Abstract

This article presents a facile and green route to the synthesis of hollow silica particles by means of anionic particles of poly(sodium methacrylate) (PMANa) as templates. This method was composed of the following three steps: formation of PMANa particles in ethanol by nanoprecipitation, the deposition of silica shell on the polymer cores through sol–gel process of tetraethylorthosilicate under catalysis of ammonia, and removal of the polymer templates by washing with water. The templates’ size can be controlled in the range of about 70–140 nm by altering the ratio of ethanol to water, the polymer solution concentration, the ethanol amount in polymer solution, and the silica shell thickness can be adjusted between 15 and 30 nm by varying the ratio of silica precursor to the polymer cores. A tentative interpretation about the silica-coating process on the anionic PMANa particles was also proposed according to the experimental results.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

In the last decade, the synthesis of micro-and nanosized inorganic hollow particles has attracted extensive attention because of their unique properties and wide variety of potential applications in catalysis, as adsorbents, controlled release materials, coatings, and composite materials (Zhu et al. 2005; Yuan et al. 2003; Zhu et al. 2010). Owing to the well-controlled kinetics of hydrolysis and condensation of silicon alkoxide and excellent performance, silica is the most popular inorganic matrix both for hollow structures and mesoporous materials (Lynch et al. 2005; Fuji et al. 2012; Cao et al. 2012). Many preparation methods for hollow silica particles have been reported, including hard-template (Yang et al. 2008; Zhao et al. 2009), soft-template (Liu et al. 2010; Wu and Xu2010), self-template (Zhang et al. 2008; Wang et al. 2007), and the etching methods (Chen et al. 2014; You et al. 2013).Among these, multistep hard-template and soft-template methods have been the most effective and commonly used methods (Hoffmann et al. 2006; Caruso et al. 1998).In the first step, the template particles with certain size and specific surface are synthesized by different methods. In the second step, core–shell particles are formed via the hydrolysis and condensation of silica precursor, typically tetraethyl orthosilicate (TEOS) under basic conditions, or via layer-by-layer assembly technique. In the third step, the core templates are removed by either calcinations at elevated temperature or chemical etching with acid, alkaline, or organic solvents to achieve hollow silica spheres.

The templates play a pivotal role in the control of morphology, cavity size and shell thickness of hollow silica particles. There has been growing interest in the use of polymer particles templates, such as latex or micelles because it is easy to control the surface functionality, size and structure of the polymer particles. Sufficient affinity between the silica primary particles or hydrolyzed species of silica precursor and the template’s surface is crucial for the successful coating process of outer silica shell. Polymer particles with positively charged surface are often used for silica coating because the strong electrostatic interaction between negatively charged silica and positively charged surfaces are assumed to be beneficial for formation of the core–shell structure. The cationic surface can be achieved by in situ emulsion polymerization or dispersion polymerization using cationic initiator or cationic comonomer (Chen et al. 2005; Deng et al. 2006). Post-modification is another approach to introduce positively charged groups or macromolecules onto the surface of the pre-formed polymer particles. Poly(diallyldimethylammonium chloride) or poly(allylamine hydrochloride) are often employed to modify the polymer particles’ surfaces for fabrication of polymer/silica core/shell structures and hollow particles (Zhang et al. 2009; Li et al. 2013).In addition, poly(vinyl pyrrolidone) (PVP) have been used to modify the surface of negatively charged and positively charged polymer particles and been viewed as “connective glue” or “coupling agent” during the coating process of silica (Graf et al. 2003; Chen et al. 2006; Gao et al. 2013). Incorporation of silane coupling agents, such as, γ-methacryloxypropyltrimethoxysilane, on the polymer particle templates surface via acting as a functional comonomer in heterogeneous polymerization process, is another route that can afford affinity between the silica shell and the polymer particle’s surface (Tissot et al. 2001, 2002; Ding et al. 2004). Recently, micelles of block copolymers (BCPs) have been used as the soft templates for the preparation of hollow silica particles with about 100-nm diameter. For example, PS-b-P2VP (polystyrene-block-poly-2-vinylpyridine) block copolymer nanoparticles with size of 100 nm were successfully fabricated using a reprecipitation method and served as templates to generate silica hollow nanoparticles. Poly(styrene-b-2-vinylpyridine-b-ethylene oxide) (PS-b-PVP-b-PEO) triblock copolymer has also been used to prepare hollow silica nanospheres with uniform size (Lim et al. 2012; Khanal et al. 2007). Although polymer hard templates and soft templates are attractive, such fabrication procedures are usually complicated, uneconomic, and may raise environmental concerns. For instance, the synthesis of BCPs employing living or controlled polymerization requires stringent conditions. The preparation process of uniform BCPs micelle is time consuming, and organic solvent is often employed in the synthesis system. Therefore, new strategies are highly desired for facile, energy-efficient, and low-cost preparation of templates and hollow silica spheres (Fuji et al. 2014).

