Abstract

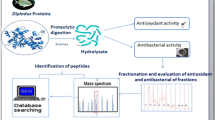

The purpose of this study was to separate and purify antioxidant peptides from the scorpion (Buthus martensii Karsch) protein hydrolysates (SPHs). Scorpion protein (SP) was first hydrolyzed by trypsin, papain, and alcalase, respectively. Results from hydrolysis tests revealed that peptides hydrolyzed with papain showed the highest degree of hydrolysis (DH), yield and antioxidant activity. The effect of papain hydrolysis on scorpion protein was optimized using the response surface methodology. The highest DH (31.31%) and yield (52.02%) of SPHs were obtained under the following conditions: hydrolysis time, 4.0 h; hydrolysis temperature, 50 °C; and enzyme/substrate ratio, 2.43%. Ultrafiltration, gel filtration and reversed-phase high-performance liquid chromatography was used and two novel antioxidant peptides were obtained. The sequences of the peptides determined by MALDI–TOF–MS/MS were LPTETLH (MW: 810.43 Da, P4-1) and IEEDLER (MW: 903.44 Da, P4-2), respectively. The results revealed SPHs as a potential valuable bioresource for production of antioxidant peptides in the food system.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Free radicals can be defined as molecular or molecular fragments containing one or more unpaired electrons in molecular orbitals, including active oxygen species (ROS) and reactive nitrogen species (RNS) (Chao-Zhi et al. 2013; Zhang et al. 2019). Currently, a plethora of studies have identified and characterized protein hydrolysates and antioxidant peptides from dietary sources by enzymatic hydrolysis, including those from chicken (Yangying et al. 2012), nuts (Yang et al. 2017), fish (Pan et al. 2016), egg white (Fan et al. 2019), and cereal (Agrawal et al. 2019).

Scorpions are edible and have been used for treatment and health care in China and other Asian countries for thousands of years, and large-scale commercial farming has achieved good social and economic benefits (Guo et al. 2013; He et al. 2013; Yao et al. 2014). Scorpion has pharmacological effects of anti-thrombosis, anticoagulant, fibrinolysis, analgesic, anti-tumor, and anti-epileptic. (Shi et al. 2015). With the emergence of large number of new methods for the study and identification of scorpion body parts and venom components, several bioactive peptides have been proved to be valuable tools for the development of drugs for the treatment of several diseases (Díaz-García et al. 2013; Goudet et al. 2002; Shubho et al. 2007).

Yao et al. (2014) have isolated and identified a novel anticoagulant peptide from scorpion protein by enzymatic hydrolysis. The body of scorpion contains several proteins, but until now there is little information about antioxidant peptides from scorpion protein. Therefore, the purpose of this study was to (1) investigate antioxidant activities of scorpion (Buthus martensii Karsch) protein hydrolysates (SPHs) prepared by using trypsin, papain, and alcalase; (2) The effect of condition of the papain hydrolysis on scorpion protein was optimized using the response surface methodology (RSM); (3) The hydrolysates with best antioxidant activity were fractioned and purified by ultrafiltration and successive chromatographic steps, and the resultant peptides identified by liquid chromatography–tandem mass spectrometer (LC–MS/MS). Our findings suggest that peptides purified from SPHs were natural antioxidants and could be used as food additives. The findings of this study will make significant contribution to the current trend of developing alternative sources of proteins to increase functionality and nutritional value of foods.

Materials and Methods

Materials

Scorpions (Buthus martensii Karsch) were purchased from local farmers (Turpan Prefecture, Xinjiang, China). 10% Sodium dodecyl sulfate (SDS), Tetramethylethylenediamine (TEMED), 30% acrylamide (Acr/Bis = 29/1), 1 M Tris–HCl (pH 6.8), 1.5 M Tris–HCl (pH 8.6), protein sample buffer (× 5) were purchased from Biosharp Beijing Lanjeco Technology Co., Ltd. 1, 1-diphenyl-2-picrylhydrazyl (DPPH) and 2,20-azinobis (3-ethylbenzothiazoline-6-sulfonic acid) diammonium salt (ABTS) were purchased from Sigma-Chemical (St. Louis, Missouri, USA). Protein markers papain, trypsin, alcalase were purchased from Beijing Solarbio Science and Technology Co. Ltd. Other reagents used were of analytical grade.

Extraction of Scorpion Protein (SP)

Dried scorpions were ground and fat was removed by petroleum ether (60–80 °C) using a Soxhlet extractor until the solvent turns colorless. The final residue was collected and air dried. SP was extracted with 0.5 M sodium chloride (NaCl) using an ultrasonic generator (JY98-OOON Ningbo Scientz Biotechnology Co. Ltd., China) for 4 h, ultrasonic power was 400 w. The extraction steps were repeated 3 times and dialyzed against distilled water for 48 h at 4 °C using F0136-1 Dialysis Membrane, MWCO 1000 Da (USA). The obtained dialysate was lyophilized using FDU-1110, EYELA Company, Japan and were kept at − 20 °C until use.

