Abstract

The paper is devoted to the use of carboxylic acids and salts for the elaboration of stable suspensions of ZnO engineered nanoparticles (40 and 200 nm) in physiological media at pH 6–8. It was shown that the aggregation degree of ZnO-200 particles increases with the growth of carboxylic anion activity, e.g., at pH 7 in the row «Acetate−–Citrate3−–Oxalate2−» the average size of ZnO-200 particles in suspensions amounts to «169–523–770» nm, zeta potential–«35.9–−19.9–+5.42 mV», respectively. The aggregation degree of ZnO-40 particles increases in the row «Citrate3−–Acetate−–Oxalate2−», at pH 7, the average size of ZnO-40 particles in suspension amounts to «50–121–430» nm, zeta potential–«−28.3–−14.5–+2.3» mV, respectively. pH-impact was found to be size-dependent: there was a significantly less effect of pH on adsorption, dispersion, and electrokinetic properties of ZnO-40 particles when compared to ZnO-200 particles. The main reason for the difference between micro- and nanosized particles behavior is a change of the ratio of acidic, basic, and neutral Bronsted centers for particles of nanosized scale.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Among all metal-containing nanoparticles, the zinc oxide has the third biggest global output after SiO2 and TiO2 (550 ton/year) (Piccinno et al. 2012). Zinc nanoparticles are used in the chemical technology (Hasanzadeh et al. 2012), medicine, and biotechnology (Chibber et al. 2013; Zhang et al. 2007; Barnes et al. 2013), in the cosmetic and paint and varnish industries (Fan and Lu 2005; Serpone et al. 2007), and in the semiconductor and sensor manufacturing processes (Singh et al. 2013; Yuzhen et al. 2006; Morkoc et al. 1994; Suchea et al. 2006). The constantly growing output of ZnO causes the growth in the number of nanoparticles emission sources, including the ones into the working air, which leads to their direct contact with a human body (Kolesnikov et al. 2013) and the environment (Ma et al. 2013).

Various scientists have shown that after getting into the respiratory tract, ZnO nanoparticles suppress the phagocytic function of alveolar macrophages, thus causing acute immunodeficiency (Liu et al. 2013), induce cellular apoptosis which leads to tissues destruction (Zhang et al. 2012), and cause the damage of cell membranes as a result of oxidative stress (Huang et al. 2010). Therefore, nowadays, nanoparticles are viewed as pollutants of a new type with unknown toxic doses (Boverhof and David 2010); the mechanisms of their biological action are insufficiently explored.

At the same time, in order to perform biological tests of nanomaterials in ecotoxicology, it is necessary to make stable nanoparticles suspensions, as their dispersity changes much more significantly upon getting in the aquatic environment than the dispersity of micron-sized particles (Buffle 2006). Moreover, nanoparticles suspensions are unstable: their high reactivity promotes dissolution, coagulation, and sedimentation of particles, which impedes the processes of nanoparticles dispersion and their delivery to test organisms (Römer et al. 2011; Farre et al. 2009; Krug 2008).

The nature of a selected solvent is one of the most important criteria of assessing its acceptability. By adding specially selected electrolytes and surfactants, it is possible to effectively maintain the dispersity of suspensions in the physiological environment with a complex composition for a long period of time (Farre et al. 2009). For instance, the lethal dose of fullerenes decreases four times (!) with tetrahydrofuran, which is one of the most efficient fullerene stabilizers (Zhu et al. 2006). Therefore, the search for efficient and non-toxic nanoparticles stabilizers is an urgent nanotoxicology task.

One of the effective nanoparticles stabilizers is carboxylic acids. It has been demonstrated that under certain conditions they are capable of decreasing the coagulation of gold (Jiang et al. 2009; Ghosh 2010), aluminum oxide (Hidber et al. 1996), platinum (Ershov 2001), aluminum (Karepina et al. 2013), silver (Prathna et al. 2011), and other nanoparticles.

As stabilizers, carboxylic acids are capable of performing the function of surfactants by means of adsorbing on a particle and creating a structural-mechanical barrier, and the function of an electrolyte by making an electrostatic barrier due to the dissociation of functional groups (Birdi 2008). The stabilizing function of carboxylic acids and their salts significantly depends on the solution pH, apart from the nature of the substances that constitute the suspension. Despite the fact that carboxylic acids are widely used as stabilizers, the possibility of their usage for making suspensions based on industrial powders is not sufficiently explored.

