Metrological problems that arise in the measurement of the temperature of physical objects performed by means of pyrometers, where the emissivity of the particular object differs from unity and may vary as a function of wavelength, are considered. Methods of correction of spectral (CT) ratio pyrometers are analyzed. A disturbance in the traceability of pyrometers provided with components for correction to the primary standard of the unit of temperature is identified. Recommendations for establishing traceability are given.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Metrological problems that are typical of energy pyrometry are analyzed in [1]. In the present article, which is a continuation of [1], we will consider metrological problems associated with methods of spectral similitude and the spectral ratio as well as methods of solving these problems.

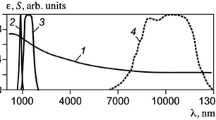

Method of spectral similitude. The essence of the method lies in the measurement of the spectral distribution of an energy flux from a measured object, subsequent mathematical transformation of the result of the measurements, and its comparison with the Planck (or Wien) dependences of the spectral distribution transformed by this same method with different values of the temperature [2]. The spectral emissivity may be constant, which is characteristic of a gray object, or vary as a function of wavelength for a nongray object. In the former case the temperature may be determined without any additional information, moreover, the precision of its measurement is defined only by the instrumental error of the measuring instrument employed. In the latter case, it is necessary to know the spectral emissivity of the measured object (which is usually unknown) and, using the emissivity, to correct the measured spectral distribution of the energy flux from the measured object and only then find the desired temperature.

There are no specialized measuring instruments anywhere in the world today that implement this method and that are traceable to the corresponding state primary standard of the unit of temperature (in Russia, this is State Primary Standard GET 34–2007 of the unit of temperature in the range from 0 to 3000°C). Disappearing-filament pyrometers that implement this method are removed from production practically every day. Spectrometers to determine the temperature are still used today only under laboratory conditions and are not instruments for the measurement of temperature, but are specifically spectrometers that may be verified in measurement chains for spectrometric measuring instruments.

Spectral-ratio method. Within the framework of this method, the ratios of the signals of a measured object at two different wavelengths (in two different spectral ranges) are measured, and are then compared with the ratios of the signals at the same wavelengths (in these ranges) of an absolutely black body at different temperatures. The method is close to the spectral-similitude method, though they cannot be combined, in that equality of the ratios of signals at two different wavelengths (in two different ranges) follows from the similitude of the spectral distribution, though the converse assertion is false.

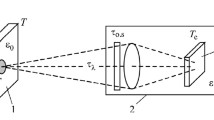

A typical spectral-ratio pyrometer that implements the method functions in the following way. A heated object emits a flux of energy into a hemisphere in which a pyrometer has been placed. A portion of the energy is incident on the lens of the pyrometer, is collected in a beam-splitter and enters two receivers. A corresponding light filter is situated in front of each receiver. The receivers process the electrical signals, which are proportional to the energy fluxes. These signals are then amplified by electronic amplifiers and their ratio is computed and subsequently transformed into the value of the temperature of the measured object.

What are known as tandem photodiodes have become widely used in recent years as spectral-ratio pyrometer receivers. These devices constitute two-layer semiconductor structures, the upper layer being sensitive to the short-wave part of the spectrum, but transparent to the long-wave part, to which the lower layer is sensitive. Because of the presence of tandem photodiodes, the construction of a spectral-ratio pyrometer is simplified and there is no need to incorporate a beam splitter into the filters.

The temperature of a gray body may be determined by a spectral-ratio pyrometer without any additional information. There should not be any types of controls in the pyrometer by means of which the operator could arbitrarily vary the measured ratio of the output signals of the pyrometer receivers [3, 4]. Such pyrometers are traced to the primary standard of the unit of temperature. The measurement error is determined exclusively by the error of the pyrometer itself. Measurement of the temperature of a gray body is a special field of modern pyrometry for which there exist measuring instruments that are traceable to the primary standard of the unit of temperature, and no additional method errors are present in the result of a temperature measurement.

A systematic method error (the mechanism by means of which it arises is described in detail in [7]) will be present in the determination of the temperature of a nongray body as a result of the measurement. It is thus necessary to correct the measurement result to eliminate the influence of this error.

Methods of correction of the results of a measurement of the temperature of nongray bodies by means of spectral-ratio pyrometers. There exist several methods of correction today. Let us consider their features and metrological problems.

