at 300 and 600 rpm, respectively.

HPHT fluid loss experiments were carried out using a 175 mL single-capped OFITE HPHT filter press with a 40 cm2 filtration area (model #170-00, OFI, USA). Samples were sheared for 30 min and ~160 mL was loaded into a mud cell. Cell was then assembled and placed inside a heating jacket, where it was allowed to reach the target temperature over a 30-min period. Temperature varied between 80 and 120 °C to match the testing conditions used by mud companies. During the heat-up period, 100 psi of pressure was applied by means of compressed CO2 bulbs to prevent vapor pressure build up. Subsequently, pressure differential was adjusted to 500 psi and the bottom valve stem was opened to initiate filtration. Volume of filtrate was recorded after 30 min and reported as a multiple of 2 to convert the filtration area to the API standard. Cell was then emptied and the thickness of a mud cake was measured using a digital caliper with accuracy of ±0.1 mm. Three readings were taken at different sites of a cake and reported as an average.

Volumetric composition of the drilling fluid samples was performed using an OFITE 50 mL retort kit (part #165-14). Sample cup was filled with a freshly sheared invert in several portions, followed by gentle tapping to release gas bubbles, until the fluid level reached the top of the cap. Fine steel wool was packed into the top part of the holder to prevent non-volatile components from entering the condenser. Liquid fraction was collected in a 50 mL graduated cylinder, and the experiment was stopped when the volume remained constant for 10 min. Total volume in the cylinder as well as the volume of the bottom aqueous phase were recorded and used to calculate volumetric composition of the mud as follows:

where V t is the total volume of liquid fraction, V w is the volume of aqueous fraction, and OWR is the oil–water ratio.

Field test implementation

Six full-scale field tests were conducted in horizontal wells in Alberta, Canada, in partnership with a local drilling fluids company in 2014. The results were compared to control wells, which included historic HPHT fluid loss and mud losses from offset wells in the area provided by the mud operator. All the wells used in the analysis were drilled using the same telescoping double type rig. Lithology in all the cases was represented by fine-grained to conglomeratic sandstone, shale, and coal, with a pay zone in the Cardium Formation. Since the control and test wells employed a similar drilling program and invert emulsion drilling fluid, it was assumed that any significant and consistently reproducible deviation from the average control values was due to the presence of the 10 vol% NP carrier emulsion. Field data for the test wells were collected by the mud company representative as well as our group to further improve experimental accuracy of the results. A subsequent comparison revealed <1 % difference in average values. Finally, to further account for slight variations in experimental conditions, control and test wells were split into four groups based on their surface location, as summarized in Table 2.

A typical field test was conducted per the following standard procedure. Upon arrival to the drilling site, the carrier emulsion was transferred to an empty storage tank. Initially, 10 % vol/vol (~7–8 m3) of carrier was mixed with the circulating drilling fluid to achieve the target concentration of 0.5 wt% CNPs. Following this initial addition, 1 m3 of carrier was used per each 9 m3 of drilling fluid added to the active tank to maintain the 10 vol% ratio, i.e., 0.5 wt% CNPs. Theoretical concentration of CNPs in the mud at a given depth was calculated based on the volume ratio of carrier to the circulating fluid. Samples of the drilling mud were collected from the rig at certain depth intervals of 200–300 m and tested on-site for its MW, rheology, volumetric composition, ES, and filtration properties, as detailed above. Simultaneously, mud loss calculation was performed, as described below. A schematic of field implementation is provided in Fig. 2.

Calculation of mud losses

Mud losses while drilling were estimated via volumetric balance on the total drilling fluid on-site at different depths. While a common practice in industry, this method may be susceptible to large errors if careful measurements are not taken. In addition, the volumetric approach only provides total mud losses without regard to surface versus subsurface sources. As shown schematically in Fig. 3, control volume consisted of five elements; namely a tank farm (V TF), a pre-mix tank (V PM), active tanks (V AT), and a hole (V H). Tank volumes were provided by floating sensors, while the hole volume was calculated for each given depth on the basis of displacement and capacity of each element of a drilling string. Since caliper logs were unavailable, the effect of wellbore enlargement was ignored, i.e., no washout was assumed. In principle, this assumption should not impact our calculations, since they are based on differences between control and field test as long as similar washout is encountered in both. The difference between calculated control volumes at a given depth and the one prior to it corresponds to the ‘instantaneous’ mud losses while drilling (V IL). The total sum of instantaneous losses at a given depth is referred to as cumulative mud loss (V CL). In order to account for differences in measured depth and to standardize the data, cumulative mud losses were converted to losses per 100 m drilled (V L100).

