We propose a theoretical and experimental approach to the quantitative evaluation of the influence of hydrogen on the mechanical properties of 40Kh steel. We experimentally determine the characteristics of strength and plasticity and construct analytic dependences of the yield strength, true fracture stresses, and relative narrowing of 40Kh steel on the concentration of hydrogen in steel.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

It is known that hydrogen acting upon a metal affects its physicomechanical characteristics [1]. Therefore, a procedure was developed to determine the influence of hydrogen on the physicomechanical properties of the material in the case of its deformation. The procedure is based on the force scheme of tension of cylindrical specimens [2] in a high-pressure chamber.

Materials and Experimental Procedure

To determine the mechanical characteristics of 40Kh steel, we used smooth specimens with round cross sections of type IV (according to GOST 1497-84). They had the following nominal diameter in the working part: d 0 = 10 mm, a length of 100 mm, and a screw grip part. The specimens were made of a rod of 40Kh steel in the as-delivered stat with regard for the standard requirements concerning the site of cutting-out of the specimen from the blank and the modes of cutting and cooling.

The strength tests were carried out in a FP-100/1 universal tearing machine under static tension. The characteristics of strength (σ0.2, σu) and plasticity (δ, ψ) of the analyzed steel were determined under the following conditions: a temperature of 20°С, a humidity of 50–60%, an atmospheric pressure of 0.1 MPa, and a rate of loading of the specimen of 1.667°10–5 m/sec (remains constant in the course of testing of all batches of the specimens). According to GOST 1497-84, the mechanical characteristics were measured by testing three specimens.

We loaded the specimens up to fracture with simultaneous recording of the “load P –elongation ∆l ” and “load P –contraction ∆d ” diagrams with the use of a specially developed measuring system. After fracture, we measured the elongation l c and neck diameter d c of the specimen and used these results to compute the mechanical characteristics [2].

To estimate the influence of gaseous hydrogen on the resistance of steel to hydrogen degradation, we performed experimental investigations of nonhydrogenated specimens in the as-delivered state in air and specimens hydrogenated in special testing chambers with specified parameters of the medium. The specimens were hydrogenated in the chamber at a temperature of 400°С under pressures of 0.1, 0.9, and 10 МРа for 4 h. Then they tested in a chamber filled with hydrogen and destroyed under the indicated pressures. In the course of the tests, we recorded the “tensile force vs. elongation” diagrams to the memory of a PC with the use of an analog-todigital converter.

Determination of Hydrogen Concentration in the Analyzed Steel

To establish the dependences of mechanical characteristics on the amount of hydrogen, we developed a method according to which the concentration of hydrogen was measured on the side of fracture surface in a fragment of a broken hydrogenated specimen tested under pressures of 0.1, 0.9, and 10 МPа.

We placed a cut-out fragment of the investigated specimen 2 × 3 mm in size in liquid nitrogen. The hydrogen concentration in this fragment on the side of the fracture surface was measured by the method of vacuum extraction [3] within the measurement range 10–5 –10–2 wt.% with an accuracy of ± 3%. The procedure of gas extraction from the metal was carried out by pulse heating to a temperature of 2500°C. The results of analysis (Table 1, numerators) were conveyed to a digital voltmeter. In the denominators, for the sake of comparison, we present the theoretical results obtained by the Sieverts law.

As follows from Table 1, as the hydrogen pressure in the chamber increases to 10 МPа and the cylindrical specimens of 40Kh steel are destroyed, the concentration of hydrogen in the fragment of the specimen on the side of the fracture surface (corresponding to the maximal stresses) increases.

Results of the Tests

The determined mechanical characteristics of 40Kh steel in air and hydrogen are shown in the histogram (Fig. 1).

On the basis of the results of analysis of the fracture diagrams for 40Kh steel obtained in air and in hydrogen, we discovered that the characteristics of strength σ0.2 and σu under the action of hydrogen increase by 2–3%, whereas the relative narrowing ψ c and true fracture stresses Sc decrease by 8–10%. Hence, the influence of hydrogen on the physicomechanical characteristics of the material becomes stronger for high stresses and strains that lead to its plastic deformation.