Although positive charge on the templates as mentioned above is assumed to be important for the coating of negatively charged silica, negatively charged templates were also reported in several studies. Wan and Yu employed the colloid particles of ammonia-neutralized poly(acrylic acid) as the template cores for silica coating (Wan and Yu 2008), and Cohen improved the process and mechanism proposed by Yu (Du et al. 2010). Nomura used negative bacterium templates to prepare hollow silica microparticles (Nomura et al. 2010). Konno investigated anionic and cationic liposome templates for silica coating and found that well-dispersed hollow silica particles could be obtained by using anionic liposome templates, whereas silica aggregation occurred for cationic liposome cores (Ishii et al. 2012).

Herein, we introduce a simple method for the fabrication of hollow silica templated by water-soluble negatively charged polyelectrolyte particles formed via nanoprecipitation. First, poly(sodium methacrylate) (PMANa) aqueous solution was added into ethanol, and polymer particles were formed instantly because ethanol acted as a nonsolvent toward PMANa. As the precipitated PMANa particles have negative charge on the particle’s surface, the formed particles remain stable in the mixed solvent of ethanol and water, due to the repulsive forces among the same charges on the particle surface. Then, the deposition of silica shell was performed by sol–gel process of TEOS catalyzed by ammonia. At last, the polymer templates were removed by washing with water. In comparison with other techniques, the main differences and advantages of the method used in this paper are that PMANa particles are prepared in an ethanol/water medium, in which hydrolysis and condensation of TEOS is conducted directly, and no exchange of solvent is required; and the removal of the polymer templates was carried out in water, which is energy-saving compared to templates removal by thermal decomposition and environmental-friendly compared to those dissolution strategies using organic solvent.

Experimental section

Materials

Poly(sodium methacrylate) (PMANa, M w = 9500 g mol−1, 35 wt% aqueous solution) was purchased from Polysciences, Inc. TEOS, ethanol (99.5 % by volume), and ammonia solution (28 wt%) were purchased from Wako Pure Chemical Industries, Ltd. and used without further purification. Deionized water was used for all reaction and treatment processes.

Preparation of PMANa particles

PMANa particles were prepared by nanoprecipitation using ethanol as the nonsolvent. First, PMANa solution was diluted with water to form homogeneous solution with different concentrations. In a typical synthesis of polymer particles, 0.6 mL ethanol was added dropwise to 2.0 mL of 6.0 w/v % PMANa aqueous solution under magnetic stirring. Thereafter, the polymer solution was poured into 40 mL ethanol under continuous agitation with magnetic stirrer. With the addition of polymer solution, the transparent ethanol solution turned to slightly milky with bluish opalescence, indicating the formation of polymer nanoparticles. Then the suspension was stirred for 30 min before silica coating.

Synthesis of silica-coated PMANa particles and the corresponding hollow particles

Silica was directly coated onto the surface of the resulting PMANa particles to form core–shell particles at room temperature by the Stőber method. Ammonia solution was added to the as-formed PMANa suspension and stirred for 5 min. A desired amount of TEOS ethanol solution (ethanol volume is twice that of TEOS) was added dropwise to the as-synthesized PMANa suspension to carry out the silica growth reaction for 12 h under continuous agitation with magnetic stirrer. Afterward, the as-prepared particles were collected by centrifugation (15,000 rpm, 12 min), and washed three times with ethanol to remove the residual ammonia and unreacted compounds. The removal of the polymer cores was performed by successive centrifugations/redispersions in water. Finally, the particles were dried at 100 °C to get the hollow silica particles.

