Abstract

Background

High quality RNA is required for the molecular study. Sample preparation of the spore-forming, Gram-positive bacteria like Bacillus sp., remains challenging although several methods have been proposed. Those techniques were simply developed using cell samples at certain growth stages despite some molecular studies like transcriptomic analyses require RNA samples from different physiological stages.

Methods and results

We developed the rapid, simple yet effective cell-lysis technique with limit use of harsh reagents by modifying the kit-based protocols. Appropriate lysozyme loading (20 mg/mL), incubation time (30 min), and temperature (37 °C) enabled cell lysis and enhanced RNA extraction from both vegetative cells and endospores of Bacillus subtilis TL7-3. High RNA Integrity Numbers and ratios of A260/A280 and A260/A230 of all RNA products collected during the batch cultivation confirmed that invert mixing with absolute ethanol prevented RNA damage during protein denaturation. With the process modification of the major steps in cell lysis and RNA extraction compared with the kit-based protocols that are typically used in laboratory work, interestingly, our modified protocol, simple-yet-effective, yielded higher concentration, purity, and integrity of RNA products from all cell samples collected at different physiological stages. While the kit-based protocols either failed to provide high RNA concentration or RNA purity and integrity for all cell samples particularly during the late-log, stationary, or sporulation.

Conclusions

Therefore, we can claim the significance of this modified protocol to be applicable for RNA extraction to those spore-forming Gram-positive bacteria not limited to B. subtilis growing at varied physiological stages.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Bacillus sp., the spore-forming Gram-positive bacteria, are typically used as the model organism for many molecular biology applications. Sample preparation process to acquire the high-quality nucleic acids (DNA, RNA) of Bacillus sp. remains challenging toward the integration of full analytical steps in the downstream applications although several methods have been proposed including conventional or kit-based protocols. Those protocols were mainly developed for certain point of the cultivation stages. However, some downstream applications in systems biology and synthetic biology like transcriptome analysis require nucleic acid samples gathered under different physiological stages of growth and process conditions. During growth and propagation, bacteria regulate macromolecular synthesis to replicate precisely. Growth stages and process perturbation stimulate metabolic responses resulting in differences in osmotic stability and cell morphology including cell wall architecture to develop the robustness [1]. This phenomenon becomes more profound for Bacillus sp. since in bacterial population, sporulation does not occur homogeneously throughout the growth stages, but rather occurs in subpopulation [2]. Sporulation involves an asymmetric septation to produce a mother cell and the forespore. Engulfment of the smaller forespore by the larger mother cell leaves the forespore surrounded by two membrane where the spore peptidoglycan is synthesized within this intermembrane space. This spore peptidoglycan plays role in the attainment of spore core dehydration; therefore, becomes environmentally resistant [3]. Therefore, the extraction workflow in the manufacturing kits seems not applicable for all samples collected from different physiological growth stages or those obtained from different process perturbation.

Cell wall disruption was reported to be the most tedious step as the integrity and rigidity depended on the structural unit of peptidoglycan [4]. Peptidoglycan is composed of alternating units of N-acetylglucosamine (NAG) and N-acetylmuramic acid (NAM), linked by β-(1,4) bonds [5]. The mechanical cell wall disruption such as bead milling and ultrasonic methods require specialized laboratory equipment; however, they are simpler and more efficient than the enzyme-based technique [6]. Lysozyme and its disruptive effect on bacterial cell wall have been reported in several literatures. High quality of nucleic acids can be acquired with lysozyme pretreatment during cell-lysis particularly in Gram-positive bacteria. Lysozyme assists cell wall disruption in combination with the lysis buffer [7,8,9]. We observed the effect of lysozyme on cell wall disruption in Bacillus subtilis TL7-3. The cell samples collected during the batch cultivation were subjected to different cell-lysis procedures and the RNA yield obtained from the conventional cell-lysis was compared with those obtained from the modified kit-based techniques in combination with lysozyme pretreatment. Lysozyme loading, incubation time, and temperature were also varied for improved RNA recovery yield. Contamination by proteins, buffers, chemicals, detergents, enzymes, salts, and solvents in the nucleic acid samples are strictly prohibited in the application in molecular diagnosis that requires PCR amplification [6, 10]. Highly purified yet intact nucleic acid samples are therefore mandatory. Ethanol was reported for nucleic acid precipitation and washing [11]. Several factors including pH, ionic strength, water purity, and working protocols, are claimed to be responsible for the obtained nucleic acid purity and integrity.

