We study the electrochemical deposition of gold nanoparticles in solutions of 0.002–0.008 M H[AuCl4] + 0.05 M Bu4NClO4 in dimethylformamide on the surfaces of glassy carbon, titanium, and ITO-glass (Indium-Tin Oxide glass). It is shown that the electric reduction of the metal begins at a cathode potential E = – 0.1 V and continues up to – 1.2 V. As a result, we observe the formation of discrete particles from tens to hundreds nanometers in size. It is shown that the main factors affecting the morphology of deposits are the cathode potential, the duration of electrodeposition, and the concentration of H[AuCl4] in the solution.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

In various fields of science, the researchers give much attention to the production nanosized gold particles and investigation of their properties [1–9]. This is explained by their application in sensors [1–4, 6], as catalysts [7–9], in medical technologies [1, 3], and in electronics [1]. The last decades are also marked by the extensive investigation of the problems of deposition of nanoparticles and nanostructural films on various substrates, such as ITO-glass (Indium-Tin Oxide glass) [2, 4, 6, 8], glassy carbon [5], titanium polyaniline [7], and graphite [9]. The problem of electrochemical production of gold nanoparticles is well studied for aqueous solutions. However, the pH factor and, hence, the necessity of buffering additives, hydrogen release at high cathodic potentials, and the instability of some components of electrolytes restrict the applicability of aqueous media. Therefore, in the last years, we observe an increasing interest in the elecrochemistry of metals in nonaqueous solutions [10–12]. Thus, the organic aprotic solvents, including, e.g., dimethylsulfoxide, dimethylformamide, propylenecarbonate, and acetonitrile, are characterized by high electrodonor properties, electrochemical stability, and inertness to the major part of metals, including their nanosized particles. This determines the following specific features: the formation of stable solvates with metal ions, which favors the cathodic polarization; the adsorption of molecules of solvents on the metal surface, which affects the formation of the geometry of particles, and the electrochemical deposition of metals for high values of the electrode potentials without side processes. The indicated characteristics of the media of organic aprotic solvents are favorable for the electrodeposition of nanoparticles and nanostructural deposits of metals, which was demonstrated on the examples of palladium [10], gold [11], and silver [12].

The aim of the present work is to study the possibility of cathodic reduction and the regularities of formation of fixed particles of gold by the electrodeposition in dimethylformamide solutions of H[AuCl4].

Experimental Procedure

Electrochemical investigations and electrolysis were carried out in a standard three-electrode thermostated glass electrolyzer 50 cm3 in volume at temperatures of 25–55°C. Gold was deposited from dimethylformamide solutions of (0.002–0.008) M H[AuCl4] + 0.05 M Bu4NClO4 on the surfaces of glassy carbon, ITO-glass, and titanium. The working electrodes (glassy carbon and titanium) were made in the form of cylinders with ∅ 5 and 10 mm, respectively, whose lateral surfaces were insulated by fluoroplastic strips. The ITO-glass (Aldrich) had a resistance of 70–100 Ω /sq and a working surface 10 × 10 mm in size. The role of anode was played by a gold plate. Prior to each experiment, the glassy carbon and titanium electrodes were ground with fine-grained emery paper. Then they were washed with dimethylformamide. The ITO-glass was only washed with dimethylformamide. The electrodeposition was studied for potentials within the range – 0.1–(– 1.4) V with the use of an IPC-Pro potentiostat. The potentials are presented relative to the silver-chloride reference electrode.

The total duration of electrolysis was determined according to the amounts of electric charge required for the deposition of conventional gold films 10, 30, and 50 nm in thickness. The obtained cathodic deposits were successively washed in dimethylformamide and isopropanol without removing from the substrate and dried by a flow of hot air. To study the specimen surfaces, we used a ZEISS EVO-40XVP scanning electron microscope. The images of the surfaces were obtained by recording secondary electrons by means of scanning of the surface with electron beams. The secondary emission was excited by electron beams with an energy of 15–20 keV. The images were processed with the help of the SMARTSEM software package.