Characterization

Dynamic light scattering (DLS) and zeta potential analysis were carried out using a Brookhaven Instruments PALS (diode laser BI-DPSS wavelength of 659 nm). The morphologies of the polymer particles, core–shell, and hollow silica particles were observed using a scanning electron microscope (SEM, JSM-7600F, JEOL, 15.0 kV) with secondary electron image and transmission electron diffraction. The particles were dispersed in ethanol by ultrasonication, and the suspension was dropped on a microgrid, and then dried in the air. The thermal properties of the samples were investigated using thermogravimetry (TG, TG-8120, Rigaku, Japan) under air atmosphere. The temperature was increased at the rate of 10 °C/min from 25 to 800 °C.

Results and discussion

Synthesis of PMANa particles

Nanoprecipitation is a simple approach to generate polymer nanoparticles and is also called solvent displacement method. Nanoparticles are precipitated from polymer chains in solution due to supersaturation resulting from displacing a solvent with a nonsolvent (Andre’s et al. 2010; Nagavarma et al. 2012; Lou and Archer 2008). In general, it involves the precipitation of a preformed polymer from an organic solution and the diffusion of the organic solvent in the aqueous medium in the presence or the absence of a surfactant. The key variables determining the success of polymer nanoparticles by nanoprecipitation are those associated with the conditions of adding the organic phase to the aqueous phase, such as organic phase concentration, aqueous phase agitation rate, and the ratio of organic phase to aqueous phase, etc. In this study, water-soluble anionic PMANa was employed to fabricate the polymer template particles via nanoprecipitation using ethanol as the nonsolvent.

When the aqueous solution of PMANa was added to a large amount of ethanol, PMANa macromolecules would precipitate as ethanol acts as a nonsolvent toward PMANa. When 10 and 7.5 w/v % PMANa aqueous solutions were added into ethanol under stirring, macroscopic precipitates were generated at the bottom of the container. When the concentration decreased to about 6.0 w/v %, semitransparent stable suspension with blue opalescence was obtained, indicating the formation of small particles in the medium. Therefore, the concentration of PMANa aqueous solution used was controlled below 6.0 w/v %.

By varying the ratio of ethanol to water and the concentration of PMANa solution, PMANa particles with different diameters were prepared, and the results are summarized in Table 1 together with synthetic conditions. From Table 1, it can be seen that the diameter of the obtained particles was in the range of 78–142 nm. From the comparison of the diameter data of Samples 1 and 2, it can be seen that the particles size decreased significantly with the increasing ratio of ethanol/water (nonsolvent-to-solvent ratio). The influence of polymer concentration can be found through the data of Samples 6 and 7. Keeping other conditions constant, the particle size decreased from 142 to 85 nm when the polymer solution concentration decreased from 4.62 to 3.46 w/v %. Furthermore, nonsolvent incorporation into polymer solution often results in particle size reduction (Chorny et al. 2002). The size reduction may be attributed to two aspects: the decrease of polymer concentration by nonsolvent dilution and the more contracted conformation of macromolecular chains in the mixture of solvent and nonsolvent. Therefore, little amount of ethanol was added in several samples. Although the ethanol/water ratio in Sample 5 was much higher than that in Sample 4, the diameter values of Sample 4 were smaller than that of Sample 5, which can be ascribed to the addition of ethanol in polymer solution in Sample 4. Meanwhile,the addition of ethanol in PMANa aqueous solution has another effect. In water, charged polymers like PMANa often exhibit significant intramolecular electrostatic repulsion causing them to behave like stiff elongated structures. While in the mixture of ethanol/water, PMANa macromolecular chains may adopt slightly tight and contracted conformation because the charge density of PMANa is reduced. The contracted conformation may be another factor for the decrease of PMANa particle size. The total polymer concentration was in the range of 32.0–50.0 g/L. It is worth pointing out that the polymer concentration used in this study is much higher than those recommended concentrations varying between 0.2 and 1 wt% in the literature (Lince et al. 2008). Furthermore, the particles sizes are smaller than those reported in the literature. These differences may be attributed to the significant difference between the polyelectrolyte employed here and those uncharged polymers in the literature. The zeta-potentials of all the PMANa particles were ranging from −46.0 to −25.4 mV, indicating the existence of negative charge on the particle surface. The electrostatic repulsive forces among the negatively charged particles endow the formed suspension with excellent stability. All the PMANa suspensions can be stored for at least 2 weeks without noticeable change of the particles sizes and size distribution.

