We study the noise of an electrode sensor and the influence of the motion of liquid and pulsations of its velocity and pressure on this noise. The experimental investigations are performed with the help of a specially developed installation. Recommendations concerning the possibility of improvement of the sensitivity and accuracy of the electrode sensor are given.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Electrode sensors find applications in geophysical investigations: in measurements of the low-frequency electric-field strength in sea and in systems of radio communication with underwater objects [1, 2]. The intrinsic noise of these sensors restricts the sensitivity and accuracy of measurements. The results of investigation of the noise of electrode sensors are presented in [3,4,5]. In particular, the relationship between the fluctuations of potential drop between the electrodes and the velocity of liquid was discovered. However, the obtained results require refinement and the nature of the electrode noise is not clarified.

The aim of the present work is to study the electrode noise and the influence of the motion of liquid and the pulsations of its velocity and pressure on this noise and give recommendations concerning the possibility of improvement of the sensitivity and accuracy of the electrode sensor.

The investigations were carried out on an installation whose schematic diagram is presented in Fig. 1. The steel box 1 playing the role of a magneto- and electrostatic screen contains battery 2 for the power supply of a centrifugal pump, which creates the flow of liquid and two additional steel boxes 9 and 10 also playing the role of screens. Box 10 contains cell 12 with electrodes simulating a sensor and preamplifier 11. Moreover, box 9 contains reservoir 13 filled with a liquid (a NaCl solution simulating seawater) and the electric pump 14. The liquid flows through a dielectric pipeline 3.5 mm in diameter from reservoir 13 to pump 14 and then to the cell with electrodes. After this, it returns to the reservoir. The velocity of liquid is changed by using connecting resistors 8 included in the feed circuit of the pump. The photoelectric sensor 7 with preamplifier 6 is used for the monitoring of pulsations of the liquid velocity. The outputs of preamplifiers 6 and 11 are connected in turn to the measuring amplifier 5, which increases the analyzed voltage up to a level required for the operation of the analog-to-digital converter (ADC) 4 connected with computer 3 used to process the data of measurements.

Schematic diagram of the installation for the investigation of the electrode noise in the course of motion of the liquid: 1, 9, 10) steel boxes (screens); 2) battery; 3) computer; 4) analog-to-digital converter; 5) measuring amplifier; 6, 11) preamplifiers; 7) velocity sensor; 8) block of voltage-dropping resistors; 12) cell with electrodes; 13) reservoir filled with an electrolyte; 14) pump.

Sensor 7 was calibrated for different liquid velocities and, hence, can be used for the determination not only of qualitative but also of quantitative relationships between the velocity pulsations and the electrode voltage; however, the frequency characteristic of the sensor was not measured.

Electrode cell 12 has a hermetically sealed case made of organic glass in the form of a cube with inlet and outlet tubes mounted on its opposite faces. On the lid we place two electrodes simulating the operation of electrode sensor in the flow of liquid. The measuring electrode is located opposite the inlet tube at a distance of 5–10 mm from its nozzle (see Fig. 1). Therefore, we can assume that the velocity of liquid near the surface of the electrode is equal to its velocity in the inlet tube. The vector of velocity of the flow is parallel to the end surface of the measuring electrode. The reference electrode is located away from the flow and has a much larger area. This is why pulsations of voltage between the electrodes are caused by the processes running on the surface of the measuring electrode. The electrodes are made of steel in the form of cylinders whose lateral surfaces are insulated from the electrolyte, while the end surfaces are polished and play the role of working surfaces of the electrodes. The electrodes and the inlet and outlet pipes are made of 12Kh18N10T stainless steel. To decrease the influence of vibration, the measuring cell was packed in foam rubber and cotton. The pipeline was also damped with cotton and foam rubber at all possible places. The level of noise of preamplifier 11 does not exceed 2 dB.

The E20-10 ADC was used to record series of 20 realizations of voltages on the electrodes and the velocity sensor with a duration of 1 sec each in the computer memory. The indicated series were processed by using the LGraph 2 software and averaged. The measurements were performed at room temperature of 20–22°C without thermostatting.