Correction of external variation of the ratio of signals. In the course of measuring the temperature of nongray bodies spectral-ratio pyrometers may exhibit an additional error of 5–20% and even greater than 20%, hence manufacturers of pyrometers have begun to equip the articles with a control to enable the operator to arbitrarily vary a measured ratio of signals in the spectral channels 1.5–2-fold [3]. It has been suggested that users measure the temperature of an object by a contact method and then adjust its value by means of the control in a measurement of the temperature of the same object by a spectral-ratio pyrometer until the results of measurements by means of the contact method and by means of the pyrometer coincide. It is further recommended that the correction factor selected by this method should be stored and used in measuring the temperature of this particular object.

The fact that it is metrological not justified to adopt the result of a measurement as correct is considered in [1]. We would also like to note that the presence of a control in the pyrometer leads to a break in the traceability chain of the device to the primary standard of the unit of temperature. The reason is the same as in the case of energy pyrometers: the calibration and determination of the metrological characteristics, including the error, is performed with the same characteristics of the amplifying circuit of the pyrometer, while the measurement of the temperature of physical objects, with different characteristics. Therefore, once the basic error in the case of the initial ratio between the signals is known, nothing may be said concerning what will be the error if the ratio between the signals is increased or decreased, where the latter is selected in the course of measuring the temperature of a nongray object by the same pyrometer.

It is extremely difficult to establish traceability in this case. For one and the same spectral-ratio pyrometer in the case of a nongray object with one and the same spectral characteristic, the value of the correction factor input into the pyrometer proves to be different for different temperatures of the object. Table 1 presents values of the spectral ratios K1/K2 of a nongray object (Fe) and an absolutely black body as a function of temperature, i.e., correction factor; the data for K1 and K2 are borrowed from [4].

From the table, it follows that the correction factor depends on temperature. Thus, if some value of the factor is established that yields readings of the pyrometer that are correct for one value of the temperature, for other temperatures the result of the measurements will be overstated or understated, and to a greater extent, the greater is the difference between these values of the temperature. Therefore, it is not possible to establish an unbroken chain of traceability of spectral-ratio pyrometers with controls to the primary standard of the unit of temperature.

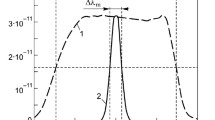

Correction of narrow-band pyrometers by a computational technique. For narrow-band measuring instruments without controls, correction is achieved on the basis of the well-known relationship [6]

where Teff is the effective temperature of the measured object; Tm, the temperature measured with the use of a pyrometer; c2 = 1.4380·10–2 m·K, second radiation constant; λ1 and λ2, working wavelengths of pyrometer; and ε1 and ε2, emissivity coefficients at the wavelengths λ1 and λ2, respectively.

The pyrometers are traced to the primary standard of the unit of temperature, i.e., their basic error in the case of correct measurements in a traceable chain is metrologically evaluated. Measured values of λ1, λ2, ε1, ε2 are substituted into formula (1) and the effective temperature of the measured object found. The error in the result of the measurements is composed of the basic error of the pyrometer and the error in the measurements of the quantities λ1, λ2, ε1, ε2 based on their contributions to the total error computed using the formulas for indirect errors.

It should be recalled that formula (1) is obtained in the Wien approximation, which also introduces an additional error, which is usually increasing with increasing temperature. Moreover, if a calculation by means of (1) is performed by the pyrometer microprocessor, and not by the user manually according to the measurement protocol or some other document, there arises the danger of program errors, which may lead to a breakdown in the traceability chain. In this case, it is necessary to verify a spectral-ratio pyrometer with nongray standard emitters with known values of λ1, λ2, ε1, ε2, as is done for energy pyrometers.

Correction of wideband pyrometers by a computational method. For wideband pyrometers without controls correction may be achieved on the basis of [7]. As in the preceding case, the pyrometers are traced to the primary standard of the unit of temperature and their basic error in the case of correct measurements in a traceable chain is metrologically evaluated. The results of measurements of λ1, λ2, ε1, ε2 are substituted into the computational formulas from [5] and the effective temperature of the measured object found. The error in measurements of wideband pyrometers is obtained as in the case of the error of narrowband pyrometers, and it is also necessary to verify them with nongray standard emitters in order to avoid breaking the traceability chain.

It should be noted that in the overwhelming majority of cases the characteristic of the spectral emissivity of a wideband pyrometer depends on temperature [8, 9]; that is, a set of values of ε1 and ε2 corresponds to each temperature. Based on (1), this must also be taken into account in the correction. If a correction is performed using the formulas from [5], the dependences ε(λ, T) corresponding to values of the temperature T must be used in the integral functions, which greatly increases the time it takes to perform a correction by computational methods.