Results and Discussion

The difference between the values of electron-donor capability of the dimethylformamide and dimethylsulfoxide organic aprotic solvents equal to 26.6 and 28.9, respectively, is insignificant.

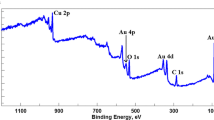

Thus, it is possible to assume that the electrochemical reduction of gold from [AuCl4]– ions in dimethylformamide solutions runs in two stages, just as in dimethylsulfoxide solutions [11]. According to the accumulated results, we can conditionally separate two ranges of cathodic potentials in the polarization curves (Fig. 1): up to – 0.1 V, where [AuCl4]– ions are reduced to [AuCl2]–, and higher than – 0.1 V, where we observe the process of reduction of [AuCl4]– and [AuCl2]– ions to metallic gold. In this case, the behavior of the curves is almost independent of temperature. An insignificant increase in currents as temperature increases (by less than 20% per 10°) reveals the predominantly diffusion character of this factor.

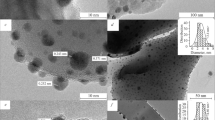

The results of electron-microscopic studies of the deposits indicate that, within a broad range of the cathodic potentials of electrolysis, the discrete particles are relatively uniformly distributed over the surface of the substrate (Fig. 2). At the same time, their geometry strongly depends on the value of the potential. Thus, for E = (– 0.2)–(– 0.8) V, we observe the formation of flower-like clusters with a mean size of 300 nm. They are formed by “thorns” 40–80 nm in size (Fig. 2a, b). This is typical of the deposition of gold for low values of the cathodic potentials from solutions containing [AuCl4]– ions [11]. For higher cathodic potentials within the range (–0.9)–(–1.2 V), we observe a trend to the formation of spheroids whose sizes vary within a broad range: 70–800 nm (Fig. 2c). This means that, in the course of electrolysis, the processes of formation of nuclei and their growth run simultaneously. Note that the nature of substrate insignificantly affects the geometry of gold particles and their distribution over the surface, which was demonstrated by the examples of ITO-glass and titanium. The subsequent increase in the cathodic potential (– 1.3–(– 1.4) V) leads to an increase in the amount of deposits and the appearance of bulky conglomerates with highly developed surfaces (Fig. 2d). This is caused by the attainment of the limiting value of current. For higher values, we observe the formation of dispersed deposits.

As the duration of deposition increases, we observe an increase in the total number of particles and their sizes (Fig. 3). This confirms the assumption made above concerning the simultaneous realization of two processes on the cathode surface, namely, the processes of formation of nuclei and their growth.

As the concentration of H[AuCl4] increases, we observe a trend to increase in the sizes of gold particles (Fig. 4). Thus, for E = – 1.2 V in a 0.002 M H[AuCl4] solution, the particles formed on the glassy-carbon surface mainly have the sizes that do not exceed 100 nm (Fig. 4a). At the same time, in a 0.008 M solution, the corresponding sizes are 100–200 nm (Fig. 2b). In this case, we also observe an increase in the range of particle sizes.

Hence, the formation of the geometry of discrete particles of gold on the surfaces of substrates in dimethylformamide solutions of tetrachloroauric acid strongly depends on the value of the cathodic potential, the duration of electrodeposition, and the concentration of H[AuCl4].

Conclusions

Discrete particles of gold from tens to hundreds nanometers in size are formed on the surfaces of glassy carbon, titanium, and ITO-glass in (0.002–0.008) M H[AuCl4] + 0.05 M Bu4NClO4 solutions with dimethylformamide within the range of cathodic potentials (– 0.1)–(– 1.2) V. The main factors affecting the size of gold particles are the value of the cathodic potential, the concentration of H[AuCl4], and the duration of electrodeposition.

The reduction of gold from dimethylformamide solutions of H[AuCl4] starts at a potential of – 0.1 V but its deposition in noticeable quantities is detected only for – 0.2 V. Depending on the cathodic potential, we observe the formation of the following types of gold particles: flower-like clusters (∼300 nm) formed by particles 40–80 nm in size within the range (– 0.2)–(– 0.8) V; spheroids with a broad range of sizes (70–600 nm) formed within the range (– 0.9)–(– 1.2) V, and conglomerates with highly developed surfaces (dispersed particles several micrometers in size) formed within the range (– 1.3)–(– 1.4) V.