As aforementioned, the kit-based protocols were typically developed for the certain endpoint samples. The failure to obtain the intact nucleic acid of all samples collected from different physiological growth stages or different process conditions are often observed when using the extraction workflow in the manufacturing kits. In this study, we attempted to determine the RNA extraction workflow that could be applicable for the spore forming Gram-positive bacteria like Bacillus sp. By modifying the kit-based techniques, we successfully developed the rapid procedure for purification of intact RNA from both the vegetative cells and spores of B. subtilis TL7-3. Our detailed procedure in comparison with the conventional and the 2 kit-based methods were elucidated and reported in this work.

Materials and methods

Bacterial strain and culture conditions

The bacterial isolate TL7-3 screened from local Thai fermented food soybean by Professor Somboon Tanasupawat was used as a model spore producing bacterium for RNA extraction in this study. It was later identified by 16S rRNA gene sequencing as B. subtilis TL7-3. The nucleotide sequence (16S rRNA gene sequence) of this isolate was deposited in NCBI GenBank and could be accessed through the accession number MW820294.

B. subtilis TL7-3 was subcultured onto GYP agar slants and incubated at 37 °C for 24 h. GYP (Glucose Yeast extract and Peptone) agar medium contained (per liter) 10 g glucose, 5 g yeast extract, 5 g peptone, 0.25 g KH2PO4, 0.25 g K2HPO4, 20 g agar, and 10 mL salt solution. Salt solution contained (per liter) 40 g MgSO4⋅7H2O, 2 g MnSO4⋅5H2O, 2 g FeSO4⋅7H2O, 2 g NaCl. The pH of GYP medium was adjusted to 6.8. After 24 h, the cells were harvested and mixed with sterile 0.85% NaCl solution. The optical density of the cell suspension was measured at 600 nm and it was adjusted to 25 by sterile NaCl solution to be used as an inoculum later.

B. subtilis TL7-3 was cultivated in GY medium containing (per liter) 60 g glucose, 3 g yeast extract, 4 g NH4Cl, 0.25 g KH2PO4, 0.25 g K2HPO4, 5 g CaCO3, and 10 mL salt solution. The cultivation was started by transferring 0.5 mL inoculum into 49.5 mL GY medium. The culture was incubated at 37 °C, 200 rpm until the growth approached the stationary phase. Culture broth samples were collected every 3 h for analyses.

RNA extraction and purification

Culture broth sample was centrifuged at 10,000 g, 4 °C for 10 min and the supernatant was discarded. Cell pellet was stored at − 80 °C until use. The cell pellet (approximately 107 CFU/mL) was washed in sterile deionized water for 3 times before use in RNA extraction process. The washed cell pellet was subjected to cell-lysis, the first step in RNA extraction process. Four different cell-lysis methods were conducted, and the RNA recovery was investigated (Fig. 1). Lysozyme pretreatment was claimed to be responsible in cell-lysis in several previous publications. In this study, we investigated this crucial step in cell-lysis by conducting lysis process with and without lysozyme pretreatment and the RNA extraction yield was compared. In Method 1 RNA extraction was performed without lysozyme pretreatment while in the other methods, lysozyme was introduced to the suspension of the cell pellet before adding the lysis buffer to allow cell breakage. Without lysozyme, cell pellets were subjected to cell wall denaturation using 350 μL lysis buffer containing β-mercaptoethanol provided in RNeasy® mini kit; Qiagen, Germany. The suspension was vortexed until lysis. After that the suspension was centrifuged at 10,000 g for 2 min to remove the cell debris. The supernatant was then mixed with 600 μL 70% ethanol. The solution was then inverted until well mixed before RNA purification in the RNeasy® mini spin column.

