We present the results of complex high-temperature testing of commercially pure vanadium. It is shown that vanadium is characterized by the high stability of physicomechanical properties and structure after holding in the oil-free vacuum at 1073°K for 1000 h under stresses of static loading of up to 75% of the ultimate long-term strength.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

The functional characteristics of vanadium are much better than for the major part of candidate materials for elements (first wall, circuits of the cooling system, etc.) of promising breeder and synthesis reactors of different kinds. Vanadium is also used in the airspace, chemical, and other branches of industry [1,2,3,4,5]. However, at temperatures higher than 750–1000°С, due to the intensification of diffusion processes and possible softening, the application of vanadium and alloys based on vanadium is disputable. The problem of prediction of the variations of their properties in the course of long-term operation is especially urgent. At the same time, the problems of stability of the physicomechanical properties of structural materials and evaluation of the residual service life of the corresponding products remain unsolved up to now. The objective of investigations in this field is to establish conditions of their loading under which their properties remain stable, to study the accompanying processes and, therefore, to get new results required for the prediction of their deformation and fracture. In simple cases, some dependences of the deformation of materials on the level of fracture stresses are known for a long period of time [6]. However, the relationship between the levels of acting stresses and the behavior of the metal in the process of deformation becomes more complicated, especially in the case of complex conditions of investigation, namely, under the combined action of preliminary deformation and temperature, preliminary deformation and working media, and other type of interactions. Moreover, the long-term operation leads to the degradation of the operating properties of most structural materials. As important factors accelerating this degradation, we can mention temperature, level of loading, duration of action of these factors, and structural instability.

In what follows, we study the influence of tensile stresses and the time of their action at elevated temperatures (1073°K) on the physicomechanical properties of vanadium with an aim of evaluation of their stability and the efficiency of application of different testing methods.

The object of investigation is commercially pure VnМ2 vanadium with a total concentration of interstitial impurities (oxygen, nitrogen, and hydrogen) in the initial state (after vacuum recrystallization annealing) that does not exceed 0.14 wt.%.

We applied a method [6, 7] of application of (nondestructive) preloading, which enables one to establish the regularities of deformation, the changes in the physicochemical properties, the structural transformations, and the relationships between them. The analysis of all these features enables us to predict the ultimate state of the material prior to fracture.

We used small specimens [7] obtained by cutting out from a sheet material with a thickness of 1 mm and a total length of 40 mm and subsequent grinding to a prescribed shape. The validity of using specimens of these sizes for the durability tests was justified in [6, 7] and, for vanadium, alloys based on vanadium, and other metals intended for high-temperature applications, was corroborated in [1, 4, 6, 8].

Since, for the investigation of the physicomechanical properties of deformed metals, it is necessary to have identical conditions both in the case of preloading and in the course of subsequent tests, it is reasonable to use multiple-station installations developed and described in [6]. On the basis of the analysis of the results of shortterm tensile-strength tests at 1073°K in a vacuum of 1.03·10–4 Pa (Fig. 1), by the extrapolation method, we determined the levels of preloading corresponding to the specific loading coefficients k p with steps taking into account the nonlinear character of their influence on the properties of the metal. In particular, the level of pre–stressing was equal to \( {\sigma}_p={k}_p{\sigma}_{ls}^{\ast }, \) where \( {\sigma}_{ls}^{\ast } \) is the critical level of fracture stresses (coincides with the ultimate long-term strength (σ ls ) and k p varies within the range 0 ≤ k p ≤ 1 (see Table 1).

To minimize possible influence of the components of residual atmosphere, the durability tests were performed in an oil-free vacuum of ~ 10–4 Pa. Then we studied structural changes by the methods of metallographic (MIM-9) and X-ray diffraction (DRON-3) analyses and the physical [microhardness and microthermoelectromotive force (TERS); tungsten needle, 373°K] and mechanical properties in tension at a strain rate of 5 ·10–3 sec−1 in an atmosphere of spectroscopically pure argon. The X-ray diffraction investigations of the lattice parameter were performed by the Debye–Scherrer–Hall method in an URS-55 installation with the help of a BSV-2 tube with chromium anode (in the mode with U = 40 kV and I = 12 mA). The specimens were held in the form of bars with a diameter of 0.5 mm in an RKU chamber.