Dependences of Mechanical Characteristics on the Hydrogen Concentration

To describe the results of experimental investigations by analytic dependences, we use the least-squares method [4]. For a given system of n experimental points (x i , y i ), we have to find an analytic dependence Y(x) = F(x, a 1, a 2, …, a m ) for which the condition of the least standard deviations from y i at x i is satisfied. In other words, it is necessary to find the minimum value of the functional

where a j are unknown parameters that, along with the function F, guarantee the equality

and m is the number of parameters in the relation for the function F.

For this functional, we can represent the formal expression as follows:

We select the type of the function F by analyzing the experimental results and find the values of arbitrarily chosen m parameters from the solution of the system of algebraic equations

where

in accordance with (3).

Hence, in the general statement, we have to solve the following system of m algebraic equations with respect to the parameters aj ( j = 1, 2,⋯, m) :

By analyzing the experimental data that reveal the influence of hydrogen concentration CH on various mechanical properties, such as the conventional yield strength σ0.2 , true ultimate strength S c , and relative narrowing at fracture Ψ c , we can show that the required dependences are monotone within the analyzed ranges and have no characteristic inverse points.

To describe these dependences, we use a fractional rational function with three parameters a j , i.e.,

where a 1, a 2 , and a 3 should be found from conditions (6), where the partial derivatives of the chosen function (7) with respect to the parameters a j can be written as follows:

Substituting the specific expressions (7) and (8) in system (6), we arrive at the following nonlinear system of three algebraic equations with respect to the parameters a j ( j = 1, 2, 3) :

Example of Application of the Proposed Method

To apply the proposed method, we use the experimental results (Table 2) of our study of the influence of hydrogen concentration on the mechanical characteristics of 40Kh steel.

For the sake of convenience, in order to represent the results of analytic processing of these experimental data, we pass to relative quantities (Table 3) under the assumption that the concentration of H2 is equal to zero in nonhydrogenated specimens of 40Kh steel.

On the basis these data and the function given by relation (7), we get the following dependences of three relative mechanical characteristics on the hydrogen concentration:

where \( i={A}_i,A=\left\{\begin{array}{c}\hfill 1\hfill \\ {}\hfill 2\hfill \\ {}\hfill 3\hfill \end{array}\right\} \), and the unknown parameters are presented in Table 4.

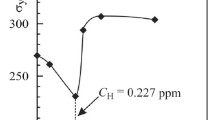

In Fig. 2, we show the results of three-parameter interpolation of the experimental data.

Conclusions

We determine the characteristics of strength and plasticity of 40Kh steel in the as-delivered state in air and in hydrogen under fixed pressures of 0.1, 0.9, and 10 МРа. To determine] the dependences of the mechanical characteristics on the level of hydrogenation of steel, we realized the approximation of the experimental results. The proposed approach can be used in studying the fracture resistance in hydrogen-containing media for different classes of low-alloy structural steels in arbitrary pressure ranges.

References

O. E. Andreikiv and O. V. Hembara, Fracture Mechanics and Durability of Metal Materials in Hydrogen-Containing Media [in Ukrainian], Naukova Dumka, Kyiv (2008).

GOST 1497-84 (ST CÉV 471-77). Metals. Methods for Tensile Testing [in Russian], Izd. Standartov, Moscow (1985).

A. B. Vainman, R. K. Melekhov, and O. D. Smiyan, Hydrogen Embrittlement of Elements of High-Pressure Boilers [in Russian], Naukova Dumka, Kiev (1990).

C. L. Lawson and R. J. Hanson, Solving Least Squares Problems, Prentice-Hall, Englewood Cliffs, NJ (1974).

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated from Fizyko-Khimichna Mekhanika Materialiv, Vol. 50, No. 5, pp. 111–115, September–October, 2014.

Rights and permissions

About this article

Cite this article

Ivanyts’kyi, Y.L., Hembara, O.V., Shtayura, S.T. et al. Estimation of the Influence of Hydrogen on the Mechanical Characteristics of 40KH Steel. Mater Sci 50, 748–754 (2015). https://doi.org/10.1007/s11003-015-9781-4

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11003-015-9781-4