Abstract

The study aims to determine the effect of pre-treatment applications and optimum drying condition in a hybrid microwave dryer at 350 W + 50 °C, 350 W + 60 °C and 350 W + 70 °C. In terms of color values, the closest value to fresh was found in samples soaked in citric acid pre-treatment at 60 °C. The highest effective diffusivity value was determined in citric acid pre-treated lemon samples at a drying temperature of 70 °C. The highest activation energy was determined in the lemon juice pre-treated samples. The highest specific moisture removal rate (SMER) and lowest specific energy consumption values were determined in natural lemon pre-treatment at 50 °C. The enthalpy values of the lemon juice pre-treatment carried out at 50 °C drying temperature were higher than the other methods. The entropy and Gibbs Free energy values were lower. Considering the energy efficiency values, the method with the highest energy efficiency was determined in the pre-treatment of lemon juice. The highest thermal conductivity and thermal diffusion of the dried samples were determined in the samples immersed in 70 °C citric acid mixture. The highest density values has determined in the samples immersed in 70 °C natural lemon juice. The lowest specific heat was determined at 50 °C drying temperature in the samples with citric acid pre-treatment. Considering all drying processes and pre-treatment applications, it was determined that citric acid pre-treatment increased the evaporation energies of the samples. Drying data was best estimated with the Midilli–Küçük model (R2: 0.9998).

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Drying method is the most preferred method for the preservation of agricultural products. The most well-known and oldest drying method is the sun drying method. The sun drying method offers low energy consumption and the possibility of drying large quantities of product. However, it also has negative features such as being adversely affected by weather conditions, not being able to reduce the desired humidity level, and long drying times [24, 29, 32, 34]. In addition, when agricultural products dried in the sun drying method are compared with their fresh properties, significant quality losses occur. Therefore, over time, alternative drying methods have been developed to sun drying. Conventional or hybrid conventional hot air drying processes are one of the most preferred methods developed and later in drying processes. According to the open drying method, since the drying conditions can be controlled with these methods, the products are reduced to the desired moisture level in a better quality and faster way [6, 18, 26, 46].

It is reported that 10–25% of the total energy consumed is spent only in drying processes [20], which varies between 7 and 15% in industrialized countries [2]. Due to the high amount of energy consumed in drying processes, some pre-treatments (physical, chemical, thermal, etc.) are applied both to reduce the amount of energy consumed and to preserve the quality characteristics of the products [15, 34]. The pre-treatments applied to agricultural products prevent or reduce the occurrence of local problems such as shrinkage by ensuring that the drying heat is distributed uniformly in the product and on its surface [31].

One of the dried agricultural products is lemon. Lemon (Citrus limon L.) fruit is an agricultural product grown in many countries with warm summers and winters. Due to its unique smell and taste, it is used in many sectors, especially in the food field. It is a species rich in essential oil, vitamins, and amino acids that are beneficial to human health [1, 33, 48]. In addition to being consumed fresh, lemon is also used as a natural flavor and sweetener by brewing after drying and turning it into tea and powder [43]. There are many studies in the literature on drying lemon fruit. However, the originality of this study is to investigate the effect of drying pre-treatment and drying conditions on the energy analysis of the lemon drying process in detail.

In this study, it was aimed to dry the lemon slices at different drying conditions (350 W + 50 °C, 350 W + 60 °C and 350 W + 70 °C) in a hybrid microwave oven and to determine the effectiveness of citric acid and natural lemon juice pretreatment. The optimum drying method was investigated in terms of physico-chemical properties (color, effective diffusion-activation energy) and energy analyzes (SMER, SEC, evaporation energy Qw and thermodynamics) of the dry product with citric acid and natural lemon juice.

Materıals and methods

Drying material and pre-treatments

Fresh lemons used as trial material were purchased from a local market in Tokat Province in the Black Sea Region of Turkey. The rot-free and clean lemons to be used for moisture determination and drying processes were separated and stored at + 4 ± 0.5 °C in refrigerator conditions throughout the trial period [37]. It was then dried by slicing it into a circle with a thickness of 5 ± 0.01 mm with the help of a sharp knife.

In this study, Ariston Hotpoint Brand MWHA 33343 model 2450 MHz (Italy) was used as a hybrid drying oven. Drying trials were carried out at 350 W constant power at 50, 60, and 70 °C drying temperatures. The hybrid microwave oven used in the study is given in Fig. 1.