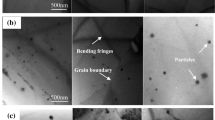

The metallographic analysis of the internal layers of the metal indicates that, in the course of holding, the number of elongated grains decreases with time as compared with their number in the metal in the initial state after annealing. The degree of equilibrium of the granular structure increases. At high magnifications, we detect an insignificant amount of highly dispersed precipitates of the secondary phases, which are obviously vanadium oxides and carbides [1]. The quantitative and morphological correlations of precipitates with time or the level of prestressing were not detected, which agrees with the results obtained in [1, 9].

According to the results of mechanical testing (see Table 1), after holding under loading, the ratio σ s /σ0.2 decreases from 1.4 down to 1.02. If the stresses of preliminary loading increase up to σ p = 30 МРа, then (independently of the duration of holding) the ultimate strength of vanadium remains almost constant, while the yield strength becomes somewhat higher than in the initial state. For σ p > 30 МРа (k p ≈ 0.5), a trend to insignificant decrease is observed for σ s and σ0.2 (Fig. 2). The numerical values lie within a narrow range 0–5 МРа, which is close to the spread of errors for this type of testing. The curves shown in Fig. 2 reveal a high stability of the mechanical properties of vanadium. However, this is insufficient to believe that, at this temperature, thermally activated processes are retarded and that their harmful influence (softening and embrittlement) is impossible. It is necessary to use additional methods of investigations and, in particular, physical methods.

The unalloyed VNМ2 vanadium is characterized by a BCC lattice with a parameter of 0.30323 nm. In the durability tests, we established an almost linear increase in the lattice parameter of the specimens with time and the level of loading (Fig. 3) as compared with the lattice of reference specimens tested under identical temperature and time conditions but in the absence of loading. This means that, in the matrix, one may observe the ordering of interstitial impurities, the inleakage (from the residual atmosphere), in particular, of carbon and oxygen [8, 9], their binding in the V2C and VO compounds, and the decomposition of similar impurity compounds.

The processes running in the metal can be additionally evaluated by analyzing the changes in its thermoelectric properties.

The thermoelectric phenomena in metals and alloys are quite complicated but sensitive to the changes in their chemical compositions and the presence of defects [10, 11]. In these metals and alloys, one may observe the appearance of a thermoelectromotive force (TEMF) caused by the contact drop of potentials and depending on thermal vibrations of the lattice and the diffusion of electrons.

In Fig. 4, we present the dependences of the TEMF on the conditions of life-cycle tests. The behavior of the curves of TEMF shows that, only after holding for 500 h, the thermoelectric properties of vanadium are stabilized (Fig. 4а). Independently of the level of applied loads, its fluctuations are insignificant for 500 and 1000 h (Fig. 4b). However, within the first 100 h, stabilization is typical only of the material subjected to the action of the maximal load.

Thus, it was established that, in the course of life-cycle tests, the unalloyed vanadium is characterized by the high stability of its mechanical properties in vacuum at 1073°K. This conclusion is confirmed by insignificant changes in σ s and σ0.2 observed for reference specimens after holding. However, the deviations of the lattice parameter observed as the holding time increases and depending on the level k p reflect the accumulation of defects in the lattice (Fig. 4). In particular, the increase in the lattice parameter is possible due to the dissolution of interstitial impurities and, first of all, of oxygen (whose source is a high-temperature medium) in a solid solution based on vanadium. According to [12], the dissolution of these impurities in the vanadium lattice in amounts of up to 1 at.% leads to the increase in the lattice parameter by 0.00038–0.00041 nm. Thus, the oxygen-absorption ability at high temperatures is preserved even under the conditions of oil-free high vacuum.