Figure 1 shows the intensity-average diameters of partial PMANa particles (Sample 3–Sample 6) determined by DLS. The size distributions presented by DLS were relatively narrow. The polydipersities of all of the particle sizes were in the range of 0.11–0.13. We try to observe the particles using SEM. However, smooth polymer film was observed on the microgrid, while no particles or particle aggregates were found. This result reveals that the polymer particles in the medium was soft and may be in solvent-swollen state. A certain amount of water should be trapped inside the as-formed particles due to the high hydrophilicity of PMANa. During the evaporation of ethanol and water when drying the sample on copper mesh, the water-rich particles fused and adhered together to form a smooth film. This unique property of PMANa can also explain the significant diameter difference between Sample 1 and Sample 2. More water was absorbed by PMANa particles with more water content in the precipitation system, leading to larger particles’ sizes. More importantly, the trapped water will facilitate the silica deposition on the resultant PMANa cores (this will be discussed in the subsequent section).

DLS results of synthesized PMANa particles with different sizes. Conditions see Table 1

Synthesis of hollow silica particles using PMANa cores

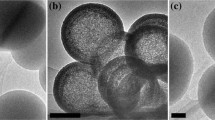

With the as-synthesized PMANa particles as template cores and ammonia as catalyst, the hydrolysis and condensation of TEOS were performed at room temperature for 12 h. Figure 2. shows the SEM and STEM images of the obtained silica particles using Sample 3 in Table 1 as templates before (Fig. 2a, b) and after the removal of the polymer particles by extraction with water (Fig. 2c, d). The noticeable contrast between the core and the shell of the particles in Fig. 2d implies the formation of hollow core structure. Interestingly, the particles before washing with water also exhibits inner void (Fig. 2b), although the contrast between the core and the shell was not as clear as that in the samples after washing with water. This may be attributed to the solvent-swollen state of PMANa cores in the reaction system as mentioned above. After evaporation of ethanol and water, the PMANa macromolecules in the core–shell particles would precipitate on the inner surface of the silica particles, leaving the hollow space inside. It can be seen from Fig. 2 that besides some spherical particles, more particles exhibit irregular morphologies, like podiform or peanut-shaped morphologies. It seems that the bigger irregular particles were fused by the smaller ones, as evidenced by the uniform size in width of most particles. The shape and size of the silica particles remained almost unchanged before and after washing with water, which indicates that the removal of PMANa cores by water did not destroy the silica shell. The reason might be that the pores in silica shells prepared by the Stöber method are sufficiently large for the diffusion of dissolved macromolecule chains out of the shell (Lu et al. 2004).The outer size in width, shell thickness, and cavity sizes of the most of the particles in Fig. 2c, d were estimated to be from 60 to 90, 15 nm, and from 38 to 60 nm, respectively. The outer size in width and shell thickness in Fig. 2a, b were estimated to be in the range of 70–100 and 15 nm, respectively. Figure 3 shows the images of the hollow particles templated by Sample 3 using the same amounts of ammonia as in Fig. 2 but more amount of TEOS (1.2 mL in Fig. 2 and 2.0 mL in Fig. 3). Compared with the images in Fig. 2, the structure of the podiform or peanut-shaped particles can be observed clearly. The irregular particles have two or more cavities with border among them. It was obvious that two, three, or even more spheres aggregated to form a merged particle during the coating process. These phenomena were commonly found in the case of increased TEOS addition when soft micelle templates, or even quasi-hard templates were adopted (Khanal et al. 2007; Su et al. 2011).The main values of the outer diameter in width, thickness of the shell, and void diameter of the hollow particles in Fig. 3 were from 90 to 130, 30 nm, and from 22 to 55 nm, respectively. The shrinkage of the cavities size in Fig. 3 compared to those in Fig. 2 is reasonable because the solvent-swollen core may become compact after the deposition of solid silica shell, especially when the water dissipated by hydrolysis of TEOS was taken into account. Furthermore, it is obvious from both SEM and STEM images that the surface of the hollow particles obtained with more TEOS is smoother compared to the rough surface shown in Fig. 2.