The results of measurement of the alternating electrode voltage (electrode noise) show that, if the pump is switched on, then the indicated voltage contains a periodic component, whose frequency is determined by the rotation velocity of the electric motor of the pump. The increase in the rotation velocity leads to the corresponding increase in the frequency of the periodic component. In Fig. 2, we show the averaged amplitude spectra of the electrode noise (curve 1) and voltage (curve 2) for the velocity sensor on the logarithmic scale. On the ordinate axis, a value of 0 dB corresponds to the spectral density of noise voltage equal to 1 V/Hz1/2. The velocity of liquid (electrolyte) is equal to 0.5 m/sec and the time of holding of the electrodes in the electrolyte (NaCl solution with a concentration of 4.5 g/liter) was 17 days. The diameters of electrodes are 2.5 mm (measuring electrode) and 9 mm (reference electrode). The coefficient of amplification of the entire measuring channel is 8.75·105. In constructing the spectrum of electrode noise, we take into account the influence of impedance of the electrode sensor on the transfer coefficient of the voltage on the sensor to the preamplifier.

To prove the absence of both vibration and electric noises from the electric motor of the pump, we performed the following experiment.

A section of the pipeline shunting the cell with electrodes was clamped in the course of measurements of the electrode noise. To determine the level of noise from the electric motor, the pipeline passing to the cell with electrodes was blocked; in this case, the shunting section was open. As a result, the liquid transported by the pump did not pass through the cell and the electrode voltage was measured. According to the results of measurements, we revealed the complete absence of noise from the electric motor. In the case of shunting of the measuring cell with a conductor connecting the inlet and outlet tubes of the cell, the electrode noise did not change, which proves the absence of electric noise from the pipeline.

The spectra presented in Fig. 2 have comb structures. Moreover, the frequencies of peaks in the spectra of the electrode noise and the voltage of the velocity sensor coincide. The peaks of the spectrum of velocity pulsations (curve 2) are located at frequencies of 46, 92, and 138 Hz (the first, second, and third harmonics of velocity pulsation). The peaks of the spectrum of electrode voltage (curve 1) are located at frequencies of 46 and 92 Hz and also at 85 and 100 Hz. At a frequency of 138 Hz (on the third harmonic of velocity pulsations), we do not observe any clear peak. The peak of the spectrum at a frequency of 100 Hz is explained by the penetration of the second harmonic of commercial frequency (network frequency). The peak of the spectrum at a frequency of 85 Hz is a consequence of penetration of an external noise of unknown origin. It is also observed in the absence of motion of the liquid.

The frequency of the first harmonic of the velocity pulsations changes by the same factor as the velocity of liquid. The value of peak in the spectrum of the electrode noise at a frequency of 46 Hz is higher than the level of background noise by 10 dB.

According to the results of its calibration, the sensitivity of the velocity sensor is 7.4 V·sec/m. The absolute value of velocity pulsations on the first harmonic is 0.02 m/sec and the relative values of velocity pulsations both on the first and second harmonics are equal to 0.4%. For these insignificant velocity pulsations, the sensor can be regarded as linear, i.e., the pulsations of the electrode voltage and velocity are proportional. The sensitivity of the electrode to the velocity pulsations at a frequency of 46 Hz can be evaluated as 1.2·10–6 V·sec/m.

As the velocity of the liquid grows as a result of increase in the rotation velocity of the electric motor of the pump, we observe the increase in the absolute pulsations of the velocity and electrode noise. However, the elevation of the peak of the first harmonic of electrode voltage is less pronounced than the growth of velocity pulsations. This enables us to believe that the electrode processes responsible for the electrode potential are characterized by a significant lag.

The lag of the electrode processes was estimated according to the results of measurements of the peak in the spectrum of the electrode noise (see Fig. 2, curve 1) on the first and the second harmonics of the velocity pulsations. The peak in the spectrum of the velocity (see Fig. 2, curve 2) for the second harmonic of pulsations was reduced to the same value as for the first harmonic, i.e., was increased by 2 dB as the corresponding peak in the spectrum of the electrode noise. It was assumed that the electrode sensor is a sluggish link with the following frequency characteristic:

where ƒ is a frequency, and τ is a time constant.

According to the measured peaks U 1 and U 2 (reduced value) for the frequencies of the first ƒ1 and the second ƒ2 harmonics, we can find the time constant

According to the results of calculation according to formula (2), we get τ = 4.4 msec. This means that the mechanism of initiation of pulsations of the electrode voltage is characterized by a noticeable lag. The frequency characteristic of the electrode sensor relative to the velocity pulsations of the liquid can be regarded as flat only for frequencies lower than 35 Hz. As the time of holding of the electrodes in the electrolyte decreases, the time constant increases up to τ > 10 msec. In this case, the frequency characteristic cannot be any longer described by relation (1) and is obviously caused by the action of several processes with lag.