Citric acid and lemon juice pre-treatments were applied to reduce the drying time and energy consumption of lemon slices drying processes and to preserve their quality characteristics. Pre-treatments have been applied by dipping lemon slices into 3% lemon juice and 3% citric acid solution for 15 min. Pre-treatment rates and durations were determined as a result of researches in the literature.

Drying parameters

To determine the initial moisture content, it was dried in an oven (Şimşek Laborteknik brand-ST-055 model) set at 70 °C [24] until the mass change was stabilized. 15.05 ± 0.68 g sample was used for moisture determination. Equation 1 was used to determine the initial moisture content of the samples.

Here Mi; Initial mass (g), Ml; final mass (g), Nk.b: g moisture/g dry matter.

The initial moisture content of the lemon slices was determined as 87.07 ± 0.10 g moisture/g dry matter on average. AND brand GF-300 model precision balance (0.01 g) was used to follow the mass change of lemon slices. Equation 2 has been used to determine the drying speed of lemon slices.

where Mt Moisture content at time t (g water g drying substance−1), dt minute, DS drying speed (g water g drying substance min−1). Equation 3 was used to determine the time-dependent drying rates of the samples.

where MR Moisture rate, M Instant moisture content of the product (g moisture/g dry matter), Me the Equilibrium moisture content of the product (g moisture/g dry matter), Mo It is the initial moisture content of the product (g moisture/g dry matter).

CR400 model/Japanese colorimeter was used to measure the brightness (L), red/green (a), and yellow/blue (b) values of fresh and dried lemon slices. Chroma, hue, and total color change values were calculated using the measured values. While chroma indicates color tone, low values are calculated for pale fruits, while high values are calculated for vivid colors. Hue indicates the location of product color values within 360° color radiant. 0° from limit angle values; red, 180°; green, 90°; yellow and 270°; Blue represents the primary colors. The total color change represents the value of the total color pigments that are heat-decomposed (non-enzymatic) in drying processes. Calculated color values were used in Eqs. 4–6 [27, 3, 36].

Browning index value (BI) shows the browning value of the product after the drying process of Jerusalem artichokes was completed. The browning index was calculated with the use of Eq. 7 [25].

Whiteness Index (WI) are commonly measured to derive numbers that closely correlate with consumers’ preference for white color. It mathematically combines lightness and yellow-blue into one term. WI represents the overall whiteness of food products, which can indicate the degree of discoloration during drying [11, 22]. Equation 8 was used to calculate the whiteness index [28].

Yellowness Index (YI) is associated with exposure to light, chemicals, extreme heat and processing, contamination, and general product spoilage. Yellowness indices are mainly used to measure such deterioration with a single value. They can be used to measure clear, colorless liquids or solids in transmission and nearly white, opaque solids in reflection [22]. Equation 9 was used to calculate the jaundice index [28].

Equation 10 was used to calculate the effective diffusivity and activation energy values [7, 49].

Here Deff effective spread value (m2 s−1), L Half the thickness value (m) of the product, D0 value the diffusion coefficient (m2 sec−1), R value gas constant (8.3143 kj mol°K−1), Ea activation energy value (kj mol−1) and T (Kelvin°) is given as the drying air temperature.

Polaxtor brand PLX-15366 model power meter (± 0.02 kWh) was used to measure the energy consumed in drying processes. By using these energy consumption values, the specific moisture absorption rate and specific energy consumption values were calculated.

Equation 11 was used to calculate the amount of moisture removed (SMER) versus the unit energy value in drying processes [35].

where SMER; specific moisture removal rate (kg kWh−1).

The amount of energy consumed to remove 1 kg of moisture in drying processes was calculated using the equation numbered 12 [19].

where SEC specific energy consumption (kWh kg−1 water), Meat total consumed energy (kWh), mw the amount of water removed (kg).

Equation 13 was used to calculate the latent heat of evaporation in the drying processes of lemon slices [5].

where Qw evaporation energy (kWh), hfg latent energy of evaporation (kJ kg−1), mw the amount of evaporated moisture (kg). Td drying temperature (°K).

Thermophysical properties

As a function of dry-based moisture content of Jerusalem artichoke samples, thermal conductivity, thermal diffusivity, specific heat and specific mass properties were calculated. The thermal conductivity value of Jerusalem artichoke was calculated with the use of Eq. 14 [29].

where k is thermal conductivity (W m K−1).

Thermal diffusivity of Jerusalem artichoke samples was calculated with the use of Eq. 15 [29].

where ∝ is thermal diffusivity (m2 s−1), p is density (kg m−3).