The purpose of the work is to evaluate the influence of the nature of carboxylic acid-based surfactants and their salts on the stability of ZnO nanoparticles suspensions in a physiological solution with different pH.

Materials and methods

The objects of research

Industrial nanopowders

The nanoparticles of ZnO with the average particle size of 40 and 200 nm were supplied by Nanostructured & Amorphous Materials, Inc., USA, and Empils Zinc, Inc., Russian Federation, respectively. Both types of nanoparticles were obtained by plasmochemical synthesis. The nanopowders were kept in closed containers without moisture access.

Preparation of suspensions and dispersion of particles

Environment for the dispersion of nanoparticles

As a solvent, the 10−2 M HEPES aqueous buffer solution (2-[4-(2-hydroxyethy l)-1-piperazinyl] ethanesulfonic acid) (manufacturer: Biological Industries) was chosen. HEPES is an environmentally safe solvent (Hanitzsch and Küppers 2001) and is widely used in biochemical and ecotoxicological research (Good et al. 1966). The buffer solution was prepared on the basis of distilled water in glassware (the Gesellschaft Labortechnik mbH, D-30938 distiller) at the temperature of 25 °C. The prepared solution was left for 24 h, with the pH amounting to 5.52–5.81. For the purpose of the research, the solutions with the pH equaling 6, 6.5, 7, 7.5, and 8 were used. The pH of the buffer solution was gradated using acid–base titration by 2 % NaOH and HNO3 solutions, constantly stirred with a magnetic stirrer (the Heidolph MR Hei-Tec stirrer, the frequency of 200 cycles per second). The value of the pH was registered using the all-purpose Expert-001 pH indicator (Electronics Expert Ltd., Russia).

Carboxylate-anion solutions

The following sodium salts of carboxylic acids were used as nanoparticles stabilizers in the aquatic dispersion environment: sodium acetate (NaCH3COO, NaAc, Acetate−), sodium oxalate (Na2C2O4, Na2Ox, Oxalate2−), and sodium citrate [Na3C3H5O(COO)3 Na3Cit, Citrate3−].

All surfactants are the key components of intercellular, intracellular, and physiological fluids (Marques et al. 2011) and are not toxic. The surfactant stock solution was prepared on the basis of distilled water (pH 6.11 ± 0.2; 0.2 mcS conductivity); the surfactant concentration in the solution corresponded to the ionic strength (I) of 100 mM. Using the dilution method, a 10 mM solution was prepared from the stock solution. In order to study the nanoparticles aggregation in surfactant solutions with different pH, the dilution of the stock aqueous surfactant solution was performed using the buffer with the necessary pH value.

Preparation of nanoparticles suspensions

The stock suspension of nanoparticles had the 100 mM concentration. The stock suspension was prepared by adding a dry powder sample (the AND GR-202 scales, ±0.0001 g, A&D Co Ltd., Japan) to the HEPES aqueous solution with pH 7 in glassware at the temperature of 25 °C and stirred with the magnetic stirrer (Heidolph MR Hei-Tec) at the frequency of 620 cycles per minute during 3 min (the magnetic stirring component size of 5 × 10 mm). Each time the stock suspension was prepared directly before the experiment.

We added 5 ml of the fresh made stock suspension to the 25 ml of the prepared solutions with the necessary surfactant content and the set value of the pH for nanoparticles dispersion. The measurements were being taken during 2 h, after which the suspensions were utilized and not used for the research.

Suspensions research techniques

The pH monitoring technique was used to evaluate the integral acidity of nanoparticles surface in the suspensions prepared on the basis of deionized water (pH 6.11 ± 0.2, 0.2 mcS conductivity). We poured the 0.8 g powder sample with deionized water, and then the pH in the suspension was measured while constantly stirred with the automatic DL-15 potentiometric titrator (Mettler Toledo GmbH) using the silver chloride electrode DG 115-SC. The reliability of the pH evaluation in a solid body suspension was 90 %, the error—0.05 pH unit.

The value of the suspension pH measurement during the first 5–10 s of the samples’ contacts with water (ΔpH = H10 − pH0) provides information about the air-dry surface condition under which the interaction in the sample-solvent system is represented by dissociation of the surface groups due to the mutual strengths of their fields.