Results and discussion

Carrier emulsion

Properties and long-term stability

In order to provide feedback on the effectiveness of the industry-scale mixing and preparation of the carrier fluid, samples from the 20 m3 carrier fluid were compared with a carrier fluid prepared in the laboratory under controlled environment, e.g., mixing, temperature, etc. The parent drilling fluid was a diesel-based invert emulsion, Distillate D822, with MW of 1050 kg/m3, 83/17 O/W ratio and 8 vol% solids. Organophilic clays were used to impart desirable rheological properties to the final formulation. Table 3 shows a comparison between the two carrier fluids. The relative similarity between the results suggests that the carrier approach was robust even when implemented on a large scale.

Normally, field mud is stored in a tank farm until required and often can remain stagnant for several days at a time. Eventually, this leads to settling of solids at the bottom of the tank, which are then re-suspended by circulating the tank for several hours. Therefore, it was essential to monitor stability of a carrier emulsion upon static aging to further ensure compatibility of the approach with the field conditions. Results of a long-term stability study (not shown) suggested that both laboratory- and field-based samples of a carrier emulsion exhibited similar settling to that of a typical commercial mud. Following 1 week of aging, all three samples were completely homogenized by regular shaking.

Particle characterization

TEM photographs of CNP isolated from the carrier emulsion are provided in Fig. 4. Particle size was estimated manually using ImageJ processing software. Analysis of 86 particles showed that CNP exists as individual rhombohedral calcite nanocrystals with the average size of 51 ± 11 nm. A size distribution histogram provided in Fig. 4 shows relatively narrow size distribution between 10 and 80 nm.

In addition, the particle size distribution of the as-prepared carrier emulsion was determined using dynamic light scattering (DLS) analysis. However, it should be pointed out that the technique is sensitive to the polydispersity in the sample and to the presence of agglomerating or sedimenting particles, which makes invert emulsions very difficult to investigate. Nevertheless, the results presented in Table 4 show that the intensity-average particle size in the laboratory and field prepared carrier was 283 ± 12 and 300 ± 62 nm, respectively. The lower end of this spectrum probably captures CNP size, as suggested by the TEM photograph. On the other hand, intensity size distributions shown in Fig. 5 reveal differences between the samples. While the laboratory prepared carrier shows a range of 150–500 nm, the field sample covers a wider range of particles size, from 50 to 900 nm. In turn, this likely indicates that the high-shear mixing achieved on a laboratory scale provided better size control than the shear employed in the industry-scale process. Husein et al. (2012) suggested that larger size distribution may, in fact, provide the spectrum of sizes needed to plug the different pores encountered during a field application.

Laboratory testing of the carrier emulsion approach

Impact on the properties of invert emulsion drilling fluids

A laboratory-based carrier emulsion was tested with six commercial invert emulsion drilling fluids to determine impact on MW, ES, plastic viscosity, yield point, gel strength, and volume composition.

MW is an important parameter of a drilling fluid, which is maintained within a specified range to ensure proper drilling conditions. Results indicated that addition of 10 vol% carrier emulsion resulted in negligible increase in the MW of the host fluids. This highlights the ability of NPs to impart desirable properties to the drilling fluids without affecting its final density. Conversely, the samples with 0.5 wt% CNPs exhibited lower ES compared to control samples. This effect was especially pronounced in the case of virgin mud samples. Since the recycled fluids were fully conditioned to attain the optimum properties, they also demonstrated better tolerance to the presence of the carrier emulsion. Nevertheless, in all cases the resulting ES was within an acceptable range. The effect of a carrier emulsion on rheology of invert emulsion drilling fluids showed that, while the virgin mud samples were not affected dramatically, plastic viscosity and yield point in the recycled samples increased by up to 15 % in the presence of CNPs, probably due to interaction with other constituents of the recycled mud, e.g., cross linking of polymers. Again, this effect was deemed acceptable for a field application. Finally, addition of a carrier emulsion did not affect gel strengths and volume composition in all six mud samples and the difference remained within the standard deviation of the control samples.