Specific heat values of Jerusalem artichoke samples were calculated with the use of Eq. 16 [12].

where Cp is specific heat (J kg K−1), X is drybased moisture content (kg water kg dry matter−1).

Specific heat values of Jerusalem artichoke samples were calculated with the use of Eq. 17 [23, 42].

where Pp is density (kg m−3), X0 is initial drybased moisture content (kg water kg dry matter−1).

Thermodinamic analysis

Equations [18,19,20] were used to analyze the thermodynamic behavior of lemons under different drying temperatures [13].

here ∆H enthalpy (cal mol−1), Ea activation energy (kJ mol−1), ln kB Boltzmann constant (J s−1), ln hP Boltzmann constant (J °K−1), ∆S entropy (cal mol−1) and ∆G represents Gibbs free energy (J mol−1) values. Here; aw represents the water activity value.

Uncertainty analysis

Equation 21 was used to calculate the total uncertainty value arising from the standard deviation values occurring during the drying process and measurement stages [17].

X1; X2; X3; … Xn shows the precision values of measuring instruments.

Mathematical modeling

The change in the moisture content of the drying material over time creates the drying curve of that product. The drying curve takes a value at the initial time and undergoes a rapid change at the beginning and decreases towards the zero value. A value of zero is obtained when there is no moisture left in the drying material. Equality parameters have obtained using the Sigma Plot program. The Sigma Plot program also gives the model variance analysis results and the coefficient of stability (R2) value. The stability coefficient can take values between zero and one. If the values calculated by the program are equal to the measured value, the coefficient of determination value is determined exactly. For this reason, in order to determine the best predictive model, it is desired that the calculated values and the measured values are close, that is, the R2 value is high. To determine the most suitable thin-layer drying model for lemon slices, the mathematical equations commonly used in the literature were chosen. The selected equations are given in Table 1.

Statistical analysis

It was modeled using SigmaPlot 10. Program to model the drying data. The R2 and reliability values of the models were calculated according to the determined reliability value P < 0.05. Statistical analysis of color values SPSS17. ANOVA multiple comparison tests were performed with the program. Reliability values of color analyzes were calculated according to P < 0.05.

Results and discussıon

Drying parameters

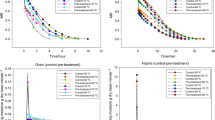

Lemon samples were dried at different temperatures in a hybrid microwave dryer as pre-treated (citric acid-lemon juice) and without pre-treatment (control). These processes continued until the lemon samples reached their final moisture values. The initial moisture content of the lemon samples was determined as 88.07 ± 0.10%. Yoğurtçu [47] dried 8 mm lemon slices using the microwave method using 4 different powers (90–180–360–600 W). In the study, they found the initial moisture value of lemon slices to be 87.3 ± 0.5%. Güler and Doğan [9], examined the drying performance of lemon slices by pre-treatment in a convective dryer. In the experiments, the moisture content of fresh lemon samples was measured as 87.43 ± 0.1%. They determined that the pre-treatment (ohmic scalding) they applied increased the drying rate. Similar results were found in the literature about the moisture content of lemon samples. In line with the findings, it was determined that the drying properties of lemon slices were affected by the pre-treatment and drying temperatures. It was determined that the increase in temperature values and the applied pre-treatments increased the drying rate. The drying performance values of the samples under drying processes are given in Fig. 2.

When the drying performance values given in Fig. 2 are examined, the shortest drying time was found to be 26 min in the samples dipped in 70 °C natural lemon juice, while the longest drying time was determined as 40 min in the 50 °C control samples. Pre-treatment of immersion in lemon juice reduced the drying time of the lemon slices. It is thought that the natural citric acid in lemon juice affects the microstructure of the lemon, evaporating more moisture during drying and affecting the drying rate. Polatci et al. [50] ın their drying study, they applied pre-treatment (Ethyl oleate) to the fruits before drying. They determined that the pre-treatment (Ethyl oleate) affects the drying organs by affecting the microstructure of the fruit and thus shortens the drying time. Similar results with the literature were also seen in different pre-treatments. Sadeghi et al. [30] used a convective, microwave, and combined drye in their lemon drying study. In the combined drying process in which they applied microwave power and temperature, the shortest drying time was obtained after 38 min. A temperature of 60 °C and a microwave power density of 12.04 W g−1 have been used. It has been determined by the literature findings that microwaves using power and temperature reduce the drying rate. The highest drying rate value was determined as 0.2969 g moisture g−1 dry matter.minute at a drying temperature of 70 °C at 350 W constant power in lemon juice pre-treatment.