Preparation of Scorpion Protein Hydrolysates (SPHs)

In the present study, the enzymatic hydrolysis procedure was performed using the methods described by (Ha et al. 2013), with minor modifications. SP was hydrolyzed with three different enzymes (trypsin, papain and alcalase) at optimum pH, temperature conditions and enzyme concentration for 4 h. The optimal conditions were as follows: (1) Alcalase: pH 9, 45 °C; (2) Papain: pH 5.8, 50 °C; (3) Trypsin: pH 7.8, 37 °C. The Enzyme to Scorpion protein ratio (E/S ratio, W/W) was 2%. The pH value of the solutions was adjusted using 1 N HCl or 1 N NaOH solution every half hour. After hydrolysis, the reaction was stopped by boiling for 10 min to inactivate the enzymes. The hydrolysates were centrifuged (High-speed refrigerated centrifuge CR22N Hitachi Koki Co., Ltd. Tokyo Japan) at 8000 r/min for 15 min to collect supernatant, absolute alcohol was mixed with supernatant at a ratio of 3:1 (v/v) and the mixture was kept at 4 °C for 12 h, then centrifuged at 4 °C, 8000 r/min for 15 min to collect supernatant. The SPH was obtained after rotary evaporation (RE252A, Shanghai Yarong biochemical) of ethanol. The yields of SPHs were determined using the following equation.

where mse was the weight of scorpion protein hydrolysates (mg), msd was the weight of scorpion protein extraction (mg).

Determination of Degree of Hydrolysis (DH)

DH (%) of SPHs was calculated using ortho-phthalaldehyde aldehyde (OPA) method described by (Nielsen et al. 2010), with minor modifications. 10 µL of each peptides fraction was mixed with 1.0 mL of OPA reagent, and shaked for 2 min at room temperature. The mixture was further centrifuged for 15 min at a rate of 4500 rpm. The absorbance in each fraction was read at 340 nm using a spectrophotometer (UV2550, Shimadzu, Japan). After 2 min, distilled water was used as blank solution. DH (%) was calculated using the method of (Church et al. 1983) as follows:

where no—the total amount of free amino groups; n—the amount of free amino groups released after hydrolysis; A340 nm after—the absorbance at 340 nm after hydrolysis; A340 nm before—the absorbance at 340 nm before hydrolysis; ε—molar extinction coefficient.

Amino Acid Composition

The amino acid composition of scorpion protein and different peptide fractions of SPHs were analyzed with a Diamonsil AAA 5 μm 250 × 4.9 mm column (Agilent 1100 Series) after hydrolysis with 5.7 M HCl (containing TFA, HCl: TFA = 2:1) for 24 h at 110 °C.

Single-Factor Experiments

The influence of hydrolysis time (h), temperature (°C) and enzyme/substrate ratio (%) on peptide yield (%) and DH (%) of the hydrolysis were investigated. Based on the hydrolysis experiments of three proteases, SP hydrolyzed with papain showed the highest DH and antioxidant activity. Hydrolysis time (1, 1.5, 2, 2.5, 3, and 4 h), temperature (40, 45, 50, 55, 60, and 65 °C) and enzyme/substrate ratio (1, 1.5, 2, 2.5, 3, and 4%) were tested.

Box-Behnken of RSM and Statistical Analysis

RSM is a statistical tool for solving multivariable problems by using reasonable experimental design method and obtaining certain data through experiments and by analyzing regression equation to determine the optimal technological parameters (Lin et al. 2015; Tanyildizi and Elibol 2005). In this study, the RSM and Box–Behnken design was used to optimize the hydrolysis conditions. Based on the single-factor experiment, the complete design was made up of 17 runs and these were done in duplicate to optimize the levels of selected variables (hydrolysis time, temperature, and enzyme/substrate ratio).

For statistical analysis, the three independent variables were coded as X1, X2 and X3, respectively using the following equation:

where xi is the coded value of an independent variable, Xi is the real value of an independent variable, X0 is the real value of an independent variable at the center point and △Xi is the step change value.

The quadratic equation of the variables is as follows:

where Y is the predicted response variable, Β0, βi, βii, and βij are constant regression coefficients of the model, xi and xj (i = 1, 3; j = 1, 3, i ≠ j) represent the independent variables.

The accuracy and fitness of the above model were evaluated by the coefficient of determination (R2) and the F-value. Based on the above results, the second order polynomial coefficients were undertaken using Design Expert (Version 8.0.6, USA) software. The model was performed to evaluate the analysis of variance (ANOVA).

Isolation and Purification of Antioxidant Peptides

Ultrafiltration

The papain hydrolysate of SP showed best antioxidant activity and was fractionated using centrifugal ultrafiltration (UF) membrane (Millipore, USA) with 3 and 10 kDa molecular weight cut-off (MWCO) values, respectively. First, the papain fraction (PF) was treated through the 10 kDa UF membrane by centrifugation (centrifuge 5417R Eppendorf, Hamburg, Germany) at 3500 rpm for 30 min. The retentate (designated as PF-I) and permeate (designated as PF-II) from this stage were collected and the PF-I was centrifuged (3500 rpm for 30 min) until maximum permeate yield was obtained. PFII fraction from the 10 kDa membrane was diluted to 30 mL and filtered through the 3 kDa membrane using the same centrifugation conditions until maximum permeate was reached and a final permeate was collected (designated as PF-III).