Impact on HPHT fluid loss of invert emulsion drilling fluids

Once it was established that the carrier approach did not dramatically affect the basic properties of invert emulsion drilling fluids, HPHT tests were employed to determine laboratory fluid loss in the presence of CNPs. The results of HPHT experiments are provided in Fig. 6. The results indicate that CNPs reduced the average HPHT fluid loss in virgin Cutter-D and Diesel OBM samples by 52 and 26 %, respectively. This reproduced previous laboratory results obtained with in situ CNPs (Husein et al. 2012). Conversely, the virgin Mineral OBM showed a 5 % increase in the average filtrate volume upon addition of carrier emulsion, which is within the experimental error for the control sample. This lack of performance was attributed to a different nature of the base oil and other components in a mineral-based drilling fluid, which apparently was not compatible with the diesel-based carrier. Correspondingly, filter cake thickness was also lower in the presence of NPs.

Impact of 10 vol% addition of a carrier emulsion on HPHT fluids loss (a, b) and mud cake thickness (c, d) at 80 °C and 500 psi of commercial virgin (a) and recycled (b) invert emulsion drilling fluids. Diagonal pattern corresponds to the control samples, while solid black denotes samples with 0.5 wt% CNPs. Data labels indicate relative change of filtrate volume compared to the control

Compared to the control virgin samples, the control recycled mud samples exhibited much lower HPHT fluid loss. As mentioned earlier, field samples were fully conditioned and already contained the optimum amount of LCM and other additives that are typically not present in the virgin fluids. Nevertheless, filtrate volumes in all three recycled drilling fluids were further reduced in the presence of 0.5 wt% CNPs. The respective reduction in HPHT values for the recycled Cutter-D, Distillate 822, and Megadrill samples was 38, 33, and 44 %, which is rather significant. The results were consistent with the theoretical model of filtration in the presence of NPs presented earlier (Zakaria et al. 2012). Furthermore, laboratory experiments provided a benchmark that was later used to evaluate field performance of a carrier emulsion produced on a large scale.

Field testing of the carrier emulsion approach

Impact on the properties of drilling fluids

Consistent with the laboratory experiments, all six field tests revealed that addition of 10 vol% carrier emulsion did not affect the basic properties of the host Cutter-D and Distillate 822 drilling fluids, which remained within the working range. At the same time, average filtrate volumes in the test wells were reduced by 20–30 % compared to control wells, as shown in Fig. 7. Performance of a field-scale carrier emulsion was comparable to the laboratory-based samples, which suggests that the scale-up process was successful and the data comparing field and laboratory prepared carriers where reliable.

To further aid interpretation of the results, theoretical concentration of a carrier emulsion at a given depth was calculated based on the ratio of storage volume to the circulating mud volume. The results are shown in Fig. 8, and demonstrate an interesting trend toward lower HPHT fluid loss with increasing concentration of a carrier emulsion. Accordingly, filtrate volumes remain constant once an optimum concentration of CNPs in the circulating system is attained. Based on the data, full effect is achieved after sufficient mixing and dispersion of NPs is provided over several circulations. This provides direct evidence of the impact of concentration of carrier emulsion on HPHT fluid loss of invert emulsion drilling fluids.

Mud losses

As stated earlier, the volumetric balance approach does not distinguish between losses that occur downhole and those that take place on the surface. Surface losses are mostly caused by solids control equipment, which include shale shakers and centrifuges. In principle, it is possible to estimate the relative amounts of surface and subsurface losses, but the information required to perform such calculations was not made available. On the other hand, using the same rig equipment and similarities between drilling programs, mud systems, and encountered lithological sequences meant that on average, each well within a given group experienced similar volume of surface-related losses while drilling. Since it was assumed that CNPs could only affect downhole losses, the resulting differences between control and test wells were attributed to the presence of a carrier emulsion.

