The magnetic properties and the changes in the domain structure of alloy Sm(Co, Fe, Cu, Zr)7.5 are studied after different variants of heat treatment, i.e. (1) quenching from 1200°C with cooling in a helium jet; (2) quenching and tempering at 800°C for 16 h, cooling at a rate of 50 K/min to room temperature; and (3) quenching, tempering at 800°C for 16 h, and cooling at a rate of 1.7 K/min. The influence of the heat treatment modes on the coercivity and the domain sizes is determined. The mechanism of variation of these characteristics is analyzed.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Improvement of the properties of permanent magnets is based today on only experimental results, while their theoretical substantiation is often contradictory. However, creation of processes of production of permanent magnets and their control requires knowledge of the nature of the highly coercive state and of the laws of the processes of magnetization reversal of the magnetic alloys.

Alloys based on the Sm(Co, Fe, Cu, Zr)z system have wide application due to the combination of high magnetic properties and temperature stability. A positive temperature coefficient of the coercivity of these alloys has been obtained recently [1, 2]. However, the mechanism of formation of a structure providing a high coercivity has not been explained exhaustively yet and is understood ambiguously. In particular, the causes of substantial growth of coercivity under controlled cooling from 800°C and of reversibility of magnetic properties under low-temperature heat treatment described in [1,2,3] have not been explained.

The aim of the present work was to study the mechanism of formation of magnetic properties and domain structure during heat treatment of an alloy of the Sm(Co, Fe, Cu, Zr)7.5 type with allowance for all the factors affecting the magnetic behavior of the material.

Methods of Study

We conducted experimental studies of an Sm(Co, Fe, Cu, Zr)7.5 alloy of the following chemical composition (in wt.%, ± 0.01): 24.83 Sm, 48.54 Co, 18,23 Fe, 5.92 Cu, 2.59 Zr. The samples were prepared by the standard method employed at the “Spetsmagnit” Company, i.e., casting, milling of the billets into powders, pressing of the powders in a magnetic field, sintering, homogenizing at 1200°C, and cooling to room temperature. Then the samples were tempered at 800°C for 16 h and cooled to 400°C at a rate of 1.7 K/min and then in air.

The metallographic analysis of the samples was conducted using a Polyvar optical microscope in polarized light. To obtain a good contrast and to study the grain boundaries, the samples were polished and then etched in a 3% solution of nital (a mixture of methanol and picric acid) for 5 sec.

The domain magnetic structure was uncovered in a plane perpendicular to the axis of the texture of the sample by the method of Kerr’s polar effect using a Neophot-30 metallographic microscope.

The magnetic properties of the Sm(Co, Fr, Cu, Zr)7.5 alloy were measured using an MH-50 hysteresisograph. The error of the measurement was ± 2%.

Results and Discussion

To analyze the formation of magnetic properties and domain structure in alloy Sm(Co, Fe, Cu, Zr)7.5, we studied specimens heat treated in the following modes: (1) homogenizing at 1200°C, cooling in a jet of cold helium to room temperature, (2 ) mode 1 + 16-h tempering at 800°C, cooling at a rate of 50 K/min to room temperature, and (3) mode 1 + 16-h tempering at 800°C, cooling at a rate of 1.7 K/min to 400°C and then in air to room temperature.

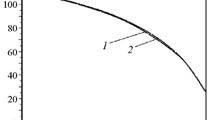

Figure 1 presents the experimental curves of demagnetization of the alloy after different heat treatments. The coercivity of the specimen after rapid cooling from the homogenization temperature (mode 1) is only 10 kA/m (0.115 kOe) (Fig. 1a). It has been reported that after such a treatment the alloy has a structure of a single-phase solid solution of a hexagonal modification of Sm2Co17 [1].