Gel Filtration Chromatography

UF fraction (PF-III) with the highest antioxidant activity was separated using gel filtration chromatography as described by (Song et al. 2017). Briefly, 50 mg lyophilized PF-III was dissolved in 2 mL of deionized water and separated by a gel filtration chromatography HW-55F column (1.5 cm × 100 cm) equilibrated and eluted with deionized water. Six fractions (designated as P1-P6) were collected at the flow of 0.8 mL/min and eluted peptide fractions were monitored at 280 nm. To obtain enough samples for further analysis, the separation was repeated 10 times and the antioxidant activity of each fraction was determined.

RP-HPLC

The highest radical scavenging activity fraction (P4) was further purified using RP-HPLC on a semi-preparative C-18 Agilent column (ZORBAX 300SB-C18, 9.4 mm × 250 mm, 5 µm, USA) with a gradient of acetonitrile (0–10% in 5 min, 10–60% in 30 min) containing 0.1% (v/v) trifluoroacetic acid (TFA) at a flow rate of 2.0 mL/min. The elution peaks were monitored at 224 nm. The final purified peptides were assayed for their antioxidant scavenging activity, analyzed for molecular weight and amino acid sequence, respectively.

Sodium Dodecyl Sulphate–Polyacrylamide Gel Electrophoresis (SDS-PAGE)

The molecular weight of SPHs was studied in comparison to standard molecular weight markers by SDS-PAGE analysis using 15% separating gel and 6% concentration gel as described in (Laemmli 1970). The samples (1 mg/mL), after incubation at 100 °C for 5 min were then loaded on a gel prior to electrophoresis being carried at 75 V for 120 min. Following electrophoresis, the gel was stained with Coomassie Brilliant Blue for 2.0 h and destained in a decoloring solution for 15 h.

Antioxidant Activity

Hydroxyl Radicals (·OH): Scavenging Activity

The hydroxyl radicals (.OH)-scavenging activity was estimated according to (Guo et al. 2006) approach with modifications. The reaction mixture, containing the peptide fractions and EDTA-Fe2+ (0.99 μM), safranine O (1.04 9 10–3 μM) and H2O2 (0.27 μM) within potassium phosphate buffer (150 mM, pH 7.4), total volume 4.5 mL was incubated at 37 °C for half an hour. The absorbance of the mixture was measured at 520 nm. The capability of scavenging.OH was measured utilizing the following equation:

ABTS·+ Scavenging Activity

The ABTS·+ radical-scavenging activity analysis of samples was determined according to the method described by (Salami et al. 2009) with minor modification. 7 mM ABTS·+ and 2.45 mM potassium persulphate were mixed for 16 h at room temperature in the dark. Subsequently, 5 mM, pH 7.4 phosphate buffer (PBS) was used to dilute ABTS·+ solution, and absorbance was measured at 734 nm. 1.0 mL of diluted solution was added to 1.0 mL of samples (2–10 mg/mL) for 15 min and the absorbance of the samples was measured at 734 nm. The ABTS·+ ability was calculated using the following equation:

where Acontrol is the absorbance of control and Asample is the absorbance of the sample.

DPPH· Scavenging Activity

The DPPH· scavenging activity was performed in the way described by (Chen et al. 2008). 0.2 mM DPPH solution was prepared with 95% ethanol. Each sample (1 mL) was mixed with 2 mL of fresh DPPH solution and 2 mL of 95% ethanol. The mixture was incubated at 37 °C for half an hour, and then the absorbance was performed at 517 nm against a blank. The DPPH· scavenging activity was calculated using Eq. 8. The equation below showed 3 substitutions: A0, A1, and A2. They can be explained as the absorbance of DPPH· solution without sample, the absorbance of the sample without solution and the absorbance of the sample mixed with DPPH· solution.

Statistical Analysis

All the statistical analysis was performed using three independent trials. The results are presented as mean ± standard deviation. Statistical significance at a level of p < 0.05 was determined using one-way analysis of variance (ANOVA) followed by Tukey’s and Games–Howell post-hoc tests.

Results and Discussion

Preparation of Antioxidant SPHs

Enzymatic hydrolysis method has become the most effective technique for modifying the functionality of dietary proteins to identify higher antioxidant activity (Agrawal et al. 2017). For the preparation of antioxidant peptide, SP was hydrolyzed by three enzymes (trypsin, papain, and alcalase) at optimal conditions, respectively. The SDS-PAGE profiles of the SP and SPHs with various enzymes for 1, 2, 3 and 4 h are shown in Fig. 1a. The SDS-PAGE profiles of SPH showed that the SP was gradually hydrolyzed to peptides over the hydrolysis time. SP above 20 kDa was mostly hydrolyzed by papain in 2 h and the complete digestion of the main proteins was achieved at 3 h.