As the concentration of H[AuCl4] in a solution increases, we observe a trend to the increase both in the sizes of gold particles and in the range of particle sizes.

References

M. C. Daniel and D. Astruc, “Gold nanoparticles: assembly, supramolecular chemistry, quantum-size-related properties, and applications toward biology, catalysis, and nanotechnology,” Chem. Rev., 104, No. 1, 293–346 (2004).

X. Dai and R. G. Compton, “Direct electrodeposition of gold nanoparticles onto indium-tin oxide film coated glass: application to the detection of arsenic(III),” Analyt. Sci., 22, No. 4, 567–570 (2006).

S. Guo and E. Wang, “Synthesis and electrochemical applications of gold nanoparticles,” Analyt. Chim. Acta, 598, No. 2, 181–192 (2007).

L. Wang, W. Mao, D. Ni, J. Di, Y. Wu, and Y. Tu, “Direct electrodeposition of gold nanoparticles onto indium/tin oxide film coated glass and its application for electrochemical biosensor,” Electrochem. Commun., 10, No. 5, 673–676 (2008).

L. Komsiyska and G. Staikov, “Electrocrystallization of Au nanoparticles on glassy carbon from HClO4 solution containing [AuCl4]–,” Electrochim. Acta, 54, No. 2, 168–172 (2008).

Yu. Wang, J. Deng, J. Di, and Yi. Tu, “Electrodeposition of large size gold nanoparticles on indium-tin oxide glass and application as refractive index sensor,” Electrochem. Comm., 11, No. 5, 1034–1037 (2009).

M. Hosseini, M. M. Momeni, and M. Faraji, ”Electrochemical fabrication of polyaniline films containing gold nanoparticles deposited on titanium electrode for electro-oxidation of ascorbic acid,” J. Mater. Sci., 45, No. 9, 2365–2371 (2010).

H.-J. Kang, S. Patra, J. Das, A. Aziz, J. Jo, and H. Yang, “Effect of aging on the electrocatalytic activity of gold nanoparticles,” Electrochem. Commun., 12, No. 9, 1245–1248 (2010).

M. Etesami and N. Mohamed, “Catalytic application of gold nanoparticles electrodeposited by fast scan cyclic voltammetry to glycerol electrooxidation in alkaline electrolyte,” Int. J. Electrochem. Sci., 6, No. 10, 4676–4689 (2011).

O. I. Kuntyi, P. Y. Stakhira, V. V. Cherpak, O. I. Bilan, Ye. V. Okhremchuk, L. Yu. Voznyak, N. V. Kostiv, B. Ya. Kulyk, and Z. Yu. Hotra, “Electrochemical depositions of palladium on indium-tin oxide-coated glass and their possible application in organic electronics technology,” Micro Nano Lett., 6, No. 8, 592–595 (2011).

M. A. L. Monzon, F. Byrne, and J. M. D. Coey, “Gold electrodeposition in organic media,” J. Electroanal. Chem., 657, Nos. 1–2, 54–60 (2011).

O. Kuntyi, Ye. Okhremchuk, O. Bilan’, J. Hapke, and I. Saldan, “Silver particles growth by pulse electrolysis in acetonitrile solutions,” Centr. Europ. J. Chem., 11, No. 4, 514–518 (2013).

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated from Fizyko-Khimichna Mekhanika Materialiv, Vol. 51, No. 6, pp. 119–123, November–December, 2015.

Rights and permissions

About this article

Cite this article

Kuntyi, O.I., Sus, L.V., Kornii, S.A. et al. Electrodeposition of Gold Nanoparticles in Dimethylformamide Solutions of H[AuCl4]. Mater Sci 51, 885–889 (2016). https://doi.org/10.1007/s11003-016-9917-1

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11003-016-9917-1