According to the contemporary classical electron theory and the Mott–Jones band theory of conductivity, the thermoelectric properties are extremely sensitive to the structural changes and the least changes in the electron-energy spectra of metals, while the presence of structural heterogeneities, such as defects of the crystal lattice, impurities, residual stresses, and plastic strains, also affects the behavior of the corresponding dependences (Fig. 4). In the case of preloading, the TEMF increases with time. Its relative changes are much more pronounced than the changes in the other characteristics. Stabilization occurs only after holding for 500 h.

On the basis of the analysis of the experimental data, it was established that, in the oil-free vacuum, the long-term loading for 1000 h and its level at 1073°K insignificantly affect the mechanical strength properties of commercially pure vanadium.

In the course of holding, the interstitial impurities can be absorbed by the metal from the residual atmosphere. This is accompanied by the increase in the lattice parameter and in the TEMF. Their values increase with time and with the level of stresses. The maximum sensitivity to the state of the metal is detected with the help of the thermoelectric method.

References

V. V. Shyrokov, Ch. B. Vasyliv, and O. V. Shyrokov, “Ways of improving the high-temperature work service of vanadium and some alloys used in reactors,” J. Nuclear Mater., 394, 114–122 (2009).

V. М. Mikhailov, V. А. Evtikhin, I. Е. Lyublinskii, А. V. Vertkov, and А. N. Chumaniv, Lithium in the Thermonuclear and Space Power Engineering of the 20th Century [in Russian], Énergoizdat, Moscow (1999).

G. М. Gryaznov, V. А. Evtikhin, L. P. Zavyal’skii, А. Ya. Kosukhin, and I. Е. Lyublinskii, Materials Science of Liquid-Metallic Systems of Thermonuclear Reactors [in Russian], Énergoizdat, Moscow (1989).

V. V. Shirokov, “Methods of improving the high-temperature strength and corrosion resistance of vanadium and certain alloys used in reactors,” Fiz.-Khim. Mekh. Mater., 35, No. 3, 91–104 (1999); English translation: Mater. Sci., 35, No. 3, 401–417 (1999).

Z. А. Duryagina, O. I. Eliseeva, V. N. Fedirko, and V. P. Tsisar, “Concept of application and protection of structural and functional materials for nuclear and power installations,” Metalloved. Term. Obrab. Met., No. 3, 77–84 (2001).

G. G. Maksimovich (editor), Strength of Deformed Metals [in Russian], Naukova Dumka, Kiev (1976).

G. G. Maksimovich, Micromechanical Investigations of the Properties of Metals and Alloys [in Russian], Naukova Dumka, Kiev (1974).

V. V. Shyrokov, O. S. Tcvikilevitch, and Ch. B. Vasyliv, “Stability of strengthened niobium alloys in long-term high-temperature loading conditions,” Z. Metallkunde, 93, No. 11, 1123–1131 (2002).

V. V. Shyrokov and O. V. Shyrokov, “Influence of durability tests on the structure and physicomechanical properties of vanadium,” in: Proc. of the 18th Open Sci-Eng. Conf. of Young Scientists and Experts at the Karpenko Physicomechanical Institute of the Ukrainian National Academy of Scientists “KMN-2003” (October 8–10, 2003) [in Ukrainian], Lviv (2003), pp. 81–85.

A. A. Lukhvich, Influence of Defects on the Electric Properties of Metals [in Russian], Nauka Tekhnika, Minsk (1976).

А. A. Soldatov, А. I. Seleznev, I. I. Fiks, А. I. Soldatov, and Kh.-М. Kröning, “Nondestructive rapid testing of plastic strains by measuring the differential thermal EMF,” Defektoskopiya, No. 3, 49–52 (2012).

E. Fromm and E. Gebhardt, Gase und Kohlenstoff in Metallen, Springer, Berlin (1976).

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated from Fizyko-Khimichna Mekhanika Materialiv, Vol. 53, No. 4, pp. 66–70, July–August, 2017.

Rights and permissions

About this article

Cite this article

Shyrokov, V.V., Shyrokov, O.V. Influence of Long-Term Aging Under Loading on the Physicomechanical Properties of Vanadium. Mater Sci 53, 495–500 (2018). https://doi.org/10.1007/s11003-018-0100-8

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11003-018-0100-8