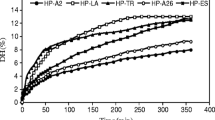

a 15% SDS-PAGE of the enzymatic hydrolysis of scorpion protein (SP) with three types of enzymes. b Degree of hydrolysis of SP with three types of enzymes, the hydrolysis time is from one hour to four hours (E/S ratio was 2%). c DPPH, Hydroxyl radical (OH), and ABTS radical scavenging activity of three different enzymes of SPHs (5 mg/ml of concentration)

The DH was monitored by the estimation of the DH, and the DH evolution as time function as shown in Fig. 1b. The order of DH hydrolyzed by single enzyme is as follows: Papain > Alcalase > Trypsin. As shown in Fig. 1b, the peptides hydrolyzed by three enzymes showed different hydrolytic processes, and the DH of SPHs increased with the hydrolysis time. Papain had a significantly higher hydrolysis effect compared with other enzymes, reaching a final value of 26.46 ± 0.4% after 4 h hydrolysis times. It was supposed that different cleavage sites of the three enzymes result in the difference of DH value during the hydrolytic processes.

The antioxidant activity of three scorpion protein peptides was measured using.OH, ABTS+ and DPPH· radical scavenging assays as shown in Fig. 1c. As shown in Fig. 1c, at 5.0 mg/mL of concentration, the scavenging effect of peptides on ABTS• + was in this order; papain (77.45 ± 0.07%) > alcalase (37.15 ± 0.49%) > trypsin (30.75 ± 0.5%), on DPPH• the order is papain (75.54 ± 0.23%) > trypsin (58.65 ± 0.25%) > alcalase (48.60 ± 0.57%), and on the.OH the order is papain (49.44 ± 0.29%) ≈ alcalase (48.35 ± 0.19%) > trypsin (30.95 ± 0.78%). Papain fraction has the highest antioxidant activity among the three kinds of scorpion peptide fractions. The results of this study obtained from SDS–PAGE profile, DH and antioxidant activity indicates that the hydrolysis of SP with papain was noticeably different from the other enzymes and papain can be effectively used to prepare SPHs. Meanwhile, for the trypsin and alcalase enzyme treatments, the hydrolysis of the SP to peptides needed a longer time.

Analysis of Single Factor Results

Effect of Hydrolysis Time on DH and Yield

When the temperature is 50 °C, E/S ratios 2%, the hydrolysis times were evaluated to be in the range of 1–4 h, and the effect of hydrolysis time on the DH and yield is shown in Fig. 2a. When hydrolysis time is increased, the DH and yield increased rapidly when the extraction time is less than 3.0 h and then balanced after 3.0 h. The maximum DH (27.26 ± 0.24%) and yield (46.75 ± 0.11%) were obtained at 3.0 h. This may be due to the decrease of protein substrate and the inhibition of protease itself by the accumulation of hydrolyzed products, or the further hydrolysis of peptides into amino acids. Therefore, the enzyme hydrolysis time of 3 h was selected as the hydrolysis time of the next orthogonal experiment.

Effect of Temperature on DH and Yield

Temperature plays a vital role in the hydrolysis of proteins. The hydrolysis process was evaluated in the range of 40–65 °C, and the effect of temperature on the DH and yield are presented in Fig. 2b. When the reaction temperature was below 60 °C, the DH and yield increased rapidly with increase in temperature. Maximum DH (31.71 ± 0.11%) and yield (49.48 ± 0.12%) were obtained at 60 °C. When the reaction temperature was higher than 60 °C, the DH and yield decreased. This can be linked to the fact that protease can be easily denatured when the hydrolysis temperature is too high or too low, which is not beneficial for maintaining enzyme activity. The physical and chemical properties of the composition vary with the change of temperature, so the hydrolysis process was conducted at approximately 60 °C.

Effect of E/S Ratio on DH and Yield

The effect of E/S ratio on the DH and yield was shown in Fig. 2c. The diagram shows that the E/S ratio has a certain effect on the DH and yield. When the hydrolysis time is 4 h, the temperature is 50 °C, and the ratios of E/S were evaluated in the range of 1–4%. The DH and yield of peptides increased obviously when the amount of enzyme was from 1 to 3%, which shows that when the amount of enzyme i saturated, the hydrolysis degree of the substrate could be effectively increased and a large number of peptides could be produced. When the amount of enzyme was more than the equilibrium point of binding with the substrate, the substrate was insufficient, and then the increase of enzyme content had little effect on the increase of DH and peptide yields. The maximum DH (30.46 ± 0.30%) and yield (49.49 ± 0.28%) were obtained when the E/S ratio was 3%.

Optimization of Hydrolysis Parameters by RSM

The initial single-factor experiments suggested the optimum for each of the three parameters: 4 h as the hydrolysis time, 50 °C as the hydrolysis temperature, and 3% E/S ratio for DH and peptide yield. Based on these results, an RSM with a 3-factor-3-level central composite rotatable design (CCRD) was employed for optimization of the enzymatic hydrolysis of SP (Table 1). Table 2 shows that there was a considerable variation in the DH and yield at different values of selected parameters. The data obtained was analyzed by applying multiple regression analysis method based on Eq. (5). After multiple regressions fitting with Design-Expert V8.0.6 software, the regression model equation is as follows:

where Y1 and Y2 are the predicted conversion (%) of DH and yield, hydrolysis time (X1, h), temperature (X2, °C) and E/S ratio (X3, %), respectively.