The performed investigations enable us to believe that the reaction of electrochemical oxidation of the metal surface of the electrode is the main cause of the electrode noise in the moving electrolyte. The electrode potential relative to the electrolyte is determined by the ratio of the surface charge to the capacitance of the electric double layer. The electric double layer is formed in the process of adsorption of oxygen dissolved in the electrolyte on the electrode surface. Oxygen penetrates to the electrode surface as a result of diffusion in the diffusion layer of liquid adjacent to the electrode. According to the first Fick law, the oxygen deposition rate on the unit area of the electrode surface (density of diffusion current) is proportional to the gradient of its concentration in the diffusion layer [6]. The gradient of oxygen concentration is inversely proportional to the thickness of the diffusion layer, which depends on the liquid velocity [7]. This explains the influence of pulsations of the velocity of liquid flow on the voltage between the electrodes. The adsorbed oxygen reacts with the electrode metal and forms an oxide film. In chemically stable metals, this film is dielectric. The indicated process also affects the electrode potential relative to the electrolyte. The motion of liquid accelerates the electrochemical processes running on the electrode surface, namely, increases the rate of oxygen adsorption and the growth rate of the oxide film, activates the operation of local galvanic elements on the electrode surface formed by inclusions of other metals, and therefore, increases the electrode noise at frequencies lower than 30–50 Hz. In the same frequency range, we also record an increase in the level of electrode noise as compared with the thermal noise and in the absence of liquid motion [3, 5]. These processes vanish with time and, against the background of decrease in the electrochemical activity, the noise caused by the fluctuations of the velocity becomes more pronounced.

The formation of a diffusion layer in the presence of a jump of the liquid velocity is a mechanical process with time constant τ1. The adsorption of oxygen atoms is a lag process with time constant τ2 depending on the surface area of the electrode [8]. It can be supposed that, for small times of holding in the electrolyte, the area of adsorption of oxygen atoms can be quite large, and both time constants determine the lag of the jump of electrode potential relative to the jump of velocity. As the surface is filled with oxygen, the constant τ2 decreases after which the inertial properties of the electrode are mainly determined by the time constant τ1.

We now consider in more detail the background electrode noise detected between the peaks of the spectral characteristic of the electrode noise. It is possible to distinguish three components of the background noise. The first component is the thermal noise of the electrode sensor, the second component is formed by the uncorrelated fluctuations of potential in different parts of the electrode surface caused by the processes of adsorption and desorption of oxygen and chlorine ions, the growth of oxide films, and the activity of local galvanic elements formed by inclusions of other metals on the electrode surface [6]. Chlorine ions can displace oxygen from the electrode surface. In this case, the electrode potential relative to the electrolyte changes. In the presence of the flow of liquid, the processes of oxygen and chlorine adsorption and desorption are randomly alternating, which affects the electrode potential relative to the electrolyte. The third component is the fluctuation of the electrode potential caused by small-scale turbulence in the flow of liquid (in particular, turbulence may appear as a result of flowing around the electrode). For large areas of the electrode, this component has the form of uncorrelated fluctuations of the potential in different parts of the electrode surface. The motion of liquid activates the electrochemical processes on the electrode surface, which leads to an increase in the level of background noise.

After switching the pump on, we observe a “run-out” of the electrode noise, i.e., a decrease in the spectral density of the background noise by more than an order of magnitude at frequencies lower than 50 Hz for 1–2 min. For the first hours of holding of the electrodes in the electrolyte and in the case where the motion is switched on after an idle period of the pump lasting more than one hour, the background value of the electrode noise is high and masks, to a certain extent, the indicated peaks in the spectral characteristic of the electrode noise corresponding to the pulsations of the liquid velocity. The background noise becomes weaker with the increase in the electrolyte concentration and in the area of the electrodes [3].