SEM and STEM images of the silica particles before (a, b) and after (c, d) extraction with water. Conditions Sample 3 in Table 1 served as the templates; the volumes of ammonia solution and TEOS were 1.0 and 1.2 mL, respectively

SEM and STEM images of the hollow silica particles using Sample 3 as templates. Conditions Sample 3 in Table 1 served as the templates; the volumes of ammonia solution and TEOS were 1.0 and 2.0 mL, respectively

When the amount of ammonia was increased to 1.5 mL and the other conditions were kept constant as those in Fig. 3, the silica particles with high percent of peanut-shaped particles with uniform width were obtained as shown in Fig. 4. In addition, the surface was rougher in comparison to those in Fig. 2. This is consistent with the observations in the literature that the high hydrolysis and the condensation rates of TEOS under high ammonia concentration lead to larger primary or secondary silica particles (Kim et al. 2013). Also, larger constituent particles or loosely packed particles in silica shell in Fig. 4 made the shell brighter under TEM due to higher electron beam transmission compared with the silica shell of other hollow particles. The total size in width in Fig. 4 was ranging from 90 to 105 nm with shell thickness of about 20 nm. Furthermore, the void size increased to the range of 55–70 nm and there were no silica edges like in most of the nonspherical particles, which existed in Fig. 3. It seems that the swollen degree of polymer cores become higher when more ammonia was introduced to the medium. As ammonia has extremely high solubility in water, part of ammonia will diffuse into the water-swelling cores, as well as water introduced by ammonia solution. As a result, two or three soft cores fused completely to form one void in one irregular particle during the silica-coating process. It is worth pointing out that both the colloidal stability in the reaction medium and the overall dispersibility of the obtained hollow particles were excellent, although in some cases, two or three cores aggregated to form merged particles during the silica-coating process. This is one major advantage of the technique in this study. Furthermore, this finding was consistent with Konno’s report that well-dispersed hollow silica particles could be obtained by means of anionic liposome templates (Ishii et al. 2012).

SEM and STEM images of the hollow silica particles using Sample 3 as templates. Conditions Sample 3 in Table 1 served as the templates; the volumes of ammonia solution and TEOS were 1.5 and 2.0 mL, respectively

When Samples 5 and 6 were employed as the templates with 1.0 mL ammonia and 2.0 mL TEOS, hollow silica particles with typical spherical morphology and smooth surface were obtained, as shown in Fig. 5, 6. The size of most of the hollow particles in Fig. 5 was in the range of 60–140 nm with shell thickness in the range of 22–30 nm and cavity sizes in the range of 22–75 nm. The main values of the outer diameter, thickness of the shell, and the void diameter of the hollow particles in Fig. 6 are in the range of 76–128 nm, 30 nm and in the range of 22–55 nm, respectively. More importantly, most of the particles have only one cavity inside. From Table 1, it is clear that the ethanol/water ratios in Sample 5 and 6 are much higher than that in Sample 3. With the increasing ethanol/water ratio, PMANa particles become much harder, and thus, aggregation among the polymer cores was reduced dramatically.

SEM (a) and STEM images (b and c) of the hollow silica particles using Sample 5 as templates. Conditions Sample 5 in Table 1 served as the templates; the volumes of ammonia solution and TEOS were 1.0 mL and 2.0 mL, respectively

SEM and STEM images of the silica particles using Sample 6 as templates. Conditions Sample 6 in Table 1 served as the templates; the volumes of ammonia solution and TEOS were 1.0 and 2.0 mL, respectively