When the sign of a factor is positive, it means that the amount of the response variable increases by increasing its value and vice versa. Figure 3a, c can also be used to compare the model predicted and the experimental results. Figure 3b, d is the normal probability chart indicating that the points follow a narrow linear pattern. The analysis of variance of the regression equation is shown in Table 3. The F-value of the regression model on DH and yield were 31.05, 52.21 and the P-value were < 0.0001, < 0.0001, respectively. This data showed that the model obtained was very significant. The F-value and P-value of Lack of Fit on DH and yield were 5.87, 1.11 and 0.0601, 0.4443, respectively, which means that the equation has a good fitting degree and high reliability. In addition, the decision coefficient (R2) of the model were 0.9756, 0.9853 and the adjusted coefficient of determination (Adj-R2) were 0.9441, 0.9664, respectively. Values of R2 and adjusted R2 for the models are shown in Table 3, which indicated that the regression equation can predict the result of scorpion protein hydrolysis very well.

Standard statistical diagrams for model verification. a, c Shows model-predicted values versus actual data. This figure shows a comparison between the model-predicted values and the actual values which have been obtained by the experiments. b, d Shows normal probability plot of the residuals. Monotonous distribution and linearity of the data which are obvious from these figures confirm the validity of the model and its capability to predict the results

Analysis of the Influence of Various Factors on the Hydrolysis of SP

The influence degree of each factor on the test index can be compared by the F-value (Table 3). F (X1) = 48.32, 26.78, F (X2) = 11.83, 12.25, F (X3) = 39.37, 131.82, these data indicate that the order of influence of each factor on the hydrolysis of scorpion protein was hydrolysis time (h) > E/S ratio (%) > Tetperature (°C). The response surface can describe the interaction between variables and predict the optimal conditional values of each factor. Figure 4a–f shows the effect of operational variables on the DH and yield. The effect of hydrolysis time (h) on the DH is greater than the temperature (°C), and the E/S ratio (%) is greater than the temperature (°C). According to the above analysis, the order of the influence of each variable on the hydrolysis technology of scorpion protein was: Hydrolysis time (h) > E/S ratio (%) > temperature (°C).

Contour plot show the effect of operational variables on DH and yield. a Interaction between temperature and hydrolysis time on DH; b Interaction between E/S ratio and hydrolysis time on DH; c Interaction between E/S ratio and temperature on DH; d Interaction between temperature and hydrolysis time on yield; e Interaction between E/S ratio and hydrolysis time on yield; f Interaction between E/S ratio and temperature on yield

Interactions of Variables

To visualize the combined effects of the three factors on DH and yield, contour plots were generated for each of the fitted models that display the effects of the three variables. Figure 4 illustrates the 2D plots of the binary interactions of the variables on DH and yield via the contour plots. The interaction between the hydrolysis time and the temperature is shown in Fig. 4a, d. This plot indicates that DH and yield depend more on X1 than on X2. Accordingly, Fig. 4a, d reveals that at low values of X1, maximum DH and yield occurs at higher values of X2. However, at higher values of X1, maximum DH and yield occur at lower values of X2. As it is observed from the diagram, the interaction between the two factors is weak. The interaction between the hydrolysis time and E/S ratio is shown in Fig. 4b, e. This plot indicates that DH and yield depend more on X3 than on X1. In Fig. 4c, f, the effect of the interaction between the E/S ratio and the temperature is depicted. The diagram shows that increasing the E/S ratio at different temperature has no important effect on the DH and yield, so this plot indicates that DH and yield depend more on X3 than on X2. Therefore, the optimum values of X1, X2, and X3 determined by the software are 4 h, 50 °C, and 2.43%, respectively.

Isolation and Purification of Antioxidant Peptides

In considering scavenging effects on ABTS·+ scavenging activity,.OH scavenging activity, and DPPH· scavenging activity, papain fraction was selected for isolation and purification of the antioxidant peptide, As shown in Fig. 5a, PF-III (< 3 kDa) exhibited stronger ABTS·+ scavenging activity (77.45 ± 0.08%),.OH scavenging activity (49.44 ± 0.23%), and DPPH· scavenging activity (75.54 ± 0.30%) compared to PF-II (3–10 kDa) and PF-I (> 10 kDa) fractions at 5.0 mg/mL of concentration. Oun Ki et al. (2013), Bing et al. (2018), and Liu et al. (2013) reported that lower molecular weight peptides had higher antioxidant activity, which agrees with previously reported data showing that usually antioxidant peptides contain 2–20 amino acids (Tovar-Pérez et al. 2017). This might be why the PF-III fraction showed higher antioxidant activity than other two fractions. The peptide fraction (PF-III) with the best antioxidant activity was further fractionated by a gel filtration chromatography HW-55F column (1.5 cm × 100 cm), and six remarkable fractions, P1, P2, P3, P4, P5, and P6 were collected (Fig. 5b). When compared with the other five fractions, fraction P4 showed the best antioxidant activity, with scavenging activities of 80.75 ± 0.35, 85.90 ± 0.14%, and 64.50 ± 0.71% on ABTS·+, DPPH·, and.OH scavenging activity, respectively, at a concentration of 2.0 mg/mL, and followed by fraction P6 (Fig. 5c). Therefore, the fraction P4 with stronger antioxidant scavenging activity was freeze-dried and further purified by the preparation RP–HPLC method. As shown in Fig. 6a, two single peptides (P4-1 and P4-2) were collected between the retention times from 10 to 20 min and used to determine their antioxidant activity. Figure 6b showed that the antioxidant scavenging activity of P4-1 on ABTS·+, DPPH·, and.OH are 83.32 ± 0.81, 78.87 ± 0.44, and 62.96 ± 0.89%, respectively, at a concentration of 1.5 mg/mL; the antioxidant scavenging activity of P4-2 on ABTS·+, DPPH·, and.OH is 78.75 ± 0.74, 81.22 ± 0.55, and 58.69 ± 1.09%, respectively, at a concentration of 1.5 mg/mL. The yield of each purification procedure of P4-1 and P4-2 are shown in Table 4. The final yield of P4-1 is 1.04%, and P4-2 is 1.39%, which indicates the approximate percentage of P4-1 and P4-2 in hydrolysates of scorpion protein without regard for the loss during purification.