Color is an important quality parameter in drying process. Because the colors of the dried products affect the sales. A product with a bad color has no appeal and is sold less. In this study, the effect of pretreated and untreated (control) samples on the color values of lemon sliwere were investigated using different temperatures at constant 350 W power in a hybrid microwave. The obtained results are given in Table 2. According to Table 2, drying temperatures and applied pre-treatments affected the color values of lemon samples statistically (P < 0.05). It was determined that the gloss value of the pre-treated samples was higher than the control samples. L* gloss value was obtained close to fresh values in all drying processes performed at 70 °C drying temperature. In a*, b* and C values, it was found that the samples dipped in lemon juice at 60 °C drying temperature was found to be statistically similar (P < 0.05) compared to fresh. When the total color change value was examined, the maximum color change was determined as 40.10 in the samples that were pretreated with citric acid at 60 °C. In this method, a lot of color increase has occurred compared to fresh. Ghanem et al. [8], stated that the significant increase in the total color difference in their lemon drying study may be due to the Maillard reaction between reducing sugars and compounds containing amino groups and resulting in the formation of colored melanoidins.

Due to the color of the lemon, the yellowness (YI) and whiteness of Windexesdex are more important in terms of color values. The whiteness index value of the fresh was statistically (P < 0.05) best preserved by the drying process performed at 70 °C drying temperature in the pre-treatment of dipping in lemon juice. In terms of yellowness value, the samples that were pretreated with citric acid at 70 °C were found to be statistically similar compared to the fresh ones. It was determined that there is a positive relationship between drying temperature and browning index. In other words, it was determined that the browning index increased as the temperature increased. Wang et al. [43], found that the browning index increased with the increase in temperature in the study of drying lemon slices in a pulse vacuum dryer. It was observed that the obtained findings and the literature findings overlapped. Alkaç et al. [4] when conducting a qualitative analysis in the study of drying sliced lemons in a heat pump infrared dryer, they that darkening occurred in lemon slices after drying. They predicted that this situation may create a disadvantage in the marketing of the product. They suggested that a pre-treatment of the lemon slices could be done before drying to prevent the lemons from darkening. In this study, the effect of pre-treatment applied to lemon slices on the color is given in Fig. 3.

The effect of drying temperature and pre-treatment on the effective diffusivity and activation energy values of dried lemon samples are given in Table 3 and time dependent ln MR values are given in Fig. 4.

According to Table 3, the drying temperature and the applied pre-treatments affected the effective diffusivity and activation energy values of the lemon slices during the drying process. Effective diffusivity is a kinetic parameter associated with the transport of moisture lost by dried products [51]. In drying trials, we want this convection to be fast so that drying takes place faster. For this reason, effective diffusivity values should be high in drying trials. The highest effective diffusivity value was found in the citric acid dipping process at a drying temperature of 70 °C. The effective diffusivity values of the citric acid pre-treatment have higher than the control and lemon juice pre-treatment samples. It has been determined that the effective diffusion value increased as the temperature value increased. Sadeghi et al. [30] found that the effective diffusivity values increased with the increase of microwave power and drying air temperature in lemon drying studies. Activation energy is the minimum energy required to start a chemical reaction. The activation energy must be low. Because the activation energy is high means that the reaction will start difficult. Activation energy values have the lowest in the control samples. Horuz et al. [10] applied a hybrid (W + °C) drying process in apple drying studies. According to the study results, respectively activation energies of 120 W + 50–60–70 °C, 150 W + 50–60–70 °C and 180 W + 50–60–70 °C C are 32,46, 32,48 and 13.04 kJ mol−1. According to the literature results, it was observed that the increase in the power value caused a decrease in the activation energy. In addition, it has been determined that the increase in temperature decreases the activation energy and increases the effective diffusion values.

Energy consumption and thermodynamic analysis values

Energy and thermodynamic analysis values of dried lemon slices were affected by pre-treatment applications and drying temperature. The data of the determined parameters are given in Table 4. The applied pre-treatments improved the SMER and SEC energy values. It has been determined that SMER values increased and SEC values decreased as the temperature value increased in the control samples. However, it was observed that drying temperatures of 50 and 70 °C had higher SMER values and lower SEC values in citric acid and lemon juice pre-treatment compared to 60 °C. After drying, it is desired that the SMER value is high and the SEC value is low. A high SMER value means that the energy consumed in 1 kWh and the amount of moisture removed from the lemon slices are high. That is, more moisture is evaporated with less energy. A decrease in the SEC value means that the amount of energy spent to remove 1 kg of moisture is less. The main purpose of determining the SMER and SEC values is to find the energy consumed by the moisture loss in the product during drying and to determine the effect of the applied pre-treatments, the determined drying method and temperature on the energy.