It is worthy to note that no dense SiO2 particles are observed in all of the synthesized samples, indicating that strong affinity existed between the polymer cores and silica nanoparticles or hydrolyzed species of TEOS. The selective growth of silica on the PMANa cores may be attributed to three aspects. First, the water content trapped in the precipitated PMANa particles is higher than that in the continuous phase medium due to high water-absorbing and water-reserving abilities of PMANa, which has been demonstrated by the particles size data with different ethanol/water ratios (Samples 1 and 2 in Table 1). Since ammonia has much higher solubility in water than that in ethanol, ammonia will diffuse into the water-rich polymer particles, which can be verified by the void size differences shown in Fig. 4, 3. Therefore, the water-rich and ammonia-rich polymer cores would serve as nanoreactors for hydrolysis and condensation of TEOS. Poly(acrylic acid) shell was viewed as a nanoreactor for TEOS sol–gel reaction under catalysis of ammonia in Wang and coworker’s work (Chen et al. 2013). Second, PMANa is a weak polyelectrolyte (pKa value of conjugate acid PMAA is about 5.5), which means that part of –COONa groups will be hydrolyzed into COOH forms in aqueous solution. As PMAA has good compatibility with ethanol, the COOH groups tend to locate on the surface of the as-formed particles. The hydrogen-bonding interaction of the carboxylic acid groups on the particles surface with the hydroxyl groups of the hydrolyzed monomer or oligomer of TEOS in the sol–gel process may be the additional driving force for coating of silica on the PMANa particles, which has been put forward in Yang and Kang’ study and D’Acunzi’s dissertation (D’Acunzi 2010; Li et al. 2008). Finally, owing to their relatively small sizes and corresponding large specific surface areas, the surface energy of PMANa nanospheres is very high, thus providing additional interaction for the absorption of hydrolyzed species of TEOS and silica nucleation on the surface of the particles.

Figure 5c presents an enlarged STEM image of the hollow particles using Sample 5 as templates. The silica shell seems to be composed of two layers, especially those with bigger diameter. During the silica-coating process, TEOS, partially hydrolyzed TEOS molecules or oligomers, were not only adsorbed onto the surface of the template but also permeate the surface of the template to inhabit the outer layer of the microspheres, forming the inner silica layer. The remaining hydrolyzed species of TEOS were continually deposited onto the formed silica shell, leading to the formation of the outer silica layer. This unique shell structure is a good proof that the PMANa particles serve as nanoreactors for the reaction of TEOS.

The TG results in Fig. 7. indicate the complete removal of polymer templates. The TG curve shows about 5 % weight loss below 100 °C which is due to the evaporation of the physically adsorbed water from the PMANa cores and within the hollow particle structure. For the core/shell particles, the weight-loss stage in the region of 300–450 °C is a result of the decomposition of the polymer. The weight loss between 300 and 450 °C for the hollow spheres is much less than that of the core/shell particles, indicating that almost all the PMANa is removed by washing with water.

TG curves of the core/shell and hollow silica particles. Conditions see those in Fig. 2

Conclusion

A facile and robust method for the fabrication of hollow silica particles was developed by using water-soluble anionic polyelectrolyte as templates. PMANa nanoparticles were prepared by nanoprecipitation in ethanol and successfully used as the templates for the fabrication of hollow silica particles with size in nanoscale and controlled shell thickness. Based on the silica shell structure, the effects of ammonia amount on the particle size and morphologies, and ethanol/water ratio on the core size, the deposition process and the mechanism of silica shell on the anionic particles were elaborated. As the polymers are stable under reaction conditions, the template materials may be recycled after purification. Furthermore, as there are many kinds of water-soluble anionic homopolymers and copolymers, it means that the template materials may be extended to a variety of negatively charged polymers.

References

Andre´s GM, Jorge PJ, Luis MLM (2010) Recent progress on silica coating of nanoparticles and related nanomaterials. Adv Mater 22:1182–1195

Cao Z, Dong L, Li L, Shang Y, Qi D, Lv Q, Shan G, Ziener U, Landfester K (2012) Preparation of mesoporous submicrometer silica capsules via an interfacial sol–gel process in inverse miniemulsion. Langmuir 28:7023–7032

Caruso F, Caruso RA, Möhwald H (1998) Nanoengineering of inorganic and hybrid hollow spheres by colloidal templating. Science 282:1111–1114

Chen M, Zhou SX, You B, Wu LM (2005) A novel preparation method of raspberry-like PMMA/SiO2 hybrid microspheres. Macromolecules 38:6411–6417

Chen M, Wu LM, Zhou SX, You B (2006) A method for the fabrication of monodisperse hollow silica spheres. Adv Mater 18:801–806