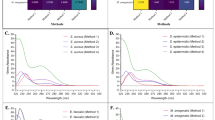

Process modification during cell-lysis steps in RNA extraction. In Method 1, the protocols provided by rapid RNA extraction of RNeasy® mini kit was conducted. In Method 2, the modified Invitrogen protocol was conducted for cell-lysis. Cell-lysis in Method 3 was conducted using bacterial RNA extraction protocol of RNeasy® mini kit. Method 4 was the lysis protocol developed in this study

To improve RNA recovery yield, peptidoglycans and other glycol polymers were hydrolyzed by lysozyme at the first step. Lysozyme loading and incubation time were varied. In Method 2 following the protocol developed by Invitrogen (PureLink RNA® mini kit; Invitrogen, USA), we used the lysozyme solution containing 10 mM Tris–HCl (pH 8.0), 0.1 mM EDTA, 0.5 μL 10% SDS, and 10 mg/mL lysozyme. While in Method 3, we followed the protocol developed by Qiagen (RNeasy® mini kit; Qiagen, Germany). The lysozyme solution contained 30 mM Tris–HCl (pH 8.0), 1 mM EDTA, and 15 mg/mL lysozyme. Method 4, our modified procedure, the lysozyme solution containing 20 mM Tris–HCl (pH 8.0), 2 mM EDTA, 1.2% Triton X-100, and 20 mg/mL lysozyme was introduced in the first step in cell-lysis. Then, ice-cold absolute ethanol was added into the mixture before gentle inversion for nucleic acid precipitation. All cell-lysis experiments were conducted in triplicate.

After cell-lysis, RNA was recovered and purified by loading the sample to RNeasy® mini kit (Qiagen, Germany) by following the manufactural protocol. The RNeasy mini spin column was loaded with 350 μL washing buffer I (RW1). DNA denaturation was performed to eliminate the bound DNA on a silica-based membrane by treating with DNase I for 15 min at room temperature. Then, another 350 μL RW1 was loaded, and the mini spin column was centrifuged at 10,000 g, 15 s. After DNA denaturation, washing step was further performed by loading 500 μL washing buffer II (RPE) into the column and the column was centrifuged at 10,000 g, 15 s. This step was repeated by adding another 500 μL RPE into the column and centrifugation was carried out at 10,000 g for 2 min. The collecting tube was replaced by a new one before eluting the purified RNA by 30 μL RNase-free water. The column was centrifuged at 10,000 g, 1 min to collect the RNA sample. The collected RNA sample was then used for detection in term of recovery yield and RNA product purity.

Qualitative and quantitative RNA analysis

Both concentration and purity of extracted RNA were described from the ratios of the absorbency at 260 nm and 280 nm, and at 260 nm and 230 nm using Nanodrop Spectrophotometer (DS-11FX+ , DeNovix®, USA). Additionally, isolation of intact RNA is essential for many techniques used in gene expression analysis. Those require RNA of extremely high integrity. We determined RNA integrity of the sample by evaluating from the 23S and 16S rRNA bands using Agilent 2100 Bioanalyzer (Agilent Technologies, Palo Alto, CA, USA) and RNA Integrity Number (RIN) was calculated.

Statistical analysis

Statistical analysis was performed using 3 experimental datasets. Mann–Whitney test was run using SPSS software (IBM® SPSS® statistics version 22, USA) to determine the p-value between pairs of the factors (sampling time and lysis method) and independent variables (RNA concentration, ratio of A260/A280, and ratio of A260/A230). The p-value less than 0.05 was identified as significant.

Results

Growth and viability of B. subtilis TL7-3

Figure 2A shows the growth profile of B. subtilis TL7-3 cultivated in GY medium during batch cultivation. The lag phase was not evident. In the first 3 h, B. subtilis TL7-3 grew at a slow rate as observed from a slowly increasing cell density (OD600) in this early log stage. Later, the culture entered the mid log where the apparent growth rate was the highest. After 12 h, the culture approached the late log stage before entering to the stationary stage at 15 h. The fermentation was carried out until 24 h without the evidence of the death stage. Spores were slowly formed since the beginning of fermentation. After 6 h, sporulation became noticeable. At 15 h, the total spore counts equaled the vegetative cell counts. Later, it was observed that the total number of spores were more than those of vegetative cells. The appearance of these metabolically dormant cells implied that the subpopulations entered sporulation in response to the metabolic regulation that relied on a series of feedback and feed-forward loops in the cell cycle development program. As the results, they could survive under unfavorable physical and chemical conditions [2, 3].