This study was examined in terms of energy consumption values, it was determined that lemon juice pre-treatment contributed positively and low drying temperature gave better results than high temperatures. In terms of thermodynamic analysis results, it was determined that the enthalpy values were higher, and the entropy and Gibbs Free energy values were lower when the drying process was performed at 50 °C drying temperature in the lemon juice pre-treatment. It shows how much energy input to the product is from the drying ambient air to perform the Gibbs free energy drying process. Considering the energy efficiency values, it varies between 9.50 and 10.50%, 10.40–11.80% and 10.80–12.30%, respectively, in control, citric acid and lemon juice pre-treatment. It has been observed that this situation is compatible in terms of consumed energy values.. Torki-Harchegani et al. [41], calculated the highest energy efficiency as an average of 5.47% in their study.

Thermophysical properties

The 3D distribution of the thermophysical properties of lemon slices is given in Fig. 5.

It was determined that drying methods significantly affect the thermo-physical properties of lemon slices. It was determined that the final thermophysical properties of the dried samples were very close to each other. Thermal conductivity and thermal diffusivity must be high in thermo physical properties. Because these two features show the spread rate and area of the heat given by the dryer during drying on the product. The faster the temperature spreads on the product, the shorter the drying time. The specific mass value should be similarly high.

While the highest thermal conductivity and thermal diffusion of the dried samples were determined in the samples immersed in 70 °C citric acid mixture, the highest specific mass values have been determined in the samples immersed in 70 °C natural lemon juice. In the specific heat value, the specific heat value of the materials with high conductivity will be low. Since the conductivity is desired to be higher in the drying process, the specific heat value should be low. Considering the specific heat value, the lowest specific heat was determined at 50 °C drying temperature in the samples with citric acid pre-treatment.

Among the thermophysical properties, specific heat, thermal conductivity, and specific mass values were obtained very close between all applications. In thermal diffusivity, these values vary. These values varied between 1.077 and 5.625 × 10–7 m2 s−1. Taşova and Polatcı [39, 40], in their study in which they dried chile peppers by applying microwave and hot water pre-treatments, determined that the thermal diffusivity value was between 1.005 and 3.944 × 10–7 m2 s−1. Similar values have been obtained in the literature. Yagua and Moreira [44], found that when they dried the potato slices in an oven with hot air at 120, 130, and 140 °C, the specific mass values of the samples varied between 1100 and 420 kg m−3 on average. In the study, these values were found to vary between 370.00 and 861.76 kg m−3. The reason why these values are higher than the values in the hand study is thought to be due to the high drying temperatures.

Evaporation energy

The effect of the pre-treatments applied in lemon drying processes on the determined evaporation energy values is given in Fig. 6.

According to Fig. 6, the pre-treatment and drying methods affected the evaporation energy values of the lemon slices. It was determined that the total evaporation energies of control, citric acid, and lemon juice samples of hybrid microwave-dried lemon slices varied between 4.8397 and 5.0128, 4.7913–5.0128, and 4.7648–4.9512 kWh, respectively. Considering all drying processes and pre-treatment applications, it was determined that citric acid pre-treatment increased the evaporation energies of the samples. Based on the drying temperature, the evaporation energies of lemon slices at 50 and 70 °C drying temperatures were found to be higher than at 60 °C drying temperatures. It has been determined that the evaporation energies decreased at the intermediate temperature.

Uncertainty analysis

The uncertainty analysis value due to the sensitivity values of the measuring instruments and equipment used during the drying processes was made. The sensitivity values of the measuring instruments and equipment used in the study are given in Table 5.

The data have been processed in Eq. 26 and the uncontrollable uncertainty value in the drying process has been calculated as 0.633%. Kumar et al. [14], conducted drying experiments and reported the uncertainty rate as 1.06%. Taşova et al. [38], found the uncontrollable uncertainty rate of the drying process as 2.324%. The reason for the low uncertainty value is thought to be due to the different devices used and their sensitivities.

Mathematical model data

Mathematical model data of lemon slices are given in Table 6. According to Table 6, the drying data was best estimated by the Midilli–Küçük model (R2:0.9999), and it was determined in the drying of the samples dipped in natural lemon juice at 70 °C in a microwave dryer.