The Hammett indicator adsorption technique was used to differentiate the acid–base surface centers. A 0.02 g sample was put into a 5-ml test tube, then added the necessary indicator volume with a certain pКa value, made up to the volume by deionized water and kept for 2 h until the equilibrium was established. At the same time, we were performing a blank experiment taking into account the influence of the sample’s interaction with the solvent on the optical density measurement in the process of dye adsorption. After the sorption, the solutions were centrifuged, decanted, and the optical density was measured in relation to the solvent (water). Deionized water was used as a dispersion environment. The research in the aqueous suspension allows the analysis in the conditions of maximum surface hydration, whichare common for the surface of samples of any kind, regardless of the way of their preliminary preparation. Degassing and surface cleaning from organic sorbates also take place in the process of hydration.

Dynamic light scattering technique

The aggregative stability of lyosols and suspensions was evaluated based on the measurement of dispersive and electrokinetic particle parameters in the liquid dispersion environment. The measurements were taken using the Zetasizer Nano laser particle analyzer (Malvern, USA) at the temperature of 25 °C (the helium–neon laser, 4 mV laser power, 633 nm wave length). A rectangular polystyrene cuvette with a lid was used for measuring the quantitative particle size distribution. A U-shaped polystyrene cuvette was used for measuring the zeta potential. The quantitative particle size distribution was used to calculate the average particle size (d av) according to the formula:

where d represents the particle size in dispersion, q—the differential percent of particles with size d in the dispersion.

Results and discussion

The surfactants’ influence was assessed by studying the adsorption, electrokinetic, and dispersive properties of the investigated samples in aqueous solutions with different pH values. The pH interval 6–8 was used as an operating range of pH solutions with carboxylic acids used as a stabilizer. There are two reasons for this choice. The first one is the pH values that are the closest to the pH of most physiological fluids. Second, with the pH < 5, the whole undissociated molecules of carboxylic acids may adsorb on the particle surface, which can lead to the neutralization of the charge and decrease the particle stability. With pH > 8.5, a negatively charged carboxylate-anion can shift to the interfacial area only being accompanied by a positively charged ion (Na+), which provokes competition for carboxylate-anion adsorption.

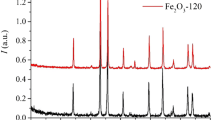

According to the experimental data, aquatic suspensions of the investigated nanoparticles are characterized by the increase of the pH (Fig. 1), which indicates the increase in the main aprotic centers number on the particles surface. With the reduction of the particle size from 200 to 40 nm, the rate of the adsorptive–desorbing equilibrium establishment (H+ ions adsorption) increases from 0.06 to 0.35 pH items per second. At this stage of the research, this can be explained by the fact that smaller particles hydrate more easily due to the surface atoms activity. In case of 200 nm particles, the H+ ions adsorption stage is preceded by a longer process of active adsorption centers formation.

However, according to the Hammett color indicator adsorption technique data, there can exist a different explanation. The results of this method allow to evaluate the adsorptive capacity of the particles and single out the neutral (pKa ≈ 7; Zn–OHδ° type), basic (pKa < 7; Zn—Oδ− type), and acid (pKa > 7; Zn—OHδ+ type) Brønsted centers on the samples surface. The influence of the environment pH on the electrosurface properties and the aggregative stability of suspensions is discussed by analyzing the reactions of acid–base interaction of water molecules with basic and acid surface functional groups:

where Zn–OHδ+ is the group that appears on the surface due to the H+ hydrogen ions adsorption from the liquid bulk phase; Zn–OHδ° is the neutral surface hydroxyl group; Zn—Oδ− is the group that appears on the zinc oxide surface due to the hydroxyl group dissociation and the transition of H+ hydrogen ions into the solution; K 1 and K 2 are the acidity and basicity constants of the surface hydroxyl groups. Such analysis implies the point of zero charge that is established provided equal concentration of the charged –Zn—OH+ and –Zn—O− surface groups and corresponds to the environment pH, i.e.

There are two main differences between particles of different sizes in the selected pH interval (Fig. 2). First, the ZnO-40 particles surface contains mostly Zn—OHδ° centers, while the ZnO-200 particles contain Zn—OHδ+ centers. This result is confirmed by the zeta-potential measurement data (Fig. 3). Indeed, smaller particles have a smaller surface charge that decreases to neutral with pH 8; the point of zero charge for the ZnO-200 particles in the selected pH interval is not registered. Second, if we compare the diagrams (Fig. 2a, b), we can notice that the sorption capacity of ZnO-40 particles is much smaller than the one of ZnO-200 particles. In this case, the result is quite natural, since the surface of 40 nm particles does not have enough charged centers.