Growth kinetics of B. subtilis TL7-3 grown in GY medium at 37 °C (A). Shown are the optical density of the fermentation broth at 600 nm and colony counting of intact cells. Error bars indicate the standard deviation (SD) of the mean value (n = 3). Cell morphology of B. subtilis TL7-3 under different physiological stages (B). The endospores (appeared in green) were stained by Malachite Green while Safranin O was used as a counterstain to dye the vegetative cells (appeared in red). (Color figure online)

It should be noted that similar profiles of cell density and total viable cell counts in term of CFU/mL clearly stated that the samples used in RNA extraction and purification were from the intact cells.

Action of lysozyme influenced RNA extraction

Gram-positive bacteria have a single lipid membrane surrounded by a cell wall incorporated a thick layer of peptidoglycan [12]. Lysozyme is an enzyme that cleaves peptidoglycan in bacterial cell walls by catalyzing the hydrolysis of β-(1,4) linkages between N-acetylglucosamine and N-acetylmuramic acid. Therefore, lysozyme promotes the enabling denaturation of lysis buffer at the plasma membrane [7, 8].

The action of lysozyme on B. subtilis TL7-3 cell wall disruption was clearly observed from the increasing RNA recovery yield (Table 1). As expected, the lowest RNA yield was obtained from the RNA extraction process without lysozyme pretreatment. This indicated that the multiple coat layers comprising of peptidoglycan and other glycopolymers in the cell wall of B. subtilis TL7-3 hindered the transport of the lysis buffer; therefore, cell membrane denaturation process was incomplete, and eventually resulting in difficulties in transport of the cellular components throughout cytoplasmic membrane and cell wall [9].

Increasing lysozyme loading [from 10 mg/mL (in Method 2) to 15 mg/mL (in Method 3) and 20 mg/mL (in Method 4)] and incubation time [from 5 min (in Method 2) to 10 min (in Method 3) and 30 min (in Method 4)] enhanced RNA recovery (Table 1). RNA recovery yield obtained from Method 4 was significantly higher than other methods (p-value < 0.05). While Method 1 without lysozyme pretreatment, the significantly lowest RNA concentration was obtained (p-value < 0.05). By this, the action of lysozyme in breaking down the cell wall structure was clearly elucidated. This could further promote membrane denaturation process by the lysis buffer. Temperature was found to be responsible for promoting the action of lysozyme in hydrolysis of peptidoglycan. Unlike in Method 2 and Method 3, the incubation temperature was set at 37 °C during lysozyme pretreatment in Method 4. This temperature was claimed to be an optimal condition for lysozyme pretreatment [13].

Bacterial growth stages and sporulation seemingly affected RNA extraction. Multiple coat layers of peptidoglycan and other glycopolymers were dynamically developed through the growth stages in response to environmental conditions such as availability of nutrients, changes of physical pH and temperature [8, 12]. The highest RNA concentration especially during the late log and stationary stages obtained in Method 4 in comparison to the other 3 methods revealed that the effect of enzyme loading, and incubation time were more profound during sporulation when the cell envelopes became much more rigid as the coated layers protected the spore from enzymatic degradation by lysozyme, for example (Fig. 2B) [2, 3].

Protein removal during cell-lysis

Purification of intact RNA from samples is required in several molecular biology applications. Complete removal of cellular lipids and proteins including cellular proteases during cell-lysis prior to RNA purification can provide good results in their further uses [6]. The lysate obtained from 4 different cell-lysis methods was subjected to further RNA recovery and purification by loading the supernatant into the RNeasy mini spin column where other components in the lysate were not bound to the column and the DNA was denatured. RNA purity was determined using the ratios of absorbency. An A260/A280 ratio of 1.8 for DNA and 2.0 for RNA indicates pure nucleic acid preparation, i.e., protein free [14, 15]. Table 2 shows protein contamination in the RNA samples of B. subtilis TL7-3. The highest protein contamination in the RNA samples was observed from the lysates obtained by Method 1. With the lowest nucleic acid contents released from the samples as a result of incomplete cell-lysis (Table 1) and the one-step precipitation and washing of nucleic acids using 70% ethanol, this could carry over the contaminated proteins into the mini spin column where RNA purification was performed [11, 16]. Therefore, the poor A260/A280 ratios were obtained.