Correction based on experimental dependences between the effective temperature and the spectral-ratio temperature. In actual practice it is simplest to obtain the experimental dependence Ts.r = ƒ(Teff) between the effective temperature Teff of an object which is to be measured and its spectral-ratio temperature Ts.r (these dependences will be different for spectral-ratio pyrometers with different spectral characteristics of the channels). The inverse function Teff = ƒ–1(Ts.r) is then found and the effective temperature determined from the value of the spectral-ratio temperature measured by the pyrometer.

In this case, the metrological problem is to correctly determine the error in implementation of the method. A determination of the relation Ts.r = ƒ(Teff) is an example of a typical direct measurement the error of which must be determined on the basis of the standard [10]. The basic error of the instruments used for measurement of the effective temperature of the object and the basic error of the pyrometer must be adopted as the systematic errors in the relationship for the measurement error. The basic error in the determination of the dependence of the spectral-ratio temperature on the effective temperature contains, besides a systematic component, a random component. In computing the effective temperature from the inverse function, the basic error in the determination of the dependence of the spectral-ratio temperature on the effective temperature and the basic error of the pyrometer must then be used as the systematic error in calculating the effective temperature from the inverse function. Here, it is assumed that the sources of other additional errors are eliminated or are taken into account in the procedures used to determine the basic errors described above.

Correction based on a specified set of spectral emissivities of nongray bodies. From (1), there follows the equality

where Δε = ε1 – ε2.

The relative error in a measurement by a spectral-ratio pyrometer caused by the nongray nature of the measured object is proportional to the relative variation Δε of the emissivity divided by the difference between the working wavelengths, i.e., in the second approximation, the tangent of the angle of inclination of ε(λ). Thus, the following correction algorithm may be realized: Select six, eight, or ten types of dependences ε(λ) that differ in terms of the value and direction of the gradient (descent or ascent) of the variation of Δε/λ2 – λ1. Three, four, or five dependences will correspondingly be increasing dependences with increasing wavelength, and the others, decreasing dependences. Create similar emitters by means of different light filters (glass, liquid, etc.). Assign the following notation to each dependence: A, B, etc. Implement an operating regime in the spectral-ratio pyrometers both with and without correction of dependence A, dependence B, ... . Such pyrometers may be verified using type A emitters (absolutely black body + light filter A), type B (absolutely black body + light filter B), type C (absolutely black body + light filter C), etc.

In measuring the temperature of a real nongray object, the user must select which of the dependences (A, B, C, ...) the dependence of the physical object is closest to, and measure its temperature, transferring the pyrometer into the correction regime of the corresponding dependence. In this case, the measurement error is estimated experimentally by heating a small volume 0.1–0.3 m3 of a sample of the material of an object with a given state of the surface in a muffle furnace and comparing the readings of the pyrometer with the readings of a contact thermometer that measures the temperature of the object. This method is analogous to the preceding method described above, though in this case several correction curves have already been incorporated into the pyrormeter whereas in the preceding case incorporation of an individual curve requires intervention into the internal circuit of the pyrometer, a step which is possible only at the manufacturing enterprise. We would also like to note that in estimating a measurement error it is necessary to take into account all the existing measurement errors of the contact thermometer and the pyrometer (both instrumental errors and method errors).

General view of the metrological problems of all the methods considered here. All of the methods of pyrometry that have been considered here in conjunction with the metrological problems inherent to them are represented in Fig. 1. The metrological problems are indicated by dark-gray rectangles and rhombuses. Even the unique branch of the spectral-ratio method, where the solution is found without additional data cannot be easily implemented, since it is not known in advance whether or not the object which is being measured is or is not gray. In all the remaining branches of the different methods there are very many serious metrological problems that require rapid solution.