a Scavenging effects (%) of fractions of papain hydrolysate at different MWCO obtained from SP. Fractions with molecular weights < 3, 3–10, and > 10 kDa were obtained by ultrafiltration of papain hydrolysate. b Gel filtration chromatography of papain fraction by TSK HW-55F (1.5 × 100 cm) column equilibrated with distillate water at a flow rate of 0.75 mL/min. Eluted peptides were monitored at 280 nm, and six fractions were collected. c DPPH, Hydroxyl radical (OH), and ABTS radical scavenging activity of eluted fractions, 5 mg/ml of concentration

a Reversed-phase HPLC chromatogram on a Zorbax C18 column of antioxidant fraction P4 from Fig. 5. HPLC operation was carried out with a linear gradient of acetonitrile (0–10% in 5 min, 10–60% in 30 min) containing 0.1% trifluoroacetic acid (TFA) at a flow rate of 2.0 ml/min using UV detector at 224 nm. b Antioxidant activities (DPPH, OH, and ABTS radical scavenging activity) of P4-1 and P4-2. The results were represent as mean ± standard deviations from three replications (n = 3). The assay peptide concentrations were 1.5 mg/mL

Amino Acid Composition Analysis

In order to understand the possible effect of amino acid profile on the antioxidant activity, the amino acid composition of SP, SPHs, and each purification procedure fractions were determined by HPLC precolumn derivation with 2,4-dinitrofluorobenzene. As shown in Table 5, 16 amino acids were detected and the total amino acids content was 544.24, 346.24, 301.99, and 273.56 mg/g, respectively. With the increase of purification process, the content of hydrophobic amino acids (Ala, Val, Leu, Ile, Pro, and Phe) was increased, especially for PF-III (72.96%) and P4 (75.49%). The hydrophobic aromatic amino acids, Tyr, Trp, His, and Phe, also increased. The percentage of Ala and Met was increased from PF-III to P4. Therefore, these hydrophobic amino acids in the SPHs peptides were mainly responsible for the antioxidant activity. It has been reported that the rich content of Tyr and Pro in peptide sequence could obtain a higher antioxidant activity (Marcuse 1960).

Determination of Amino Acid Sequence (AAS) and Molecular Mass (MW)

The amino acid sequences (AAS) of the individual two peptides (P4-1 and P4-2) were identified by MALDI–TOF–MS/MS. As shown in Fig. 7, the sequence of P4-1 was LPTETLH, the sequence of P4-2 was IEEDLER, the molecular weights (MW) of these peptides were 810.43 Da and 903.44 Da, respectively. As shown in Fig. 8, the sequences of the two peptides were searched in BLAST (https://blast.ncbi.nlm.nih.gov/Blast.cgi). The DPPH·, ABTS·+, and.OH scavenging activities of these peptides were evaluated. The LPTETLH peptide showed the highest ABTS·+ scavenging activity, with a value of 83.32 ± 0.81%, at a 1.5 mg/mL of concentration, the IEEDLER peptide showed the highest DPPH· scavenging activity, with a value of 81.22 ± 0.55% at a 1.5 mg/mL of concentration. Moreover, the.OH scavenging activities of these peptides were not significant, with a value of 62.96 ± 0.89% and 58.69 ± 1.09%, respectively, lower than that of the ABTS·+ and DPPH·.

a Amino acid sequences of scorpion peptide P4-1(NCBI database accession number WP_012097862). b Amino acid sequences of scorpion peptide P4-2 (NCBI database accession number OAJ17297, https://blast.ncbi.nlm.nih.gov/Blast.cgi). Peptide sequences identified in the Scorpion protein hydrolysates are underlined