With the lysozyme pretreatment, a lower protein contamination was observed in the RNA samples obtained from cell-lysis Method 2, 3, and 4. This could be explained by the significantly improved RNA yields obtained from these 3 methods in comparison to those in Method 1. As a result, the improved A260/A280 ratios were achieved. The highest A260/A280 ratios were obtained from the RNA samples prepared by Method 2. The purity of RNA samples obtained from Method 3 and Method 4 are similar during the early and mid-log stages of growth. When growth entered the late log and stationary stages, RNA purity of the samples prepared by Method 3 was decreased as observed from A260/A280 lower than 2.00. The lower RNA purity during the late stage of growth when sporulation became pronounced as a consequence of the lower RNA yield due to incomplete cell disruption.

Although Proteinase K was added during 10-min lysozyme treatment to facilitate protein denaturation, this indicated that the lysis conditions in Method 3 were not applicable for rigid cell wall disruption like cells at late stage of growth or during sporulation. Several studies reported different protocols for several microbes to eliminate proteins from the nucleic acid samples. The most common technique for concentration and purification of nucleic acids is precipitation in absolute ethanol while 70% ethanol is for washing [11]. Here, we found that precipitation of nucleic acids with either 70% ethanol or absolute ethanol after lysozyme pretreatment sufficiently eliminated proteins in the nucleic acid samples before loading the samples for RNA purification in the mini spin column where DNA denaturation occurred by treating with DNase I.

A260/A230 as a sensitive indicator of contaminants

While A260/A280 reveals the type of nucleic acid present (dsDNA or RNA) and provides a rough indication of protein contamination, the A260/A230 is the sensitive indicator of contaminants that absorbs at 230 nm. These contaminants including chaotropic salts such as guanidine thiocyanate (GTC) and guanidine hydrochloride (GuHCl), EDTA, non-ionic detergents like Triton X-100 and Tween 20, proteins, and phenol are several more than those absorbing at 280 nm. Polysaccharides or free-floating solid particles like silica fibers also absorb at 230 nm [14, 17]. Table 2 depicts the RNA samples contaminated by the chemicals absorbing at 230 nm by the ratios of A260/A230. Typically, A260/A230 ratio of 2.1–2.3 was reported for pure RNA. Using 70% ethanol for simultaneously precipitating nucleic acids and washing during cell-lysis could only eliminate some proteins but buffer contaminants remained. As a result, the A260/A230 ratios of RNA samples obtained by Method 1 and Method 2 were significantly lower than the others (p-value < 0.05). On the other hand, using absolute ethanol gave a better result in removal of contaminants absorbing at 230 nm as observed from higher ratios of A260/A230 of the RNA samples obtained by Method 3 and Method 4. It was noticed that the significant decrease in A260/A230 ratios of the RNA samples at 12 h and 15 h obtained by Method 3 was due to failure in cell disruption when the cell wall became more rigid after entering the late stage of growth and sporulation.

As aforementioned, the ratios of A260/A280 and those of A260/A230 of the RNA products purified using Method 4 are higher than 2.0 and 2.1, respectively, for all cell samples in regardless of their physiological stages (vegetative cells vs. spores). Therefore, the RNA samples obtained by our modified procedure (Method 4) are considered to be clean and suitable for use in the downstream applications.