Solution of metrological problems of all the methods considered. It becomes obvious that the user’s lack of knowledge of the spectral emissivity of the object being measured is the source of the metrological problems of all the methods that have been considered here. Over more than 50 years, it has not been possible to find a universal analytic relation between the spectral emissivity and the optical and electrical characteristics of materials and to create a database of the spectral emissivity of different materials, hence it is not reasonable to expect that these problems, which have remained unsolved for dozens of years, will be solved in the foreseeable future. A different approach to the solution of the problems is needed. Such an approach is suggested by metrology: instruments for the measurement of spectral emissivity are needed by means of which the spectral emissivity of particular materials under the conditions of concrete production processes may be experimentally determined. These measuring instruments will have to be simple to employ so that any trained specialist will be able to use them and the measurement process should also take several minutes to perform and not weeks or days. The appearance of such measuring instruments will make it possible to qualitatively change the present situation in pyrometry. Users will be able to obtain reliable information on the emissivity of specific though concrete objects which are to be measured with the error assigned to the given measuring instrument. Once a measured dependence of the spectral emissivity ε(λ) is known, the type of pyrometer which has to be acquired may be selected. Users will be able to easily find the emission coefficient corresponding to concrete objects and concrete conditions, and to also use fully evaluated values of the correction factor obtained on the basis of the emissivity coefficient and not selected practically intuitively from the vast variety of accessible sources. This will ultimately produce a deliberate understanding of the need not only to generate measurements in strict correspondence with fully developed and approved measurement techniques, but to also correctly compile and skillfully correct them. Whereas initially metrologists and engineers are first drawn to certification in a performance management system, it is a far more complicated task to understand the need for required knowledge and information. Moreover, the appearance of an inventory of specialized instruments for the measurement of spectral emissivity will make it possible to sharply increase the rate of accumulation of information on this very poorly studied characteristic of physical bodies. An increase in the volume of experimental data will inevitably lead to a growth in the interest of specialists and the appearance of new theoretical and mathematical models. The creation of working instruments for the measurement of spectral emissivity will require the development of standard measuring instruments, measurement chains corresponding to verification techniques, and, ultimately, a state primary standard of emissivity (monochromatic, interval, integral, spectral emissivity). Thus, all the metrological problems that have been considered here will have been solved.

Conclusion. At the present time, metrological assurance of pyrometry relates only to questions associated with the creation of standards of temperature, the improvement of the temperature of phase transitions selected as calibration transitions, the dissemination of the unit from the primary standard to working standards of lower rank, and construction and certification of standard emitters and standard pyrometers, as well as the development of measurement chains provided with verification and calibration techniques. Pyrometric measurements of the temperature of physical objects the emissivity of which is different from unity, including nongray objects, are practically metrologically unsupported. Thus, an enormous quantity of unsolved problems has accumulated over the past 50 years in practical pyrometry. The measurement instruments offered to users over more than ten years are characterized by basic errors amounting to fractions of a percent, though at the same time they measure the temperature of physical objects with error ten times the basic error assigned to them (and sometimes even greater (!))

Thus, it is necessary to develop metrological assurance of pyrometric measurements of the temperature of physical objects, including nongray objects. For this purpose, it will be necessary to create a new class of instruments for the measurement of the spectral emissivity. Such measuring instruments do not exist today, though there are no serious technical problems that might interfere with their development. Users of such measuring instruments will be able to easily measure the emission characteristics of objects whose temperature must be determined by means of pyrometers in order to reduce the method errors inherent to pyrometers down to the level of the instrumental errors of the pyrometers employed.

References

A. V. Frunze, “Metrological problems of modern energy pyrometry,” Metrologiya, No. 1, 42–57 (2018).

A. N. Magunov, Spectral Pyrometry, Fizmatlit, Moscow (2012).

G. V. Gusev and V. A. Kal’van, “Infrared spectral-ratio thermometers (dichromatic pyrometers),” in: Energy Conserving Technologies in Industry. Furnace Units. Ecology. Safety of Technological Processes: Proc. 5th Int. Sci. Pract. Conf. 2010. Increasing the Efficiency of Heat-Energy Equipment (2000), pp. 71–77.

A. V. Frunze, “Spectral-ratio pyrometers: advantages and drawbacks and methods of eliminating the drawbacks,” Fotonika, No. 4, 32–37 (2009).

M. L. Samoilov and A. V. Frunze, “Increasing the precision of measurements of the temperature of ‘nongray bodies’ by wideband spectral-ratio pyrometers,” Metrologiya, No. 6, 23–31 (2010).

Measurement of Temperature in Engineering. Reference [Russian translation], Metallurgiya, Moscow (1980).

A. V. Frunze, “On a feature of spectral-ratio pyrometers little known today,” Fotonika, No. 3, 86–94 (2013).

A. M. Belen’kii, M. Yu. Dubinskii, M. G. Ladygichev, and V. G. Lisienko, Measurement of Temperature: Theory, Practical Application, Experiment: Reference, Teplotekhnika, Moscow (2007), Vol. 2.

A. E. Sheindlin (ed.), Emissive Properties of Solid Materials. Reference, Energiya, Moscow (1974).

GOST 8.207–76, GSI. Direct Measurements with Multiple Observations. Methods of Processing the Results of Observations. Basic Assumptions.

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated from Metrologiya, No. 2, pp. 35–48, April–June, 2018.

Rights and permissions

About this article

Cite this article

Frunze, A.V. Metrological Problems of Modern Spectral Pyrometry. Meas Tech 61, 621–626 (2018). https://doi.org/10.1007/s11018-018-1474-6

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11018-018-1474-6