As the liquid moves with a velocity lower than 0.5 m/sec, the background noise, as a rule, becomes stronger as the velocity increases within the frequency range under 50 Hz. However, the subsequent increase in the velocity weakly affects the background noise because the rate of electrochemical reactions is no longer restricted by the deficiency of oxygen near the electrode surface. To a significant extent, the background noise depends on the time of holding of the sensor in the liquid. In the case of motion of the liquid with a velocity of 0.5 m/sec, the increase in the level of noise for the measuring electrode of stainless steel with a diameter of 2.5 mm and an electrolyte concentration of 4.5 g/liter attained 27 dB at a frequency of 10 Hz and 6 dB within the frequency range 60–100 Hz after holding in the electrolyte for one day. At frequencies higher than 120 Hz, the background noise did not increase. In the case of holding the electrodes in electrolytes for two days, the increase in the spectral density of the background noise at a frequency or 10 Hz attained 12 dB as compared with the noise observed for the immobile electrolyte. At frequencies higher than 50 Hz, the background noise almost did not increase. As a result of holding of the electrodes in the electrolyte for 17 days, the electrode noise in the immobile electrolyte decreased by 2–3 dB. The motion of the liquid (electrolyte) with a velocity of 0.5 m/sec increased the spectral density of the electrode noise by 7 dB at a frequency of 10 Hz, whereas at frequencies higher than 50 Hz, we did not record any strengthening of the noise. Thus, as the holding time of the sensor in the electrolyte increases, the influence of liquid motion on the background noise decreases and manifests itself at lower frequencies. The sensitivity of the sensor to velocity pulsations also decreases but the background noise decreases faster. Therefore, the peak of the spectrum of noise voltage of the sensor determined by the velocity pulsations becomes more pronounced.

The flow in the pipeline is laminar. This is caused by the high velocity of the liquid. Turbulence, which may appear in the elements of the pipeline and in the velocity sensor, does not exert any noticeable influence on the data of measurements because the velocity pulsations observed between the peaks of the spectral characteristic are lower (by 30–35 dB) than for the first and second harmonics of the rotation velocity of the pump (see Fig. 2). In the spectrum of the electrode noise, the background noise between the peaks is lower (by 10–20 dB) than the values corresponding to peaks and, hence, the influence of turbulent pulsations is not detected. The law of distribution of the noise (Fig. 3) in the band lying below the peak of the first harmonic of the velocity pulsations is close to Gaussian.

Density function of the distribution of electrode noise within the frequency band up to 60 Hz: 1) curve computed according to the measured histograms; 2) computed curve of the Gaussian distribution for the same variance; the measuring electrode with a diameter of 4.5 mm, the electrolyte concentration is equal to 9 g/liter, the time of holding is 11 days, and the velocity of liquid is 2.6 m/sec.

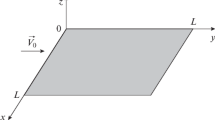

Turbulence may appear in the case where the liquid flows around the electrodes of the sensor. Since in the turbulized flow of liquid near the surfaces of the electrodes we also reveal the appearance of pressure pulsations, the influence of these pulsations on the electrode noise is also investigated. For this purpose, we constructed an installation schematically depicted in Fig. 4. The dielectric bath 10 filled with an electrolyte (NaCl solution) and the reference 9 and measuring 7 electrodes mounted on its lid were placed in the steel box 11 playing the role of electrostatic and magnetostatic screens. Electrodes 7 and 9 were mounted in dielectric plugs of the metallic tube 8 insulated from the electrolyte by a layer of a nitro dye. Tube 8 serves as an electrostatic screen and is connected with the common bus of the installation.

Schematic diagram of the installation aimed at the investigation of the influence of pressure pulsations on the electrode noise: 1) computer; 2) analog-to-digital converter; 3) low-noise amplifier; 4) magnetostatic screen; 5) audio-frequency generator; 6) dynamic loudspeaker; 7, 9) electrodes; 8) electrostatic screen; 10) dielectric bath with electrolyte; 11) steel box-shaped screen.

A sound wave was excited in the bath filled with the electrolyte in the vicinity of the working surface of one of the electrodes. As emitter 6, we used a 0.25 GD-19 dynamic loudspeaker. A light-weight dielectric rod 160 mm in length is pasted to the diffuser of the loudspeaker. At the end of this rod, we mount a dielectric head with a diameter of 20 mm. The loudspeaker is placed into the magnetostatic screen 4 and installed over the bath on a steel sheet with a hole; the indicated rod with the head passes through this hole. The head has a shape of a round fragment of a sphere with its concave side facing the measuring electrode. The distance between the electrode and the head is 15 mm. This head is the actual source of sound vibration in the bath. The alternating voltage was supplied to the loudspeaker from the audio-frequency generator 5 at a frequency of 740 Hz with a power input of 30 mW.