RIN number indicating RNA integrity

Not only concentration and purity are required, but integrity of RNA samples is also necessary. The RIN was evaluated for validation of the intact RNA. RIN values indicate overall RNA integrity by determining the ribosomal 23S/16S ratio, with a score from 1 (degraded RNA) to 10 (intact RNA). In gene expression study, RIN value greater than 8.0 is essential for successful downstream applications [18, 19]. Figures 3, 4, 56 show the electropherograms of RNA extracted using 4 different cell-lysis methods. We observed the low RIN values of all RNA extracted from cell samples collected during different stages when the cells were subjected to lysis protocol using Method 1 (the highest obtained RIN value was only 4.80) and Method 2 (the highest obtained RIN values was 6.80) (Figs. 3, 4). The low RNA concentration of the samples extracted by Method 1 was believed to be responsible for the low RIN values. While rigorous mixing by vortexing during nucleic acid precipitation was claimed to cause RNA degradation during cell-lysis protocol using Method 2. Unlike those of Method 1 and Method 2, the obtained electropherograms of the RNA samples obtained from Method 3 and Method 4 showed clear peaks, corresponding to 16S rRNA and 23S rRNA as the evidence of low RNA degradation (Figs. 5, 6). The resulting RIN values greater than 8.0 were acquired in all cell samples collected throughout the fermentation indicating that gently inverting instead of vortexing helped prevent RNA damage during nucleic acid purification step. Thus, this confirmed the great RNA integrity for further downstream usages. Nevertheless, it should be noted that the RNA yield (Table 1) and purity (Table 2) of the cell samples extracted by Method 3 at late stage of growth were significantly low when sporulation became profound. Thus, RNA extraction by Method 3 is not suitable for cell samples with the high content of endospores. From Tables 1, 2 and Fig. 6, we can claim that our modified RNA extraction approach could enhance RNA yield as well as maintaining the integrity of the RNA samples.

Discussion

Bacillus sp., the spore-forming Gram-positive bacterium lacks the outer membrane while it has a much thick cell wall incorporated multilayers of peptidoglycan, teichoic acids, and other glycopolymers [12]. Bacillus sp. is ubiquitous and readily adapts when exposed to environmental alteration. Under environmental stress, Bacillus sp. initiates various survival mechanisms. One of those is sporulation for generating a metabolically inactive dormant cell so called endospore which is able to survive under harsh conditions until the preferred growth conditions are restored [2].

Extraction and purification of RNA in spore-forming Gram-positive bacteria like Bacillus sp. usually suffers from the low product yield especially during sporulation. It was claimed that cell-lysis played a crucial role in effective RNA extraction procedure [20, 21]. Those lysis techniques are categorized into 2 groups; (1) Mechanical cell-lysis using homogenizer and bead milling and (2) Non-mechanical cell-lysis using alkali, detergent, enzyme, heat, and osmotic shock [22]. To acquire a high-quality RNA product of B. subtilis collected at different physiological stages, it is essential to determine the rapid, non-biased yet effective procedure that eases cell-lysis and enhances RNA recovery without leading to RNA damage [23, 24]. Although the lysozyme pretreatment together with Trizol reagent technique was claimed to promote cell-lysis; therefore, enhanced RNA extraction that yielded high RNA quality, this protocol is seemingly a time-consuming process (nearly 4 h) and harsh reagents (phenol–chloroform) are required during RNA recovery [9]. While there is no optimal RNA recovery from intact cells for all morphological and physiological stages, a rapid general procedure yet efficiently providing high-quality RNA product is preferable to the time-consuming standard. Here we reported a rapid, simple technique that allowed proper cell lysis for both vegetative cells and endospores of B. subtilis TL7-3, the model strain, prior to RNA extraction using the RNeasy® mini kit. Our rapid procedure with no harsh reagents yielded high quality RNA products by using lysozyme pretreatment at proper loading ratio combined with protein precipitation by absolute ethanol at the suitable temperature and time. With proper optimization on lysozyme loading (20 mg/mL) and pretreatment temperature (37 °C) and time (30 min), this promoted the breakage of β-(1,4) bonds and therefore enhanced the cell disruption process by the lysis buffer of cell samples collected at different physiological and morphological stages. The complete cell-lysis yielded high RNA concentration and subsequently allowed effective protein precipitation by absolute ethanol without uses of Proteinase K and any reagents to protect RNA products. This resulted in low impurities remained in the RNA products as observed from the high values of A260/A280 and A260/A230 ratios. Not only the high RNA purity could be acquired, but the high RIN values also indicated the intact RNA products were obtained by our simple yet effective modified protocol.