The antioxidant activity of peptides is closely related to their molecular weight, sequences, amino acid composition, and hydrophobicity (Escudero et al. 2013; Rajapakse et al. 2005). The two novel peptides were in a molecular weight range of 800–1000 Da that consisted of seven amino acid residues (Fig. 8). The results indicated that antioxidant peptides usually contained 2–30 amino acid residues with a molecular weight of less than 3000 Da. It has been reported that high content of hydrophobic amino acids have significant effects on radical scavenging and could increase their antioxidant activity(Rajapakse et al. 2005). In the present study, peptide LPTETLH (P4-1) contains 71.43% of hydrophobic amino acids, and peptide IEEDLER (P4-2) contains 85.71% hydrophobic amino acids, the hydrophobic amino acid content of each peptide was more than 50%. Similar results have also been reported by Harnedy et al (2017) who found that peptides with high hydrophobic amino acid content have stronger antioxidant activity. In addition, the existence of Leu (L) and Ile (I) at N-termini play an important role in the antioxidant activity of some peptides (Ranathunga et al. 2006). In the present study, LPTETLH and IEEDLER were found to have higher ABTS·+,.OH and DPPH· scavenging activity, presumably due to the L or I at the N-terminal.

Conclusion

The present research has demonstrated that enzymatic scorpion protein hydrolysates have a potential antioxidant activity. The antioxidant peptides were purified using ultrafiltration, gel filtration chromatography and RP-HPLC, and the amino acid sequences were determined by MALDI–TOF–MS/MS. This is the first report of novel antioxidant peptides being isolated from the scorpion protein hydrolysates. In our study, two novel peptides from scorpion protein hydrolysates such as LPTETLH and IEEDLER contributed high antioxidant scavenging activity, with potential application in the functional food system. However, the application of these peptides in food and animal models should be further studied to confirm the speculation.

References

Agrawal H, Joshi R, Gupta M (2017) Isolation and characterisation of enzymatic hydrolysed peptides with antioxidant activities from green tender sorghum. LWT 84:608–616

Agrawal H, Joshi R, Gupta M (2019) Purification, identification and characterization of two novel antioxidant peptides from finger millet (Eleusine coracana) protein hydrolysate. Food Res Int 120:697–707

Bing L, Aisa HA, Yili A (2018) Isolation and identification of two potential antioxidant peptides from sheep abomasum protein hydrolysates. Eur Food Res Technol 9:1–11

Chao-Zhi Z, Wan-Gang Z, Guang-Hong Z, Xing-Lian X, Zhuang-Li K, Yan Y (2013) Isolation and identification of antioxidant peptides from jinhua ham. J Agric Food Chem 61(6):1265–1271

Chen Y, Xie MY, Nie SP, Li C, Wang YX (2008) Purification, composition analysis and antioxidant activity of a polysaccharide from the fruiting bodies of Ganoderma atrum. Food Chem 107(1):231–241

Church FC, Swaisgood HE, Porter DH, Catignani GL (1983) Spectrophotometric assay using o-phthaldialdehyde for determination of proteolysis in milk and isolated milk proteins. J Dairy Sci 66(6):1219–1227

Díaz-García A, Morier-Díaz L, Frión-Herrera Y, Rodríguez-Sánchez H, Caballero-Lorenzo Y, Mendoza-Llanes D, Riquenes-Garlobo Y, Fraga-Castro JA (2013) In vitro anticancer effect of venom from Cuban scorpion Rhopalurus junceus against a panel of human cancer cell lines. J Venom Res 4:5–12

Escudero E, Mora L, Fraser PD, Aristoy MC, Toldrá F (2013) Identification of novel antioxidant peptides generated in Spanish dry-cured ham. Food Chem 138(2–3):1282–1288

Fan H, Wang J, Liao W, Jiang X, Wu J (2019) Identification and characterization of gastrointestinal-resistant angiotensin-converting enzyme inhibitory peptides from egg white proteins. J Agric Food Chem 67(25):7147–7156

Goudet C, Chi CW, Tytgat J (2002) An overview of toxins and genes from the venom of the Asian scorpion Buthus martensi Karsch. Toxicon 40(9):1239–1258

Guo X, Ma C, Du Q, Wei R, Wang L, Zhou M, Chen T, Shaw C (2013) Two peptides, TsAP-1 and TsAP-2, from the venom of the Brazilian yellow scorpion, Tityus serrulatus: evaluation of their antimicrobial and anticancer activities. Biochimie 95(9):1784–1794

Guo Z, Liu H, Chen X, Xia J, Li P (2006) Hydroxyl radicals scavenging activity of N-substituted chitosan and quaternized chitosan. Bioorg Med Chem Lett 16(24):6348–6350

Ha M, Bekhit Ael D, Carne A, Hopkins DL (2013) Characterisation of kiwifruit and asparagus enzyme extracts, and their; activities toward meat proteins. Food Chem 136(2):989–998

Harnedy PA, O'Keeffe MB, FitzGerald RJ (2017) Fractionation and identification of antioxidant peptides from an enzymatically hydrolysed Palmaria palmata protein isolate. Food Res Int 100:416–422

He Y, Zhao R, Di Z, Li Z, Xu X, Wei H, Wu Y, Zhao H, Li W, Cao Z (2013) Molecular diversity of Chaerilidae venom peptides reveals the dynamic evolution of scorpion venom components from Buthidae to non-Buthidae. J Proteom 89(16):1–14