Chen LL, Li L, Zhang LY, Xing SX, Wang TT, Wang Y, Wang CG, Su ZM (2013) Designed fabrication of unique eccentric mesoporous silica nanocluster-based core–shell nanostructures for pH-responsive drug delivery. Appl Mater Interfaces 5:7282–7290

Chen Y, Chen HR, Shi JL (2014) Construction of homogenous/heterogeneous hollow mesoporous silica nanostructures by silica-etching chemistry: principles, synthesis, and applications. Acc Chem Res 47:125–137

Chorny M, Fishbein I, Danenberg HD, Golomb G (2002) Lipophilic drug loaded nanospheres prepared by nanoprecipitation: effect of formulation variables on size, drug recovery and release kinetics. J Control Release 83:389–400

D’Acunzi M (2010) Core–shell particles and their application for super hydrophobic surfaces. Johannes Gutenberg-Universität Mainz, Mainz, pp 55–57

Deng ZW, Chen M, Zhou SX, You B, Wu LM (2006) A Novel method for the fabrication of monodisperse hollow silica spheres. Langmuir 22:6403–6407

Ding XF, Yu KF, Jiang YQ, Bala H, Zhang HB, Wang ZC (2004) A novel approach to the synthesis of hollow silica nanoparticles. Mater Lett 58:3618–3621

Du Y, Luna LE, Tan WS, Rubner MF, Cohen RE (2010) Hollow silica nanoparticles in UV–visible antireflection coatings for poly(methyl methacrylate) substrates. ACS Nano 4:4308–4316

Fang Y, Fang Y, Kaskel S (2010) Folate-conjugated Fe3O4@SiO2 hollow mesoporous spheres for targeted anticancer drug delivery. J Phys. Chem C114:16382–16388

Fuji M, Shin T, Watanabe H, Takei T (2012) Shape-controlled hollow silica nanoparticles synthesized by an inorganic particle template method. Adv Powder Tech 23:562–565

Fuji M, Takai C, Virtudazo RVR (2014) Development of new templating approach for hollow nanoparticles and their applications. Adv Powder Tech 25:91–100

Gao T, Jelle BP, Sandberg LIC, Gustavsen A (2013) Monodisperse hollow silica nanospheres for nano insulation materials: synthesis, characterization, and life cycle assessment. Appl Mater Interfaces 5:761–767

Graf C, Vossen DLJ, Imhof A, van Blaaderen A (2003) A general method to coating at colloidal particles with silica. Langmuir 19:6693–6700

Hoffmann F, Cornelius M, Morell J, Froba M (2006) Silica-based mesoporous organic-inorganic hybrid materials. Angew Chem 45:3216–3251

Ishii H, Sato K, Nagao D, Konno M (2012) Anionic liposome template synthesis of raspberry-like hollow silica particle under ambient conditions with basic catalyst. Colloids Surf B 92:372–376

Khanal A, Inoue Y, Yada M, Nakashima K (2007) Synthesis of silica hollow nanoparticles templated by polymeric micelle with core–shell–corona structure. J Am Chem Soc 129:1534–1535

Kim J, Lee J, Chang H, Choi JW, Jang HD (2013) Synthesis of hollow silica particles with tunable size, shell thickness, and morphology. J Cryst Growth 373:128–131

Li GL, Liu G, Kang ET, Neoh KG, Yang XL (2008) pH-Responsive hollow polymeric microspheres and concentric hollow silica microspheres from silica-polymer core–shell microspheres. Langmuir 24:9050–9055

Li D, Zhu Y, Mao C (2013) One-pot synthesis of surface roughness controlled hollow silica spheres with enhanced drug loading and release profiles under ambient conditions in aqueous solutions. J Mater Chem B 1:5515–5520

Lim CS, Seok SI, Im SH (2012) Synthesis of uniform PS-b-P2VP nanoparticles via reprecipitation and their use as sacrificial templates for inorganic hollow nanoparticles. J Mater Chem 22:8772–8774

Lince F, Marchisio DL, Barresi AA (2008) Strategies to control the particle size distribution of poly-caprolactone nanoparticles for pharmaceutical applications. J Colloid Interface Sci 322:505–515

Liu J, Qiao SZ, Hartono SB, Lu GQ (2010) Monodisperse yolk–shell nanoparticles with a hierarchical porous structure for delivery vehicles and nanoreactors. Angew Chem 122:5101–5105