Conclusion

In summary, by optimizing lysozyme loading, incubation time, and temperature, this helped facilitate RNA recovery. Gently inverting prevented RNA damage during protein precipitation by ethanol while providing sufficient nucleic acid purification. By this, we successfully obtained a large quantity of RNA products with the sufficiently high purity and integrity that could be applicable for further molecular downstream applications. Collectively, the results obtained in this study emphasized the importance of cell lysis and protein precipitation during RNA extraction throughout all stages of growth. Here we can state that our developed procedure can be implemented in other microorganisms, not limited the model organism we tested, being cultivated under varied physiological stages to validate its versatile usage in the future.

Data availability

The 16S rRNA gene sequence of B. subtilis TL7-3 has been submitted to NCBI with accession number MW820294.

References

Egan AJF, Cleverley RM, Peters K, Lewis RJ, Vollmer W (2017) Regulation of bacterial cell wall growth. FEBS J 284(6):851–867. https://doi.org/10.1111/febs.13959

Tan IS, Ramamurthi KS (2014) Spore formation in Bacillus subtilis. Environ Microbiol Rep 6(3):212–225. https://doi.org/10.1111/1758-2229.12130

Meador-Parton J, Popham DL (2000) Structural analysis of Bacillus subtilis spore peptidoglycan during sporulation. J Bacteriol 182(16):4491–4499. https://doi.org/10.1128/jb.182.16.4491-4499.2000

Vollmer W, Blanot D, De Pedro MA (2008) Peptidoglycan structure and architecture. FEMS Microbiol Rev 32(2):149–167. https://doi.org/10.1111/j.1574-6976.2007.00094.x

Primo ED, Otero LH, Ruiz F, Klinke S, Giordano W (2018) The disruptive effect of lysozyme on the bacterial cell wall explored by an in-silico structural outlook. Biochem Mol Biol Educ 46(1):83–90. https://doi.org/10.1002/bmb.21092

Hwang KY, Kwon SH, Jung SO, Lim HK, Jung WJ, Park CS et al (2011) Miniaturized bead-beating device to automate full DNA sample preparation processes for gram-positive bacteria. Lab Chip 11(21):3649–3655. https://doi.org/10.1039/c1lc20692c

Muchová K, Wilkinson AJ, Barák I (2011) Changes of lipid domains in Bacillus subtilis cells with disrupted cell wall peptidoglycan. FEMS Microbiol Lett 325(1):92–98. https://doi.org/10.1111/j.1574-6968.2011.02417.x

Choi Y, Moody IS, Sims PC, Hunt SR, Corso BL, Seitz DE et al (2012) Single-molecule dynamics of lysozyme processing distinguishes linear and cross-linked peptidoglycan substrates. J Am Chem Soc 134(4):2032–2035. https://doi.org/10.1021/ja211540z

Villa-Rodríguez E, Ibarra-Gámez C, de Los S-V (2018) Extraction of high-quality RNA from Bacillus subtilis with a lysozyme pre-treatment followed by the Trizol method. J Microbiol Methods 147:14–16. https://doi.org/10.1016/j.mimet.2018.02.011

Rantakokko-Jalava K, Jalava J (2020) Optimal DNA isolation method for detection of bacteria in clinical specimens by broad-range PCR. J Clin Microbiol 40(11):4211–4217. https://doi.org/10.1128/jcm.40.11.4211-4217.2002

Fregel R, González A, Cabrera VM (2010) Improved ethanol precipitation of DNA. Electrophoresis 31(8):1350–1352. https://doi.org/10.1002/elps.200900721

Weidenmaier C, Peschel A (2008) Teichoic acids and related cell-wall glycopolymers in Gram-positive physiology and host interactions. Nat Rev Microbiol 6(4):276–287. https://doi.org/10.1038/nrmicro1861

Hussain M, Zahoor T, Anjum FM, Shahid M, Saeed F (2015) Isolation and characterization of buffalo milk lysozyme. Int J Food Prop 18(6):1288–1297. https://doi.org/10.1080/10942912.2013.809540