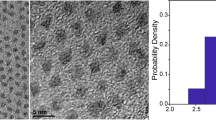

This result can be confirmed by the evaluation of the pH influence on the particles size alteration. Particles are characterized by a high degree of aggregation after getting into the HEPES buffer solutions. Figure 4 shows that the d av size for ZnO-40 particles is increased four times as compared to the original one, with the environment pH in the working interval not influencing the aggregation degree significantly. For ZnO-200 particles, the size of aggregates preserved with pH 6–7; any further increase of the OH− groups concentration leads to a strong particle aggregation (d av increases from 155 to 816 nm).

The electrokinetic measurements confirm the tendency to the intensification of the aggregation for the ZnO-40 powder, where the zeta potential of particles decreases from 15.3 to 0.9 mV with the increase of the pH from 6 to 8. For larger ZnO-200 particles, the pH dependence of the electrokinetic potential is weak and its values fluctuate in the interval of 34–38 mV, with the thickest adsorption layer of the particles registered for the suspensions with pH 6.5 (39 mV zeta potential) (Fig. 3). This agrees with the results of the data obtained by means of the Hammett color indicator adsorption technique, according to which the ZnO-200 particles have the highest sorption activity in this area.

On the whole, we can note that suspensions based on ZnO-40 nanoparticles for which the zeta potential does not exceed 10–15 mV in module have a low aggregative stability. Such systems will coagulate in a very short period of time.

The addition of surfactants to zinc oxide suspensions may cause both their stabilization and their aggregation. The use of sodium acetate and sodium citrate leads to the decrease of the particles aggregation degree (Figs. 5, 7), while oxalate anions, on the contrary, cause stronger particle aggregation as compared to a surfactant free solution. On the whole, with the pH 6–8, the aggregation degree increases with the growth of the carboxylate-anion activity. For instance, with the pH 7, d av amounts to “169–523–770 nm” in the “NaAc–Na3Cit–Na2Ox” row (Fig. 5). At the same time, the stabilizing action of surfactants is more significant for smaller zinc oxide particles (Fig. 7). This result is quite natural, since the stabilizers used in the course of our work are anionic surfactants, and the zinc oxide surface is charged either positively (ZnO-200) or neutrally (ZnO-40) (Fig. 6).

By comparing these data to the results of the zeta-potential measurement, we can notice that the selected surfactants are ineffective electrolyte stabilizers for ZnO-200 particles: NaAc does not change the zeta-potential value (Fig. 6), there is a significant zeta-potential decrease in the Na2Ox solution. There is also particle charge permutation in the Na3Cit solution; its value is minimum with the pH 8, which is essential for a stable suspension (30 mV). Introducing of stabilizers decreases the influence of the pH on the aggregative stability of ZnO-200 particles. This is because there is no surface charge permutation in the process of anions adsorption. The most significant influence of the pH on the zeta-potential value may be observed for ZnO particles with Na3Cit used as a stabilizer (Figs. 6, 8). In this case, this can be due to a partial solubility of zinc oxide in citric acid solutions (Yunda and Godymchuk 2012).

Conclusions

The experimental data allowed to conclude that with the reduction of the ZnO particle size from 200 to 40 nm in the pH interval 6–8, the influence of acidity on absorption and dispersion properties of ZnO particles weakens significantly, but the influence on the electrokinetic properties increases. The surface hydratability increases with the size reduction, and the ratio between the acid, basic, and neutral Brønsted centers alters with the transit to the nano-scale. In the selected pH interval, the ZnO-40 particles surface contains mostly Zn—OHδ° centers, while the ZnO-200 particles contain Zn—OHδ+ centers. Since the surface of 40 nm particles does not have enough charged centers, their sorption capacity in the HEPES buffer and their charge decrease. The use of only HEPES buffer for dispersion without the addition of surfactants at pH 6–7 is limited by a low zeta-potential value (≤10 mV).

It has been stated that the most favorable dispersion conditions for ZnO particles with the average size of 40 nm are the addition of sodium acetate and sodium citrate into the HEPES buffer with pH 7–8: the stable suspensions the absolute zeta-potential value of which exceeds 28 mV are formed, and the conditions allow maintaining the dispersity of the suspensions within the 50–90 nm interval.