Lou XW, Archer LA (2008) Hollow micro-/nanostructures: synthesis and applications. Adv Mater 20:3987–4019

Lu Y, McLellan J, Xia Y (2004) Synthesis and crystallization of hybrid spherical colloids composed of polystyrene cores and silica shells. Langmiur 20:3464–3470

Lynch DE, Nawaz Y, Bostrom T (2005) Preparation of sub-micrometer silica shells using poly(1-methylpyrrol-2-ylsquaraine). Langmuir 21:6572–6575

Nagavarma BVN, Hemant KSY, Ayaz A, Vasudha LS, Shivakumar HG (2012) Different techniques for preparation of polymeric nanoparticles-a review 5. Asian J Pharm Clin Res 3:16–23

Nomura T, Morimoto Y, Ishikawa M, Tokumoto H, Konishi Y (2010) Synthesis of hollow silica microparticles from bacterial templates. Adv Powder Tech 21:218–222

Su Y, Yan R, Dan MH, Xu JX, Wang D, Zhang WQ, Liu SX (2011) Synthesis of hierarchical hollow silica microspheres containing surface nanoparticles employing the quasi-hard template of poly(4-vinylpyridine) microspheres. Langmuir 27:8983–8989

Tissot I, Novat C, Lefebvre F, Bourgeat-Lami E (2001) Hybrid latex particles coated with silica. Macromolecules 34:5737–5739

Tissot I, Reymond JP, Lefebvre F, Bourgeat-Lami E (2002) SiOH-functionalized polystyrene latexes: a step toward the synthesis of hollow silica nanoparticles. Chem Mater 14:1325–1331

Wan Y, Yu SH (2008) Polyelectrolyte controlled large-scale synthesis of hollow silica spheres with tunable sizes and wall thicknesses. J Phys Chem C 112:3641–3647

Wang QB, LiuY Yan H (2007) Mechanism of a self-templating synthesis of monodispersed hollow silica nanospheres with tunable size and shell thickness. Chem Commun 23:2339–2341

Wu XJ, Xu D (2010) Soft template synthesis of yolk/silica shell particles. Adv Mater 22:1516–1520

Yang J, Lind JU, Trogle WC (2008) Synthesis of hollow silica and titania nanospheres. Chem Mater 20:2875–2877

You L, Wang TY, Ge JP (2013) When mesoporous silica meets the alkaline polyelectrolyte: a controllable synthesis of functional and hollow nanostructures with a porous shell. Chem Eur J 19:2142–2149

Yuan J, Laubernds K, Zhang Q, Suib SL (2003) Self-assembly of microporous manganese oxide octahedral molecular sieve hexagonal flakes into mesoporous hollow nanospheres. J Am Chem Soc 125:4966–4967

Zhang T, Ge J, Hu Y, Zhang Q, Aloni S, Yin Y (2008) Formation of hollow silica colloids through a spontaneous dissolution–regrowth process. Angew Chem 120:5890–5895

Zhang L, D’Acunzi M, Kappl M, Auernhammer GK, Vollmer D, van Kats CM, van Blaaderen A (2009) Hollow silica spheres: synthesis and mechanical properties. Langmuir 25:2711–2717

Zhao WR, Lang MD, Li YS, Li L, Shi JL (2009) Fabrication of uniform hollow mesoporous silica spheres and ellipsoids of tunable size through a facile hard-templating route. J Mater Chem 19:2778–2783

Zhu Y, Shi J, Shen W, Dong X, Feng J, Ruan M, Li Y (2005) Stimuli-responsive controlled drug release from a hollow mesoporous silica sphere/polyelectrolyte multilayer core–shell structure. Angew Chem Int Ed 44:5083–5087

Acknowledgments

This work was supported by the Advanced Low Carbon Technology Research and Development Program (ALCA) of the Japan Science and Technology Agency (JST).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Shi, Y., Takai, C., Shirai, T. et al. Facile synthesis of hollow silica nanospheres employing anionic PMANa templates. J Nanopart Res 17, 204 (2015). https://doi.org/10.1007/s11051-015-3010-9

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s11051-015-3010-9