Bilgin DD, DeLucia EH, Clough SJ (2009) A robust plant RNA isolation method suitable for Affymetrix GeneChip analysis and quantitative real-time RT-PCR. Nat Protoc 4(3):333–340. https://doi.org/10.1038/nprot.2008.249

Lucena-Aguilar G, Sánchez-López AM, Barberán-Aceituno C, Carrillo-Ávila JA, López-Guerrero JA, Aguilar-Quesada R (2016) DNA source selection for downstream applications based on DNA quality indicators analysis. Biopreserv Biobank 14(4):264–270. https://doi.org/10.1089/bio.2015.0064

Miranda RN, Silva CM, Porto ACM, Pereira WA (2019) Protocol adjustment improves the extraction of high-quality total RNA from common bean stems infected by Sclerotinia sclerotiorum. Ciênc Agrotec 43:1–16. https://doi.org/10.1590/1413-7054201943024618

Rezadoost MH, Kordrostami M, Kumleh HH (2016) An efficient protocol for isolation of inhibitor-free nucleic acids even from recalcitrant plants. 3 Biotech 6(61):1–7. https://doi.org/10.1007/s13205-016-0375-0

Hampton-Marcell JT, Moormann SM, Owens SM, Gilbert JA (2013) Preparation and metatranscriptomic analyses of host-microbe systems. Methods Enzymol 531:169–185. https://doi.org/10.1016/b978-0-12-407863-5.00009-5

Hitzemann R, Darakjian P, Walter N, Iancu OD, Searles R, McWeeney S (2014) Introduction to sequencing the brain transcriptome. Int Rev Neurobiol 116:1–19. https://doi.org/10.1016/b978-0-12-801105-8.00001-1

He J, Du S, Tan X, Arefin A, Han CS (2016) Improved lysis of single bacterial cells by a modified alkaline-thermal shock procedure. Biotechniques 60(3):129–135. https://doi.org/10.2144/000114389

Vingataramin L, Frost EH (2015) A single protocol for extraction of gDNA from bacteria and yeast. Biotechniques 58(3):120–125. https://doi.org/10.2144/000114263

Shehadul Islam M, Aryasomayajula A, Selvaganapathy PR (2017) A review on macroscale and microscale cell lysis methods. Micromachines 8(3):83. https://doi.org/10.3390/mi8030083

Kim J, Johnson M, Hill P, Gale BK (2009) Microfluidic sample preparation: cell lysis and nucleic acid purification. Integr Biol 1(10):574–586. https://doi.org/10.1039/b905844c

Ho CW, Tan WS, Yap WB, Ling TC, Tey BT (2008) Comparative evaluation of different cell disruption methods for the release of recombinant hepatitis B core antigen from Escherichia coli. Biotechnol Bioprocess Eng 13(5):577–583. https://doi.org/10.1007/s12257-008-0020-9

Acknowledgements

P. Jaiaue is the recipient of the Development and Promotion of Science and Technology Talents Project (DPST) provided by Thailand Research Fund. The authors would like to acknowledge National Security and Dual-Use Technology Center, National Science and Technology Development Agency (NSTDA), for supporting our study.

Funding

This study was partially funded by National Research Council of Thailand; Research Chair Professor Grant provided by National Science and Technology Development Agency (NSTDA); and Thailand Research Fund [Grant No. RTA6280014].

Author information

Authors and Affiliations

Contributions

PJ performed the experiments and statistical analysis. PS, ST, and NT conceived the research idea, designed the methodology, and scrutinized the experimental data. ST provided the strain in this study and visualized the experimental data. BC, SA, and NT provided research funding and supervised the research work. PJ and NT wrote and edited the manuscript.

Corresponding authors

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Consent for publication

All authors agreed to submit this work for publication in Molecular Biology Reports.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

This manuscript has been submitted as the preprint and can be accessed via the following link: https://www.researchsquare.com/article/rs-429777/v1.

Rights and permissions

About this article

Cite this article

Jaiaue, P., Srimongkol, P., Thitiprasert, S. et al. A modified approach for high-quality RNA extraction of spore-forming Bacillus subtilis at varied physiological stages. Mol Biol Rep 48, 6757–6768 (2021). https://doi.org/10.1007/s11033-021-06673-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11033-021-06673-7