Cumulative mud losses while drilling were estimated according to the aforementioned procedure. The results are plotted in Fig. 9 and suggest that test wells on average showed lower losses while drilling compared to the control wells.

In groups A and C, test wells deviated further from the control group at later stages of drilling, which corresponds to a lateral section in a sandstone formation. On the one hand, this may indicate that CNPs helped to reduce filtrate flux into porous and permeable rock, according to the theoretical predictions (Zakaria et al. 2012). On the other hand, this trend was not observed in well group B, and hence a definite conclusion could not be drawn. Groups B and D also exhibited good reproducibility between test wells, whereas mud losses in control group C varied by as much as 40 m3. Furthermore, mud losses in the test wells seem to follow a straight line compared to the control wells. This may suggest that wellbore strengthening took place, which provided stability to the wellbore and minimized downhole losses (Contreras et al. 2014c).

In order to compare the final mud losses in the control and test wells, cumulative losses at TD and the corresponding average losses per 100 m drilled are plotted in Fig. 10.

The average control final losses in groups A–C were in close proximity at 79 ± 3, 77 ± 3, and 82 ± 7 m3, respectively. Subsequently, the same groups showed a 22–34 % reduction of mud losses in the presence of 10 vol% carrier emulsion. Group D showed losses of 82 and 72 m3, which was comparable to the control average. However, in order to compare the data directly, it was necessary to account for differences in the TD between the wells. Figure 10b shows the average mud losses standardized per 100 m drilled. Control wells exhibited losses in the range of 2.5–3 m3/100 m, which is typical based on mud operator’s previous experience in the area. Conversely, losses in the test wells were between 1.9 and 2.5 m3/100 m, which again demonstrates volume loss reduction in the presence of CNPs.

Conclusions

In conclusion, a novel approach for introducing NPs into drilling fluids using a carrier method was developed and successfully scaled up to a field application. The bench-scale method was implemented at a specialized drilling fluids mixing facility on a 20 m3 scale and produced similar final properties of a carrier emulsion. TEM photographs suggest an average size CNPs of 51 ± 11 nm. DLS analysis suggested that the scale-up process did not affect the average size of the solid constituents of the mud, where intensity-average remained at approximately 300 nm. Carrier emulsions remained stable after 1 week of static aging and exhibited rate of settling similar to that of a commercial drilling fluid.

Employing the carrier approach of adding the CNPs, lab results suggested that HPHT fluid loss was reduced by 20–30 % in the presence of 0.5 wt% CNPs in different virgin and recycled commercial drilling fluids. Meanwhile, impact on the basic mud properties was within a range encountered during normal drilling operations.

Six field tests were conducted using a carrier approach. The process was compatible with the existing operations and did not cause any disruptions or drilling problems. HPHT fluid loss displayed the same range of fluid loss reduction, 20–30 %, encountered in the laboratory setting. Correspondingly, total mud losses were reduced by 22–34 % in the presence of 0.5 wt% CNPs, which was deemed as economically feasible by industry.

References

Amanullah M, Al-Tahini A (2009) Nano-technology—its significance in smart fluid development for oil and gas field application. In: SPE 126102, SPE Saudi Arabia section technical symposium and exhibition, AlKhobar, Saudi Arabia, 9–11 May 2009

Amanullah M, Al-Arfaj M, Al-Abdullatif Z (2011) Preliminary test results of nano-based drilling fluids for oil and gas field application. In: SPE/IADC 139534, SPE/IADC drilling conference and exhibition, Amsterdam, Netherlands, 1–3 March 2011

API RP-13B (2014) Recommended practice for field testing oil-based drilling fluids. pp 1–141

Contreras O, Hareland G, Husein M, Nygaard R, Alsaba M (2014a) Application of in-house prepared nanoparticles as filtration control additive to reduce formation damage. In: SPE 168116-MS, SPE international symposium and exhibition on formation damage control, Lafayette, Louisiana, USA, 26–28 February 2014