After 16-h tempering at 800°C and cooling at a rate of 50 K/min (mode 2), the Sm(Co, Fe, Cu, Zr)7.5 alloy acquires two phases, i.e., a solid solution with a structure of a tetragonal modification of Sm2Co17 and a solid solution based on a hexagonal phase SmCo5. The metallographic structure is represented by rhombohedral cells of phase Sm2Co17 with a size of about 120 × 70 nm, which are separated by a layer of a hexagonal SmCo5 phase with a thickness of 3 – 6 nm [1, 3]. The coercivity of the alloy in this structural state increases to 75 kA/m (about 1 kOe). It is assumed that the appearance of the fine dispersed phase of type SmCo5 creates places for pinning of the domain wall thus raising the coercivity of the alloy (Fig. 1b).

Figure 1c presents the demagnetization curve of alloy Sm(Co, Fe, Cu, Zr)7.5 after treatment 3 (slow cooling at a rate of 1.7 K/min from 800°C after a hold for 16 h). The coercivity of the alloy after such treatment attains a maximum value of 2350 kA/m (27.5 kOe).

It should be noted that according to the data of [1,2,3,4] the crystal and metallographic structures of the alloy remains virtually unchanged in slow cooling from 800°C. The composition of the boundary phase SmCo5 changes somewhat due to the growth of the concentration of copper and zinc. The width of the zone of the SmCo5 phase increases from 3 – 6 nm to 5 – 10 nm.

Figure 2 presents the photographs of the domain structures of thermally demagnetized (after the heat treatment) specimens of alloy Sm(Co, Fe, Cu, Zr)7.5 in a plane perpendicular to the easy magnetization axis. It can be seen that each subsequent mode of heat treatment causes decrease in the size of the domains.

Thus, decrease in the cooling rate after the tempering from 800°C from 50 K/min to 1.7 K/min provides substantial growth in the coercivity and decrease in the domain size of the specimens in the thermally demagnetized condition. The saturation magnetization of the alloy remains virtually unchanged. The residual magnetization decreases at a low coercivity, because in this case the alloy is demagnetized due to the internal demagnetizing fields. It should be noted that the change in the domain structure of the Sm(Co, Fe, Cu, Zr)7.5 alloy is not as considerable as the growth in its coercivity.

It can be assumed that the growth in the coercivity of the specimens is affected substantially by the elevation of the efficiency of the pinning of the domain wall on the precipitates of phase SmCo5. The intensification of the pinning is connected (1) with the growth in the microstresses on the coherent Sm2Co17/SmCo5 interphase due to the growth in the concentration of the alloying components, (2) with the broadening of the layer of the Smo5 phase, the size of which becomes close to the thickness of the domain wall, and (3) with the change in the ratio of the constants of magnetic crystal anisotropy of the Sm2Co17 and SmCo5 phases [5].

The domain sizes change under the effect of other factors. The main of them is the magnetostatic interaction between microvolumes of the material. A less substantial factor is the easiness of detachment of the domain wall from the place of its pinning in motion. Let us consider this aspect using a model of domain structure after the heat treatments studied.

Figure 3 presents the experimental and computed demagnetization curves for alloy Sm(Co, Fe, Cu, Zr)7.5 after the three variants of heat treatment.

The computation was made using the FMRM software for phenomenological simulation of processes of reversal magnetization [6]. In accordance with [7], this software allows for the magnetostatic interaction between microvolumes. The noticeable deviation of the experimental and theoretical demagnetization curves is explainable by the high error of simulation of the specimen with low coercivity, i.e., 10 kA/m (0.115 kOe).

Figure 4 presents the models of domain structure for alloy Sm(Co, Fe, Cu, Zr)7.5 obtained with the help of the Analyzer software [8] for the three heat treatment modes in question. The red and blue arrows denote the microvolumes in a single-domain condition. The length of the arrows corresponds to the projection of the magnetization of the microvolume onto the direction of the field applied. It can be seen that the size of the domains is the greater, the lower the coercivity of the specimen.

There is one more important moment. The intensity of the magnetostatic interaction depends only on the saturation magnetization of the material. After all the three treatments, the saturation magnetization remains virtually unchanged, which can be seen from the magnetic measurements (Fig. 1). However, with decrease in the coercivity, effect of the field of the magnetostatic interaction will move the domain walls to a greater distance. This means that the effect of the magnetostatic interaction on the growth of the domain size increases.