Laemmli UK (1970) Cleavage of structural proteins during the assembly of the head of bacteriophage T4. Nature 227(5259):680–685

Lin XS, Wen Q, Huang ZL, Cai YZ, Halling PJ, Yang Z (2015) Impacts of ionic liquids on enzymatic synthesis of glucose laurate and optimization with superior productivity by response surface methodology. Process Biochem 50(11):1852–1858

Liu J, Huang Y, Tian Y, Nie S, Xie J (2013) Purification and identification of novel antioxidative peptide released; from Black-bone silky fowl (Gallus gallus domesticus Brisson). Eur Food Res Technol 237(2):253–263

Marcuse R (1960) Antioxidative effect of amino-acids. Nature 186(4728):886–887

Nielsen PM, Petersen D, Dambmann C (2010) Improved method for determining food protein degree of hydrolysis. J Food Sci 66(5):642–646

Oun Ki C, Go Eun H, Gi-Sung H, Kuk-Hwan S, Hyoun Wook K, Seok-Geun J, Mi-Hwa O, Beom-Young P, Jun-Sang H (2013) Novel antioxidant peptide derived from the ultrafiltrate of ovomucin hydrolysate. J Agric Food Chem 61(30):7294–7300

Pan X, Zhao YQ, Hu FY, Wang B (2016) Preparation and identification of antioxidant peptides from protein hydrolysate of skate (Raja porosa) cartilage. J Funct Foods 25:220–230

Rajapakse N, Mendis E, Jung WK, Je JY, Kim SK (2005) Purification of a radical scavenging peptide from fermented mussel sauce and its antioxidant properties. Food Res Int 38(2):175–182

Ranathunga S, Rajapakse N, Kim SK (2006) Purification and characterization of antioxidative peptide derived from muscle of conger eel (Conger myriaster). Eur Food Res Technol 222(3–4):310–315

Salami M, Yousefi R, Ehsani MR, Razavi SH, Chobert JM, Haertlé T, Saboury AA, Atri MS, Niasari-Naslaji A, Ahmad F (2009) Enzymatic digestion and antioxidant activity of the native and molten globule states of camel α-lactalbumin: possible significance for use in infant formula. Int Dairy J 19(9):518–523

Shi L, Zhang T, Congying DU, Yuan R, Wang C, Feng LI (2015) Research progress on chemical constituents, pharmacological effects and clinical applications of scorpio. J Liaoning Univ Tradit Chin Med 4:31

Shubho DG, Anindita D, Archita S, Biplab G, Gayatri T, Joseph Rajan V, Antony G, Aparna G (2007) Indian black scorpion (Heterometrus bengalensis Koch) venom induced antiproliferative and apoptogenic activity against human leukemic cell lines U937 and K562. Leuk Res 31(6):817–825

Song JJ, Wang Q, Du M, Ji XM, Mao XY (2017) Identification of dipeptidyl peptidase-IV inhibitory peptides from mare whey protein hydrolysates. J Dairy Sci 100(9):6885–6894

Tanyildizi MS, Elibol OM (2005) Optimization of α-amylase production by Bacillus sp. using response surface methodology. Process Biochem 40(7):2291–2296

Tovar-Pérez EG, Guerrero-Becerra L, Lugo-Cervantes E (2017) Antioxidant activity of hydrolysates and peptide fractions of glutelin from cocoa (Theobroma cacao L.) seed. Cyta J Food 15(1):489–496

Yang R, Li X, Lin S, Zhang Z, Chen F (2017) Identification of novel peptides from 3 to 10 kDa pine nut (Pinus koraiensis) meal protein, with an exploration of the relationship between their antioxidant activities and secondary structure. Food Chem 219:311–320

Yangying S, Daodong P, Yuxing G, Junjiang L (2012) Purification of chicken breast protein hydrolysate and analysis of its antioxidant activity. Food Chem Toxicol 50(10):3397–3404

Yao R, Hui W, Lai F, Yang M, Li X, Tang Y (2014) Isolation and identification of a novel anticoagulant peptide from enzymatic hydrolysates of scorpion (Buthus martensii Karsch) protein. Food Res Int 64:931–938

Zhang Q, Tong X, Li Y (2019) Purification and characterization of antioxidant peptides from alcalase-hydrolyzed soybean (Glycine max L.) hydrolysate and their cytoprotective effects in human intestinal Caco-2. CELLS. 67 (20), 5772–5781.

Acknowledgements

This work was supported by the Program for National Science and Technology Major Project of China (No. 2017ZX09301045), and we thank Central Asian Drug Research and Development Center of Chinese Academy of Sciences.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that there is no conflict of interest in this study.

Informed Consent

The article does not contain any studies in patients by any of the authors.

Research Involving Human and Animals Participants

This article does not contain any studies involved with human participants or animals performed by any of the authors.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Wali, A., Wubulikasimu, A., yanhua, G. et al. Separation and Purification of Antioxidant Peptides from Enzymatically Prepared Scorpion (Buthus martensii Karsch) Protein Hydrolysates. Int J Pept Res Ther 26, 1803–1818 (2020). https://doi.org/10.1007/s10989-019-09976-3

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10989-019-09976-3