Conclusions

This study the lemon juice pre-treatment dried the lemon slices faster than the citric acid and control samples. It has determined that the pre-treatments performed better and preserved the color values compared to the applied control samples. It also had a positive effect on effective diffusion and activation energy values. While the effective spreading values were higher in the citric acid pre-treatment, the activation energy values were lower in the citric acid pre-treatment. It has determined that the effective diffusion value increased as the temperature value increased. It has determined that the increase in the power value decreased the activation energy value. The pre-treatment application had a positive effect on SMER and SEC energy values. It has determined that as the temperature value increased in the control samples, there was an increase in the SMER values and a decrease in the SEC values. Drying processes and pre-treatments significantly affected the thermodynamic analysis. Considering all drying processes and pre-treatment applications, it was observed that citric acid pre-treatment increased the evaporation energies of the samples. It is recommended to consider all pre-treatments and drying temperatures when drying lemon slices, and to dry them in a lemon juice pre-treatment and at low drying temperatures.

Abbreviations

- DS:

-

Dry speed = g moisture g dry base−1

- MR:

-

Moisture ratio

- C:

-

Croma

- WI:

-

Whiteness index

- YI:

-

Yellownes index

- SMER:

-

Specific moisture extraction rate

- SEC:

-

Specific energy consumption

- W:

-

Watt

- Nk.b :

-

Moisture content relative to dry base = g moisture g dry base−1

- Deff :

-

Effective diffusion value = m2 s−1

- Mi :

-

İNitial mass

- Ml :

-

Last mass

- Mt :

-

İNstant moisture content = g moisture g dry base−1

- dt:

-

Minute

- M:

-

İNstant moisture content = g moisture g dry base−1

- Me :

-

Equilibrium moisture content = g moisture g dry base−1

- Mo :

-

Initial moisture content = g moisture g dry base−1

- k, h, j, m:

-

Constant coefficient

- t:

-

Represents the time

- L:

-

Thickness value (m) of the product

- L*:

-

Brightness

- a*:

-

Redness

- b*:

-

Yellowness

- Et :

-

Total energy consumption

- mw :

-

Amount of removed moisture

- Qw :

-

Evaporation energy

- hfg :

-

Evaporation latent energy

- mw :

-

Amount evaporated moisture

- Td :

-

Dry temperature

- ∆H:

-

Entalphy

- Ea :

-

Activation energy

- ln kB:

-

Bolztman constant

- ln hP :

-

Planck constant

- ∆S:

-

Entrophy

- ∆G:

-

Gibbs free energy

- Wx :

-

Uncertainty analysis

References

Aguilar-Hernández MG, Núñez-Gómez D, Forner-Giner MÁ, Hernández F, Pastor-Pérez JJ, Legua P. Quality parameters of Spanish lemons with commercial interest. Foods. 2021;10(62):13–21.

Akpınar-Kavak E, Bicer Y, Çetinkaya F. Modelling of thin layer drying of parsley leaves in a convective dryer and under the open sun. J Food Eng. 2005;75(3):315–308.

Alemrajabi AA, Rezaee F, Mirhosseini M, Esehaghbeygi A. Comparative evaluation of the effects of the electrohydrodynamic, oven, and ambient air on carrot cylindrical slices during the drying process. Dry Technol. 2012;30:96–88.

Alkaç SP, Boran K, Aktaş M, Tokdemir M. Experimental analysis of sliced lemon drying in infrared dryer which is supported with heat pump. Gazi J Eng Sci. 2019;5(2):137–128.

Beigi M. Energy efficiency and moisture diffusivity of apple slices during convective drying. Food Sci Technol. 2016;6(1):154–150.

Boateng ID, Yang XM. Effect of differentdrying methods on productquality, bioactive and toxiccomponents of Ginkgobiloba L. seed. J Sci Food Agri. 2020;101:3297–3290.

Corzo O, Bracho N, Alvarez C. Water effective diffusion coefficient of mango slices at different maturity stages during air drying. J Food Eng. 2008;87(4):484–479.

Ghanem N, Mihoubi D, Bonazzi C, Kechaou N, Boudhrioua N. Drying characteristics of lemon by-product (Citrus limon. v. lunari): effects of drying modes on quality attributes kinetics. Waste Biomass Valoriz. 2020;11:322–303.

Güler P, Doğan İ. Comparıson of ohmıc and conventıonal blanchıng pre-treatments for convectıve dryıng of lemon. KSU J Eng Sci. 2022;25(1):26–17.