Contreras O, Hareland G, Husein M, Nygaard R, Alsaba M (2014b) Experimental investigation on wellbore strengthening in shales by means of nanoparticle-based drilling fluids In: SPE 170589, SPE annual technical conference and exhibition, Amsterdam, Netherlands, 27–29 October 2014

Contreras O, Hareland G, Husein M, Nygaard R, Alsaba M (2014c) Wellbore strengthening in sandstones by means of nanoparticle-based NPs applications in drilling industry. In: SPE 170263, SPE deepwater drilling and completions conference, Galveston, Texas, USA, 10–11 September 2014

El-Wazeer F, Haggag M, El-Farouk O (1999) Formation evaluation masked by mud invasion. In: SPE 53152, SPE Middle East oil show, Bahrain, 20–23 February 1999

Hoelscher KP, Young S, Friedheim J, Stefano GD (2013) Nanotechnology application in drilling fluids. In: Offshore Mediterranean conference and exhibition, Ravenna, Italy, 20–22 March 2013

Husein M, Nassar NN (2007a) Study and modeling of iron hydroxide nanoparticles uptake by AOT (w/o) microemulsions. Langmuir 23(26):13093–13103

Husein M, Nassar NN (2007b) Effect of microemulsion on copper oxide nanoparticles uptake by AOT microemulsion. J Colloid Interface Sci 316:442–450

Husein M, Nassar NN (2008) Nanoparticles preparation using the single microemulsion scheme. Curr Nanosci 4:370–380

Husein M, Zakaria M, Hareland G (2012) Novel nanoparticle-containing drilling fluids to mitigate fluid loss. PCT Application: PCT/CA2012/050075

Jiao D, Sharma M (1994) Mechanism of cake buildup in crossflow filtration of colloidal suspensions. J Colloid Interface Sci 162:454–462

Jiao D, Sharma M (1996) Mud induced formation damage in fractured reservoirs. In: SPE 30107, European formation damage control conference, Hague, Netherlands, 15–16 May 1996

Li L, Yuan X, Sun J, Xu X, Li S, Wang L (2013) Vital role of nanotechnology and nanomaterials in the field of oilfield chemistry. In: IPTC 16401, international petroleum technology conference, Beijing, China, 26–28 March 2013

Liu X, Civan F (1994) Formation damage and skin factor due to filter cake formation and fines migration in the near-wellbore region. In: SPE 27364, SPE international symposium on formation damage control, Lafayette, Louisiana, USA, 7–10 February 1994

Nelson PH (2009) Pore-throat sizes in sandstones, tight sandstones, and shales. Am Assoc Pet Geol Bull 93:329–340

Nwaoji CO, Hareland G, Husein M, Nygaard R, Zakaria FM (2013) Nano-particle drilling fluid experimental design using hydraulic fracture apparatus. In: SPE 163434-MS, SPE/IADC drilling conference and exhibition, Amsterdam, The Netherlands, 5–7 March 2013

Santos H, Villas-Boas MB, Lomba RFT, Sa CHM, Oliveira SF, Costa JF (1999) API filtrate and drilling fluid invasion: is there any correlation? In: SPE 53791, Latin American and Caribbean petroleum engineering conference, Caracas, Venezuela, 21–23 April 1999

Sensoy T, Chenevert ME, Sharma MM (2009) Minimizing water invasion in shale using nanoparticles. In: SPE 124429, SPE annual technical conference and exhibition, New Orleans, Louisiana, USA, 4–7 October 2009

Shahri P, Zabihi S (2012) A new model for determining the radius of mud loss during drilling operation in a radial fractured network. In: SPE 163028, Nigerian annual international conference and exhibition, Abuja, 6–8 August 2012

Zakaria M, Husein M, Hareland G (2012) Novel nanoparticle-based drilling fluid with improved characteristics. In: SPE 156992 international oilfield nanotechnology conference and exhibition, Noordwijk, The Netherlands, 12–14 June 2012

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Borisov, A.S., Husein, M. & Hareland, G. A field application of nanoparticle-based invert emulsion drilling fluids. J Nanopart Res 17, 340 (2015). https://doi.org/10.1007/s11051-015-3143-x

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s11051-015-3143-x