The maximum dispersion degree for Zn-200 particles suspensions with the average particle size of 150–400 nm is achieved by adding sodium acetate in the neutral medium (pH 7): the zeta potential of 35.9 mV, the average particle size of 170 nm.

For both suspensions, it is vital to take into account that deviation from the pH interval of 6–8 may cause samples dissolution.

The approaches described in the paper may be used for the development of oxide nanoparticles aggregative-stable suspensions compositions. From the point of view of practicability, the systems, in which it is possible to disperse nanoparticles using the suggested way, may be used for toxicological tests, preparation of aggregative-stable bactericidal suspensions, etc. While preparing stable suspensions, it is vital to take into account that it is almost impossible to predict the impact of stabilizers on small particles without some experimental investigation of the state of their surface.

References

Barnes RJ, Molina R, Xu J, Dobson PJ, Thompson IP (2013) Comparison of TiO2 and ZnO nanoparticles for photocatalytic degradation of methylene blue and the correlated inactivation of gram-positive and gram-negative bacteria. J Nanopart Res 15:1432–1442

Birdi KS (2008) Handbook of surface and colloid chemistry. CRC Press, Boca Raton

Boverhof DR, David RM (2010) Nanomaterial characterization: considerations and needs for hazard assessment and safety evaluation. Anal Bioanal Chem 396:953–961

Buffle J (2006) The key role of environmental colloids of nanoparticles for sustainability of life. Environ Chem 3:155–158

Chibber S, Ansari SA, Satar R (2013) New vision to CuO, ZnO, and TiO2 nanoparticles: their outcome and effects. J Nanopart Res 15:1492–1504

Ershov BG (2001) Metal nanoparticles in aquatic solutions: electronic, optical and catalytic properties. Russ Chem Bull 45(3):20–30

Fan Z, Lu JG (2005) Zinc oxide nanostructures: synthesis and properties. J Nanosci Nanotechnol 5(10):1561–1573

Farre M, Gajda-Schrantz K, Kantiani L, Barcelo D (2009) Ecotoxicity and analysis of nanomaterials in the aquatic environment. Anal Bioanal Chem 393:81–95

Ghosh SK (2010) Spectroscopic evaluation of 4-(dimethylamino)pyridine versus citrate as stabilizing ligand for gold nanoparticles. Colloid Surf A 371:98–103

Good NE, Winget G, Winter W, Connolly TN, Izawa S, Singh RMM (1966) Hydrogen ion buffers for biological research. Biochemistry 5:467–477

Hanitzsch R, Küppers L (2001) The influence of HEPES on light responses of rabbit horizontal cells. Vision Res 41(17):2165–2172

Hasanzadeh M, Shadjou N, Saghatforoush L, Mehdizadeh R, Sanati S (2012) Electrocatalytic oxidation of selected parabens on zinc hydroxide nanoparticles. Catal Commun 19:10–16

Hidber PC, Graule TJ, Gauckler LJ (1996) Citric acid—a dispersant for aqueous alumina suspensions. J Am Ceram Soc 79(7):1857–1867

Huang CC, Aronstam RS, Chen DR, Huang YW (2010) Oxidative stress, calcium homeostasis, and altered gene expression in human lung epithelial cells exposed to ZnO nanoparticles. Toxicol In Vitro 24:45–55

Jiang L, Guan J, Zhao L, Li J, Yang W (2009) pH-dependent aggregation of citrate-capped Au nanoparticles induced by Cu2+ ions: the competition effect of hydroxyl groups with the carboxyl groups. Colloid Surf A 346:216–220

Karepina E, Godymchuk A, Kuznetsov D, Senatova S, Umrikhina M (2013) Irreversible and reversible aggregation of nanoparticles in physiological solutions. Abstracts of the 2nd international school-conference “applied nanotechnology & nanotoxicology”, Russia, Lystvyanka, 15–19 August 2013. Publishing House of Boreskov Institute of Catalysis SB RAS, Novosibirsk, pp 126–127

Kolesnikov EA, Godymchuk AY, Kuznetsov DV (2013) The study of emission sources in the work area nanospray science lab.In: Proceedings of the X international conference “prospects of fundamental sciences development”, Russia, Tomsk, 23–26 April 2013. Publishing House of Tomsk Polytechnic University, Tomsk, pp 911–913