Horuz E, Bozkurt H, Karataş H, Maskan M. Simultaneous application of microwave energy and hot air to whole drying process of apple slices: drying kinetics, modeling, temperature profile and energy aspect. Heat Mass Transf. 2018;54:436–425.

Hsu CL, Chen W, Weng YM, Tseng CY. Chemical composition, physical properties, and antioxidant activities of yam flours as affected by different drying methods. Food Chem. 2003;83(1):92–85.

Huang SR, Yang JI, Lee YC. Interactions of heat and mass transfer in steam reheating of starchy foods. J Food Eng. 2013;114:174–82.

Jideani VA, Mpotokwana SM. Modeling of water absorption of Botswana bambara varieties using Peleg’s equation. J Food Eng. 2009;92(2):188–182.

Kumar C, Millar GJ, Karim MA. Effective diffusion and evaporative cooling in convective drying of food material. Dry Technol. 2015;33(2):237–227.

Lewicki PP, Das-Gupta DK. Osmotic dehydration of fruits and vegetables in hand book of industrial drying, vol. 1, 2nd Edition, Mujumdar, Marcel Dekker, AS, editors. New York. 1995, pp. 713–691.

Midilli A, Küçük H, Yapar Z. A new model for single-layer drying. Dry Technol. 2002;20(7):1513–1503.

Moffat RJ. Describing the uncertainties in experimental results. Exp Therm Fluid Sci. 1988;1(1):17–23.

Morais RMSC, Morais AMMB, Dammak I, Bonilla J, Sobral PJA, Laguerre JC, Afonso MJ, Ramalhosa ECD. Functional dehydrated foods for health preservation. J. Food Qual. 2018; 29–1. https://doi.org/10.1155/2018/1739636

Motevali A, Abbaszadeh A, Minaei S, Khoshtaghaza MH, Ghobadian B. Effective moisture diffusivity, activation energy and energy consumption in thin-layer drying of jujube (Zizyphus jujube Mill). J Agric Sci Technol. 2012;14(3):532–523.

Mujumdar AS, Law CL. Drying technology: trends and applications in postharvest processing. Food Bioprocess Technol. 2010;3:852–843.

Page G. Factors influencing the maximum rates of air drying shelled corn in thin layer. Master’s Thesis, İnstitute of science, Purdue University, West Lafayette, IN, USA. 1949; 65–1.

Pathare PB, Opara UL, Al-Said FA. Colour measurement and analysis in fresh and processed foods: a review. Food Bioprocess Technol. 2013;6:60–36.

Perusello C, Cocco V, Masson M, De-Castilhos F. Determination of thermophysical properties of yacon (Smallanthus sonchifolius) to be used in a finite element simulation. Int J Heat Mass Transf. 2013;67:1163–9.

Pixton SW, Warburton S. Determination of moisture content and equilibrium relative humidity of dried fruit-Sultanas. J Stored Prod Res. 1973;8(4):270–263.

Plou E, Lopez-Malo A, Barbosa-Canovas GV, Welti-Chanes J, Swanson BG. Polyphenoloxidase activitiy and color of blanced and high hydrostatic pressure treated banana puree. J Food Sci. 1999;64:45–42.

Purohit P, Kumar A, Kandpal TC. Solar drying vs. open sun drying: a frame work for financial evaluation. Sol Energy. 2006;80(12):1579–1568.

Ramallo LA, Mascheroni RH. Quality evoluation of pineapple fruit during drying process. Food Bioprod Process. 2012;99:283–275.

Rhim JW, Wu Y, Weller CL, Schnepf M. Physical characteristics of a composite film of soy protein ısolate and propyleneglycol alginate. J Food Sci. 1999;64(1):152–149.

Ruiz-Lopez II, Rodriquez-Jimenes GC, Garcia-Alvarado MA. Moisture and temperature evolution during food drying: effect of variable properties. J Food Eng. 2014;63(1):117–24.

Sadeghi M, Kesbi OM, Mireei SA. Mass transfer characteristics during convective, microwave and combined microwave convective drying of lemon slices. J Sci Food Agric. 2013;93:478–471.

Salim NSM, Gariepy Y, Raghavan V. Hot air drying and microwave-assisted hot air drying of broccoli stalk slices (Brassica oleracea L. Var. Italica). J Food Proces Preserv. 2017;41(3):9–1.

Sharma A, Chen CR, Lan NV. Solar-energy dryingsystems: a review. Renew Sustain Energy Rev. 2009;13(6–7):1210–1185.