By using a DEMSh-1a water-proof microphone, it was established that the amplitude of pulsations of the sound pressure near the first (measuring) electrode was as high as several tens of pascals. At the same time, near the second (reference) electrode connected with the common bus the amplitude of pulsations was lower by more than an order of magnitude. Hence, the sound pressure affects only the surface of the measuring electrode. The electrode voltage was increased by the low-noise amplifier 3 and delivered (through the ADC 2) to computer 1, where we measured the amplitude spectrum of the electrode voltage. Then we checked the presence of electromagnetic pickup on the electrodes. For this purpose, the emitting head was removed from the rod and voltage was applied to the dynamic loudspeaker. If the structure of the electrode block is insufficiently rigid, then the spectrum of the electrode noise contains a peak at the frequency of sound emission due to the microphone effect caused by the vibration of electrodes in the magnetic field of the loudspeaker.

The fourfold increase in the electrolyte concentration from 4.5 up to 18 g/liter does not affect the value of the peak. The use of a more rigid structure of the electrode block makes it possible to decrease the height of this peak up to its complete disappearance. Then we also carried out measurements in which the emitting head mounted on the rod and showed that the spectrum of the electrode noise does not contain a peak at the frequency of the emitted sound. Thus, it was proved that the pulsations of the sound pressure do not affect the potential drop between the electrodes.

Conclusions. The pulsations of liquid velocity generate the corresponding pulsations of the electrode potential. As a result, the spectrum of the noise voltage of a sensor held in an electrolyte for a long time contains a peak at the frequency of pulsation of the liquid velocity. This peak is higher by 10 dB than the level of the background noise even for the relative velocity pulsations smaller than 0.5%. In the turbulized liquid flow, this noise component can be predominant and specify the sensitivity of the sensor.

The electrochemical processes running on the electrode surface and leading to the appearance of sensitivity of the sensor to velocity pulsations are lag processes and detectable mainly at frequencies under 30–50 Hz. The motion of liquid makes the background noise of the sensor held in the electrolyte for a long time almost twice stronger within the frequency range under 50 Hz. The background noise of the sensor can be regarded as Gaussian. The influence of pulsations of the liquid pressure on the potential drop between the electrodes was not discovered.

To reduce the intrinsic noise of the electrode sensor, it is necessary to increase the area of its electrodes, the sensor must be held in the electrolyte for at least 10 days, and the electrodes should be protected against the incoming liquid flow by special fairings. The electrodes should be made of chemically stable metals, which form dense oxide films on the surface and make it possible to attain low values of the electrode noise. Among these metals, we can mention titanium, tantalum, and stainless steel [3,4,5].

References

S. L. Bernstein, M. L. Burrows, J. E. Evans, et al., “Long-range communications at extremely low frequencies,” Proc. IEEE, 62, 292–312 (1974).

E. F. Zimin and E. S. Kochanov, Measurement of the Intensities of Electric and Magnetic Fields in Conducting Media, Energoizdat, Moscow (1985).

V. G. Maksimenko, “Problems of reducing the intrinsic noise of electrode sensors of the electric field moving in electrolyte,” Radiotekh. Elektron., 47, No. 7, 809–813 (2002).

V. G. Maksimenko and V. I. Naryshkin, “‘Noise of motion’ of the electrode sensors of the electric fields in the sea and procedures of its reduction,” Radiotekh. Elektron., 48, No. 1, 70–76 (2003).

V. G. Maksimenko, “Statistical characteristics of nonstationary noise of electrode sensors,” Radiotekh. Elektron., 58, No. 8, 768–775 (2013).

V. V. Skorcheletti, Theoretical Electrochemistry, Khimiya, Leningrad (1974).

V. G. Levich, Physicochemical Hydrodynamics, Fizmatgiz, Moscow (1959).

A. N. Frumkin, V. S. Bagotskii, Z. A. Iofa, and B. N. Kabanov, Kinetics of Electrode Processes, Izd. MGU, Moscow (1952).

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated from Izmeritel’naya Tekhnika, No. 9, pp. 57–61, September, 2017.

Rights and permissions

About this article

Cite this article

Maksimenko, V.G. Noise of an Electrode Sensor in a Flow of Liquid. Meas Tech 60, 945–951 (2017). https://doi.org/10.1007/s11018-017-1298-9

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11018-017-1298-9