Krug HF (2008) Improving the understanding of the impact of nanoparticles on human health and the environment, Report of the project funded by the EC under the “Structuring the European Research Area”

Liu H, Yang D, Yang H, Zhang H, Zhang W, Fang Y, Lin Z, Tian L, Lin B, Yan J, Xi Z (2013) Comparative study of respiratory tract immune toxicity induced by three sterilisation nanoparticles: silver, zinc oxide and titanium dioxide. J Hazard Mater 248–249:478–486

Ma H, Williams PL, Diamond SA (2013) Ecotoxicity of manufactured ZnO nanoparticles—a review. Environ Pollut 172:76–85

Marques MRC, Loebenberg R, Almukainzi M (2011) Simulated biological fluids with possible application in dissolution testing. Dissolut Technol 118:15–28

Morkoc H, Strite S, Gao GB, Lin ME, Sverdlov B, Burns M (1994) Large-band-gap SiC, III-V nitride, and II-VI ZnSe-based semiconductor device technologies. J Appl Phys. doi:10.1063/1.358463

Piccinno F, Gottschalk F, Seeger S, Nowack B (2012) Industrial production quantities and uses of ten engineered nanomaterials for Europe and the world. J Nanopart Res 14:1109–1120

Prathna TC, Chandrasekaran N, Mukherjee A (2011) Studies on aggregation behaviour of silver nanoparticles in aqueous matrices: effect of surface functionalization and matrix composition. Colloid Surf A 390:216–224

Römer I, White TA, Baalousha M, Chipman K, Viant MR, Lead JR (2011) Aggregation and dispersion of silver nanoparticles in exposure media for aquatic toxicity tests. J Chromatogr A 1218:4226–4233

Serpone N, Dondi D, Albini A (2007) Inorganic and organic UV filters: their role and efficacy in sunscreens and suncare products. Inorg Chim Acta 360:794–802

Singh P, Sinha OP, Srivastava R, Srivastava AK, Thomas SV, Sood KN, Kamalasanan MN (2013) Surface modified ZnO nanoparticles: structure, photophysics, and its optoelectronic application. J Nanopart Res 15:1758–1766

Suchea M, Christoulakis S, Moschovis K, Katsarakis N, Kiriakidis G (2006) ZnO transparent thin films for gas sensor applications. Thin Solid Films 515:551–554

Yunda E, Godymchuk A (2012) Dissolution of zinc nanoparticles in pulmonary fluid. In: Proceedings of the 7th international forum on strategic technology (IFOST 2012), 18–21 September 2012, Russia, Tomsk. – IEEE, Tomsk, pp 208–211

Yuzhen L, Lin G, Huibin X, Lu D, Chunlei Y, Jiannong W, Weikun G, Shihe Y, Ziyu W (2006) Low temperature synthesis and optical properties of small-diameter ZnO nanorods. J Appl Phys. doi:10.1063/1.2200408

Zhang L, Jiang Y, Ding Y, Povey M, York D (2007) Investigation into the antibacterial behaviour of suspensions of ZnO nanoparticles (ZnO nanofluids). J Nanopart Res 9(3):479–489

Zhang J, Song W, Guo J, Zhang J, Sun Z, Ding F, Gao M (2012) Toxic effect of different ZnO particles on mouse alveolar macrophages. J Hazard Mater 219–220:148–155

Zhu S, Oberdörster E, Haasch ML (2006) Toxicity of an engineered nanoparticle (fullerene, C60) in two aquatic species, Daphnia and fathead minnow. Mar Environ Res 62:S5–S9

Acknowledgments

The work was supported by the Ministry of Science and Education of the Russian Federation, Russian Fund for Basic Research (Project # 15-03-06528_a) and in the framework of Increase Competitiveness Program of NUST «MISiS». The authors are grateful for the contributions in the research of the Tomsk regional common use center (agreement #14.594.21.0001).

Author information

Authors and Affiliations

Corresponding author

Additional information

Guest Editor: Liudmyla Rieznichenko

This article is part of the topical collection on Engineered Bioinspired Nanomaterials

Rights and permissions

About this article

Cite this article

Godymchuk, A., Karepina, E., Yunda, E. et al. Stability study of ZnO nanoparticles in aqueous solutions of carboxylate anions. J Nanopart Res 17, 123 (2015). https://doi.org/10.1007/s11051-015-2896-6

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s11051-015-2896-6