Silva AF, Monteiro M, Resende D, Braga SS, Coimbra MA, Silva AM, Cardoso SM. Inclusion complex of resveratrol with γ-Cyclodextrin as a functional ingredient for lemon juices. Foods. 2020;10(16):13–21.

Soomro AH, Miano TF, Marri A, Kumar D, Khaskheli SG, Arain UF, Baloch AB. Application of pre-treatments on banana slices for improving drying characteristics. Food Sci Qual. 2020;103:41–35.

Surendhar A, Sivasubramanian V, Vidhyeswari D, Deepanraj B. Energy and exergy analysis, drying kinetics, modeling and quality parameters of microwave-dried turmeric slices. J Therm Anal Calorim. 2019;136:197–185.

Tan M, Chua KJ, Mujumdar AS, Chou SK. Effect of osmotic pre-treatment and infrared radiation on drying rate and color changes during drying of potato and pineapple. Dry Technol. 2001;19(9):2207–2193.

Taşkın O, İzli G, İzli N. Physico chemical and morphological properties of European cranberrybush powder manufactured by freeze drying. Int J Fruit Sci. 2021;21(1):1017–1008.

Taşova M, Polatcı H, Gökdoğan O. Effect of osmotic dehydration pre-treatments on physicochemical and energy parameters of Kosia (Nashi) pear slices dried in a convective oven. J Food Process Preserv. 2022;46:e16945.

Taşova M, Polatcı H. Effects on drying models, effective diffusion and thermo-physical properties for chili (Capsicum annuum) pepper of microwave and hot water pretreatments. J Agric Mach Sci. 2021;17(3):86–93.

Taşova M, Polatcı H. Effects on drying models, effective diffusion and thermo-physical properties for chili (Capsicum annuum) pepper of microwave and hot water pretreatments. J Agric Machi Sci. 2011;17(3):86–93.

Torki-Harchegani M, Ghanbarian D, Pirbalouti AG, Sadeghi M. Dehydration behaviour, mathematical modelling, energy efficiency and essential oil yield of peppermint leaves undergoing microwave and hot air treatments. Renew Sustain Energy Rev. 2016;58:418–407.

Tzempelikos DA, Mitrakos D, Vouros AP, Bardakas AV, Filios AE, Margaris DP. Numerical modeling of heat and mass transfer during convective drying of cylindrical quince slices. J Food Eng. 2015;156:10–21.

Wang J, Law CL, Nema PK, Zhao J, Liu Z, Deng L, Xiao H. Pulsed vacuum drying enhances drying kinetics and quality of lemon slices. J Food Eng. 2018;224:129–38.

Yagua CV, Moreira RG. Physical and thermal properties of potato chips during vacuum frying. J Food Eng. 2011;104(2):283–272.

Yağcıoglu A. Agricultural products drying technique. Ege University Faculty of Agriculture Publications. No: 536. Bornova, İzmir (1999).

Yan JK, Wu LX, Qiao ZR, Cai WD, Ma HL. Effect of different drying methods on the product quality and bioactive polysaccharides of bitter gourd (Momordicacharantia L.) slices. Food Chem. 2019;271:596–588.

Yoğurtçu H. Lemon drying in microwave oven: kinetics and modeling. Fırat Univ. J Eng. 2014;26(1):27–33.

Zhang P, Zhou Z. Postharvest ethephon degreening improves fruit color, flavor quality and increases antioxidant capacity in ‘Eureka’ lemon (Citrus Limon (L.) Burm. F.). Sci Hortic. 2019;248:80–70.

Karel M, Saguy I. Effects of water on diffusion in foodsystems. In: Levine H, Slade L, editors. Water relationships in foods. Berlin: Springer; 1991. p. 157–73.

Polatçı H, Taşova M, Ergüneş G, Kırmık G. Drying of mahaleb (Prunus mahaleb) fruit drying kinetics and color change. Akademik Ziraat Dergisi. 2020;9(1):23–32. https://doi.org/10.29278/azd.608757.

Kılıç F, Tabanlıgil-Calam T. Determination of drying and rehydration kinetics of red capia pepper (Capsicum annuum L.), energy analysis of drying process. DEÜ FMD. 2020;22(65):331–42.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Aksüt, B., Polatcı, H. & Taşova, M. The effect of pre-treatment and drying temperatures on energy consumption and quality characteristics in drying of lemon (Citrus limon L.) slices. J Therm Anal Calorim 148, 10415–10427 (2023). https://doi.org/10.1007/s10973-023-12362-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10973-023-12362-3