Thus, the growth of the domain sizes upon decrease in the coercivity of alloy Sm(Co. Fe, Cu, Zr)7.5 is explainable by two factors, i.e., the lowering of the efficiency of pinning of the domain walls and the growth of the effect of the field of magnetostatic interaction on their motion.

Conclusions

1. In the case of hardening of alloy Sm(Co, Fe, Cu, Zr)7.5 from 1200°C in a helium jet, the effect of the places of pinning Hcr of domain walls is low, and the field of the magnetostatic interaction becomes an additional cause of enlargement of the domain sizes.

2. A complete process cycle (quenching, 16-h tempering at 800°C, cooling to 400°C at a rate of 1.7 K/min and then in air) enhances the efficiency of the places of pinning of domain walls in alloy Sm(Co, Fe, Cu, Zr)7.5 to a maximum and it becomes substantially higher than that of the magnetostatic interaction. The alloy has a fine domain structure.

3. Analysis of formation of domain structure in alloys of the type considered should allow for the possible change in the effect of magnetostatic interaction on the domain sizes in addition to the efficiency of the domain wall pinning.

References

X. Y. Xiong, T. Ohkubo, T. Koyama, et al., “The microstructure of sintered Sm(Co0.72Fe0.20Cu0.055Zr0.025)7.5 permanent magnet studied by atom probe,” Acta Mater., 52, 737 – 748 (2004).

P. Gutfleisch, K.-H. Muller, K. Khlopkov, et al., “Evolution of magnetic domain structures and coercivity in high-performance SmCo 2:17-type permanent magnets,” Acta Mater., 54, 997 – 1008 (2006).

O. A. Arinicheva, A. S. Lileev, M. Raizner, et al., “Effect of cyclic heat treatment in the range of 800 – 400°C on the properties of sintered magnets based on alloy Sm(Co, Fe, Cu, Zr)z,” Metalloved. Term. Obrab. Met., No. 11, 16 – 20 (2014).

A. S. Lileev, V. V. Pinkas, K. V. Voronchikhina, and A V. Gubin, “Reversible changes in the coercivity in an alloy of the Sm – Co – Cu – Fe – Zr system for permanent magnets under cyclic heat treatments,” Metalloved. Term. Obrab. Met., No. 8, 4 – 8 (2018).

H. Sepehri-Amin, J. Thielsch, J. Fischbacher, et al., “Correlation of microchemistry of cell boundary phase and interface structure to the coercivity of Sm(Co0.784Fe0.100Cu0.088Zr0.028)7.19 sintered magnets,” Acta Mater., 126, 1 – 10 (2017).

V. N. Viktorov, A. S. Lileev, A. S. Perminov, et al., Program for Phenomenological Simulation of Processes of Reversal Magnetization of Highly Anisotropic Uniaxial Magnetic Materials, Certif. State Reg. Computer Soft. No. 2009612954 (MISiS) [in Russian], appl. 29.04.2009.

E. Schabes and A. Aharoni, IEEE Trans. Magn., Nov., mag-23(6), 3882 – 3889 (1987).

A. S. Lileev, V. N. Viktorov, B. G. Razumeiko, et al., Program for Visualization of Results of Phenomenological Simulation of Processes of Reversal Magnetization of Highly Anisotropic Uniaxial Magnetic Materials, Certif. State Reg. Computer Soft. No. 2013610413 (MISiS) [in Russian], appl. 13.11.2012.

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated from Metallovedenie i Termicheskaya Obrabotka Metallov, No. 3, pp. 28 – 31, March, 2021.

Rights and permissions

About this article

Cite this article

Lileev, A.S., Konyukhov, Y.V. Magnetic Properties and Domain Structure of Alloy Sm(Co, Fe, Cu, Zr)7.5 in Different Stages of Heat Treatment. Met Sci Heat Treat 63, 140–143 (2021). https://doi.org/10.1007/s11041-021-00660-2

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11041-021-00660-2